Fixing device for metal machining

A fixing device and metal processing technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve problems such as hidden safety hazards, large size, inconsistent thickness at different positions, etc., to achieve stable clamping and wide application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

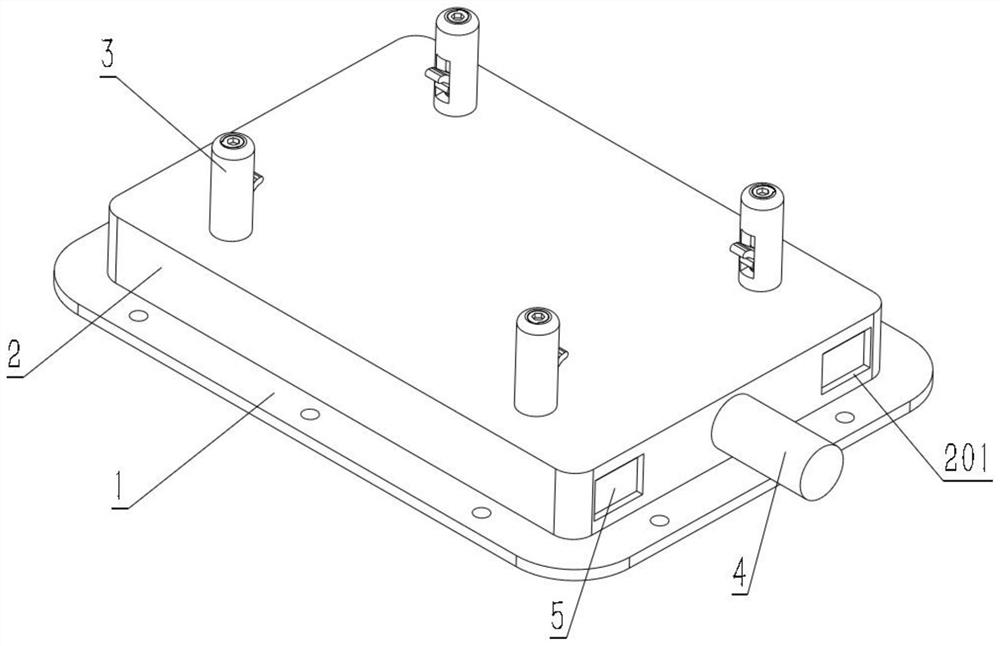

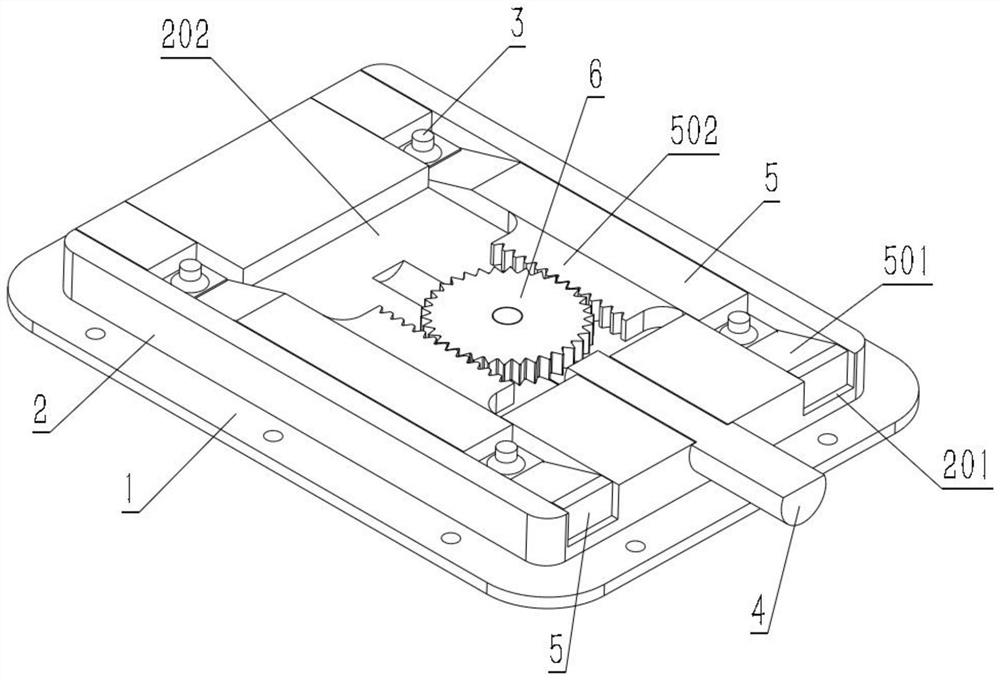

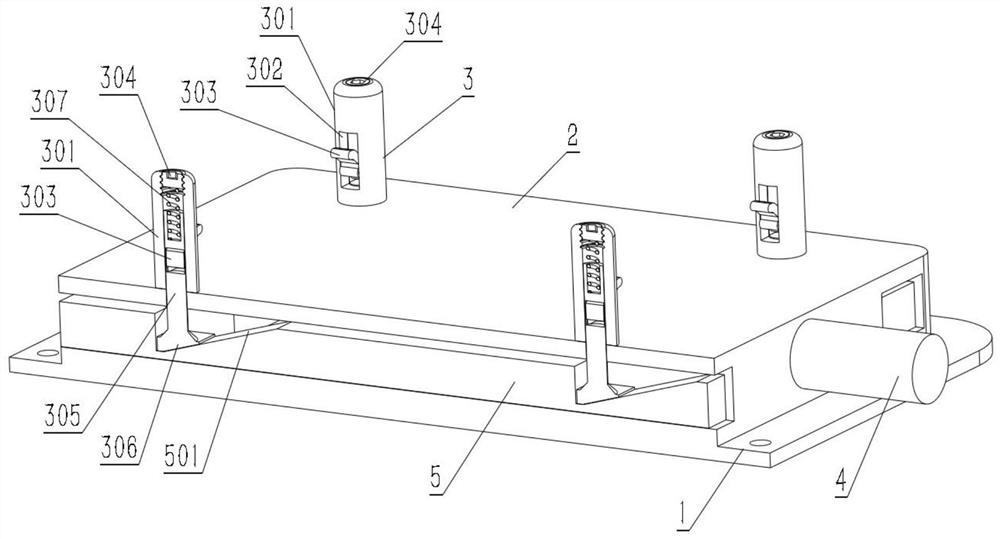

[0016] Such as Figure 1 to Figure 5 As shown, a kind of fixing device for metal processing according to the present invention adopts a technical solution that includes a fixed base 1, and is characterized in that, the upper surface of the fixed base 1 is fixedly connected with a placing platform 2, and the placing platform 2 Both sides are respectively provided with chute 201, and the inside of the placement platform 2 is provided with an installation cavity 202, the chute 201 runs through the placement platform 2 and a sliding backing plate 5 is installed therein for sliding fit, and the sliding backing plate 5 is positively Above, a clamping device 3 is fixedly connected to the upper surface of the placing table 2. The clamping device 3 extends into the chute 201 and is installed in sliding fit with the sliding backing plate 5. The middle of one end of the placing table 2 is An electric telescopic rod 4 is installed in a fixed position, and the telescopic end of the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com