Method for axially feeding, extruding, rolling and forming spline shaft by medium-frequency and high-frequency sensing heating

A technology of high-frequency induction heating and axial feeding, which is applied in metal rolling and other directions, can solve the problems of extruding and rolling forming splines without warm forming technology, achieve high deformation resistance, reduce deformation resistance, and reduce heat loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

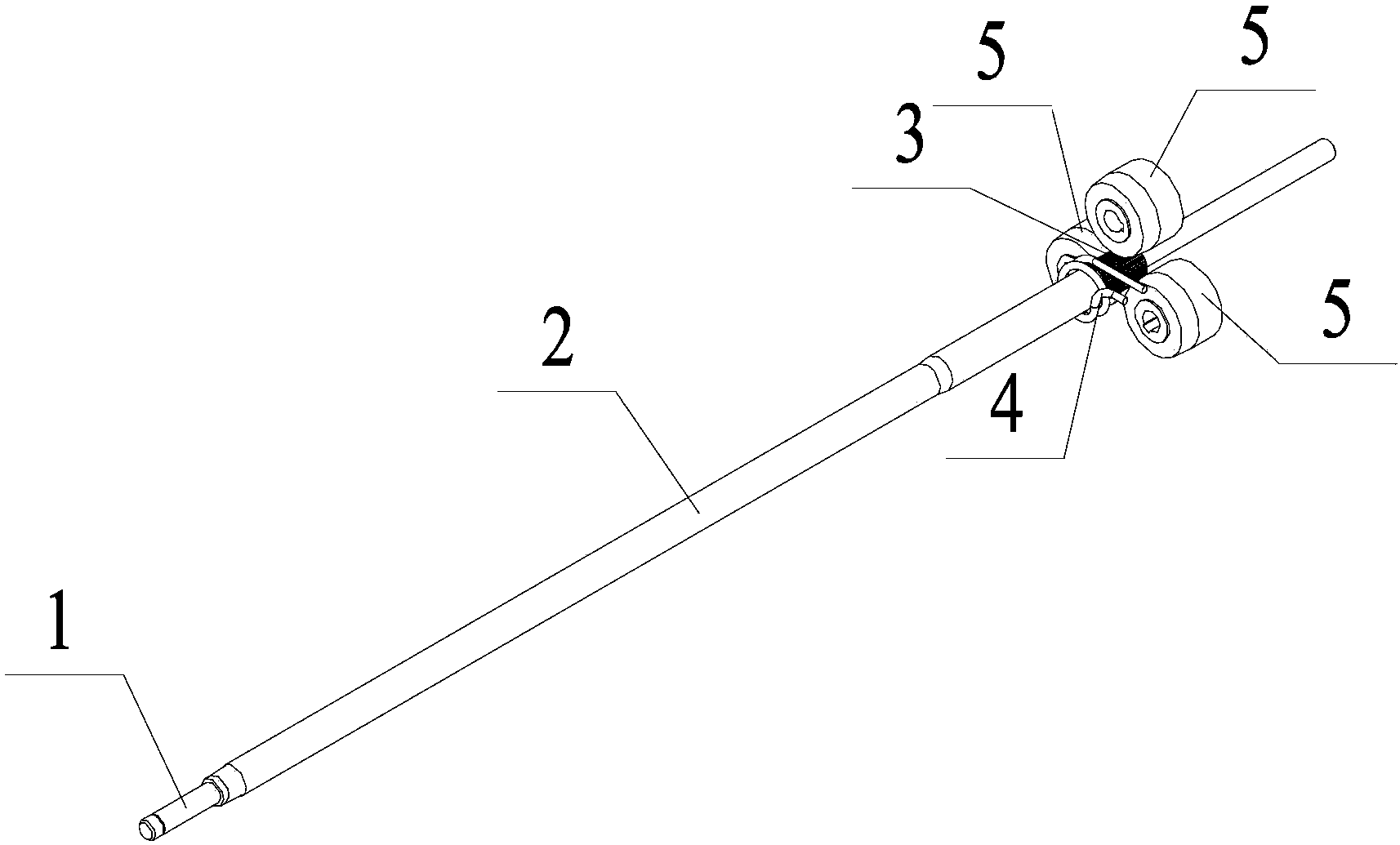

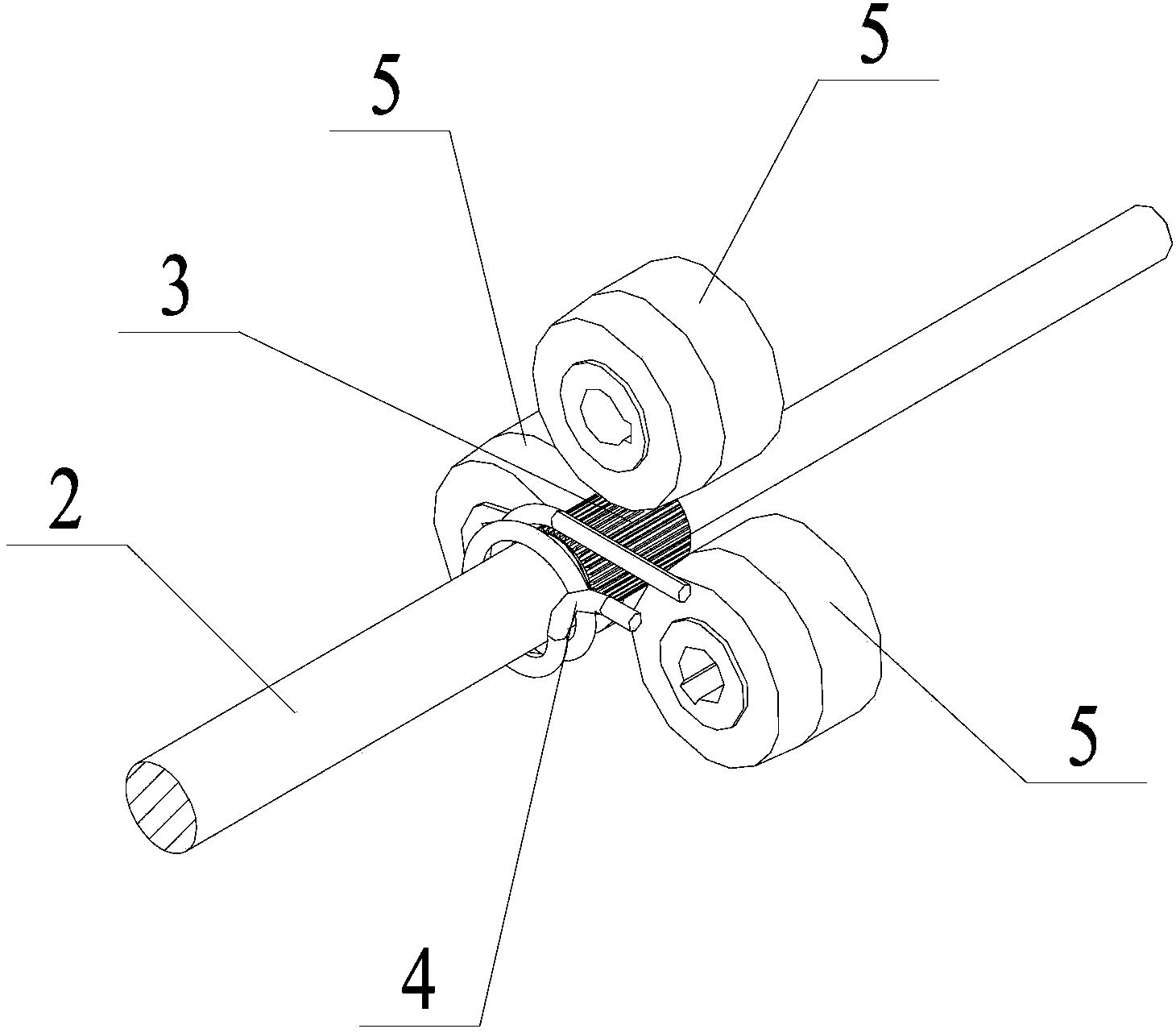

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] In this embodiment, the material of the workpiece 2 is 42CrMo high-strength steel, and the three extrusion rolling dies 5 rotate synchronously and in the same direction.

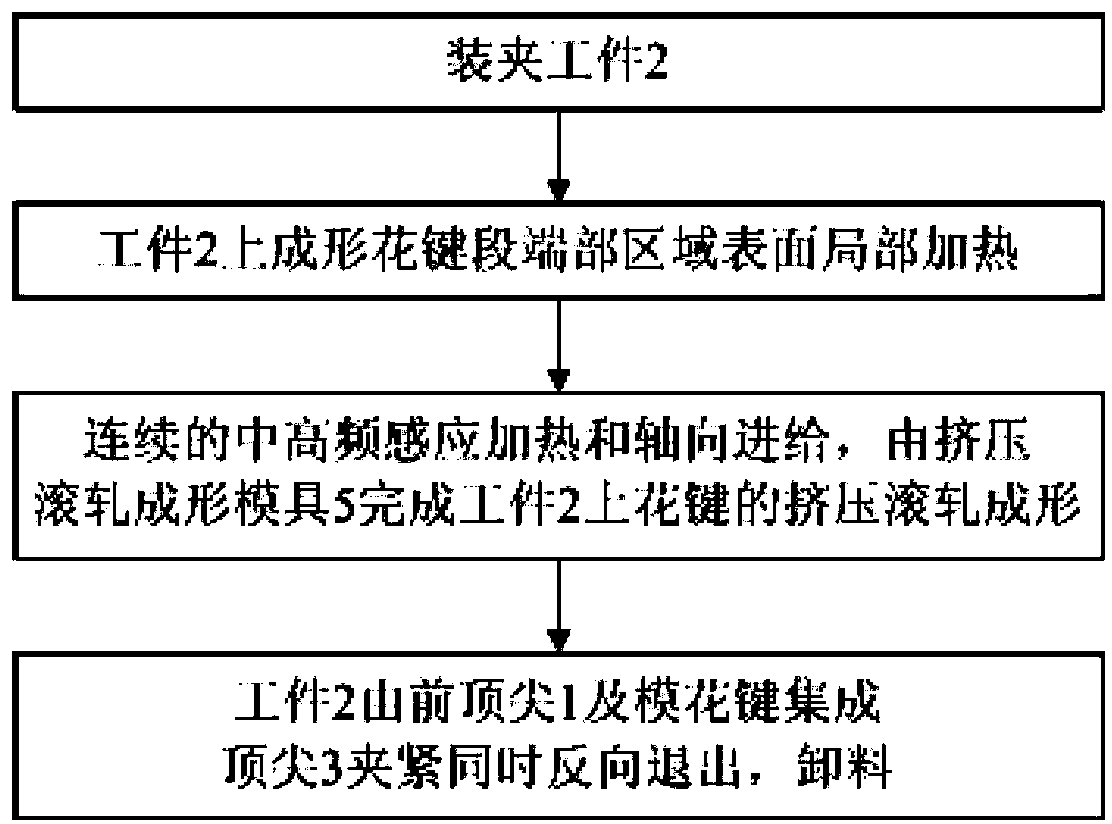

[0031] refer to figure 1 , a method for medium and high frequency induction heating axial feed extrusion roll forming spline shaft, comprising the following steps:

[0032] Step 1, clamping workpiece 2;

[0033] The workpiece 2 is clamped by the front center 1 and the die spline integrated center 3, ensuring that the theoretical indexing circle of the workpiece 2 is tangent to the indexing circle of the extrusion rolling forming die 5;

[0034] Step 2, locally heating the surface of the end part of the formed spline section on the workpiece 2;

[0035] 2.1. The workpiece 2 is fed in the direction of the extrusion rolling forming die 5, and the formed spline section on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com