Forging method of TC4 titanium alloy large-specification rods

A large-scale, titanium alloy technology, applied in the direction of metal processing equipment, etc., can solve the problems of forging billet cracking, difficult process, and increased cost, so as to increase the degree of material deformation, improve the uniformity of the structure, and reduce material loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: TC4 (Ti-6Al-4V) alloy Φ620-2800Kg cast ingot deformed Φ120mm rod forging method: 3500T forging press is selected as the forging equipment.

[0034] For the first fire, the ingot is opened. Heating temperature 1100-1150°C, heat preservation 300-360min, elongation deformation: Φ620→□350 (that is, forging an ingot with a diameter of 620mm into a square billet with a side length of 350 in cross section), divided into 7 equal parts, and the weight of a single forging is 400Kg , about 720mm in length, ground after air cooling.

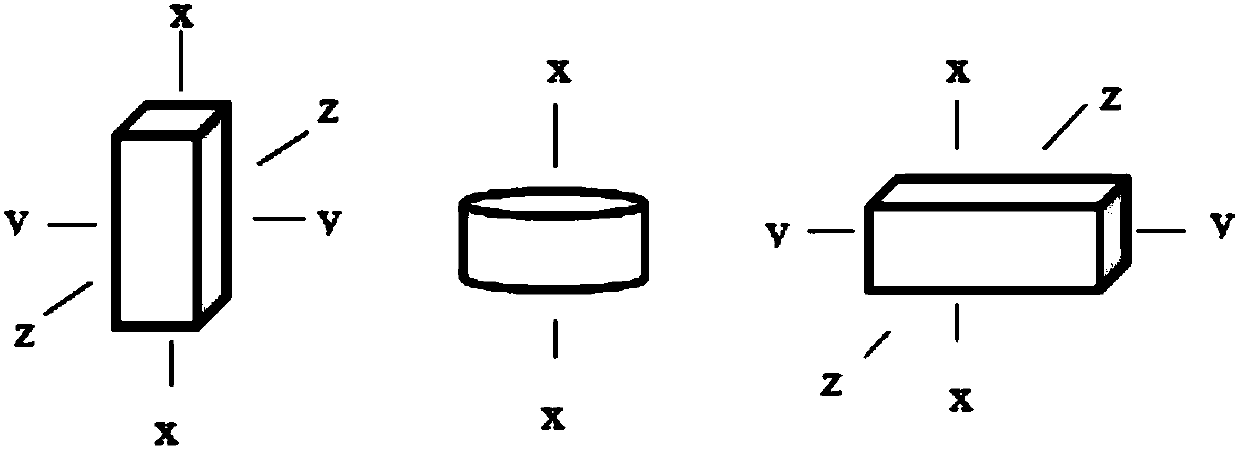

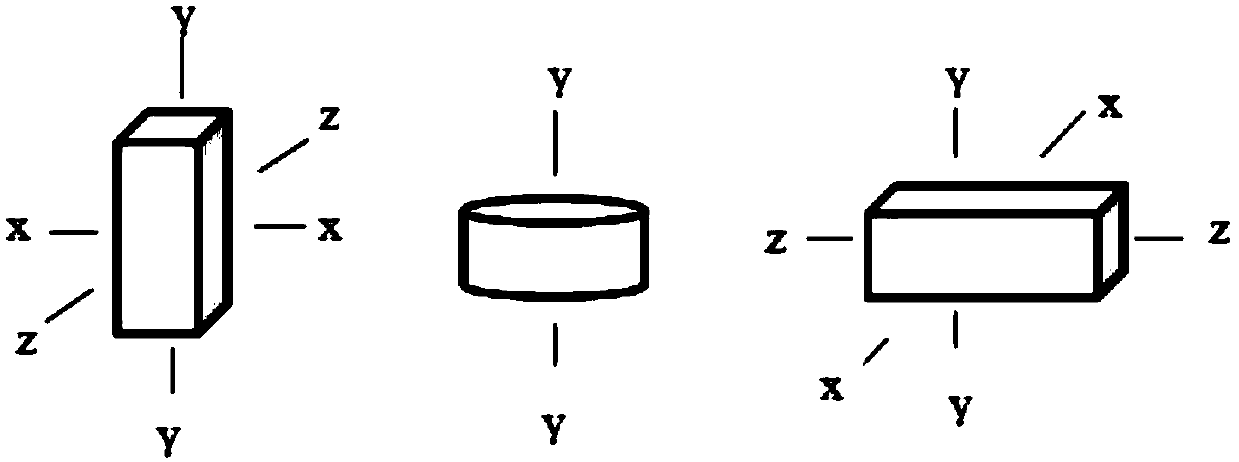

[0035] For the second fire, the heating temperature is 1020-1050°C, and the heat preservation time is 180-210min. First do deep heading in the x direction to a thickness of 250mm (the amount of deformation is about 65%), and then do the reversing elongation deformation in the y direction. Grind after air cooling.

[0036] For the third fire, the heating temperature is 980-1000°C, and the heat preservation time is 180-210min. First do de...

Embodiment 2

[0040] Example 2: TC4 (Ti-6Al-4V) alloy Φ460-1100Kg cast ingot deformed Φ120mm bar forging method: 3500T forging press is selected as the forging equipment.

[0041] For the first fire, the ingot is opened. Heating temperature 1100-1150°C, heat preservation 240-300min, elongation deformation: Φ460→□300 (that is, forging an ingot with a diameter of 460mm into a square billet with a cross-sectional side length of 300). Divided into 4 equal pieces, the weight of a single forging is 275Kg, the length is about 680mm, and it is ground after air cooling.

[0042] For the second fire, the heating temperature is 1020-1050°C, and the heat preservation is 150-180min. First do deep heading in the x direction to a thickness of 230mm (the amount of deformation is about 66%), and then do the reversing elongation deformation in the y direction. Grind after air cooling.

[0043] For the third fire, the heating temperature is 980-1000°C, and the heat preservation time is 150-180min. First do ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com