Design method of axis tension member based on microscale and axis tension member

A microstructure and microscopic technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of cost saving and precise design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

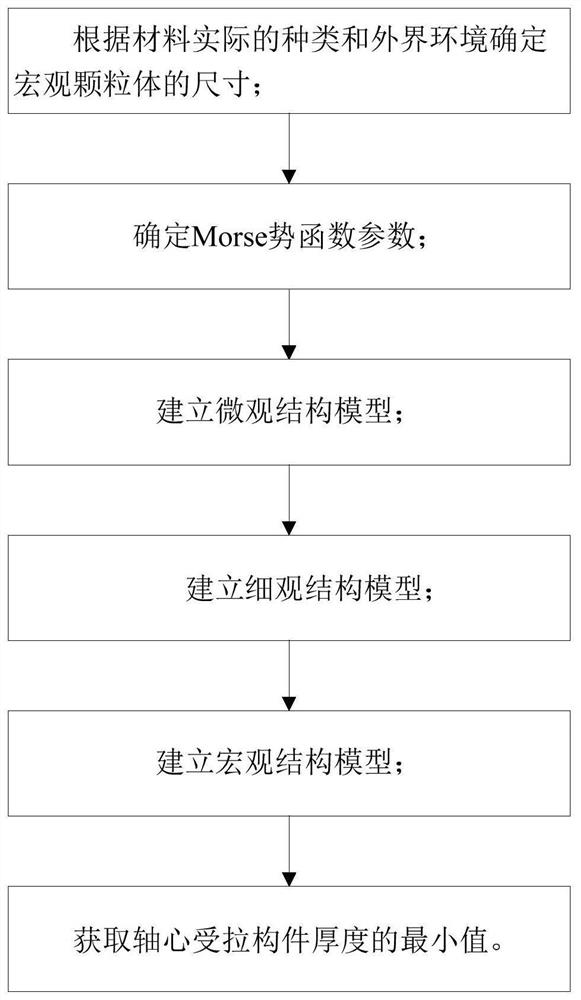

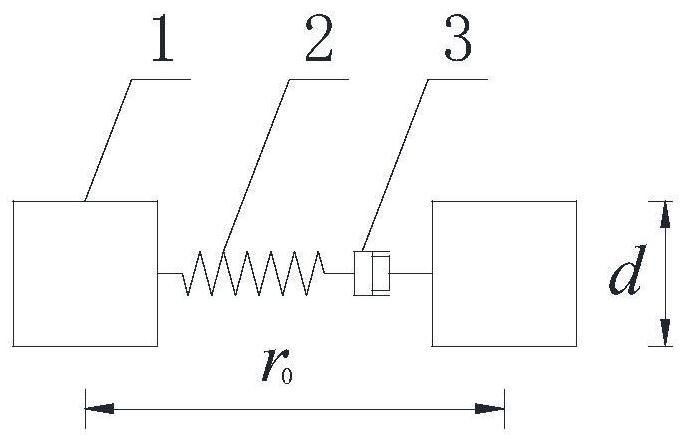

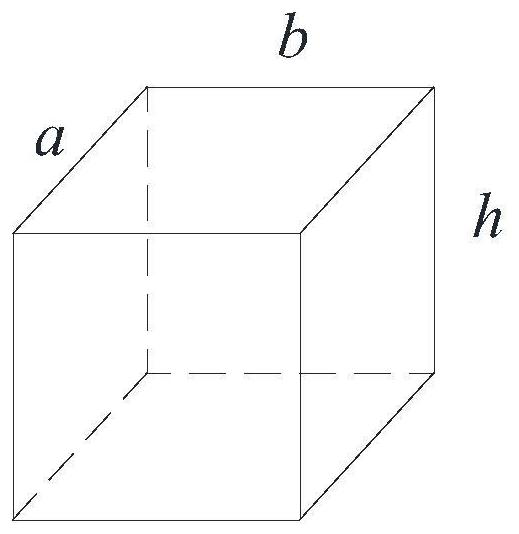

[0060] please see figure 1 , the present invention is a design method for axially tensioned members based on the microscopic scale, using a Morse potential function to describe the interaction of each cubic particle inside the steel structure material. First, determine the size of the macroscopic particles according to the actual type of material and the external environment, and then determine the parameters related to the Morse potential function. The above related symbols and their meanings are shown in Table 1;

[0061] Table 1 Symbols and meanings

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com