Welding method for target material and back plates

A welding method and target material technology, applied in the field of target material manufacturing, can solve problems such as target material deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

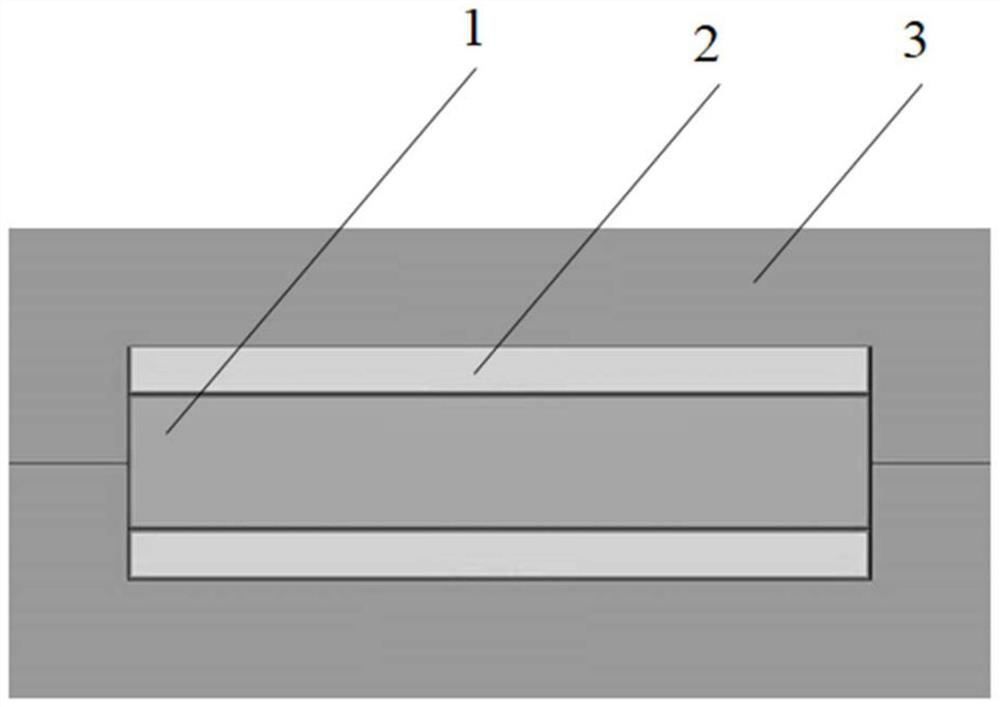

[0063] This embodiment provides a welding structure of the target and the back plate, the welding structure is as follows figure 1 shown.

[0064] The welding structure includes a target 1, an intermediate layer 2 and a back plate 3;

[0065] The target material 1 is located between two intermediate layers 2 , and two backplanes 3 are arranged symmetrically on the outside of the two intermediate layers 2 to wrap the target material 1 and the intermediate layer 2 .

Embodiment 2

[0067] This embodiment provides a method for welding a target and a back plate, and the welding structure of the target and the back plate refers to the welding structure in Embodiment 1.

[0068] Described welding method comprises the following steps:

[0069] (1) Polish the welding surface of the titanium-aluminum alloy target and the aluminum back plate, and the two surfaces of the aluminum alloy interlayer in contact with the aluminum back plate and the titanium-aluminum alloy target, and then use isopropanol for ultrasonic cleaning , after cleaning for 5 minutes, carry out vacuum drying at 90°C for 60 minutes; assemble the dried titanium-aluminum alloy target material with a thickness of 5 mm, an aluminum alloy intermediate layer with a thickness of 1 mm, and an aluminum back plate to obtain an assembly assembly;

[0070] (2) The assembled components obtained in step (1) are sheathed and welded, then degassed at 100°C for 2 hours, then hot isostatic pressed at 200°C and 5...

Embodiment 3

[0072] This embodiment provides a method for welding a target and a back plate, and the welding structure of the target and the back plate refers to the welding structure in Embodiment 1.

[0073] Described welding method comprises the following steps:

[0074] (1) Polish the contact surface between the titanium-aluminum alloy target and the aluminum alloy back plate, as well as the two surfaces of the aluminum alloy intermediate layer in contact with the aluminum alloy back plate and the titanium-aluminum alloy target, and then use isopropanol to Ultrasonic cleaning, after cleaning for 120 minutes, vacuum drying at 120°C for 40 minutes; assemble the dried titanium-aluminum alloy target material with a thickness of 20 mm, the aluminum alloy intermediate layer with a thickness of 7 mm, and the aluminum alloy back plate to obtain an assembly assembly ;

[0075] (2) The assembled components obtained in step (1) are sheathed and welded, then degassed at 400°C for 20 hours, then h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com