Turbine hollow blade rabbet processing locating clamping method and device

A hollow blade, positioning and clamping technology, used in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of toxicity, operator health damage, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

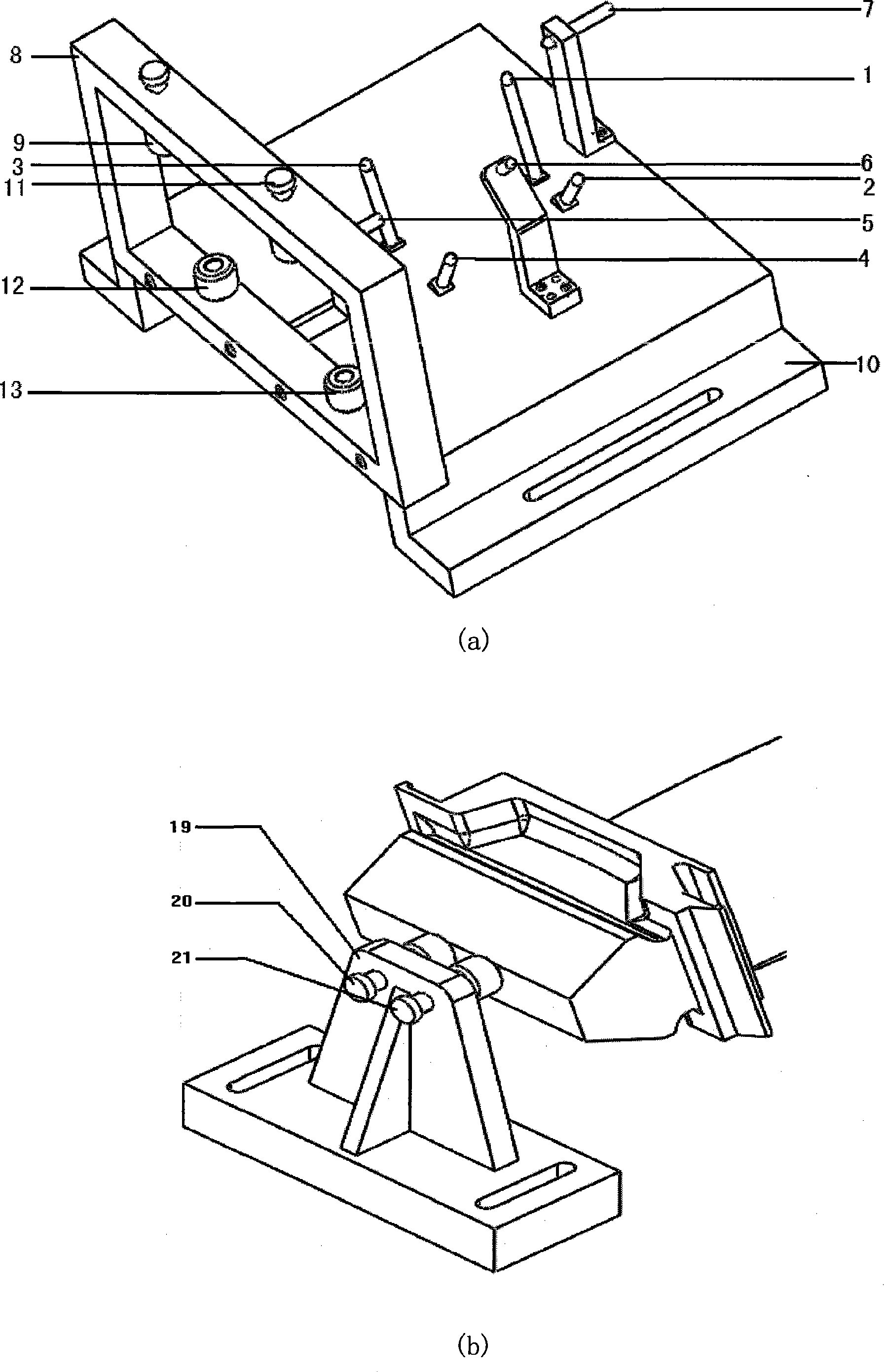

[0028] Selection scheme of anchor points

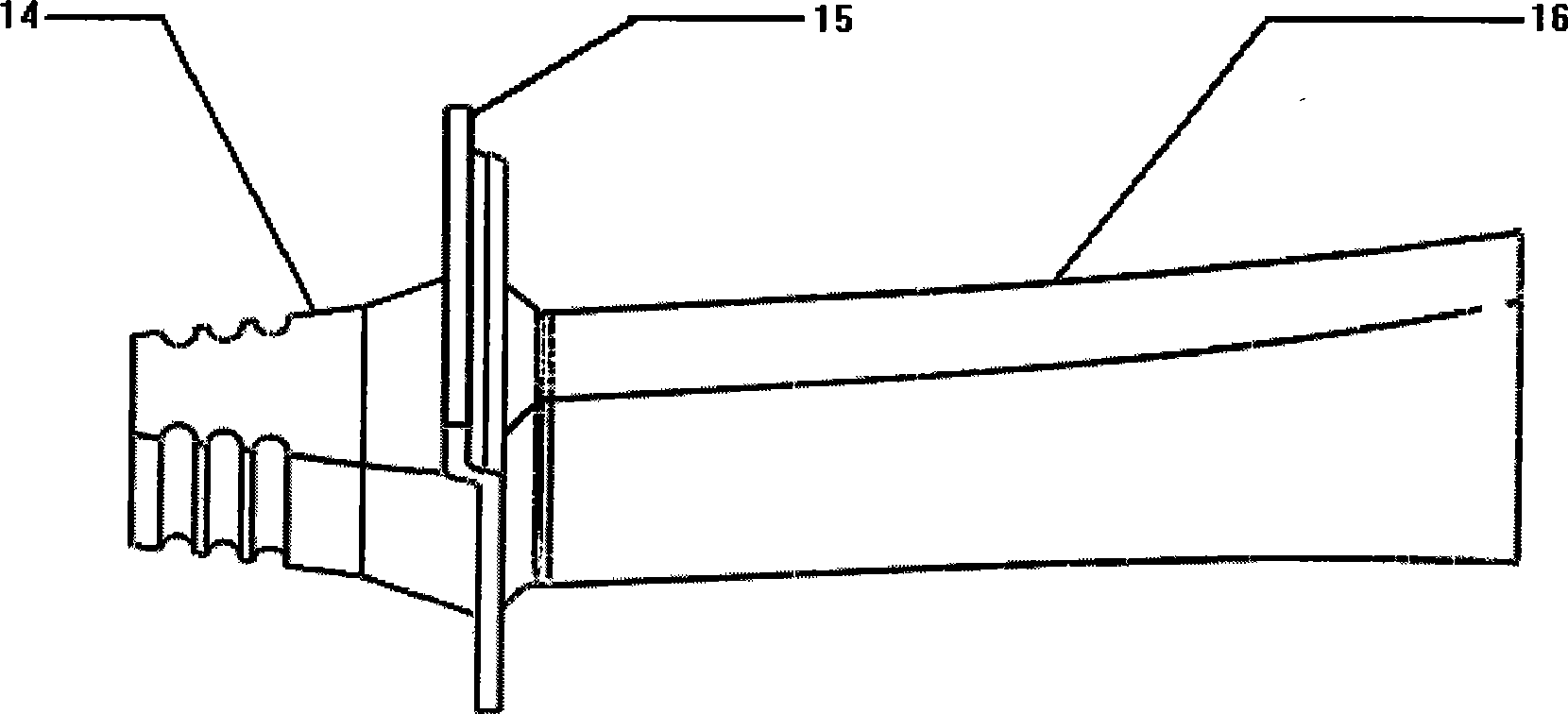

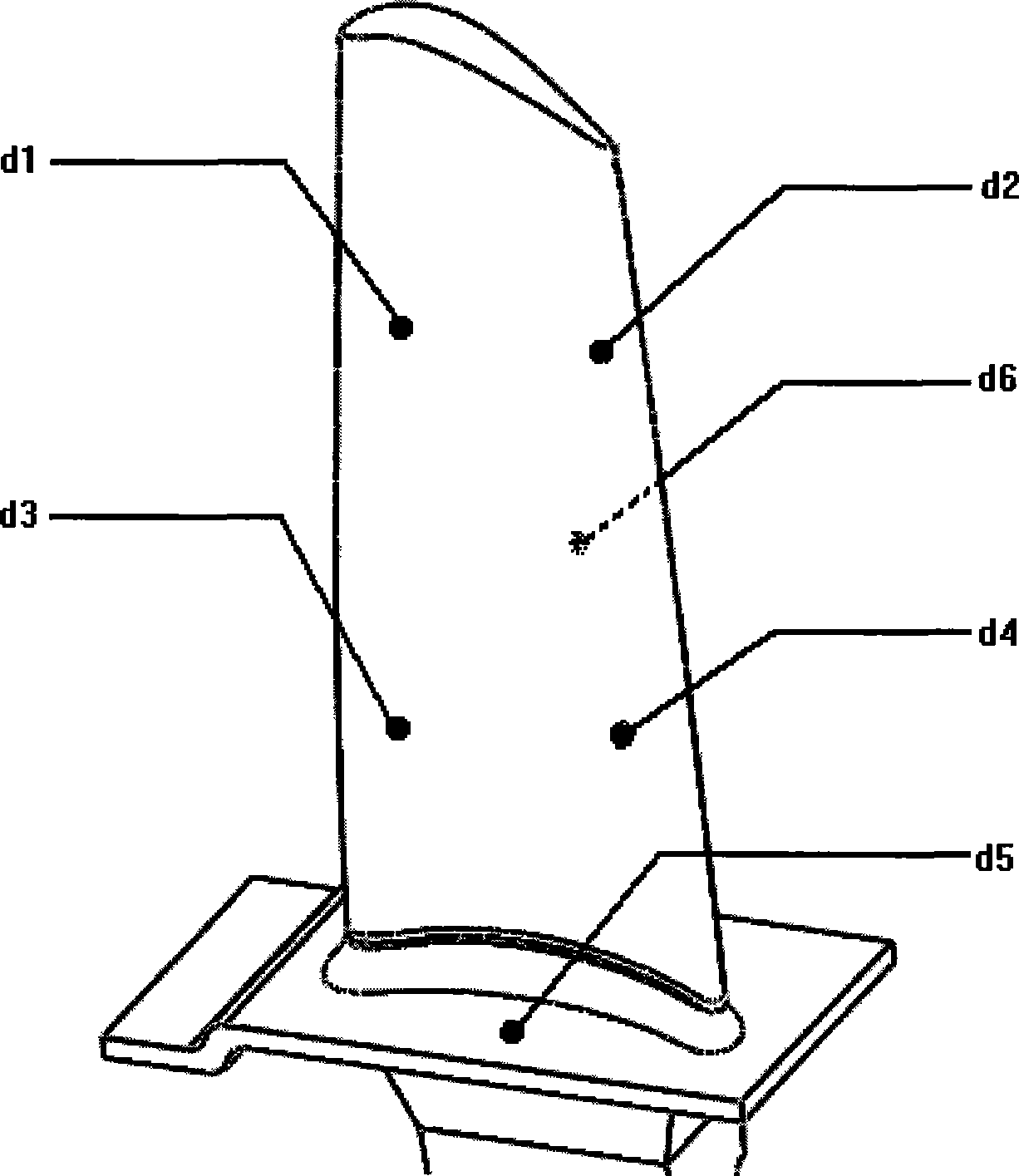

[0029] In order to ensure the stable positioning of the mortise 14 during processing, the positioning reference and the design reference should coincide as much as possible, first select the blade design reference point on the blade mounting plate 15 as a positioning point d5, and then according to the three-dimensional mathematical model of the blade surface 16, in Select another five anchor points d1, d2, d3, d4, d6 on its surface. Firstly, the precision-constrained mathematical model of the positioning point is established based on the position error of the positioning point caused by the disturbance of the workpiece position; then, the bi-cubic B-spline is used to fit the position coordinates of the feature points obtained from the design on the blade profile, and the feature points including the normal vector are calculated The space vector of the positioning point is obtained to obtain the point set space of the positioning poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com