Micron-nano scale in-situ nano indentation and scratching test system

A nano-indentation and testing system technology, which is applied in the direction of testing material hardness, measuring devices, instruments, etc., can solve the problems of loading force model error, high price, and inability to detect loading force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

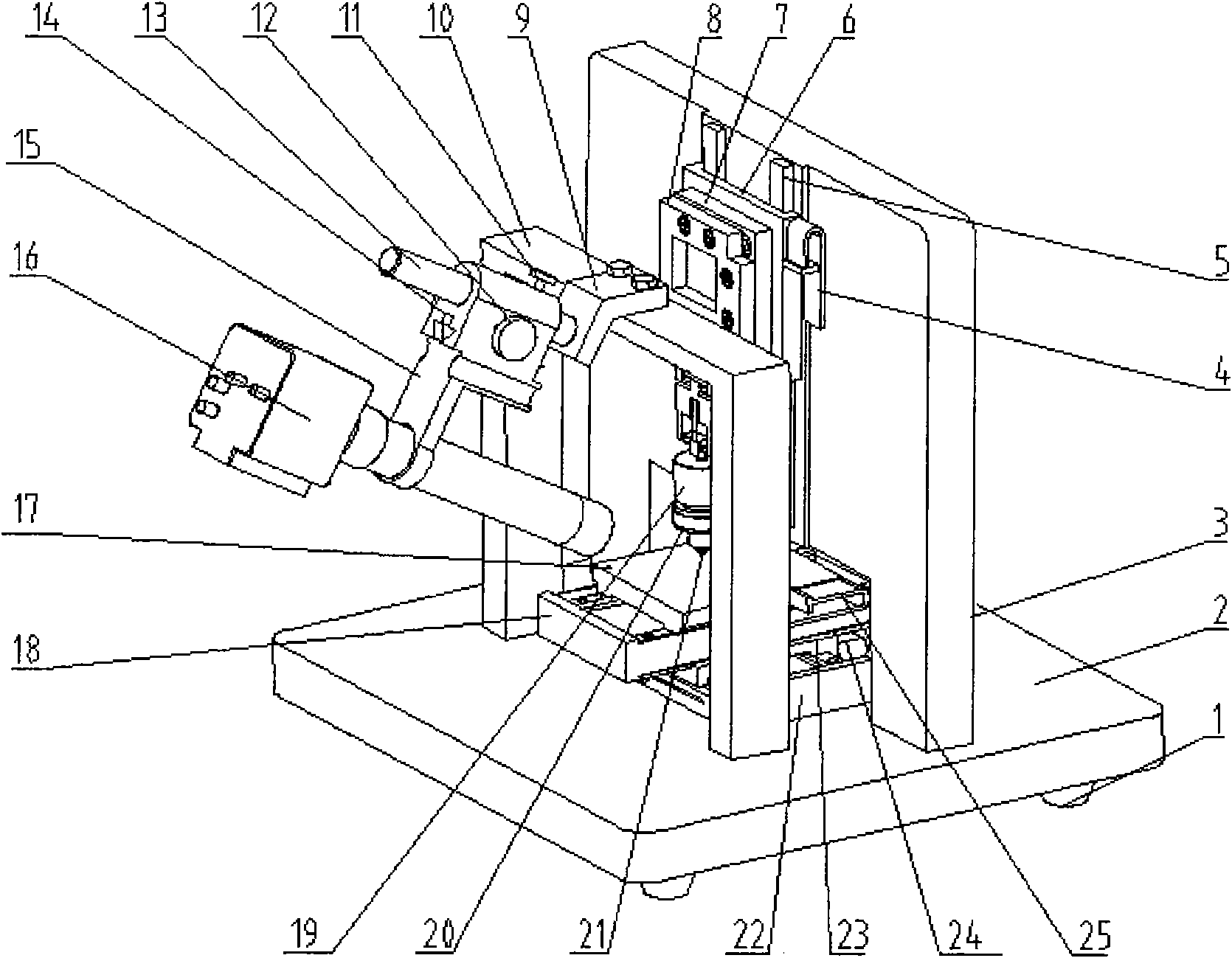

[0029] The details of the present invention and its specific implementation will be further described below in conjunction with the embodiments shown in the accompanying drawings.

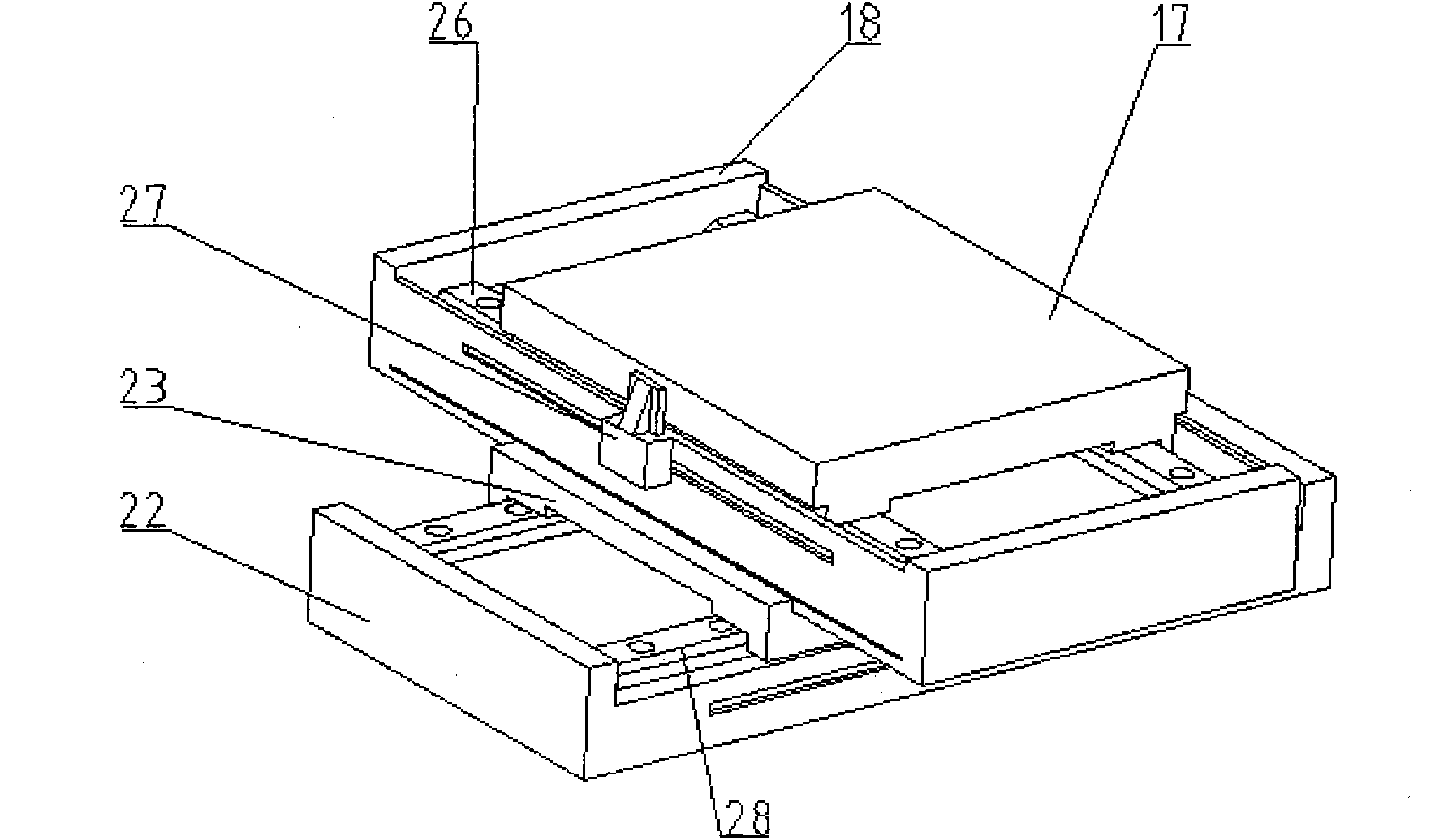

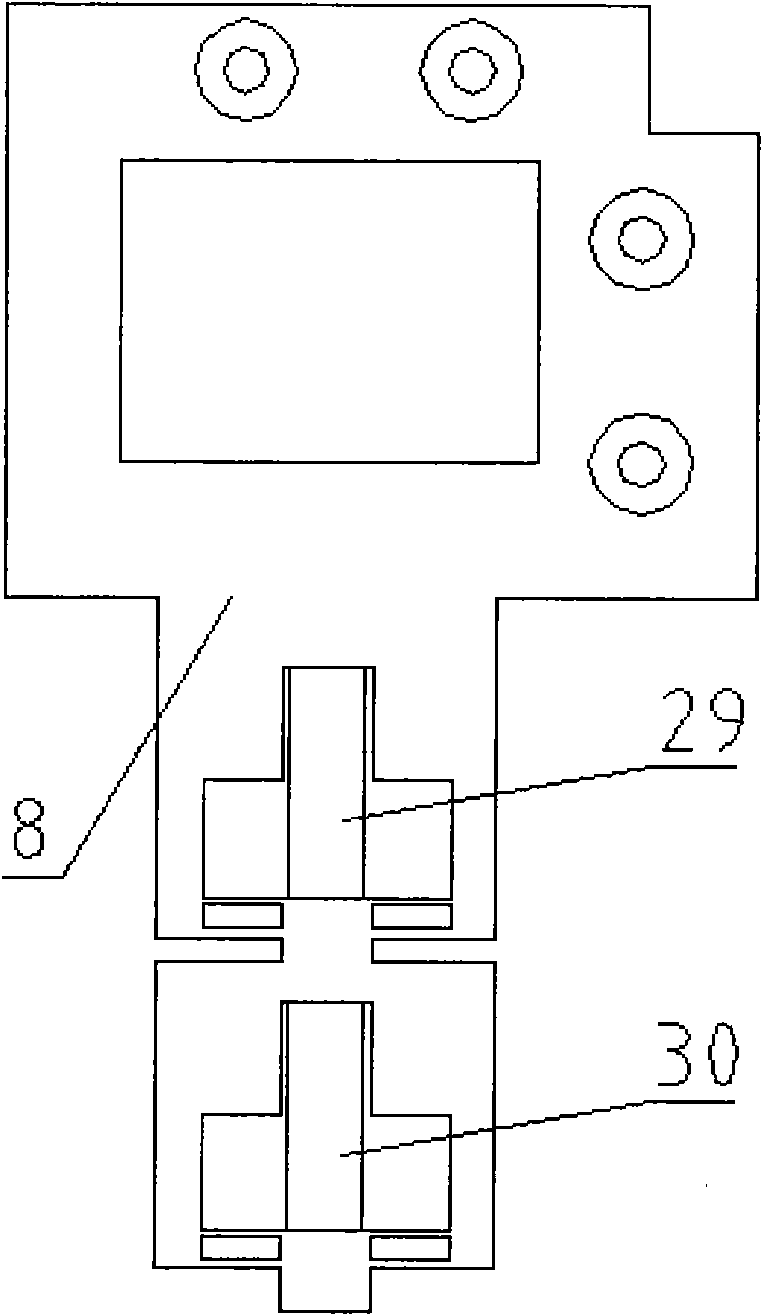

[0030] A micro-nano-level in-situ nano-indentation scoring test technology and system, mainly composed of a precision positioning platform 17 in the X and Y axis directions, a precision linear positioning platform 6 in the Z axis direction, a precision press-in drive unit, a load signal detection unit, It consists of a displacement signal detection unit and a high-resolution digital microscopic imaging system for observing material deformation and damage during storage testing. The precise positioning platform 17 in the X and Y axis directions is assembled on the base 2, and the precise linear positioning platform 6 in the Z axis direction is installed on the side plate 3, and the drive unit is precisely pressed in to detect the precision of the pressure of the diamond tool head pressed into the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com