Machining process of cylinder reinforcing rib based on laser grooving and hot rolling

A laser grooving and processing technology, applied in laser welding equipment, metal processing equipment, forming tools, etc., can solve the problems of material and energy waste, difficult to guarantee quality, excessive equipment tonnage, etc., to achieve high heating efficiency and production. Low cost and the effect of reducing deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 In the processing cylinder longitudinal ribs an example embodiment, will be described.

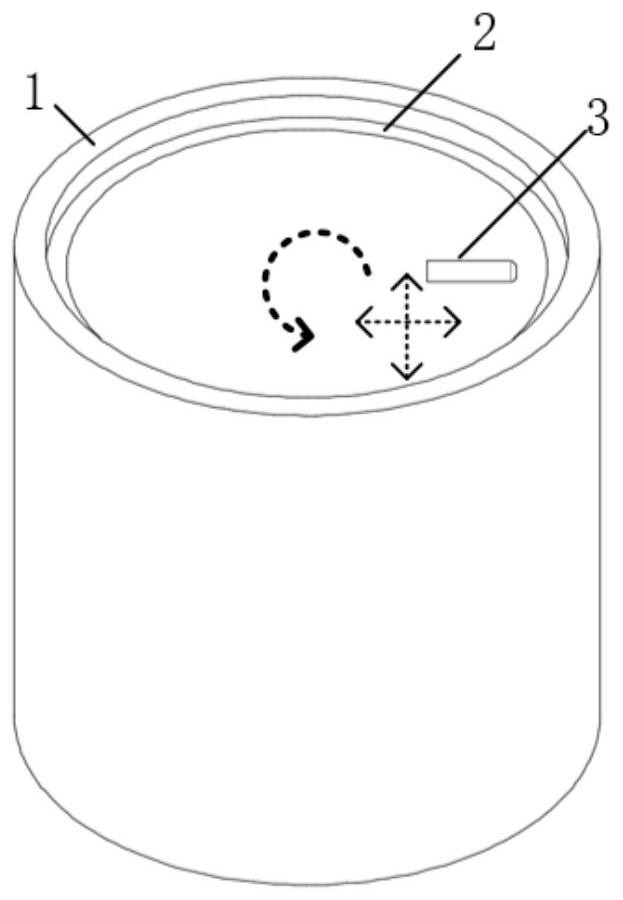

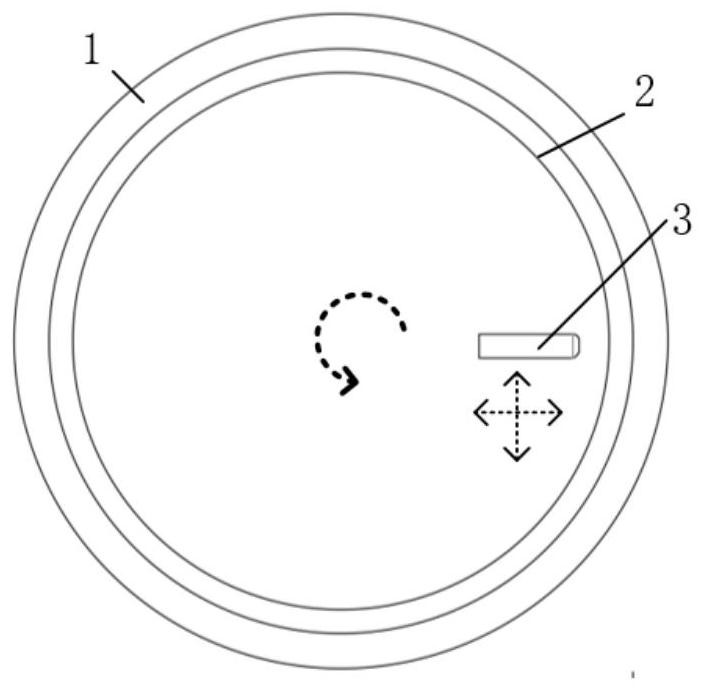

[0045] A process step, laser grooved cylinder, see this section figure 1 and figure 2 , figure 1 and figure 2 Example embodiments are isometric and schematic top view of the laser grooved 1;

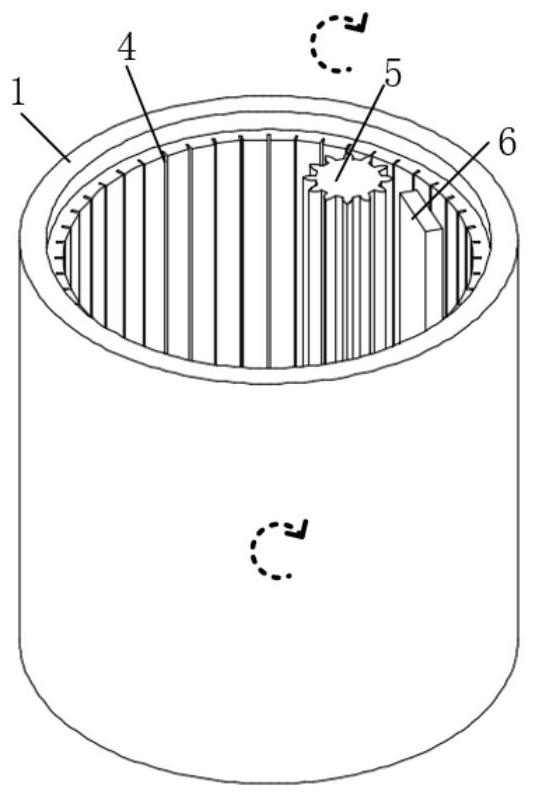

[0046] 2 is first tubular material is mounted inside the outer cylindrical split mold 1, and the laser cutting head 3 projects into the interior of the tubular blank 2. Laser grooving, the laser cutting head 3 from one end of the tubular blank 2 to the other end of the movement, processing the desired groove 2 of the tubular material. Laser cutting head 3 for each completed processing a trench, the outer cylindrical split mold 1 drives rotation of the tubular material 2 a small angle, so that the laser cutting head 3 at a position n-grooving. Is repeated until the complete processing of all the trenches, at this time becomes the cylindrical blank 2 laser grooved barrel 4. Finally, the la...

Embodiment 2

[0052] When the reinforcing rib when, the overall process is substantially the same steps as in Example 1 barrel processing aspect, the need to change the laser cutter processing path 3, to give vertical and horizontal grooves, and then use aspect, instead of longitudinal ribs nip roller 5 to the roll bars 9 to give vertical and horizontal cylindrical bars 10 processed by this process.

[0053] Figure 7 Example 1 is a longitudinal front view of the rolling rolls used in FIG ribs, wherein Figure 7 (A) is a longitudinal rib roll, Figure 7 (B) a longitudinal cylindrical rib Example 1 embodiment, it can be seen corresponding to both.

[0054] See Figure 8 , Figure 8 A front view of a roll to an aspect of the embodiment of Example 2, Figure 8 (A) for the longitudinal and transverse ribs roll, Figure 8 (B) is an aspect of the embodiment of Example 2 to the cylindrical ribs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com