Banded structure control method, gear steel and formula thereof

A banded structure and control method technology, applied in the field of steel manufacturing, can solve the problem of reducing the banded structure of gear steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

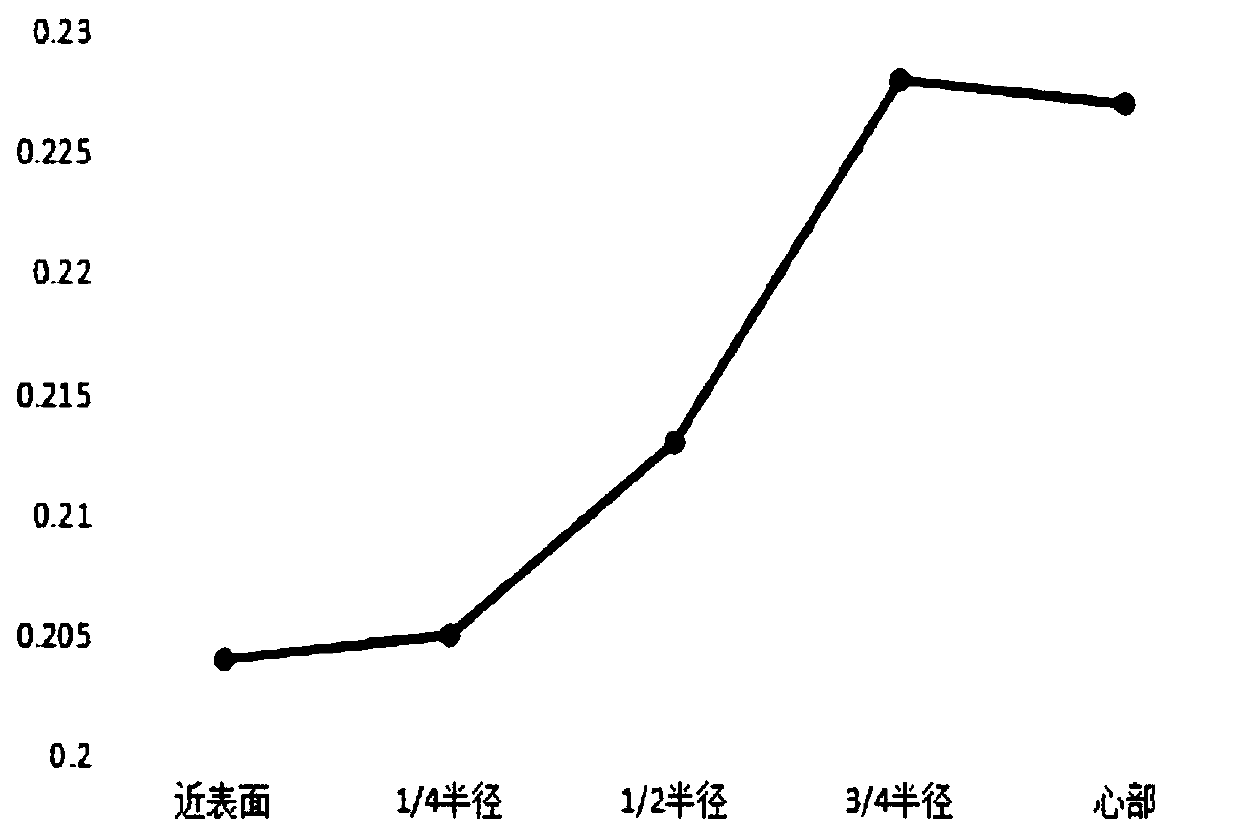

Embodiment 1

[0113] A kind of gear steel provided by this embodiment, its component formula comprises:

[0114] C: 0.22%; Si: 0.25%; Mn: 0.82%; Cr: 1.22%; Mo: 0.38%; P: 0.013; S: 0.020; Al: 0.015%; N: 82ppm; .

[0115] Continuous casting process control: 320mm cross-section billet continuous casting process is controlled by constant temperature and constant casting speed. The superheat of molten steel is controlled at 23°C, the casting speed is 0.55m / min, the electromagnetic stirring parameters of the mold are controlled at 250A / 2.0Hz, and the last stirring electromagnetic Stirring parameters were 450A / 5.0Hz.

[0116] Slab diffusion heating control: the temperature in the high temperature section of the slab is 1251°C, the time in the high temperature section is 373 minutes, and the total heating time is 586 minutes.

[0117] Billet rolling control: rough rolling rolling temperature 1203-1100°C, rolling 6 passes, single pass reduction rate 20-30%.

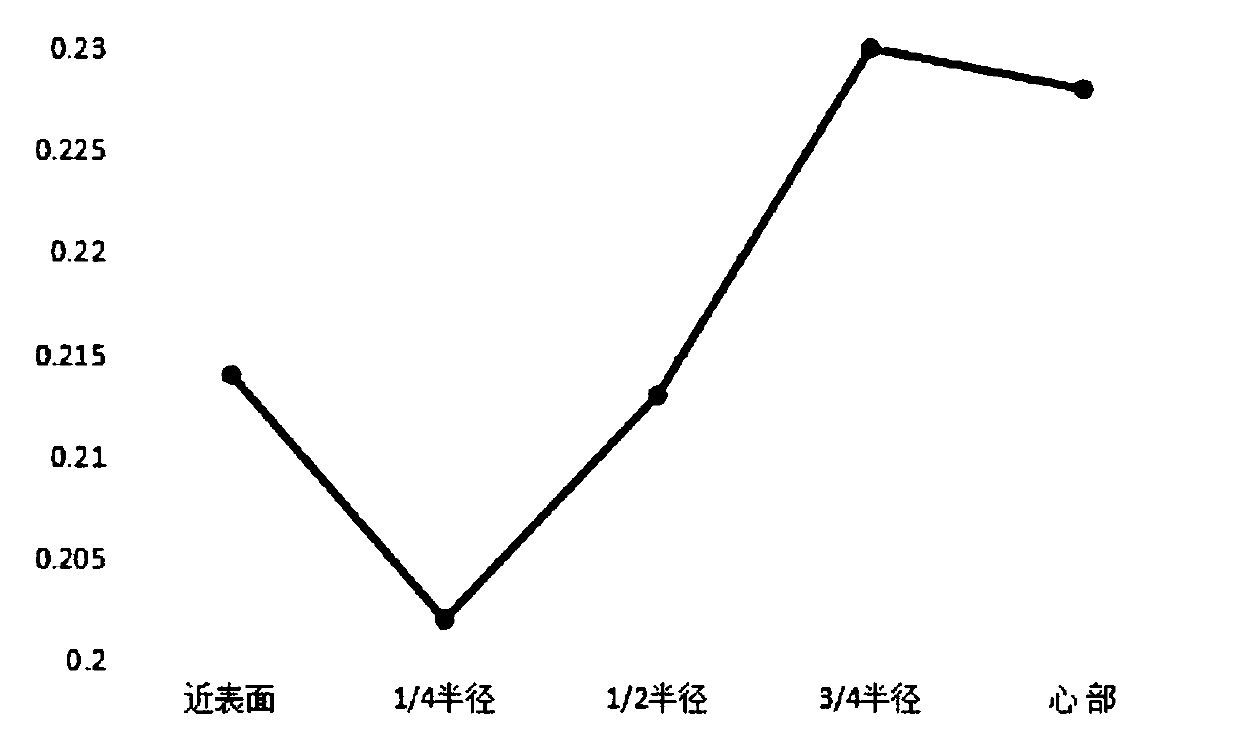

Embodiment 2

[0119] A kind of gear steel provided by this embodiment, its component formula comprises:

[0120] C: 0.20%; Si: 0.23%; Mn: 0.85%; Cr: 1.16%; Mo: 0.42%; P: 0.014%; S: 0.018%; Al: 0.021%; For Fe.

[0121] Continuous casting process control: 320mm section slab continuous casting process is controlled by constant temperature and constant casting speed. The superheat of molten steel is controlled at 25°C, the casting speed is 0.55m / min, the electromagnetic stirring parameters of the mold are controlled at 250A / 2.0Hz, and the last stirring electromagnetic Stirring parameters were 450A / 5.0Hz.

[0122] Slab diffusion heating control: the temperature in the high temperature section of the slab is 1249°C, the time in the high temperature section is 394min, and the total heating time is 592min.

[0123] Slab rolling control: rough rolling rolling temperature 1195-1089 ℃, rolling 6 passes, single pass reduction rate 20-30%.

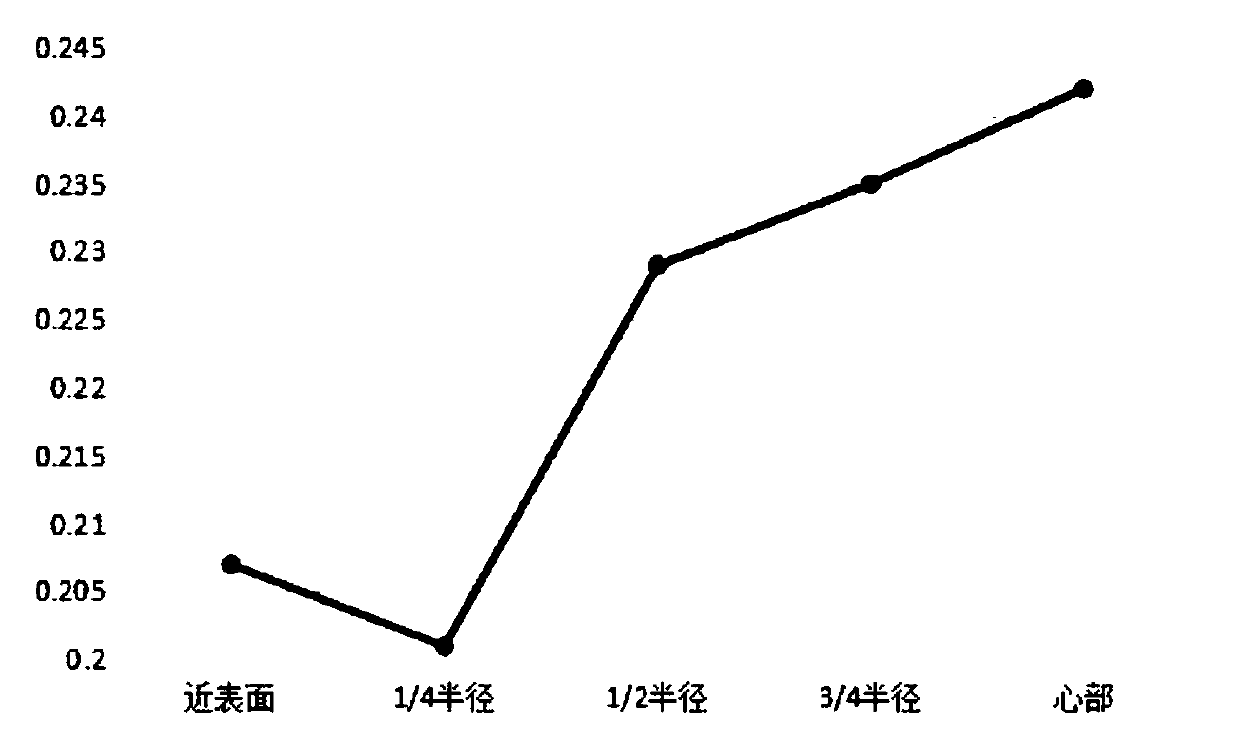

Embodiment 3

[0125] A kind of gear steel provided by this embodiment, its component formula comprises:

[0126] C: 0.19%; Si: 0.24%; Mn: 0.89%; Cr: 1.18%; Mo: 0.41%; P: 0.011%; For Fe.

[0127] Continuous casting process control: 320mm section slab continuous casting process is controlled by constant temperature and constant casting speed. The superheat of molten steel is controlled at 21°C, the casting speed is 0.55m / min, the electromagnetic stirring parameters of the mold are controlled at 250A / 2.0Hz, and the last stirring electromagnetic Stirring parameters were 450A / 5.0Hz.

[0128] Slab diffusion heating control: the temperature in the high temperature section of the slab is 1243°C, the time in the high temperature section is 406min, and the total heating time is 579min.

[0129] Slab rolling control: rough rolling rolling temperature 1194-1095 ℃, rolling 6 passes, single pass reduction rate 20-30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com