Thin steel wire atomizing cooling treatment method and device

A technology of atomization cooling and treatment equipment, which is applied in the direction of quenching equipment, heat treatment furnace, heat treatment equipment, etc., can solve the problems of large production consumption, large production investment, high energy consumption, etc., achieve uniform core and surface temperature, and improve performance , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

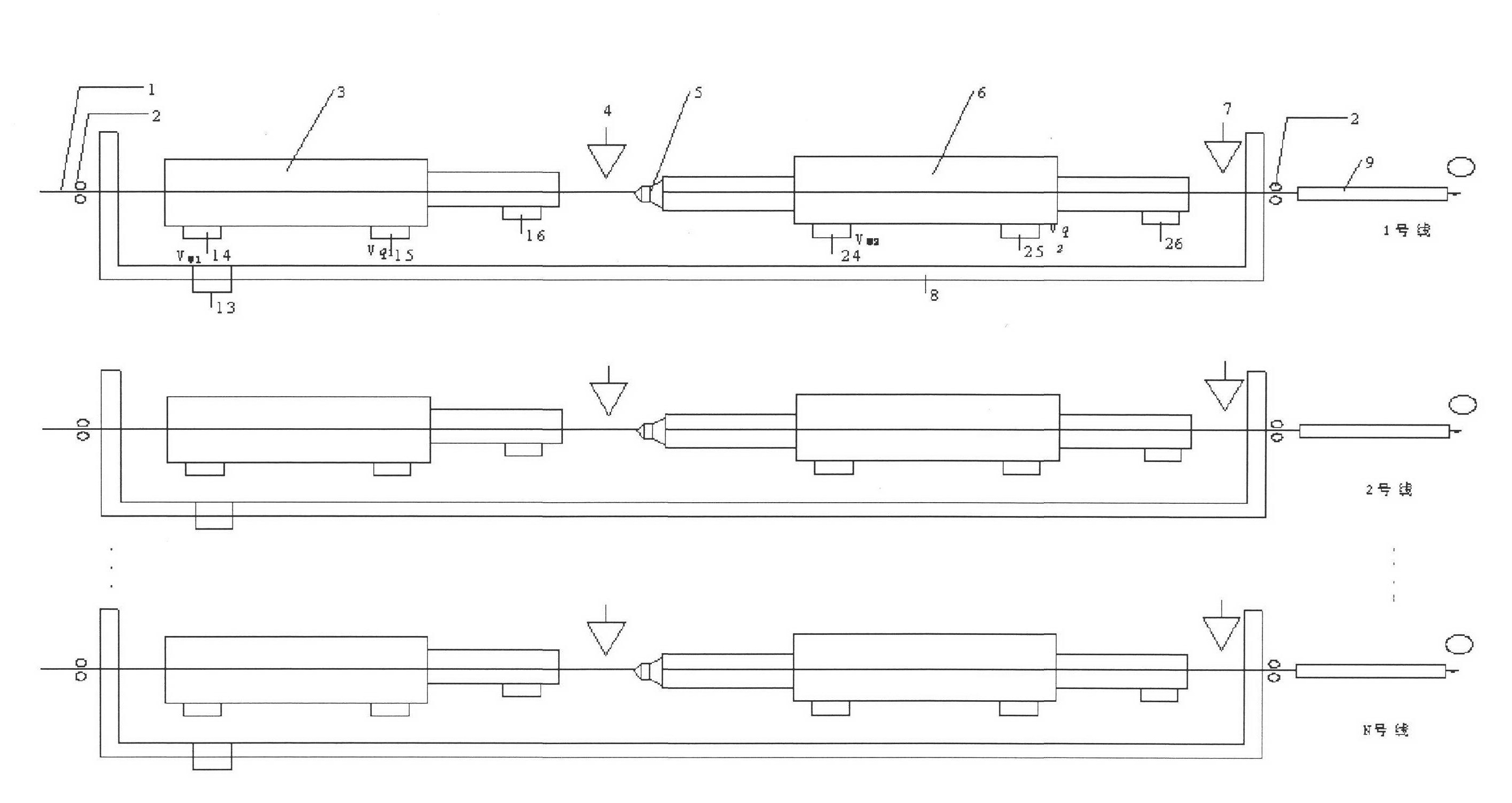

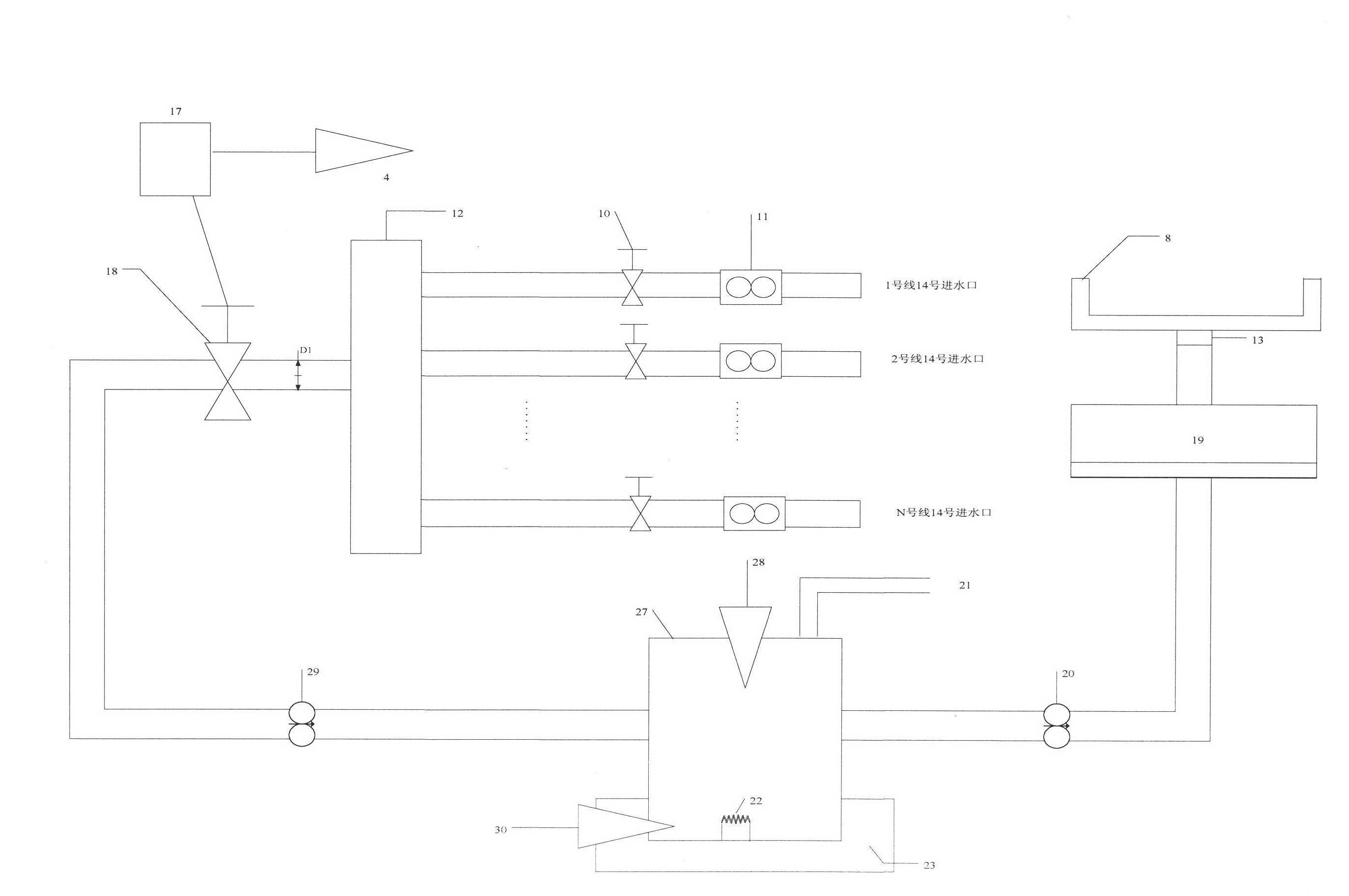

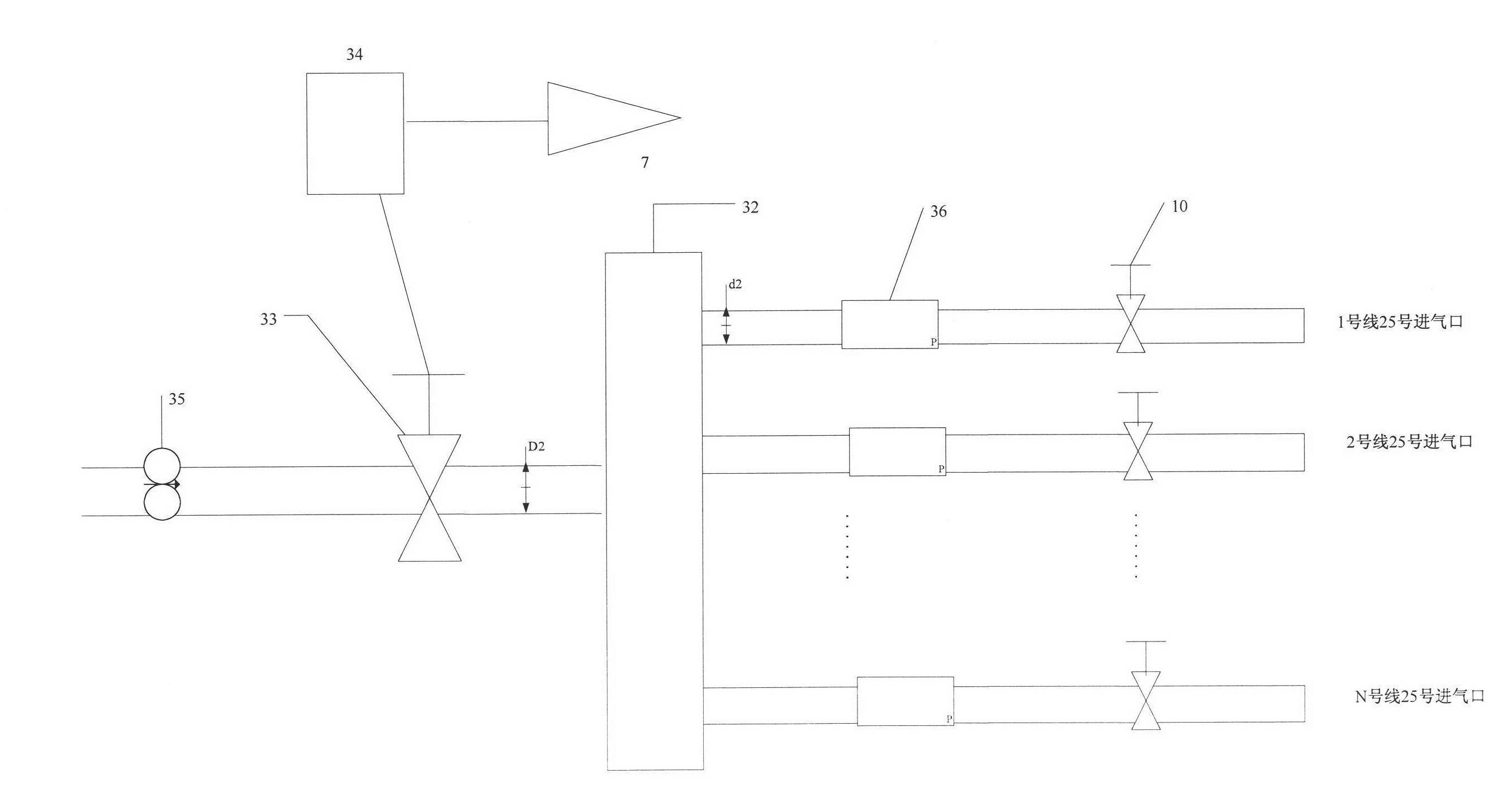

[0048] figure 1 It is a schematic diagram of the composition of the thin steel wire atomization cooling treatment device of the present invention. The device is composed of a guide wheel 2, a primary atomization chamber 3, a primary infrared thermometer 4, a nozzle 5, a secondary atomization chamber 6, a secondary infrared thermometer 7, and a heat preservation chamber 9 and other devices connected in sequence.

[0049] The atomization chamber has a water inlet and an air inlet. By adjusting the ratio of the water flow Vw in the water inlet and the air flow Vq in the air inlet, water mist with different cooling capabilities can be obtained. When Vw=0, what is injected is compressed air, and its cooling ability is the weakest; when Vq=0, what is injected is compressed water, and its cooling ability is the strongest. When the ratio of water and compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com