Permanent magnet, rotor, motor and compressor

A technology of permanent magnets and rotors, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., can solve the problems of poor manufacturability and poor mechanical strength characteristics of permanent magnets, achieve excellent manufacturability, and improve magnetic flux utilization. , cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

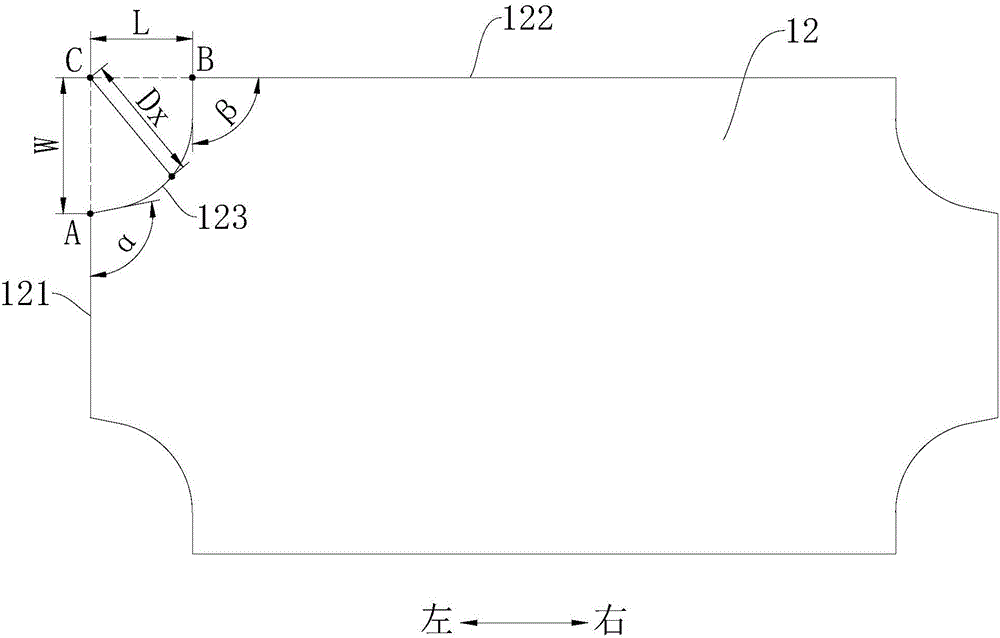

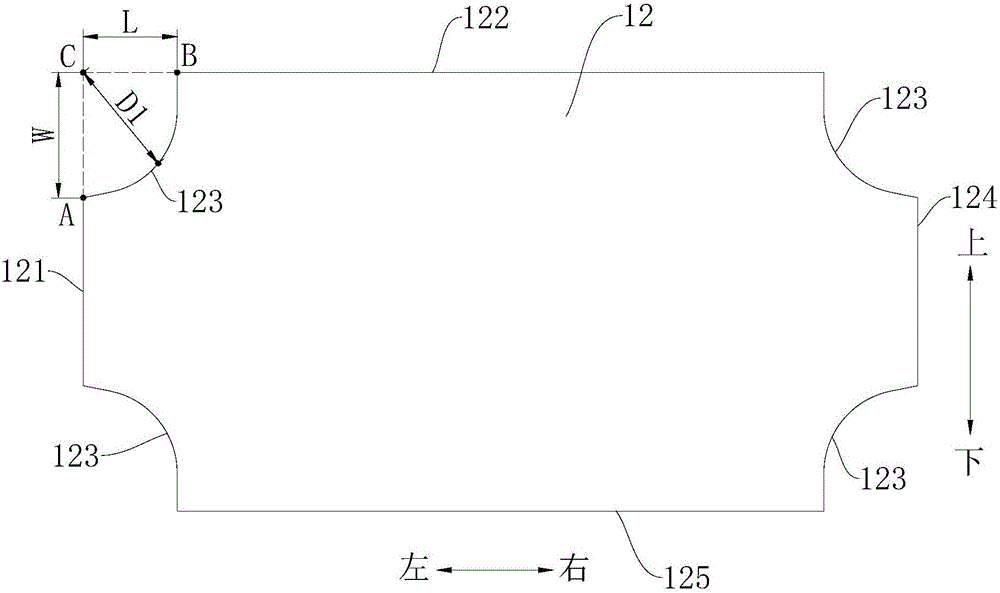

[0089] Such as figure 2 and image 3 As shown, the working surface of the permanent magnet 12 is surrounded by a first side 121, a second side 122, a third side 124 and a fourth side 125 which are connected end to end in order to form a substantially rectangular shape, and the first side between a group of adjacent sides Both the end points and the tail end points are connected by a transition edge 123 . The working face of permanent magnet 12 is about the lengthwise direction of permanent magnet 12 (for example figure 2 The centerline of the left and right directions shown in ) is symmetrical, and the working surface of the permanent magnet 12 is about the width direction of the permanent magnet 12 (for example figure 2 Centerline symmetry in the up and down directions shown in ). The transitional side 123 connected between the first end point A of the first side 121 and the tail end point B of the second side 122 will be described below.

[0090] Specifically, such as...

Embodiment 2

[0099] Such as Figure 4 and Figure 5 As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, the only difference is that: the transition edge 123 in Embodiment 1 only includes a sub-arc segment 123a, while the transition edge 123 in Embodiment 2 Contains two sub-arc segments 123a.

[0100] Assuming that the distance between the midpoint of one of the sub-arc segments 123a and the intersection point C in the transition side 123 in the present embodiment is D1, the distance between the midpoint of the other sub-arc segment 123a and the intersection point C is D2, and D1 and D2 satisfies:

[0101] W L / W 2 + L 2 ≤ D 1 ≤ 0.8 W 2 + L ...

Embodiment 3

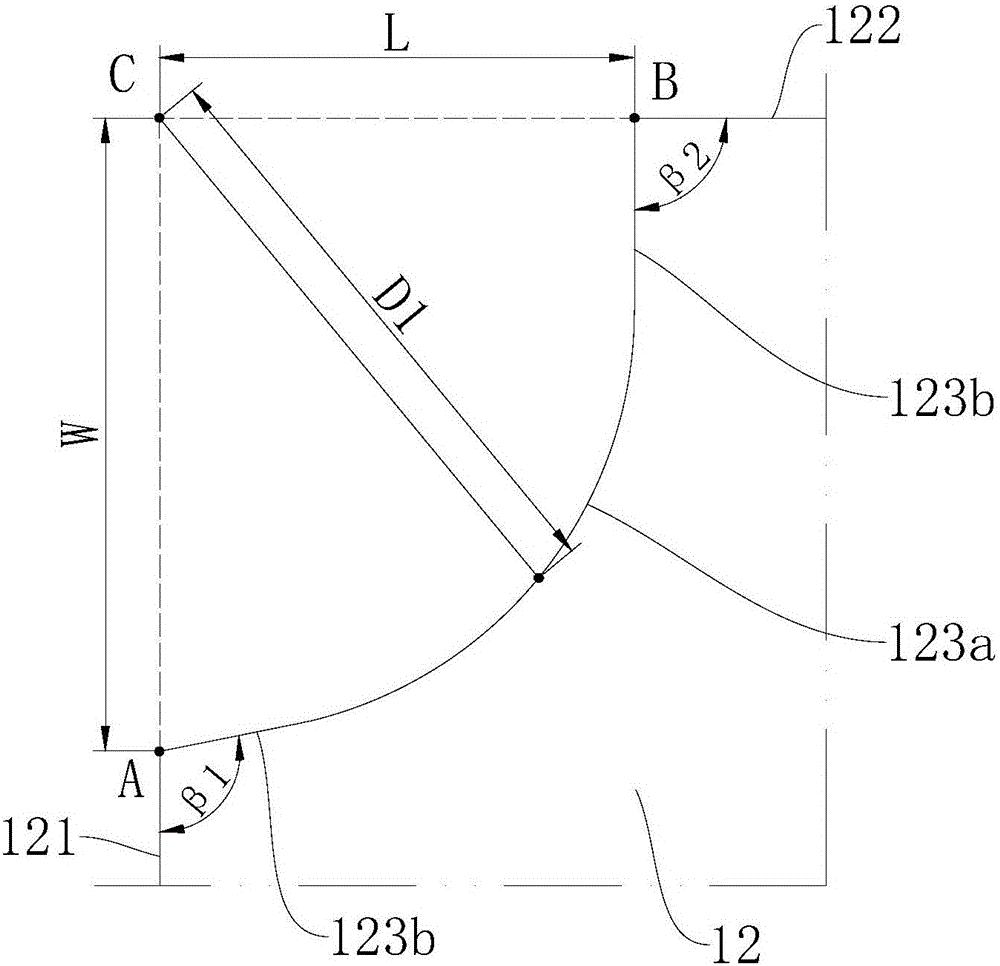

[0105] Such as Figure 6 and Figure 7 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the only difference is that the transition edge 123 in Embodiment 1 only includes one sub-arc segment 123a, In this embodiment, however, the transition edge 123 includes three sub-arc segments 123a.

[0106] Let the distance between the midpoint of the first sub-arc section 123a and the intersection point C along the direction from bottom to top in the transition side 123 in the present embodiment be D1, the midpoint of the second sub-arc section 123a and the intersection point C The distance is D2, the distance between the midpoint of the third sub-arc segment 123a and the intersection point C is D3, and D1, D2 and D3 satisfy:

[0107] W L / W 2 + L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com