Device and method for testing molecular diffusion coefficients in multi-component oil-gas system under high temperature and high pressure

A molecular diffusion, high temperature and high pressure technology, applied in measurement devices, analytical materials, instruments, etc., can solve the problems that the test accuracy, temperature and pressure conditions cannot meet the requirements of oilfield gas injection, and the component concentration profile cannot be tested. Reliable and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and examples.

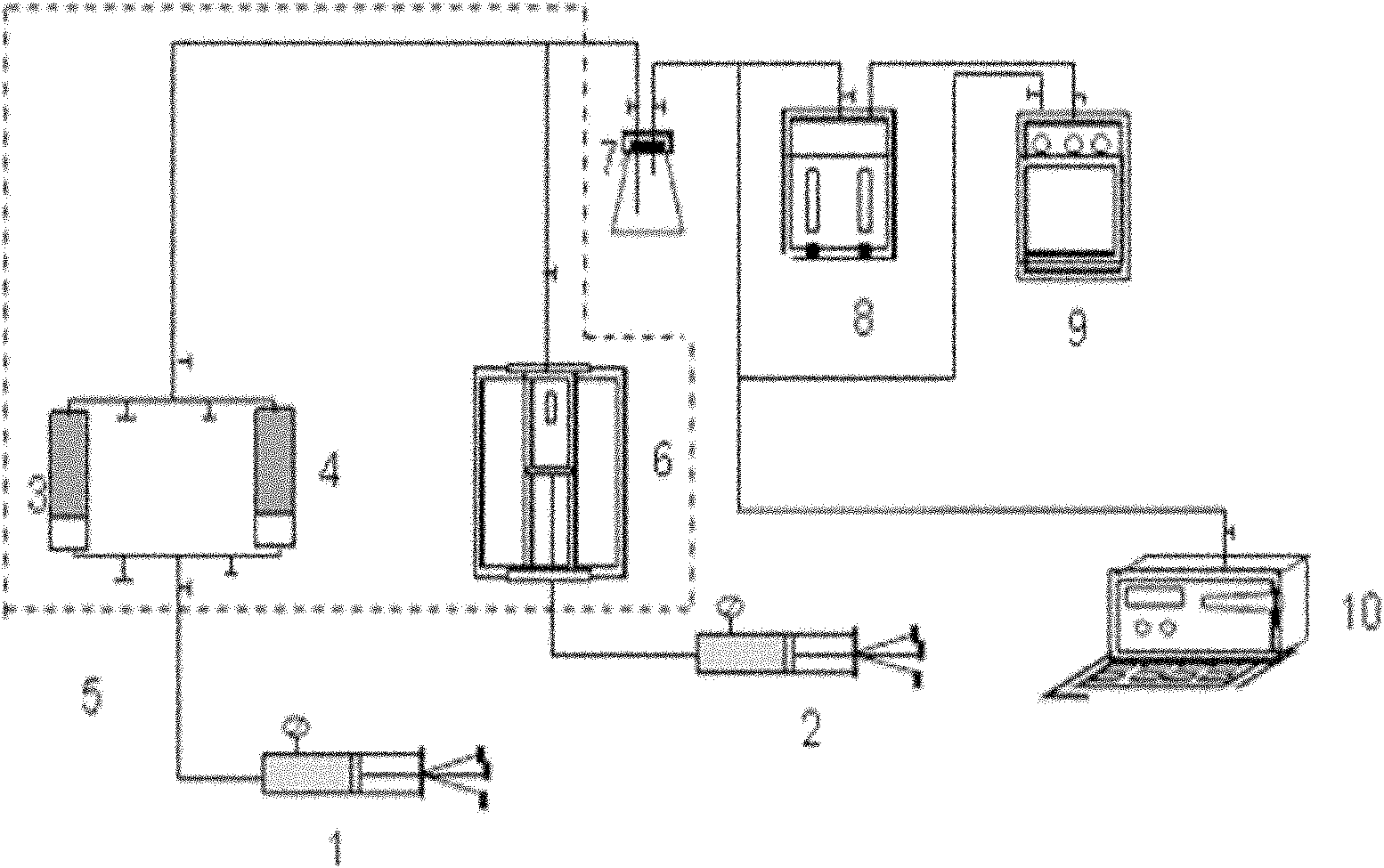

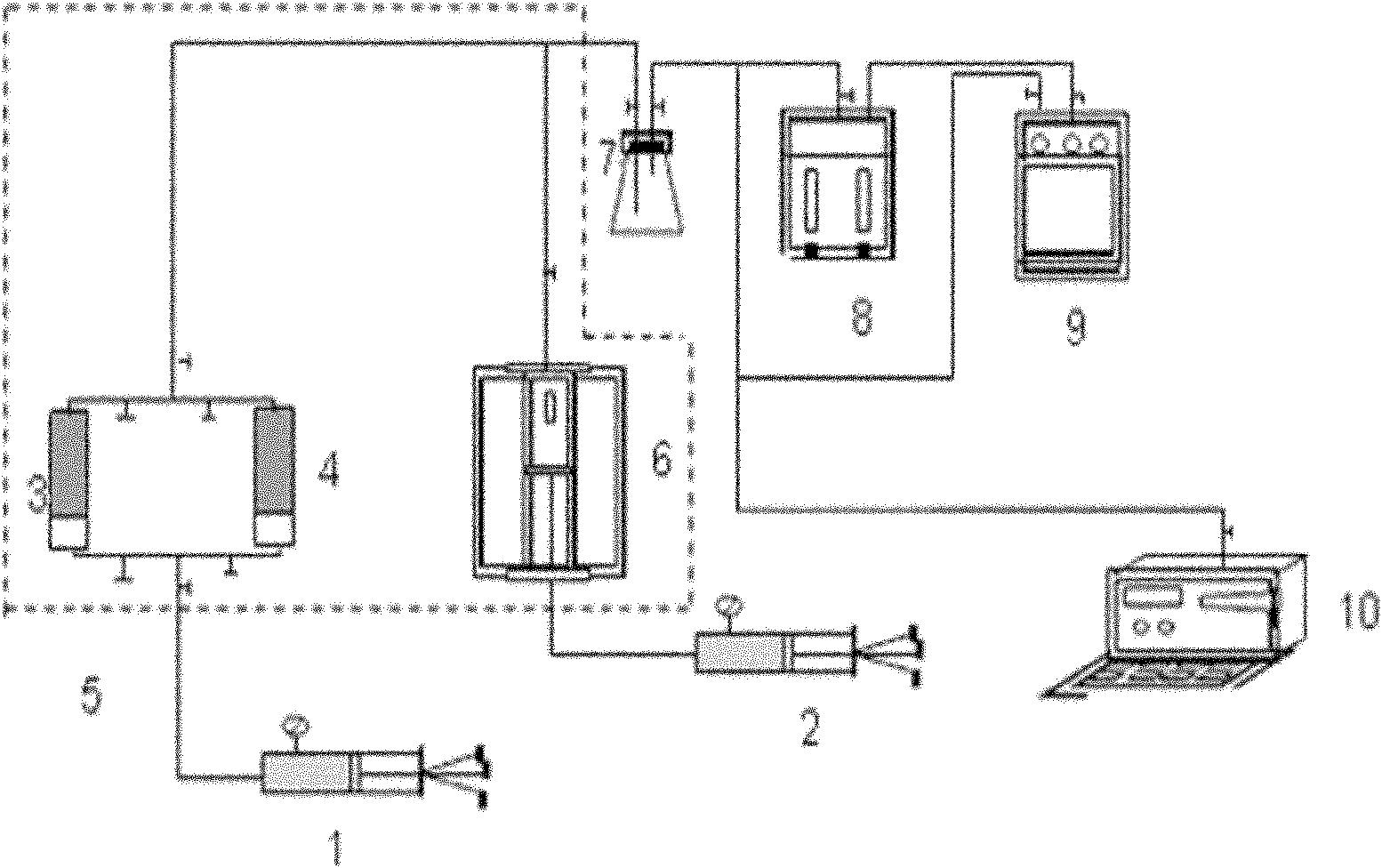

[0033] see figure 1 . The test device for molecular diffusion coefficient of high temperature and high pressure multi-component oil-gas system mainly consists of inlet pump 1, outlet pump 2, intermediate container, PVT cylinder 6, oil-gas two-phase separator 7, gas volume flowmeter 8, and liquid phase density analyzer 10 , chromatographic analyzer 9, it is characterized in that, described intermediate container comprises gas sample intermediate container 3 and oil sample intermediate container 4, and its one end is connected with inlet pump 1, and the other end is connected with PVT barrel 6, and intermediate container and PVT barrel are both Located in the constant temperature box 5, the PVT cylinder is connected with an oil-gas two-phase separator 7, and the separator is connected with a gas volume flowmeter 8 and a liquid phase density analyzer 10, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com