Method for extracting germanium from lignite by pyrogenic process

A lignite and pyrotechnic technology, applied in the field of non-ferrous rare metal extraction, can solve the problems of low grade of germanium soot, poor acid solubility and low recovery rate of germanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

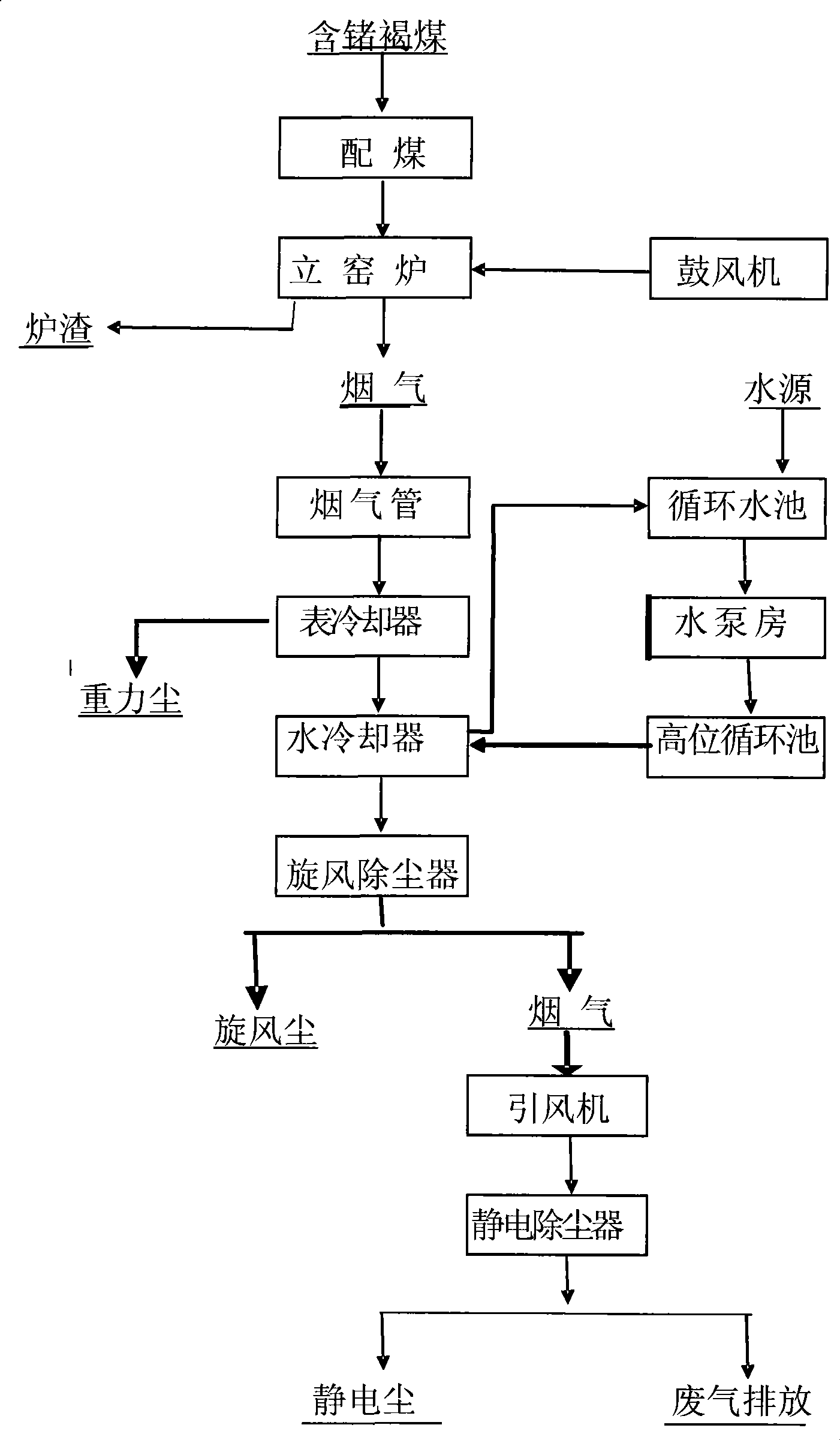

Image

Examples

Embodiment 1

[0024] Use lignite containing 248ppm germanium and a calorific value of 11077kj / kg, process 80 tons per day, crush and sieve to 5mm, mix well, and mix high-quality lignite according to the proportion of ash not higher than 55% (mass fraction). and low-quality lignite for batching, and then transported by belt to the vertical kiln for combustion and volatilization, adjust the size of the blast and air damper to the best germanium volatilization conditions, even if the oxygen content in the air flow above the coal seam in the furnace is a mass percentage 3%, so that lignite is burned in a reducing atmosphere with insufficient oxygen supply to ensure sufficient carbon and carbon monoxide. Germanium is reduced by carbon and carbon monoxide at a high temperature of 1150 ° C to form germanium monoxide. Germanium monoxide is at this temperature Volatilizes and escapes, enters the flue gas pipe with the volatilization of the furnace gas, and is oxidized by the oxygen in the air at a hi...

Embodiment 2

[0026] Use lignite containing 462ppm germanium and a calorific value of 12600kj / kg, process 80 tons per day, crush and sieve to 5mm, mix well, and mix high-quality lignite according to the proportion of ash not higher than 55% (mass fraction). and low-quality lignite for batching, and then transported by belt to the vertical kiln for combustion and volatilization. Adjust the size of the blast and induced air dampers to the best volatilization conditions for germanium, even if the oxygen content in the air flow above the coal seam in the furnace is a mass percentage 5%, so that lignite is burned in a reducing atmosphere with insufficient oxygen supply to ensure sufficient carbon and carbon monoxide. Germanium is reduced by carbon and carbon monoxide at a high temperature of 1250 ° C to form germanium monoxide, which enters with the volatilization of furnace gas In the flue gas pipe, it is oxidized to germanium dioxide by the oxygen in the air at a high temperature of 500-1200 ° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com