Crack grouting visualization tester under complex conditions

A test device and technology for cracks, which is applied in the field of test devices for rock crack grouting simulation tests, can solve problems such as failure to consider the stress state of cracks, crack deformation and relative displacement crack contact surface roughness, lack of experimental equipment, and inability to simulate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A visual test device and test method for crack grouting under complex conditions according to the present invention will be further described in detail below with reference to the accompanying drawings.

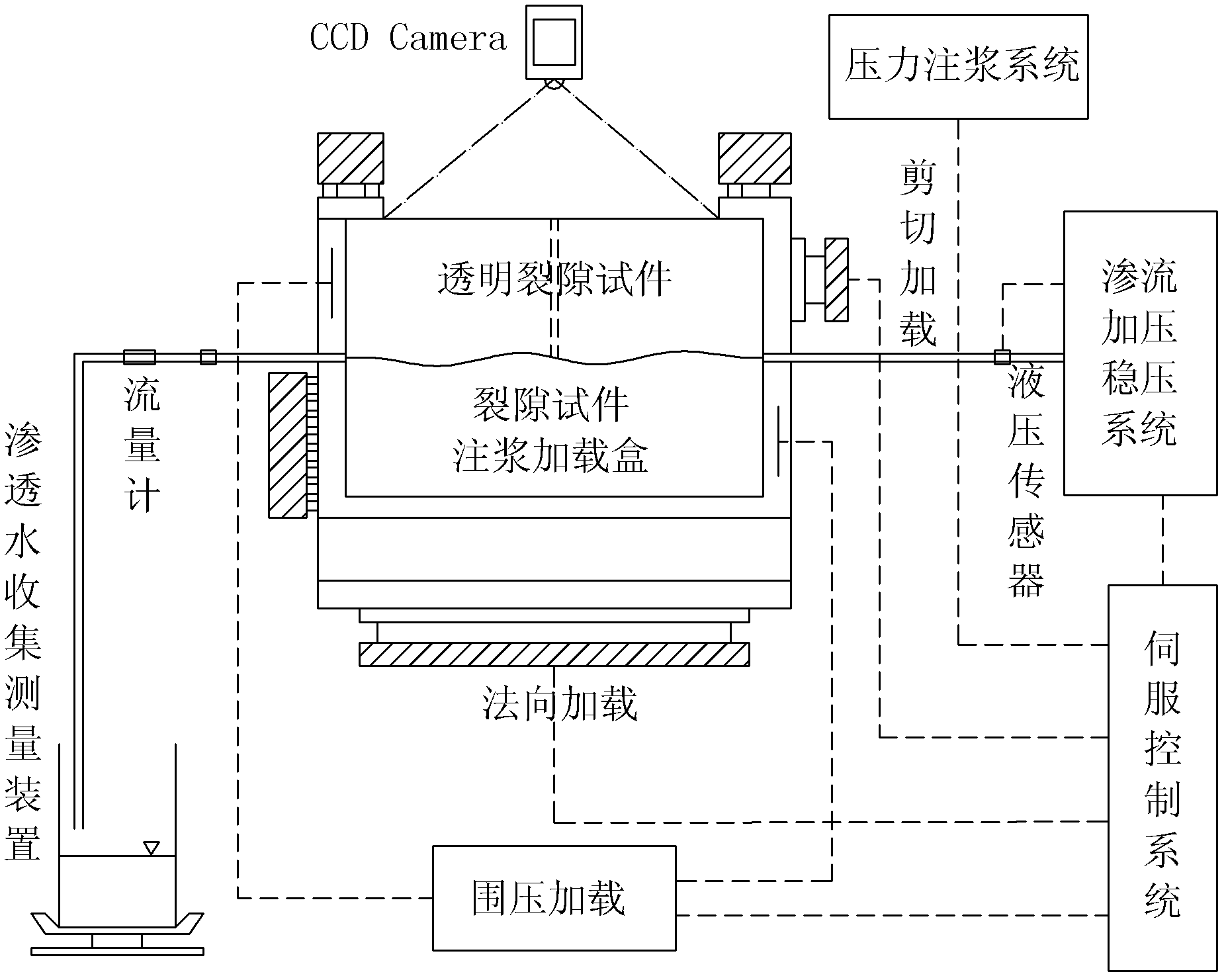

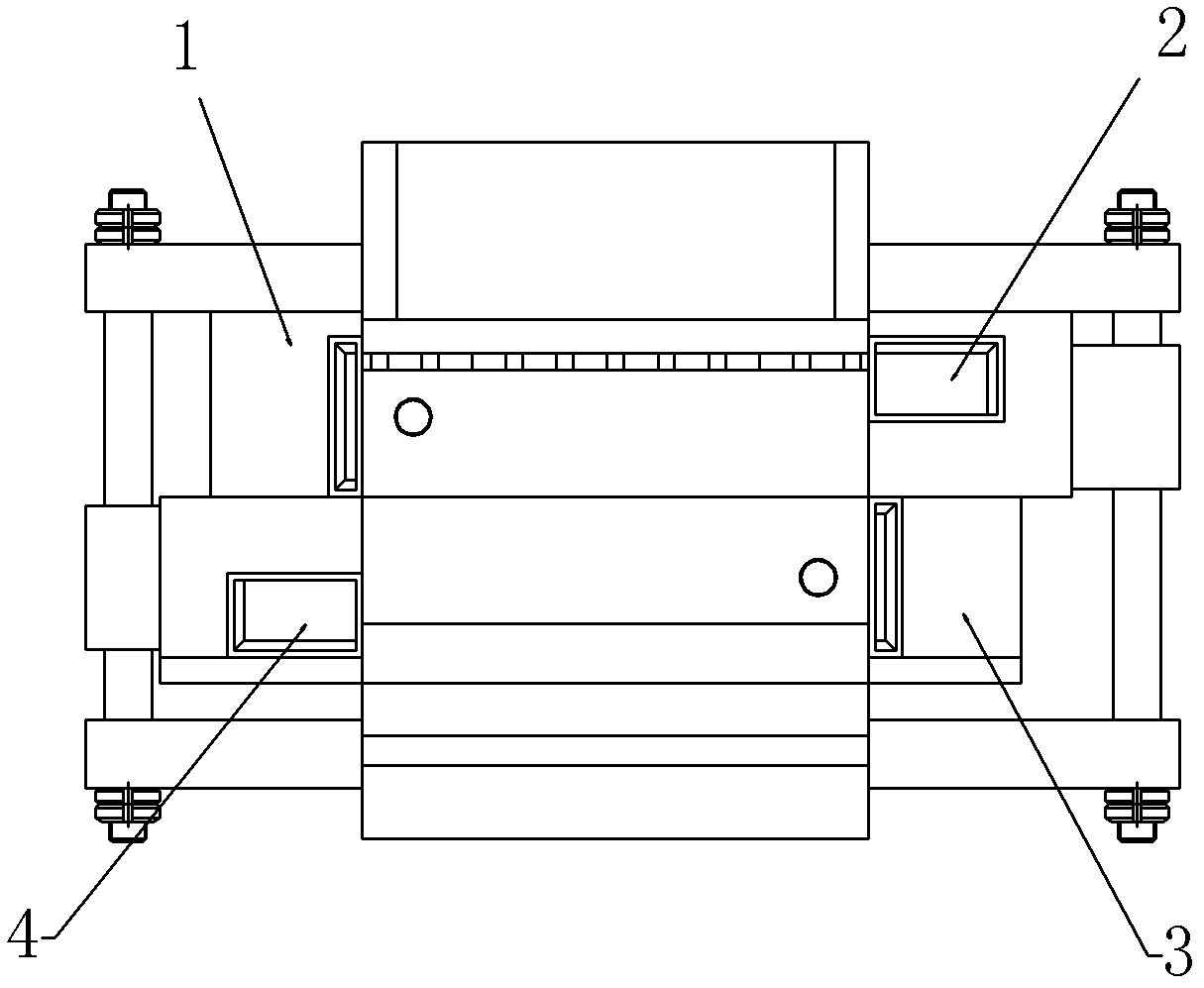

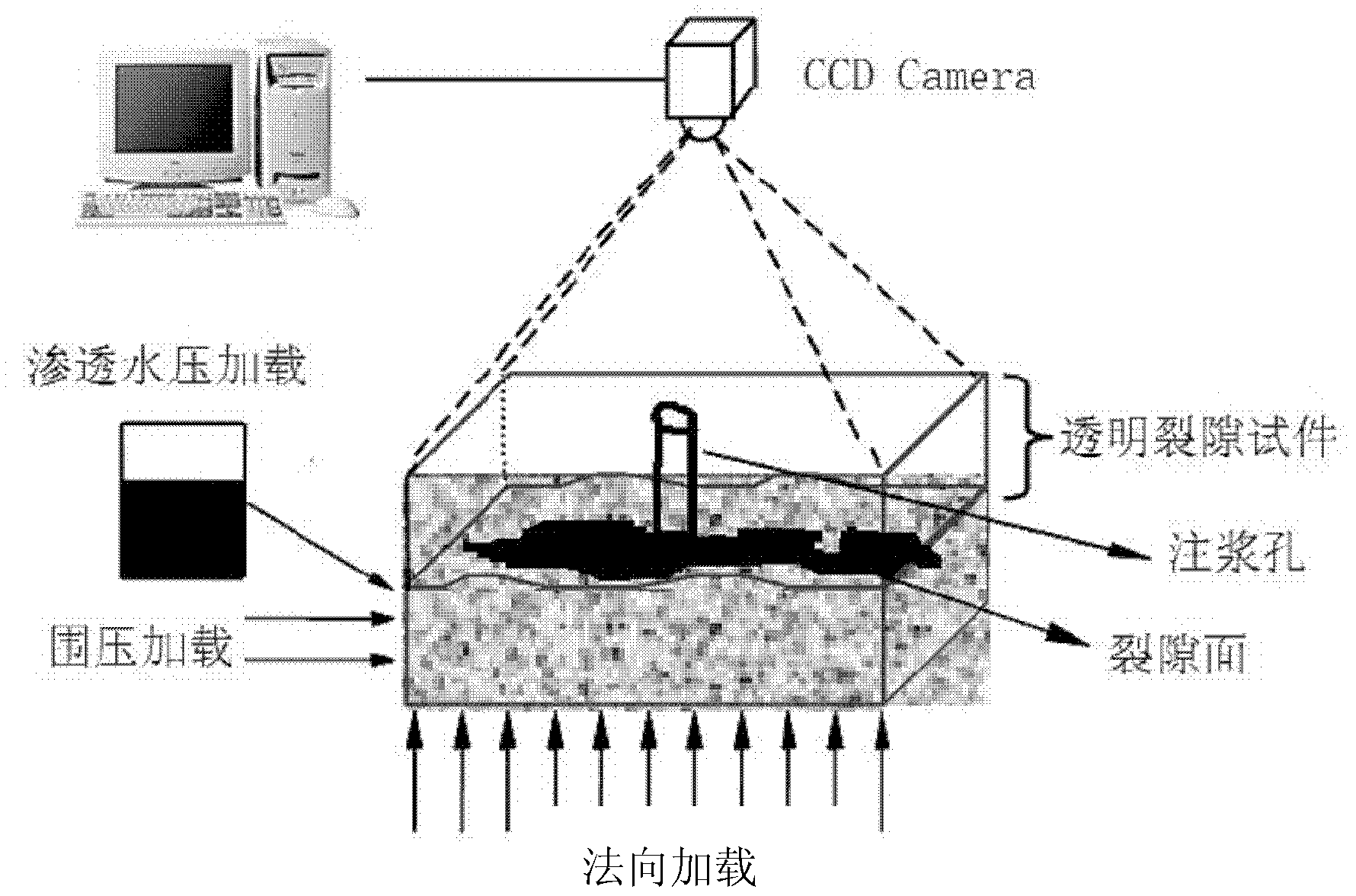

[0027] See attached figure 1 , 3 , a visual test device for fracture grouting under complex conditions, which can simulate various complex conditions such as front shear force, confining pressure, and water pressure. Including the experimental machine frame, crack specimen grouting loading box, axial loading mechanism, tangential loading mechanism, confining pressure loading mechanism, hydraulic loading mechanism, pressure grouting system, flowing water collection and measurement device, visualization system, etc.

[0028] During the experiment, the cracked specimen was placed in a complex stress state through the grouting loading box, the axial loading mechanism, the tangential loading mechanism and the confining pressure loading mechanism, and the hydrodynamic press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com