Experimental device and method for pulse hydrofracture transforming of shale gas storing layer

A technology of hydraulic fracturing and experimental equipment, which is applied in the direction of measuring equipment, using repeated force/pulsation force to test the strength of materials, instruments, etc., which can solve the problem of inability to simultaneously measure permeability changes before and after fracturing, inability to simulate, and lack of real-time monitoring Crack development law and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above is only an overview of the technical solution of the present invention. In order to better understand the technical means of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

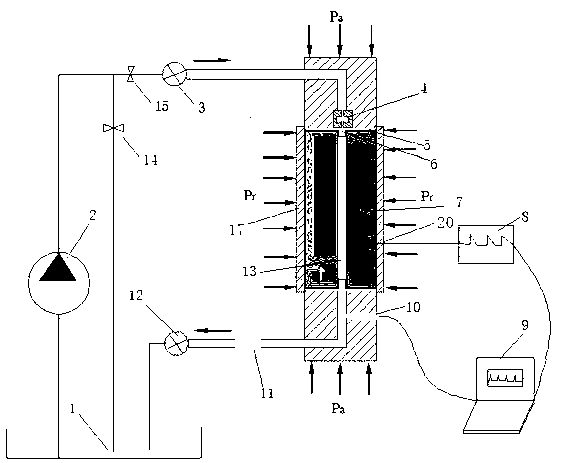

[0026] The invention relates to an experimental device for reforming shale gas reservoirs by pulse hydraulic fracturing, comprising a pulse generation, monitoring and control system, a triaxial stress loading device, a crack monitoring device and a permeability measurement system.

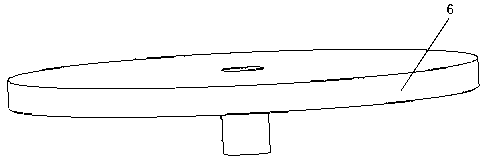

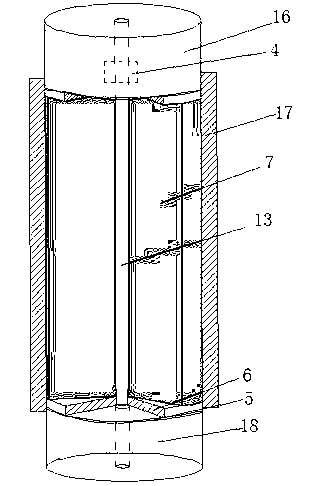

[0027] refer to figure 1 and image 3 , the triaxial stress loading device is composed of a core holder composed of an upper steel seat 16, a lower steel seat 18, and a radial clamping member 17, and a triaxial stress loading system. The triaxial stress loading system can provide 0-4000kN pressure in the axial direction , radial can provide 0-50MPa confining pressure, core size Φ100mm×200mm. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com