Processing method of deep-hole pin bush parts

A processing method and pin sleeve technology, applied in the field of metal plastic forming, can solve the problems affecting fatigue resistance, fracture, etc., and achieve the effects of convenient subsequent processing, high material utilization rate and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

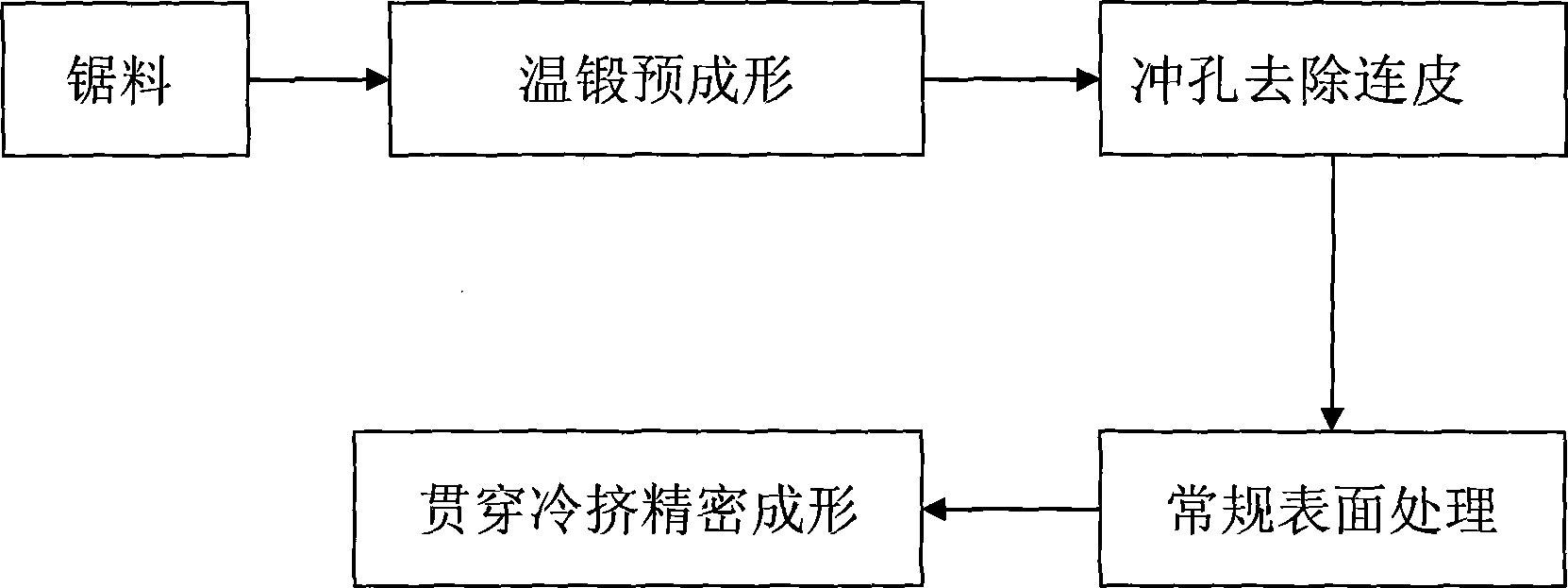

[0014] Taking the processing process of 320 pin sleeves as an example, the process flow is:

[0015] 1. For sawing, choose a hot-rolled round bar with a diameter of φ60 mm, the material grade is IE2892, adjust the cutting length, and control the weight at 2350-2390 grams;

[0016] 2. Heating, the process is as follows: heating to 870°C with the furnace, and warm extrusion after being out of the furnace.

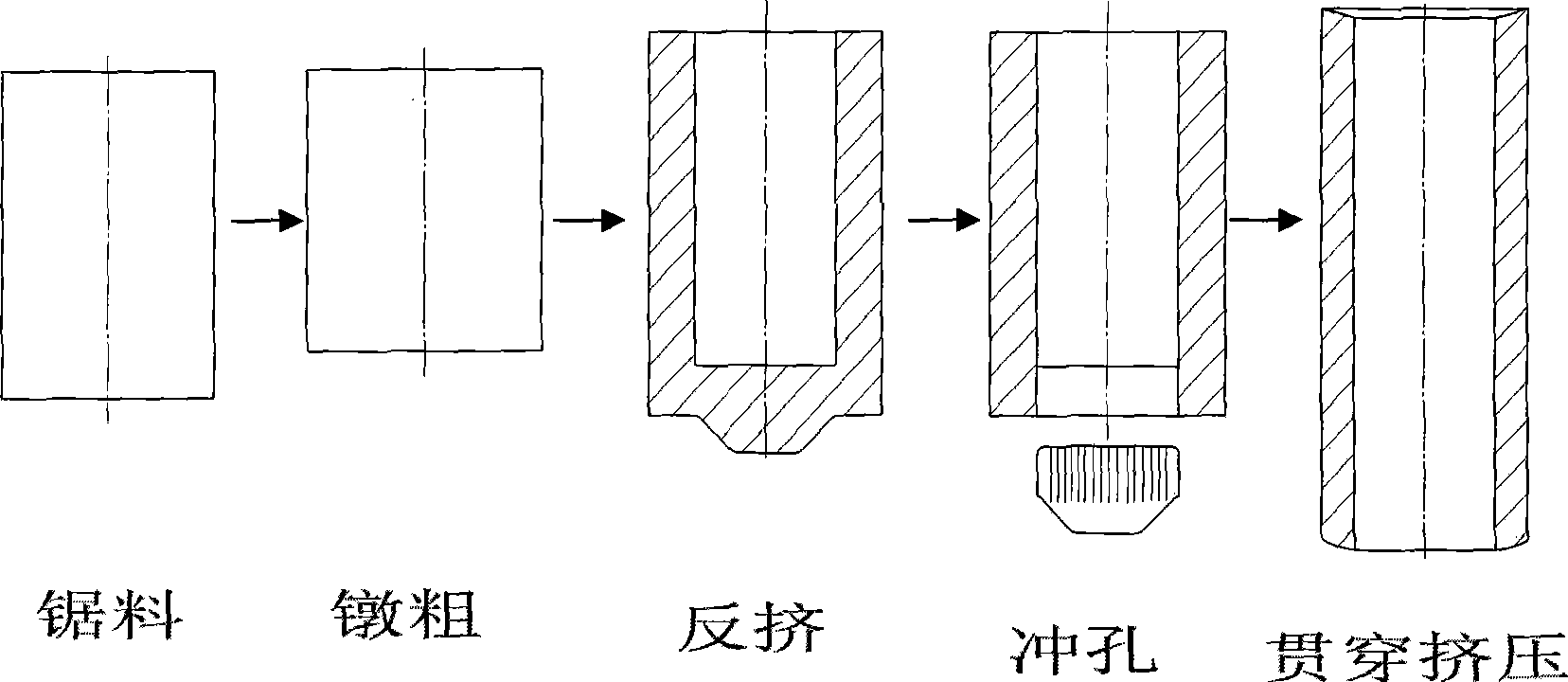

[0017] 3. Upsetting, upsetting from the billet diameter of φ60mm to φ70mm, the length is determined by the weight.

[0018] 4. Reverse extrusion, reverse extrusion from upsetting material φ70mm to outer circle φ69.5mm, inner hole φ36.5mm, hole depth 100mm, deformation is about 28.6%.

[0019] 5. Conventional temperature control cooling.

[0020] 6. Punching, punch out the through hole φ34mm from the continuous skin at the end of the inner hole φ36.5mm of the reverse extrusion material.

[0021] 7. Conventional shot blasting process.

[0022] 8. Conventional phosphorus sap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com