Ring for fluid production dispensing

A technology of fluid products and valves, which is applied in the ring field of aerosol dispensing valves, and can solve problems such as high manufacturing costs, manufacturing tolerances, and complex shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

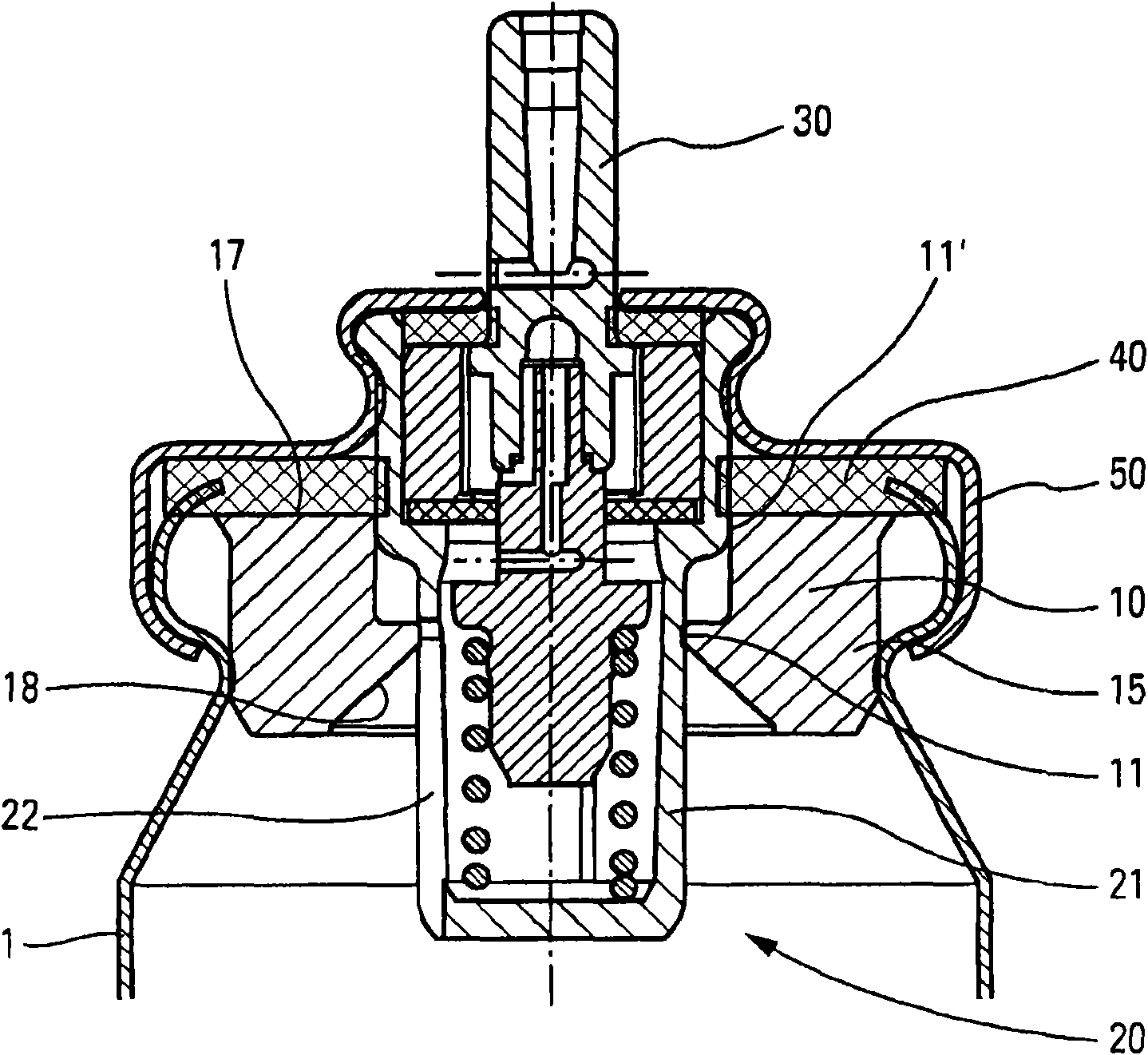

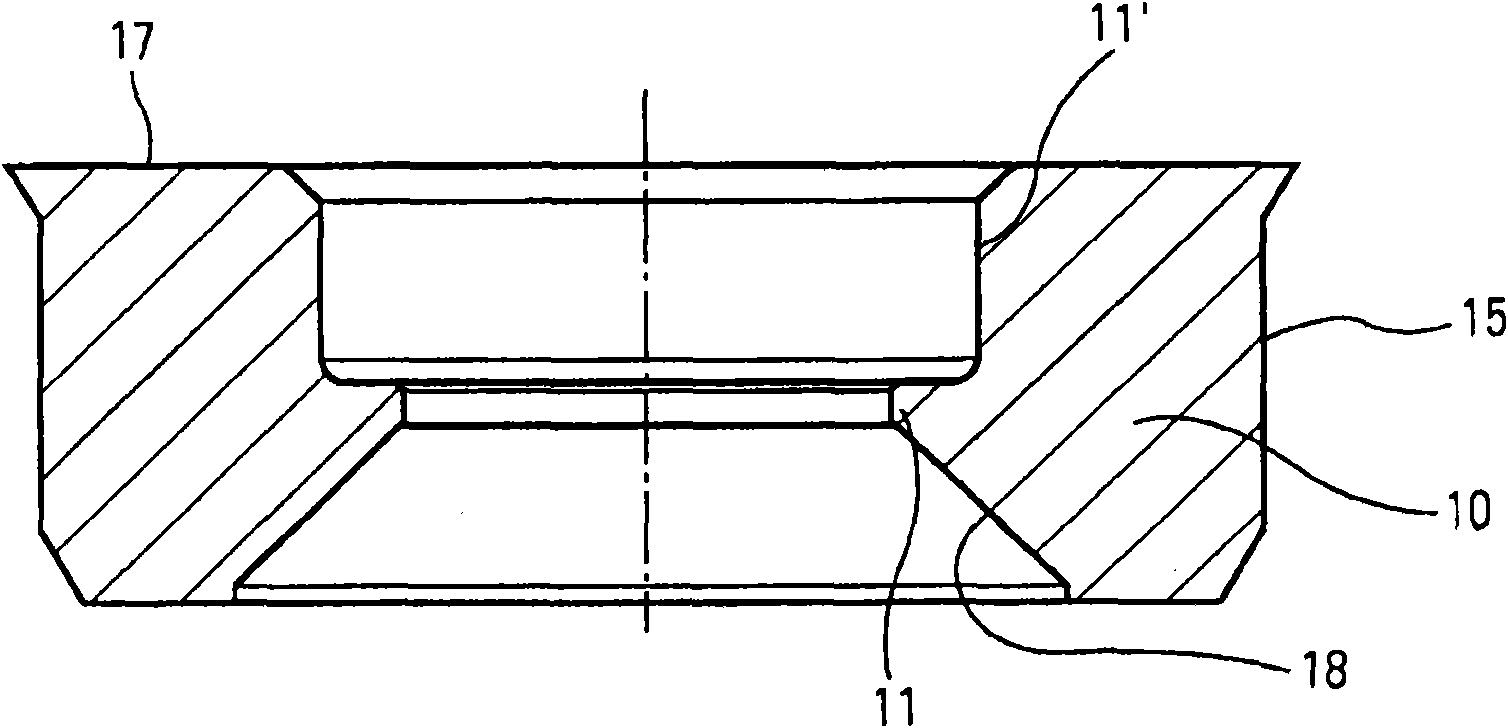

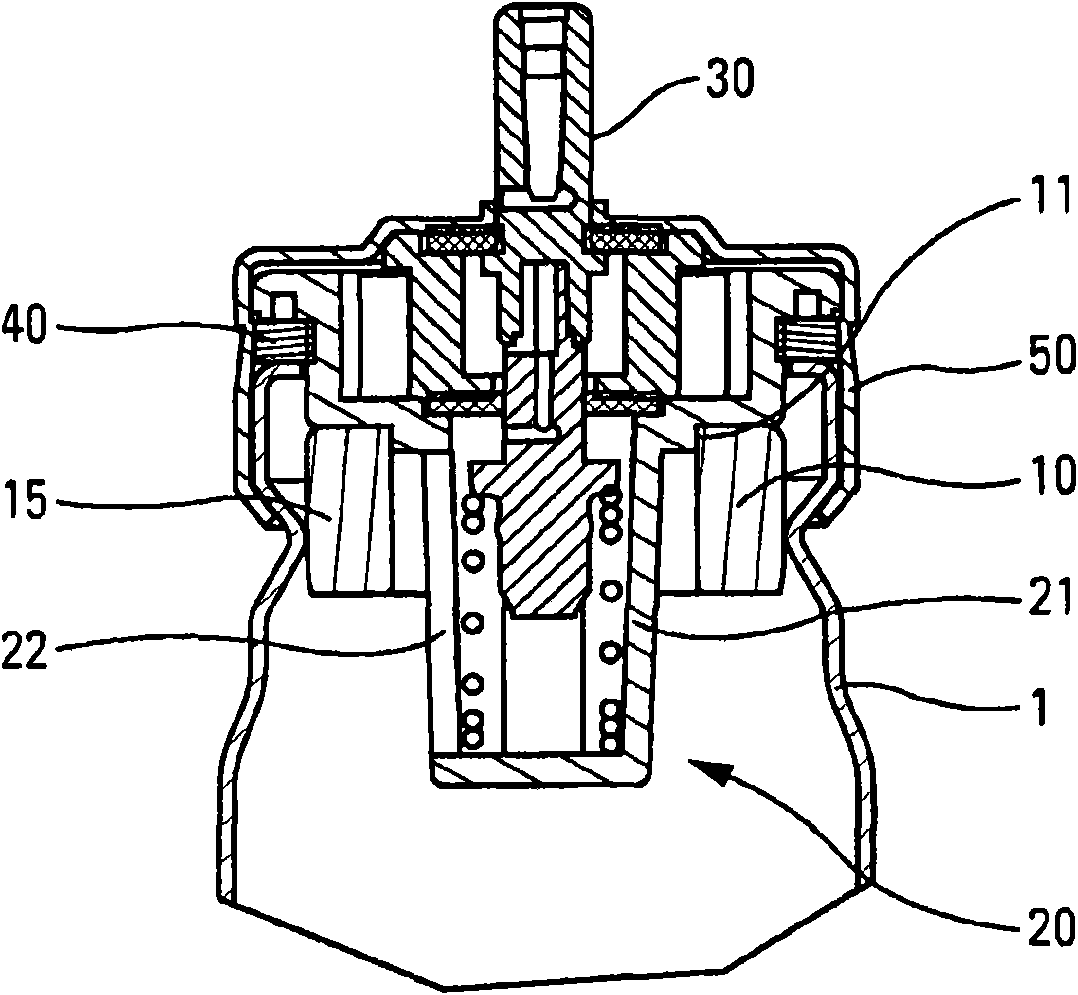

[0027] [27] Referring to the figures, the aerosol device comprises a reservoir 1 containing the product to be dispensed. The product may be of the pharmaceutical type and an actuation gas may be provided to dispense the product through an aerosol valve 20, preferably a dose valve. The aerosol valve includes a valve body 21 , and a valve element 30 slides in the valve body 21 . The valve body 21 is assembled on the neck of the reservoir 1 by means of a fixing ring or cap 50, in particular of the insertable type, with a neck gasket 40 interposed therebetween for sealing. The valve shown is particularly intended for use in an inverted position, ie the valve is located below the reservoir when a dose is expelled. The valve body 21 includes one or more openings 22 allowing the valve to be filled with product from a reservoir. The shape of said opening is shown as a longitudinal side slit 22 extending over part of the height of the valve body 21 . As a variant, one or more openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com