Device and method for detecting deformation stress of on-site cement-based material

A cement-based material, deformation stress technology, applied in the direction of measuring devices, material inspection products, analytical materials, etc., can solve the problems of high requirements for concrete deformation stress detection accuracy, influence of civil engineering construction quality, lack of test devices and methods, etc. The acquisition method is simple and direct, the detection data is comprehensive and reliable, and the detection structure is simple and reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

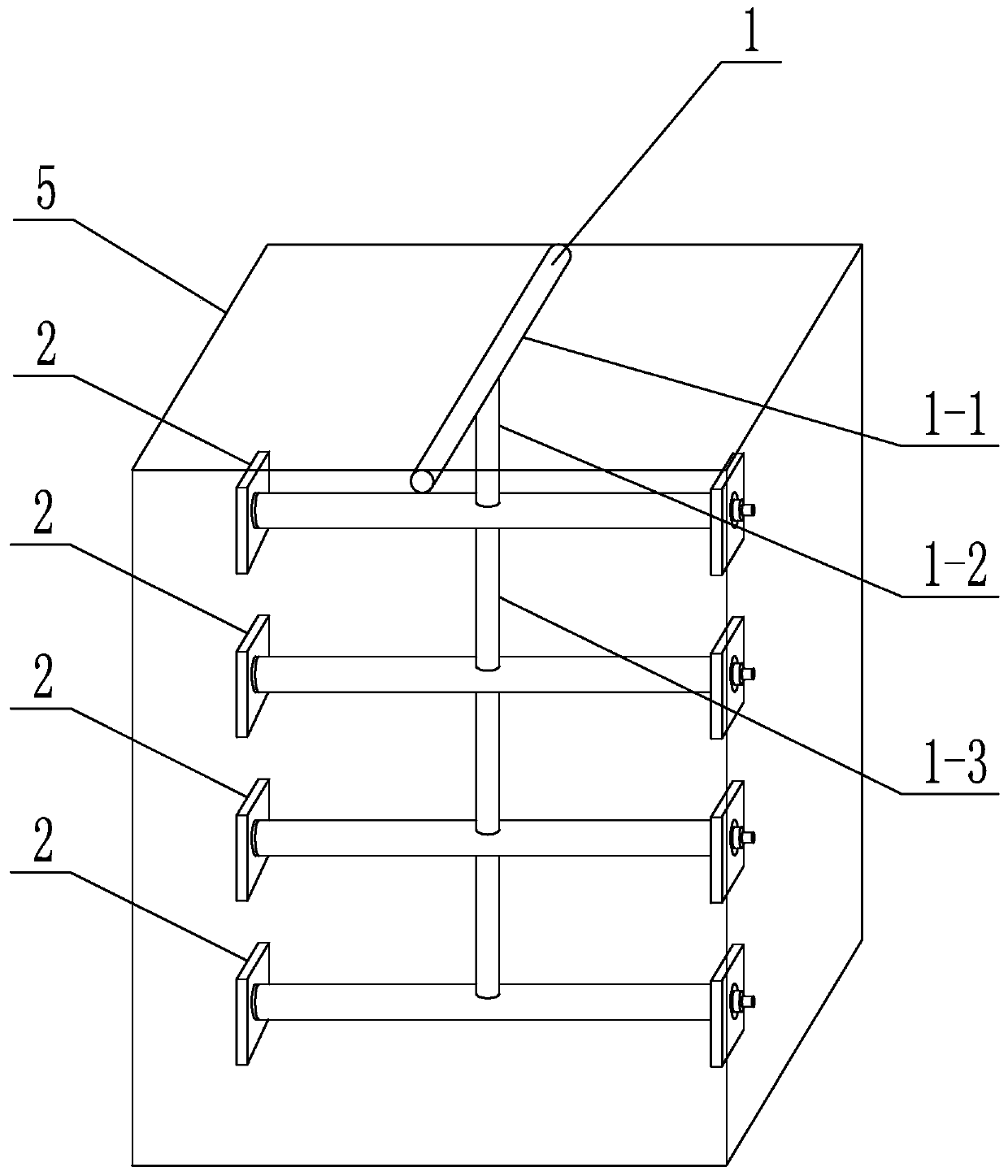

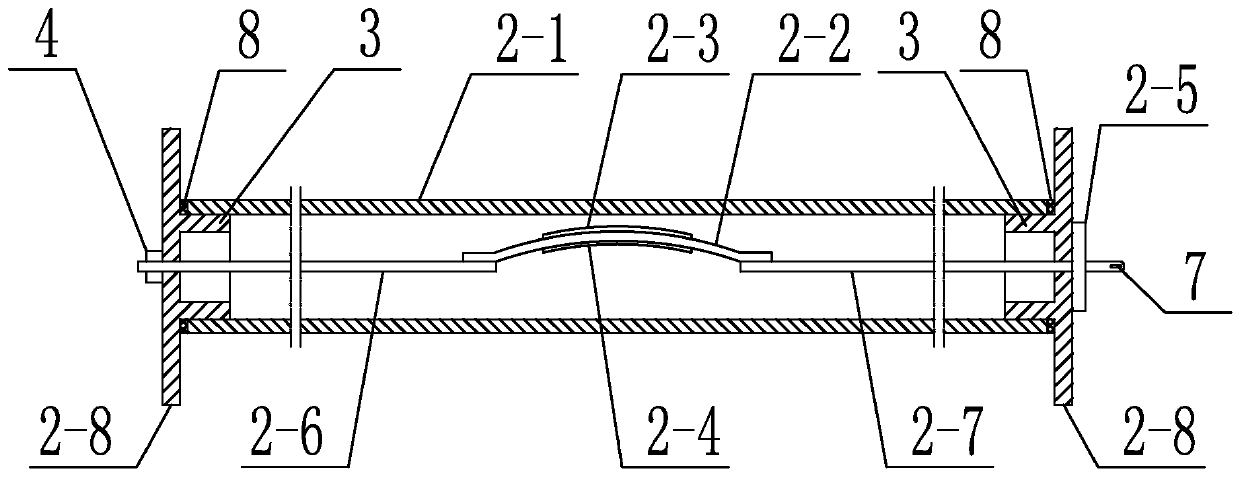

[0036] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 This embodiment is described. This embodiment includes a connection frame 1 and a plurality of test units 2, and a plurality of test units 2 are sequentially arranged on the connection frame 1 from bottom to top, and each test unit 2 includes a casing 2-1, Arched plate 2-2, upper strain gauge 2-3, lower strain gauge 2-4, moving outer cover 2-5, first thin rod 2-6, second thin rod 2-7 and two end caps 2- 8. The two ends of the casing 2-1 are detachably connected with two end caps 2-8, the arched plate 2-2 is set inside the casing 2-1, the upper strain gauge 2-3 and the lower strain gauge 2 -4 are respectively arranged on the top surface and the bottom surface of the arched plate 2-2, the two ends of the arched plate 2-2 are respectively provided with the first thin rod 2-6 and the second thin rod 2-7, the first thin rod One end of 2-6 is fixedly connected...

specific Embodiment approach 2

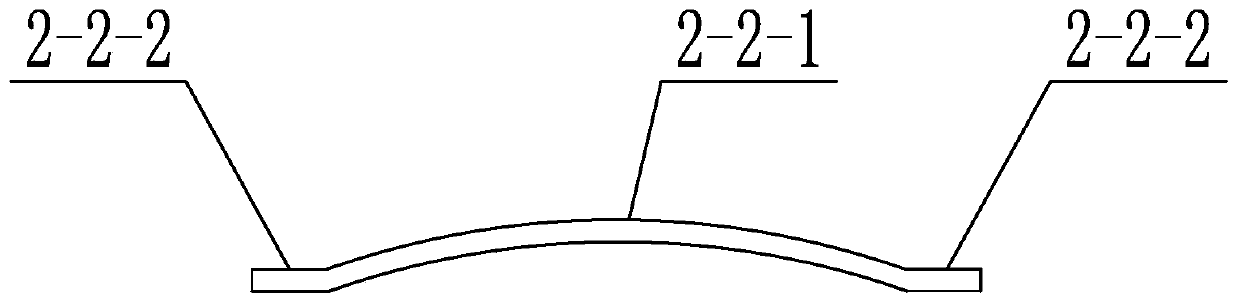

[0041] Specific Embodiment 2: This embodiment is a further limitation of Specific Embodiment 1. The arched plate 2-2 includes a curved plate 2-2-1 and two flat plates 2-2-2, and the curved plate 2-2-1 A flat plate 2-2-2 is respectively arranged at both ends of the arc plate 2-2-1 and two flat plates 2-2-2 are integrally made.

specific Embodiment approach 3

[0042] Specific embodiment 3: This embodiment is a further limitation of specific embodiment 1 or 2. The arched plate 2-2 is an elastic plate, and the arched plate 2-2 is arranged on the sleeve 2-1 along the length direction of the sleeve 2-1. within 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com