Apparatus and method for testing cement concrete penetration performance under loading action

A technology for hydraulic concrete and testing device, applied in measurement device, permeability/surface area analysis, suspension and porous material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

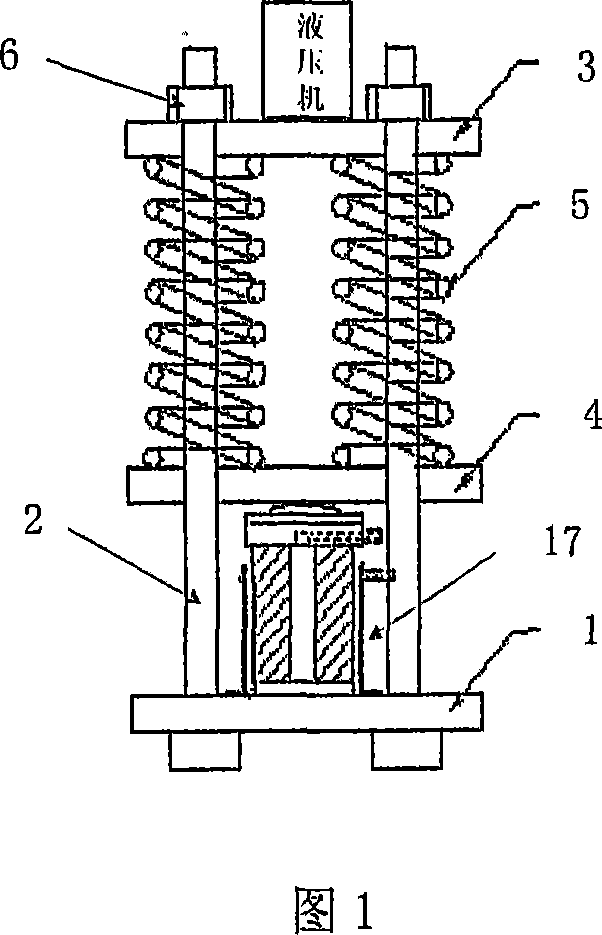

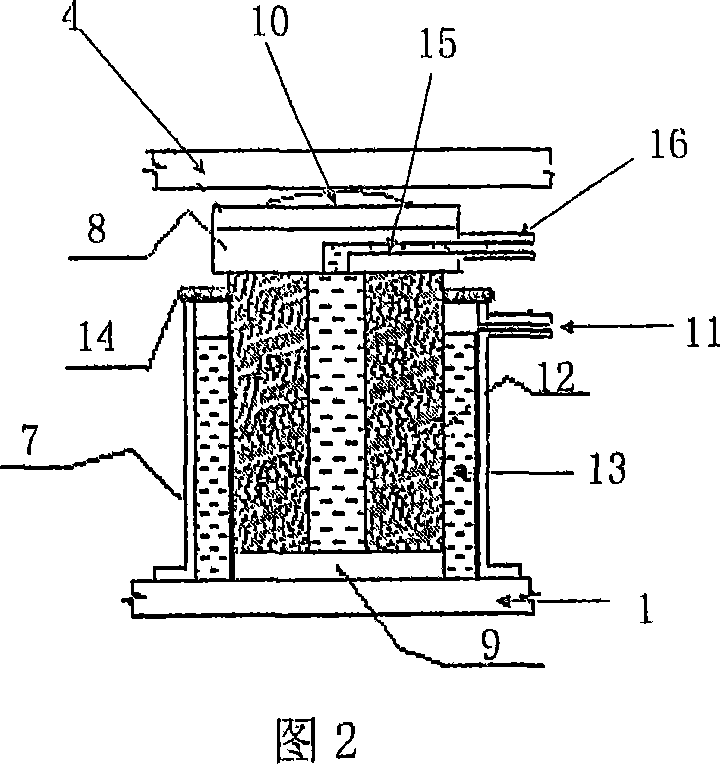

[0020] Embodiment 1 Permeability test device of hydraulic concrete under load

[0021] The test device consists of two parts: a pressurizing device and a specimen chamber (17), wherein the steel chassis (1), steel plate (3) and steel plate (4) in the pressurizing device are respectively 340mm long, 170mm wide and 28mm high , four symmetrical round holes with a diameter of 18mm are respectively drilled around it, and four steel columns (2) with a diameter of 25mm at the lower end of 650mm in length and 16mm in diameter and threaded on the upper end are inserted into the steel columns (2). In the four circular holes on the chassis (1), the specimen chamber (17) is placed on the steel chassis (1), which is placed on the steel chassis by a plexiglass sleeve (7) with a diameter of 130 mm, a height of 120 mm, and a thickness of 8 mm. (1), put the concrete test piece (12) with inner and outer diameters of 30mm and 110mm and a height of 110mm into the sleeve (7), and there is a piece ...

Embodiment 2

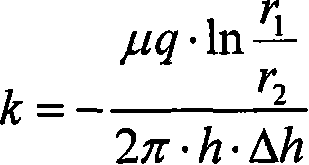

[0022] Example 2 Test method for load permeability coefficient of hydraulic concrete.

[0023] 1. Raw materials and test pieces

[0024]Use P O32.5 grade cement (see Table 1 for physical properties), II grade fly ash, river sand with a fineness modulus of 2.5, limestone artificial gravel with a maximum particle size of 10mm and tap water according to the mix ratio shown in Table 2 Concrete was prepared and formed into cylindrical specimens with inner and outer diameters of 30mm and 110mm respectively, with 6 specimens in each group. After the specimen was cured in the concrete standard curing room for 28 days, the two ends of the specimen were cut off with a diamond saw blade to obtain a specimen with a height of 110 mm. Three specimens in each group were selected to measure the compressive strength, which was used as a reference for the loading size of the remaining specimens in the impermeability test. The compressive strength of each group of specimens is shown in Table 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com