Large-scale original grade coarse granular soil vertical permeability deformation tester and test method

A coarse-grained soil, seepage deformation technology, applied in permeability/surface area analysis, instruments, scientific instruments, etc., can solve problems such as large differences, unsuitable penetration test, unreasonable, etc., to improve test accuracy, large-scale penetration test Difficulty, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

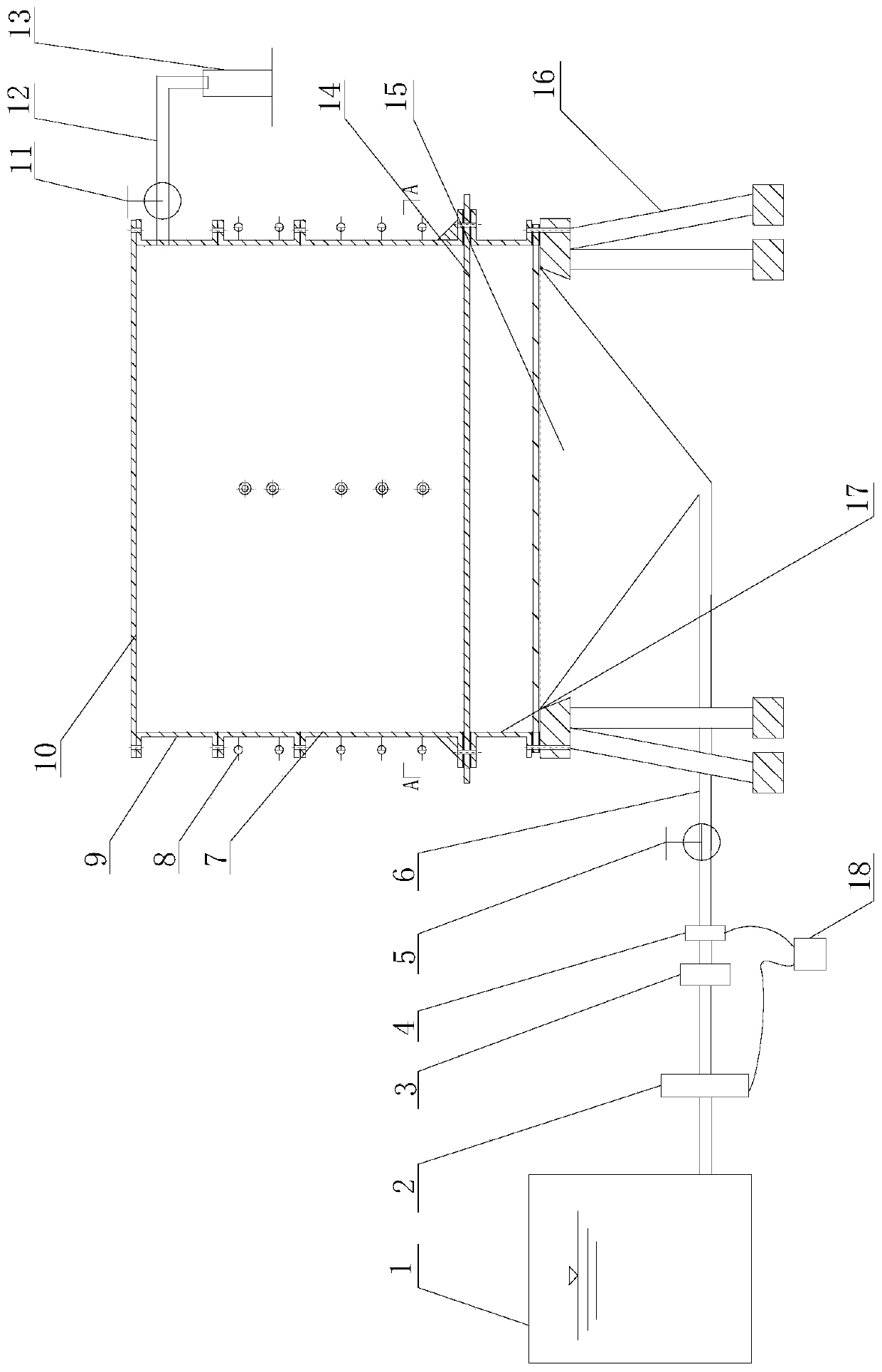

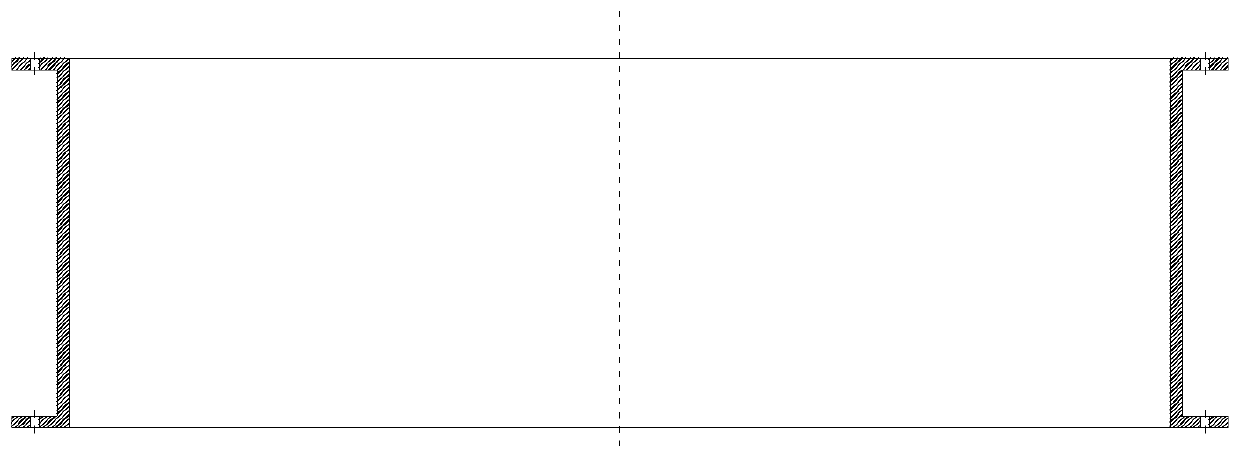

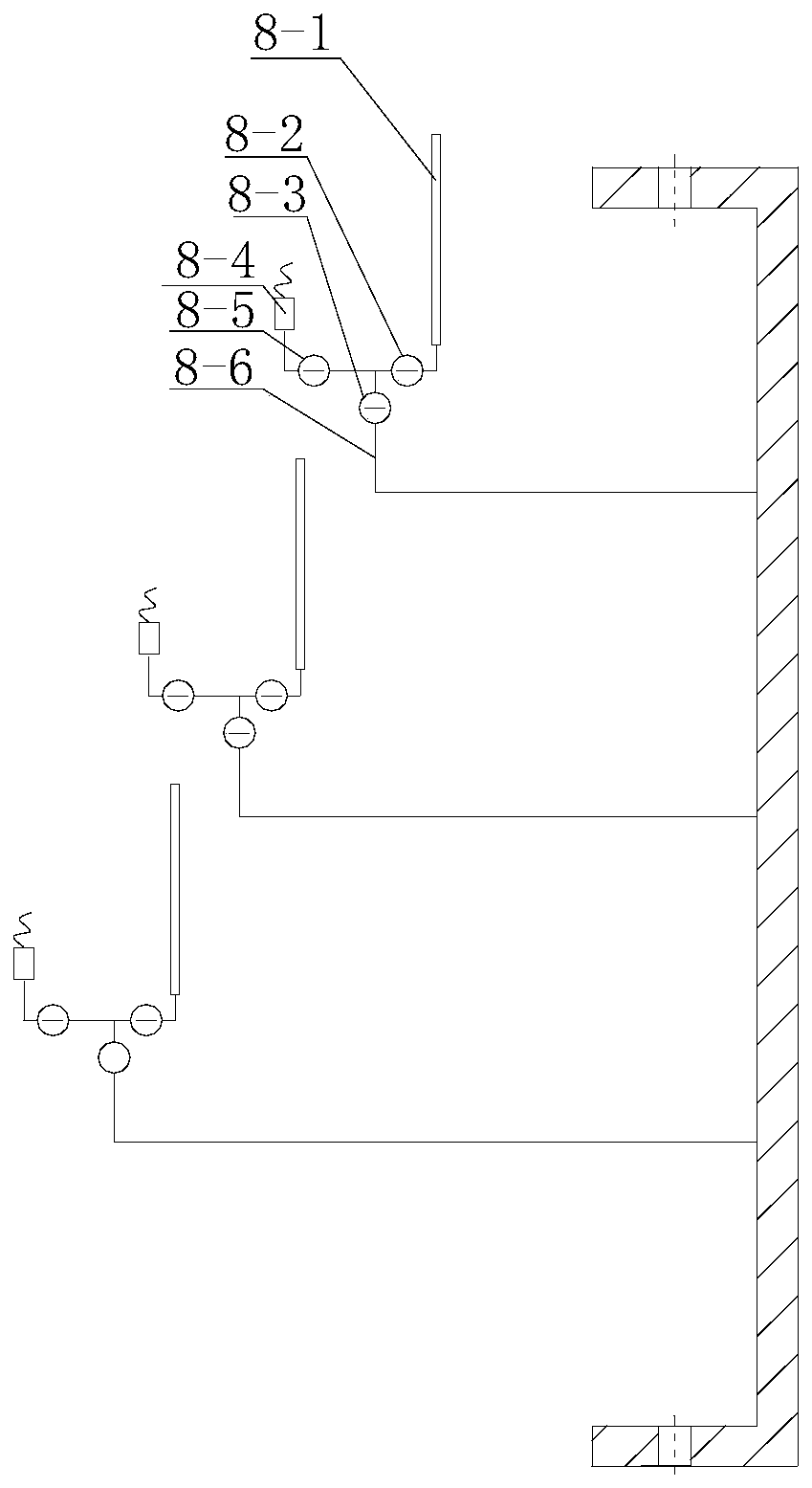

[0047] in Figure 1~7 In the present invention, a large-scale primary-graded coarse-grained soil vertical seepage deformation tester is fixedly connected with a base 15 on a bracket 16 with threaded fasteners. Further, the bracket 16 in this embodiment is made of diagonal braces 16- 1. The bracket body 16-2, the vertical support 16-3, and the ring support 16-4 are connected to form a structure. The bracket body 16-2 is welded by square steel or channel steel into a rectangular cross-section structure, and the lower part of the bracket body 16-2 is welded and fixed There are at least 6 vertical braces 16-3, the bottom part of the bracket body 16-2 and the vertical brace 16-3 are welded and fixed to the corresponding diagonal brace 16-1, and the middle part of the bracket body 16-2 is welded and fixed with an annular support 16-4. The diameter of the annular support 16-4 is adapted to the diameter of the base 15. The base 15 is formed by connecting the base body 15-1 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com