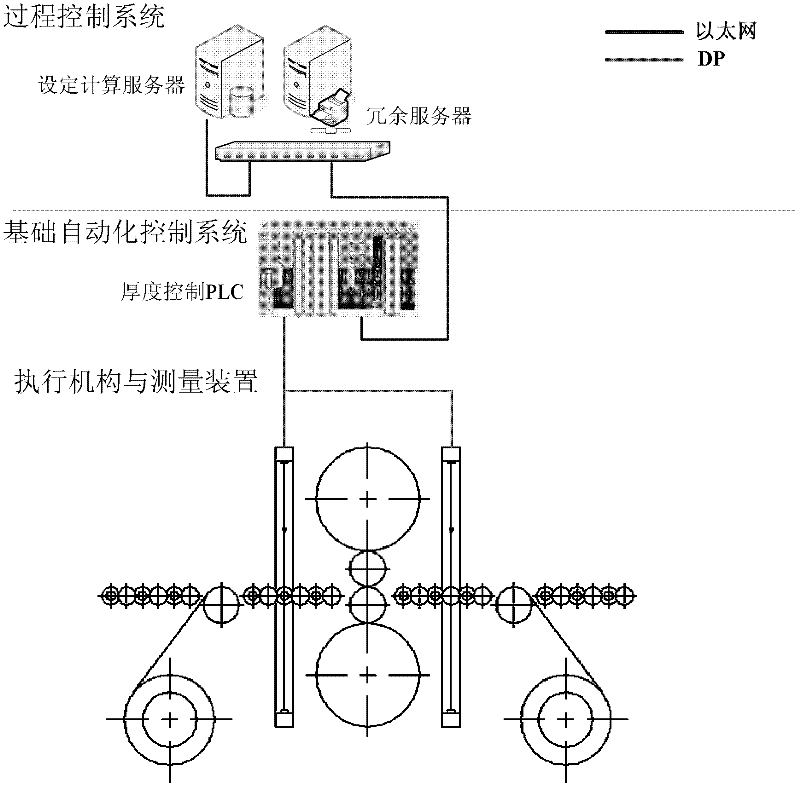

Thickness control method for single precision cold-rolled sheet thickness measuring system

A technology of thickness control and cold rolling, which is applied in rolling mill control devices, metal rolling, metal rolling, etc., and can solve the problems of thickness accuracy guarantee and inability to realize real-time closed-loop control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

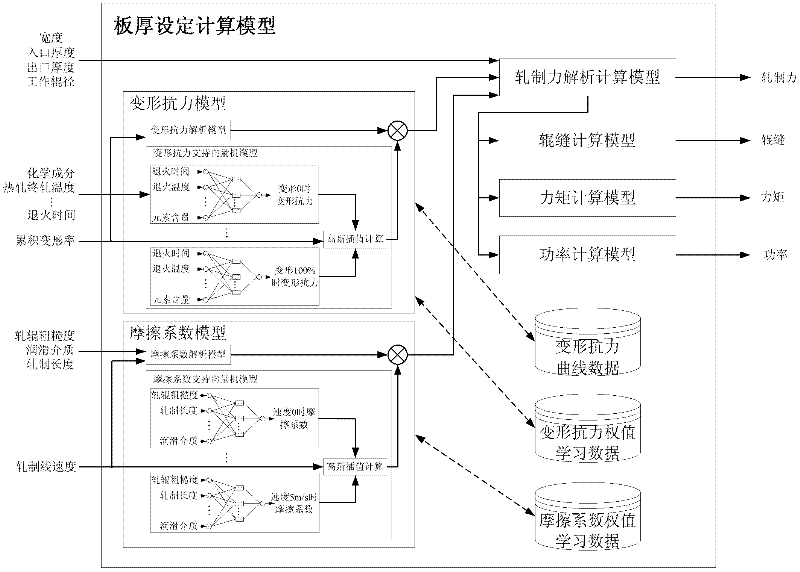

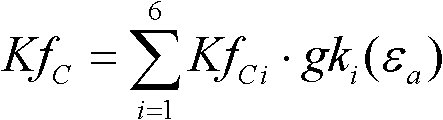

Embodiment Construction

[0057] A thickness self-learning control method for a precision cold-rolled plate thickness measurement system for a single sheet. The control method is divided into two parts: thickness setting calculation and thickness self-learning calculation; When calculating the thickness setting, the thickness of each pass is firstly distributed, that is, the set thickness at the entrance side and the set thickness at the exit side of each pass are determined. mm, the plate width is 1090mm, and it is rolled by 8 passes, and the pass thickness distribution is shown in Table 1.

[0058] Table 1 Thickness Distribution of TA1 Single Sheet (3.5~1.5×1090mm) Rolling Passes

[0059] Number of passes

1

2

3

4

5

6

7

8

Inlet thickness (mm)

3.5

2.859

2.425

2.134

1.936

1.776

1.66

1.58

Outlet Thickness(mm)

2.859

2.425

2.134

1.936

1.776

1.66

1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com