High sensitivity liquid dielectric constant measuring probe

A technology with dielectric constant and high sensitivity, which can be used in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., and can solve problems such as the influence of bubbles that cannot be excluded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below with reference to the accompanying drawings and in conjunction with an embodiment.

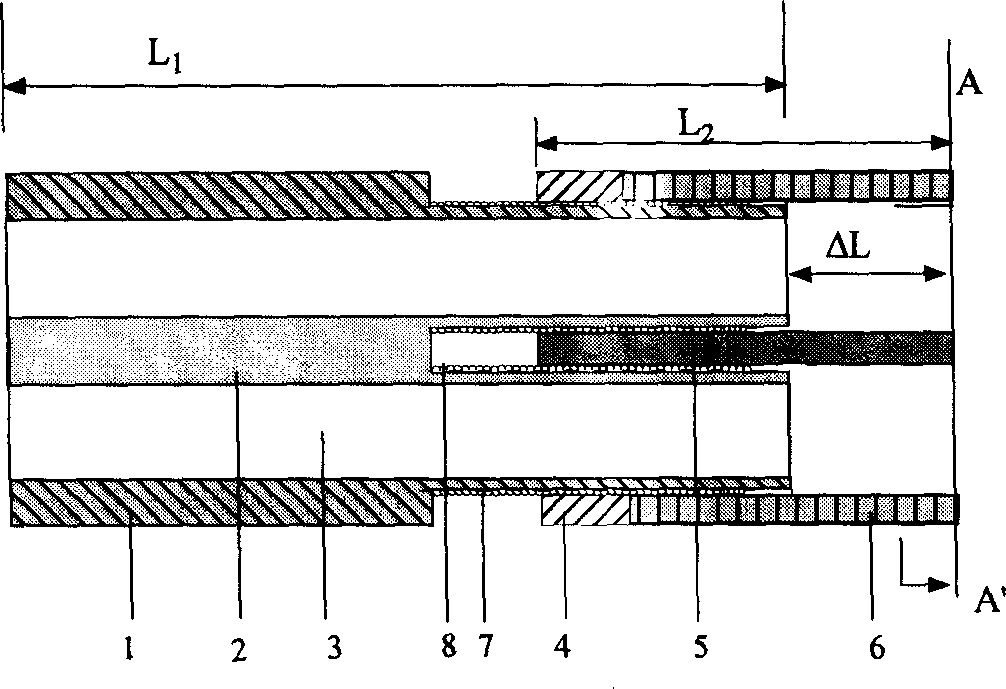

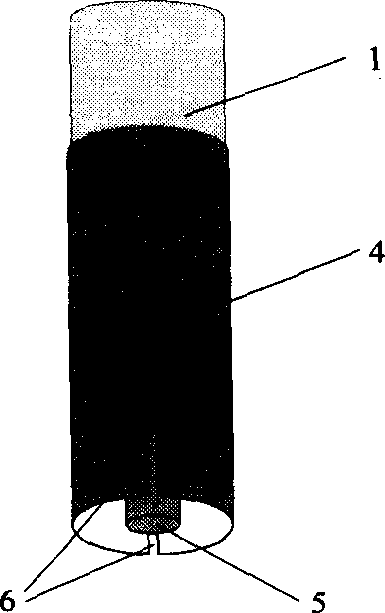

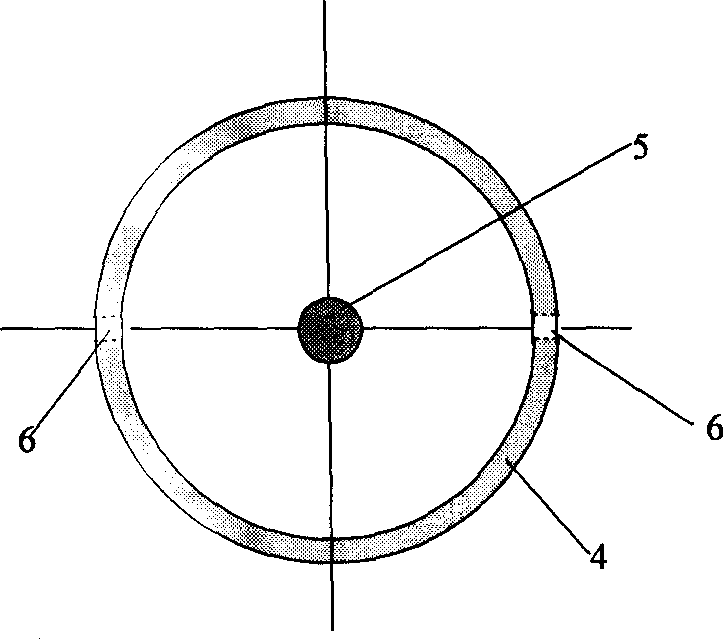

[0014] Such as figure 1 with figure 2 As shown, the probe consists of two parts: conventional coaxial wire and hollow slotted coaxial wire. Among them, the traditional coaxial line is composed of an outer conductor 1 and an inner conductor 2, and polytetrafluoroethylene 3 is filled between the inner and outer conductors; the hollow slotted coaxial line is composed of a tunable outer conductor 4, a tunable inner conductor 5, and an upper outer conductor Or more than one slot 6 is jointly formed, and the measured medium is filled between the inner and outer conductors. The part of the hollow slotted coaxial line constitutes a coaxial resonant cavity with an open terminal, and its length ΔL is tuned by adjusting the inner and outer conductors 5 and 4 . In this embodiment, the threaded connection between the tunable outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com