MEMS infrared light source and manufacturing method thereof

An infrared light source and infrared technology, applied in the field of infrared light source, to achieve the effects of improving manufacturing pass rate and reliability, reducing thermal mass, and high infrared emission capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

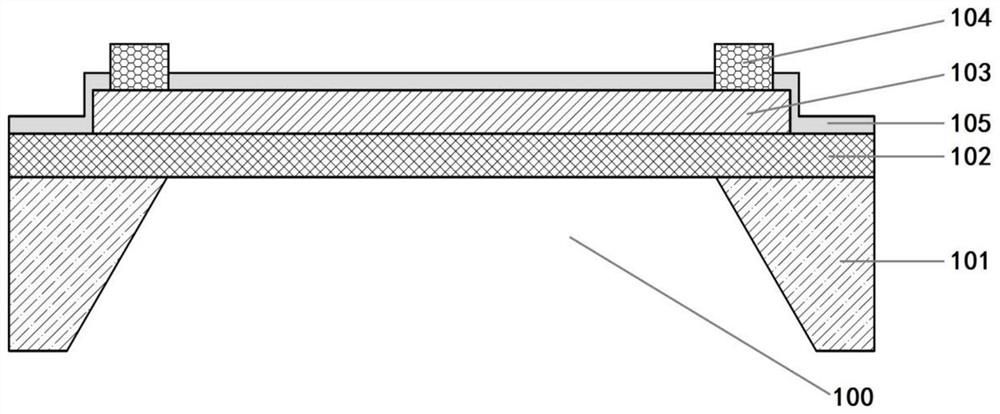

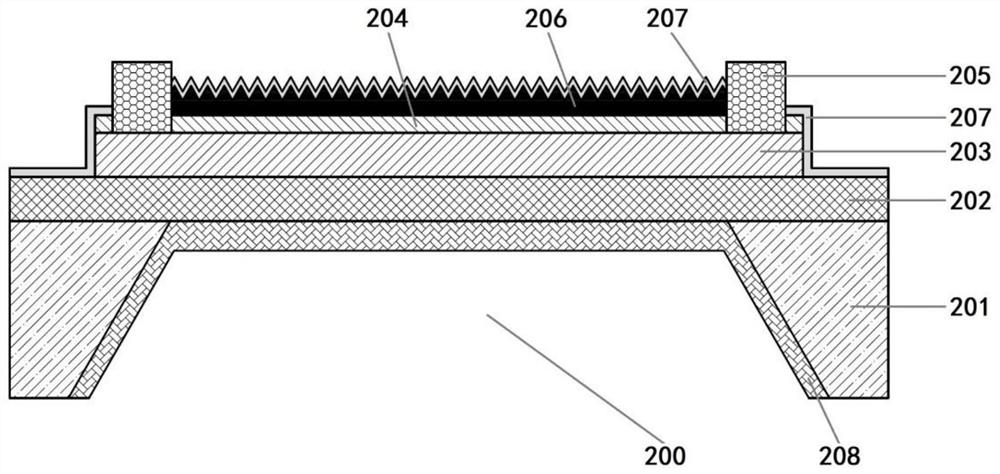

[0048] Such as figure 2 Shown is a schematic cross-sectional view of a MEMS infrared light source of the present invention, including a substrate 201, a supporting film layer 202, a heating electrode layer 203, an isolation layer 204, a heating electrode pad 205, an infrared emitting layer 206, a protective layer 207 and a reflective layer 208 , it is characterized in that: the substrate 201 includes a cavity structure 200, the support film layer 202 is arranged on the substrate 201 with a cavity structure, and forms a four-sided fixed-branch structure connection with the substrate 201, and in the cavity A suspension area is formed above the structure 200, a heating electrode layer 203 is provided above the supporting film layer 202, and heating electrode pads 205 are provided on both sides of the heating electrode layer 203 outside the suspension area, and the heating electrode pads 205 and The heating electrode layer 203 forms an electrical connection, an isolation layer 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com