Milling surface roughness online prediction method based on acoustic emission signals

A technology of acoustic emission signal and surface roughness, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., to achieve obvious effects, accurate and reliable prediction, and sufficient theoretical basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

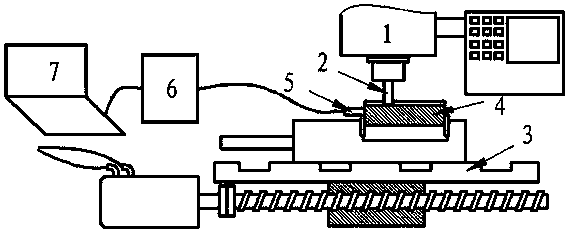

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereby.

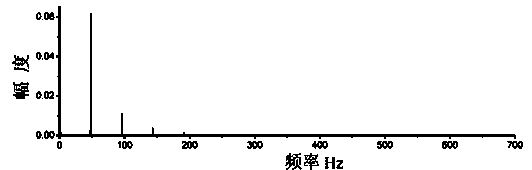

[0036] The technical idea of the present invention is: according to the theory that the change of milling chip thickness reflects the roughness of the milling surface in the milling processing theory, the acoustic emission signal released by the processed parts is detected by the acoustic emission sensor to predict the roughness of the milling processing surface. Spend.

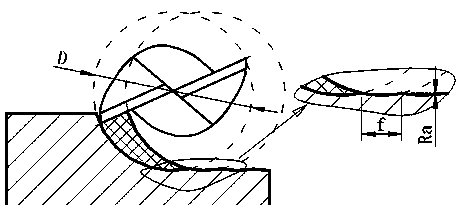

[0037] See attached figure 2 , the cutting process of each cutting edge is intermittent during milling. Without any other factors, the thickness of the milling chip will vary with the position of the cutting edge, so that the thickness of the milling chip changes periodically, so that in milling The milling surface roughness is formed by leaving jagged ripples on the machined surface. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com