Three-station combined machining tool for valve body of valve

A combined processing and three-station technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing production efficiency and product processing pass rate, affecting the economic benefits of production enterprises, and increasing labor intensity of workers , to achieve the effect of improving production efficiency and product processing pass rate, avoiding multiple clamping and correction, and retaining processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

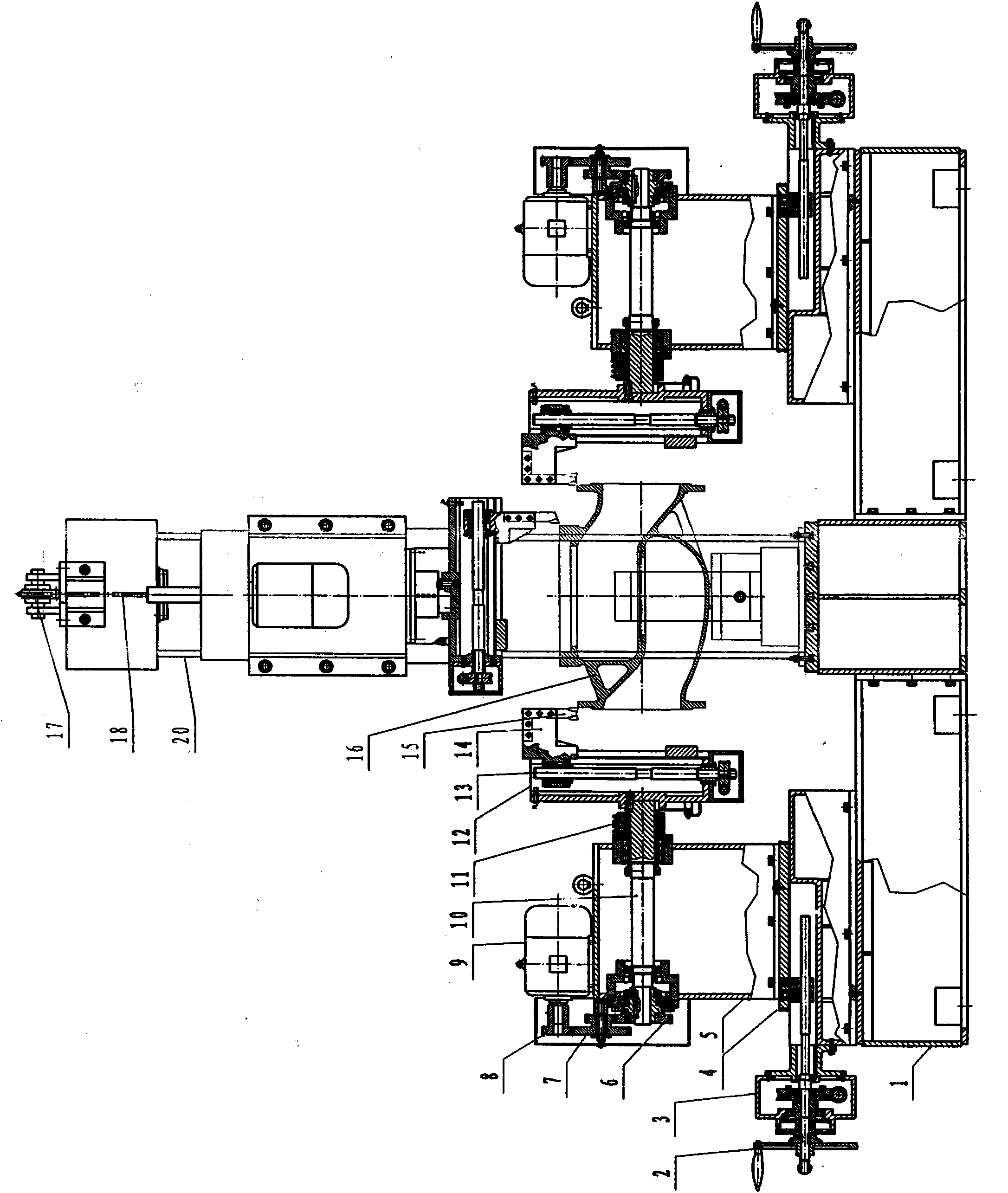

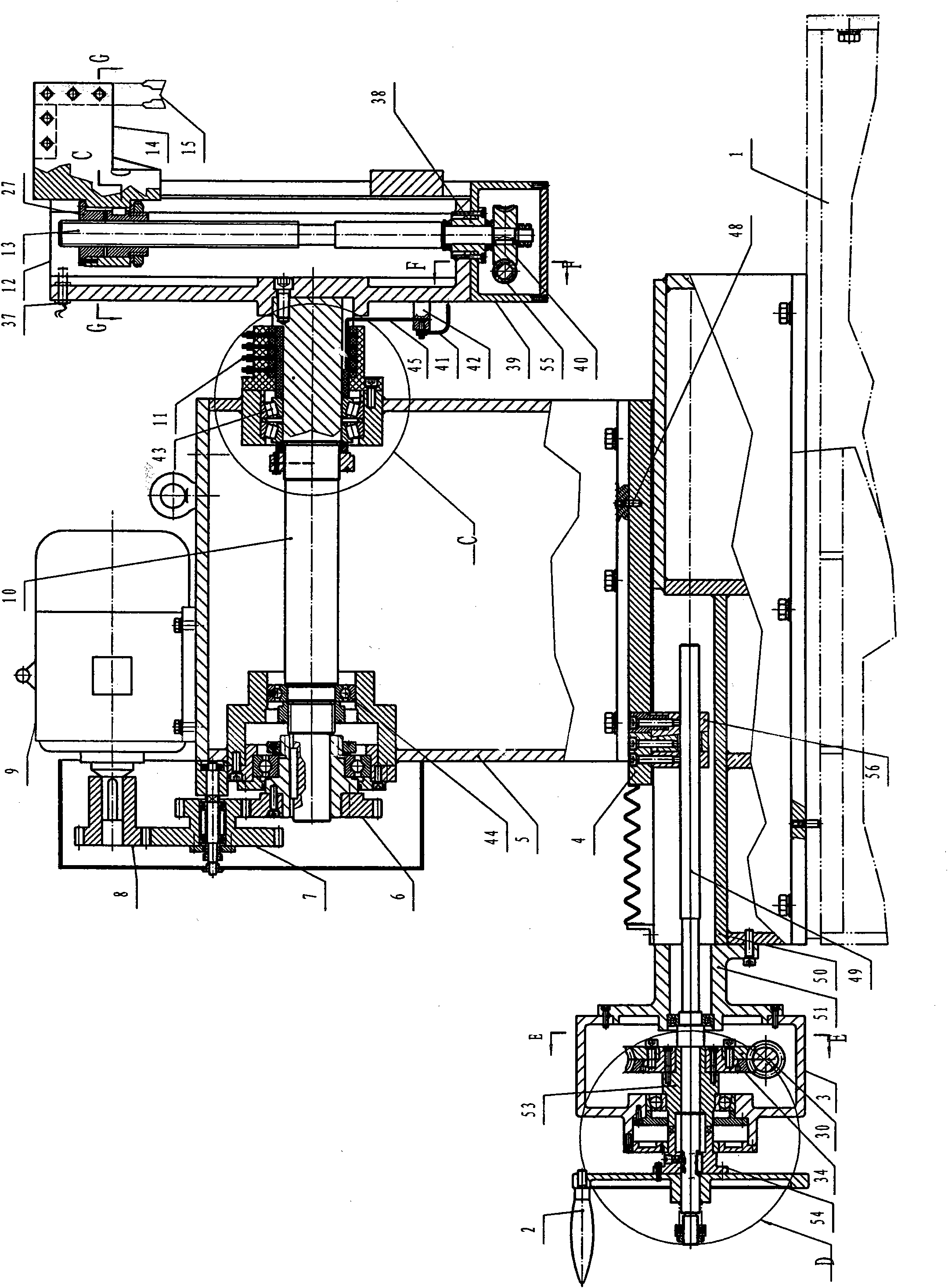

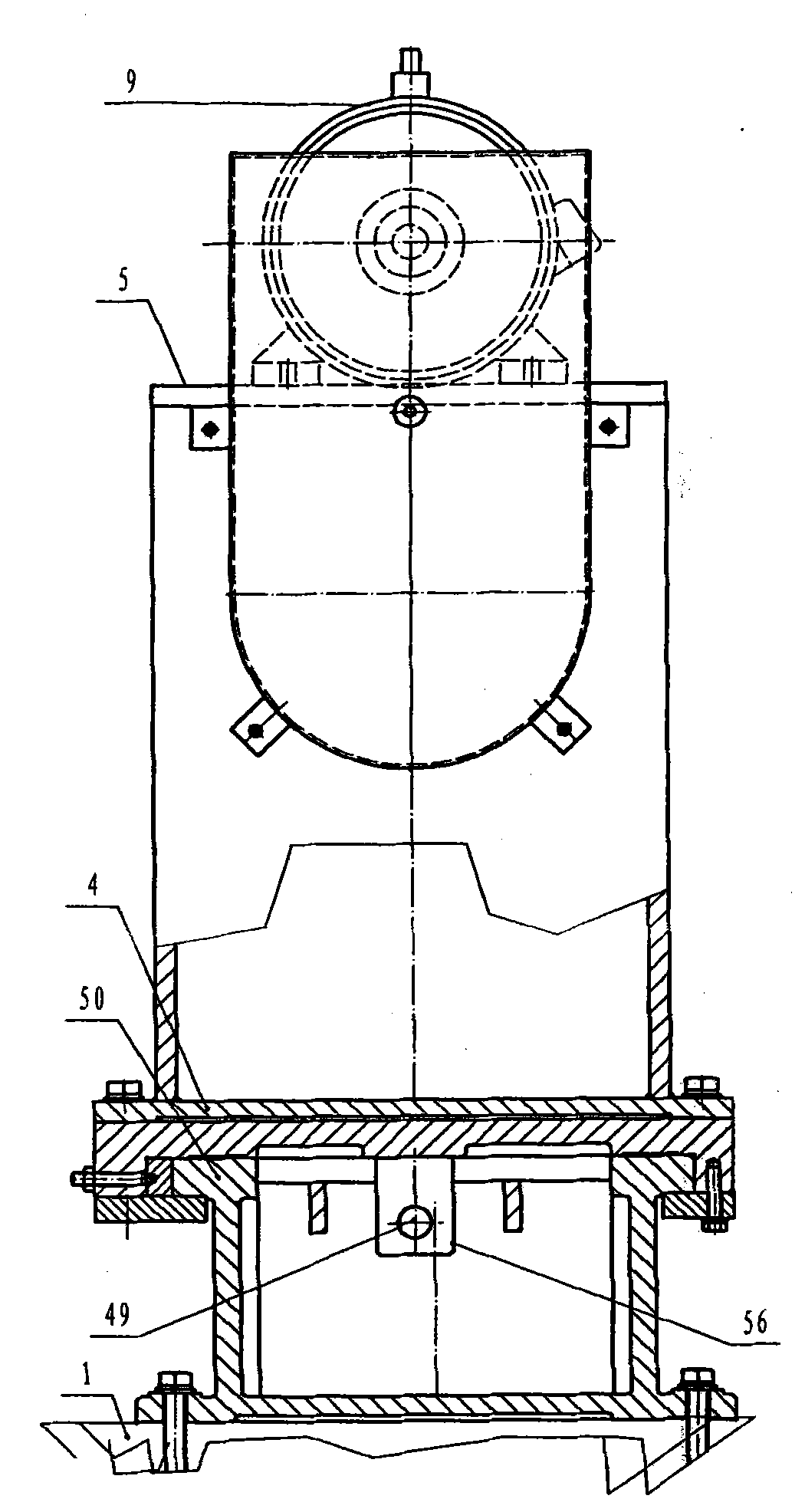

[0041] see Figure 1 to Figure 13The present invention comprises lathe bed 1 and rotary frame, and rotary frame mainly is made up of tool rest mechanism, speed change mechanism, spindle box, feed mechanism and control system. In order to reduce the weight of the frame, the present invention adopts aluminum alloy material. There are three rotary frames of the present invention, which are respectively arranged on the left, middle and right parts of the bed 1 to form a triangular structure. The left and right rotary frames are arranged opposite to each other, and the middle rotary frame is arranged vertically downward On the column 20. The bed 1 is provided with a clamp 21 for a valve or a valve body workpiece 16. The left and right sides of the clamp 21 correspond to the left and right rotary frames, and the top corresponds to the rotary frame on the center column 20. The clamp 21 It is a hydraulic V-shaped clamp, and the clamping force can be adjusted steplessly. The structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com