Magnetic collecting device for improving uniformity of deformation of pipe fitting and electromagnetic forming device of magnetic collecting device

A magnetic collector and uniformity technology, applied in the field of material processing and forming, can solve the problems of uneven deformation of pipe fittings, uneven deformation of pipe fittings or flat plates, etc., and achieve the effects of improving service life, easy operation, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

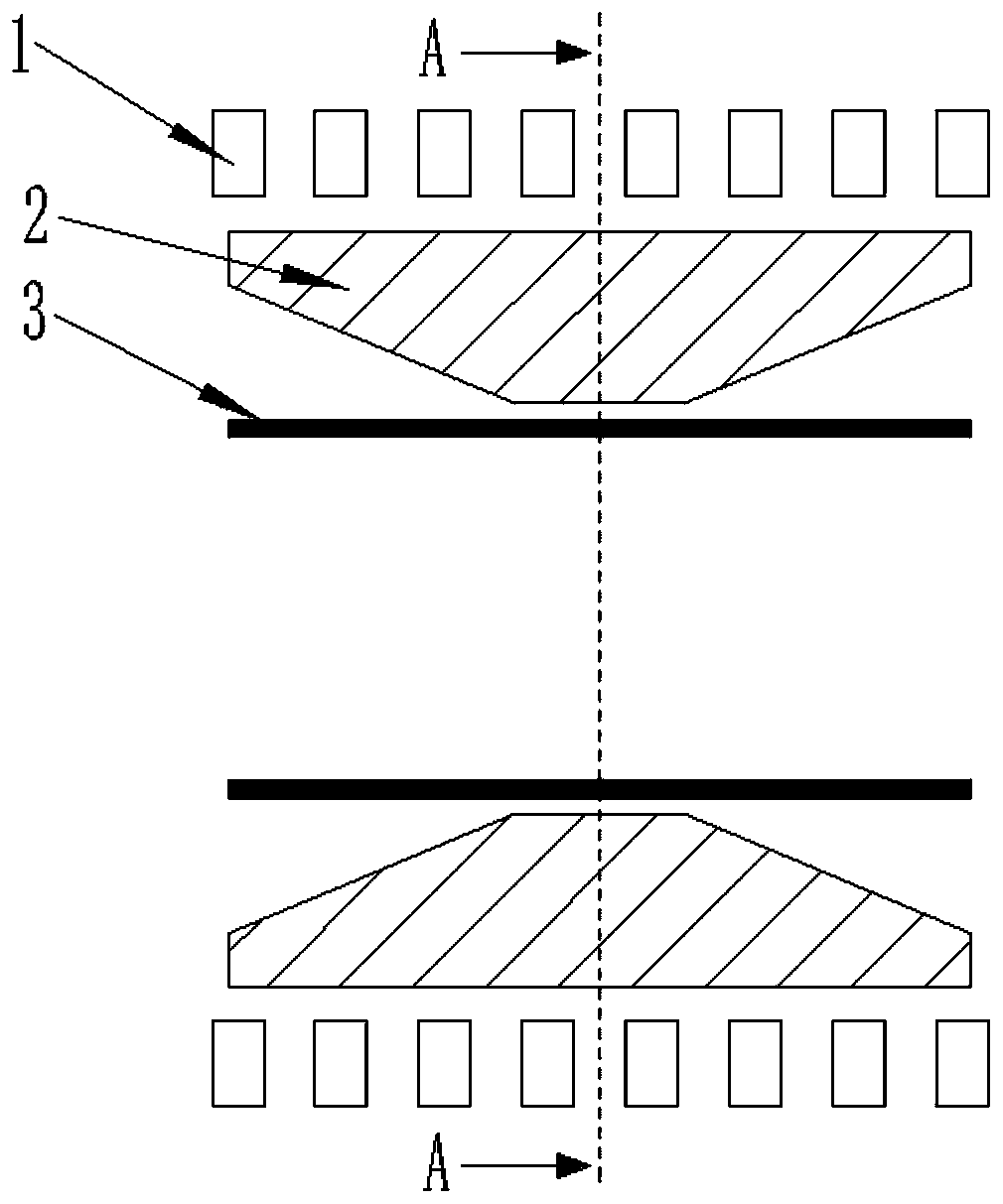

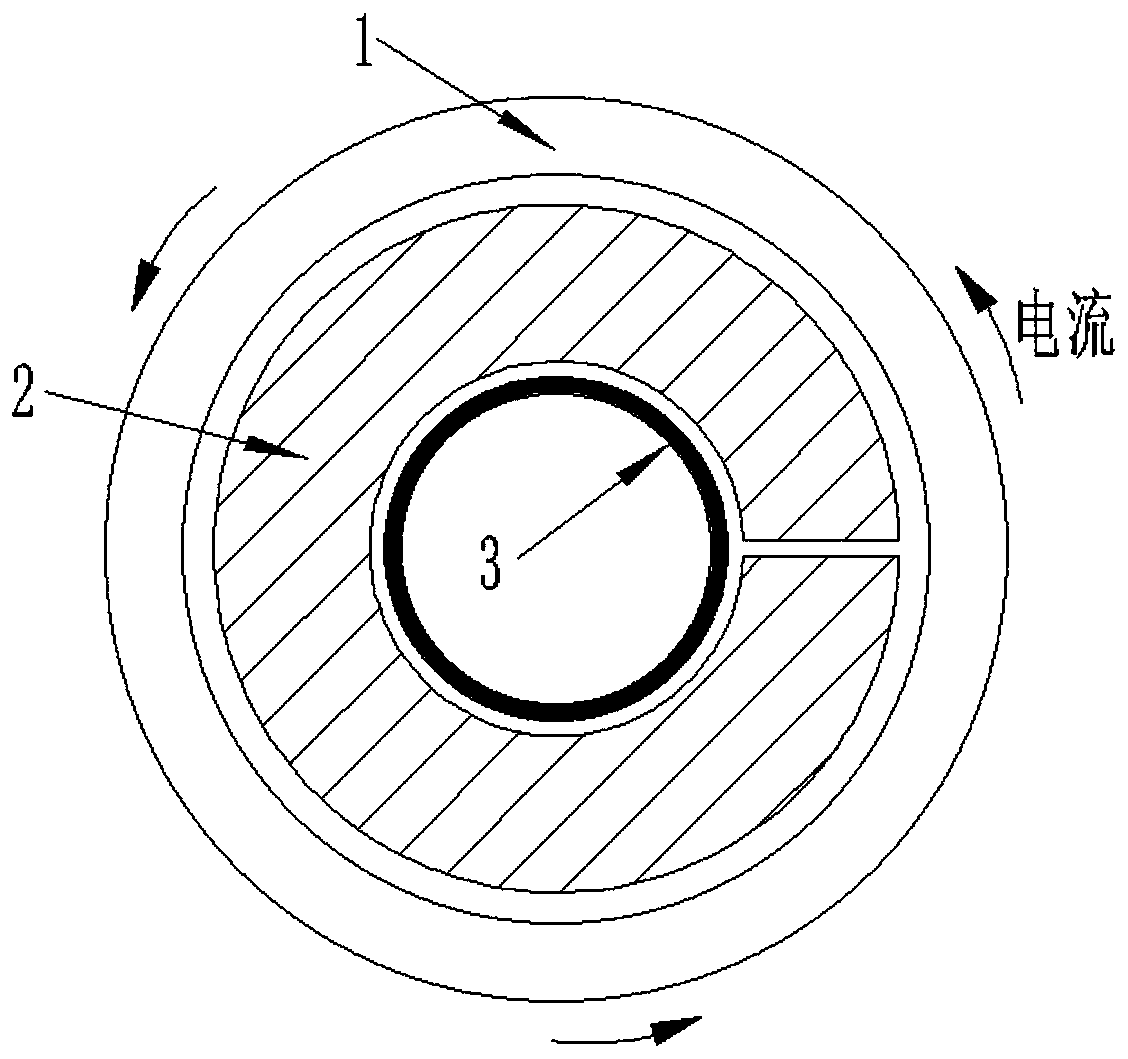

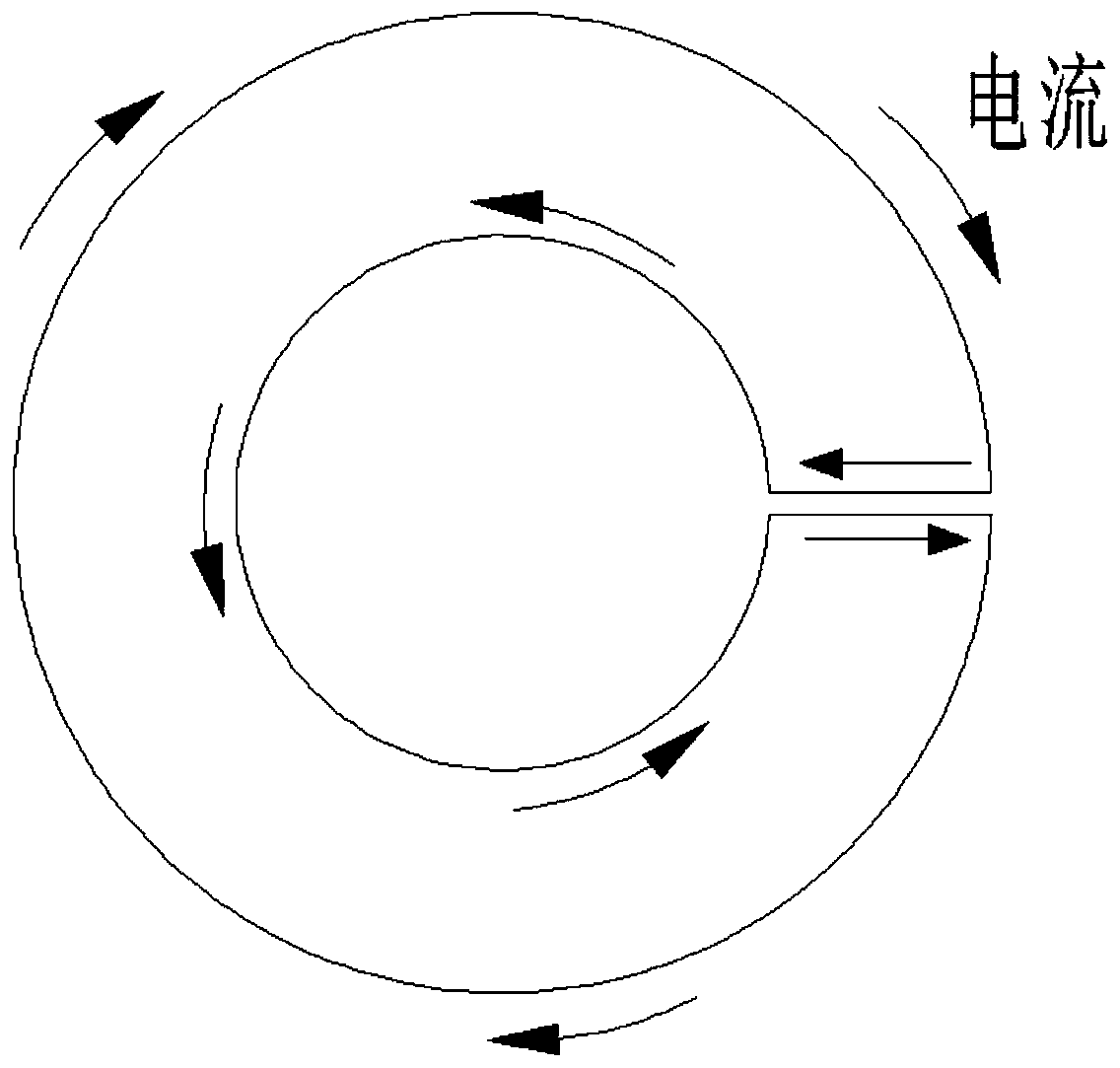

[0036] Such as Figure 4 As shown, the embodiment of the present invention discloses a magnetic collector for improving the uniformity of pipe deformation. The magnetic collector 2 is provided with a ring structure with a through hole 6 at the center, and the magnetic collector 2 is provided with a ring structure along the through hole 6. radially through the gap 4 of the side wall of the magnetic collector 2 (different from the attached Figure 1-3 The traditional single-slit magnetic collector shown), the magnetic collector 2 is located on the inner wall of the through hole 6 and is also provided with at least one slit 5, the slit 5 extends along the axial direction of the through hole 6, and the slit 5 and the gap 4 are along the through hole 6. The circumferential direction of the holes is evenly arranged. Therefore, when the magnetic collector 2 is designed with multiple slits 5 , the magnetic field force corresponding to the slits 5 is still smaller than the area corres...

Embodiment 2

[0040] In this example, if Figure 5-6 As shown, the magnetic collector 2 is a split structure, and the magnetic collector 2 includes a plurality of split magnetic collectors 21, and the plurality of split magnetic collectors 21 form a ring structure with a through hole 6 in the center, and the adjacent split magnetic collectors 21 A gap 4 is formed between them (at this time, it can also be regarded as the formation of other gaps 5 passing through the side wall of the integrated magnet collector 2), and the split magnet collector 21 and the gap 4 are symmetrically arranged along the center of the through hole 6 . In this embodiment, the magnetic collector 2 can be opened and closed conveniently, and the magnetic collector 2 can be easily moved to any area where the pipe fitting 3 is deformed, and is not affected by the length of the pipe fitting 3 and the variable section of the pipe fitting 3, making it easier to operate.

[0041]In specific setting, the width of any gap 4 ...

Embodiment 3

[0044] In this example, if Figure 7-8 As shown, the magnetic collector 2 is a split structure, and the magnetic collector 2 includes a plurality of split magnetic collectors 21, and the plurality of split magnetic collectors 21 form a ring structure with a through hole 6 in the center, and the adjacent split magnetic collectors 21 A gap 4 is formed between them, and the split magnet collector 21 is located on the inner wall of the through hole 6. At least one gap 5 is also provided. The gap 5 extends along the axial direction of the through hole 6, and the gap 5 and the gap 4 extend along the through hole. 6 are evenly arranged circumferentially. Similarly, for the convenience of processing, the slit 5 is a through-groove structure having the same width as the gap 4 and penetrating along the axial direction of the through-hole 6 .

[0045] Then, the present invention discloses an electromagnetic forming device, which includes the magnetic collector for improving the uniformi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com