Method and apparatus for improving mechanical properties of materials that can be magnetically activated

A mechanically-proper, magnetically-activated technology for corrugation in metallic materials that resolves issues of improper frictional engagement, weakened materials and smoothing rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Before the present invention is described in detail, it is not limited to specific apparatus components or specific method steps, as these may vary. The terminology used herein is for describing particular embodiments only and not in any limiting sense. Furthermore, where singular or indefinite articles are used in the specification or claims, these singular or indefinite articles also include a plurality of these elements as long as the overall context does not lead to an obvious meaning of something else.

[0039] The invention will now be explained in more detail by way of example with reference to the accompanying drawings. However, these exemplary embodiments are examples only, and they are not intended to limit inventive concepts to specific arrangements.

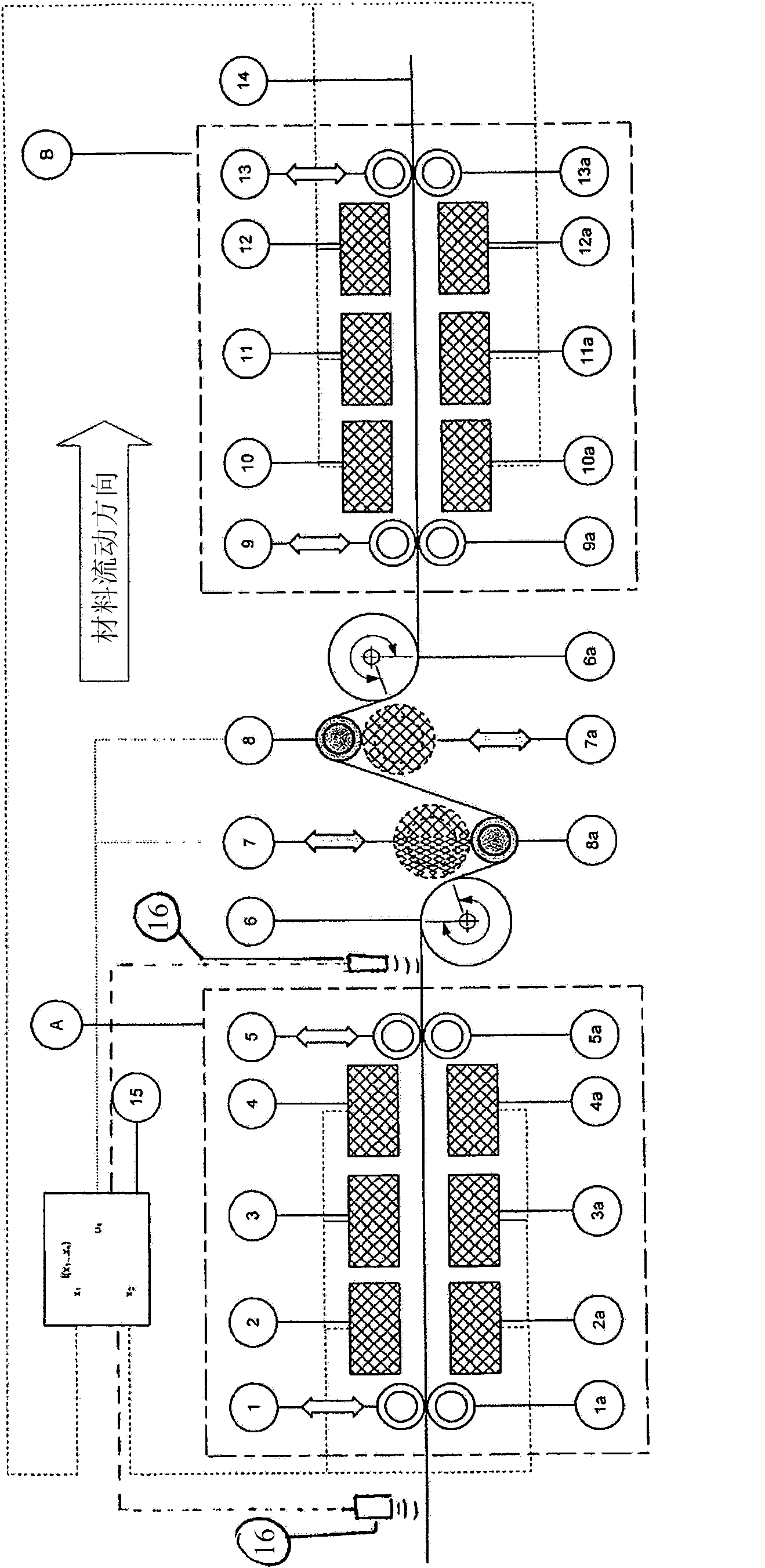

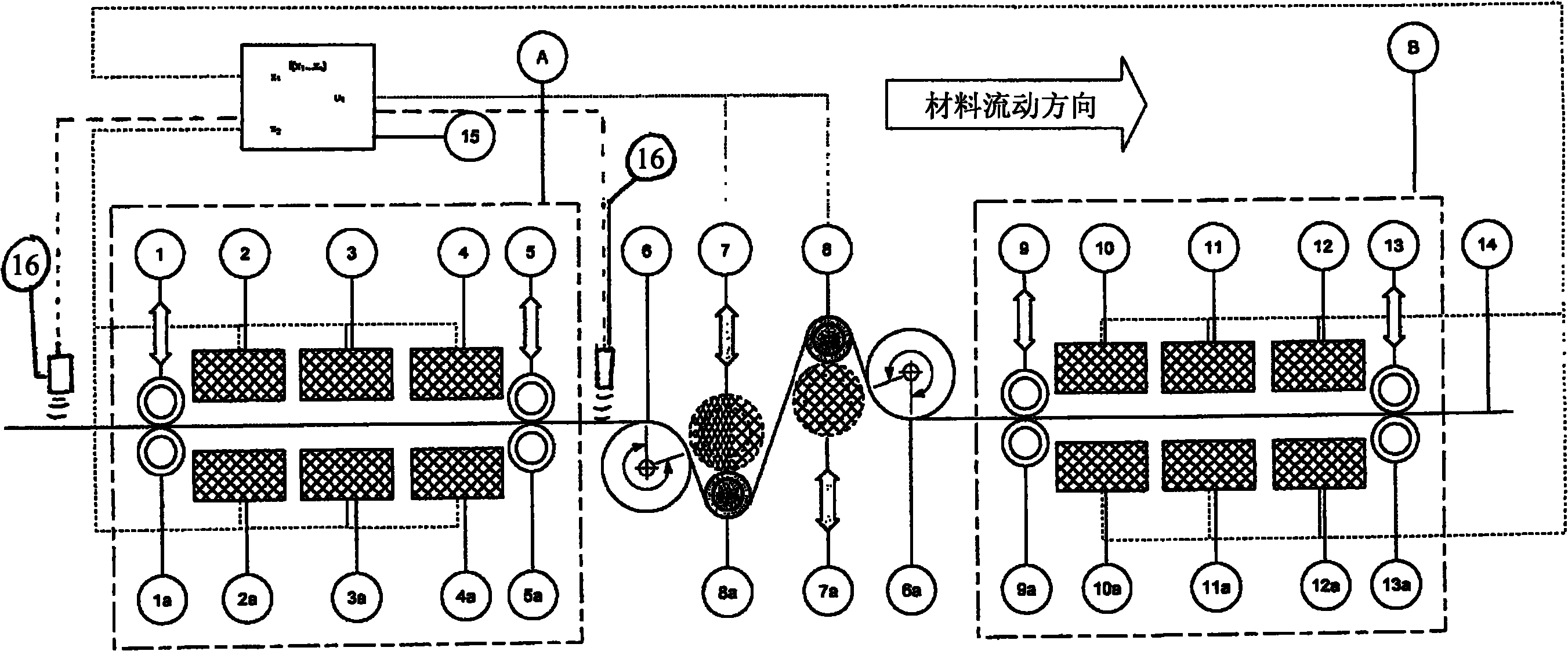

[0040] figure 1 A schematic diagram of the method according to the invention in a strip processing line is shown. exist figure 1 , material strips or material sheets (hereinafter referred to as material 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com