Helical tube hot-extrusion die in porous magnesium alloy

A technology of hot extrusion dies and inner helical tubes, applied in the direction of metal extrusion dies, etc., can solve the problems that the material flow cannot be rotated, affects the service life of the heat exchanger, and is prone to cracks, etc., and achieves good mold structure symmetry, The effect of avoiding pipe wall cracking and reducing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

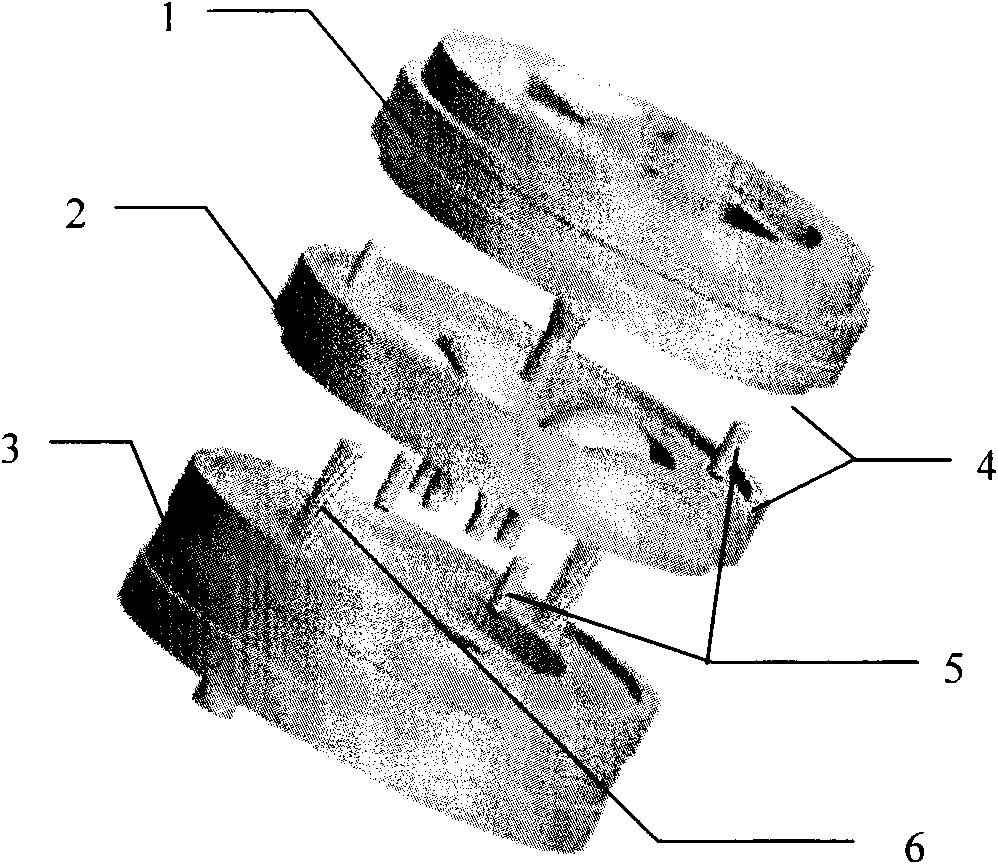

[0029] Such as figure 1 , figure 2 As shown, this embodiment includes: upper mold 1, middle mold 2 and lower mold 3, wherein: upper mold 1, middle mold 2 and lower mold 3 are socketed in sequence, and upper mold 1, middle mold 2 and lower mold 3 are all Disc structure, between the upper mold 1 and the middle mold 2 and between the middle mold 2 and the lower mold 3 are respectively provided with notches 4, positioning pins 5 and bolts 6 for fixing.

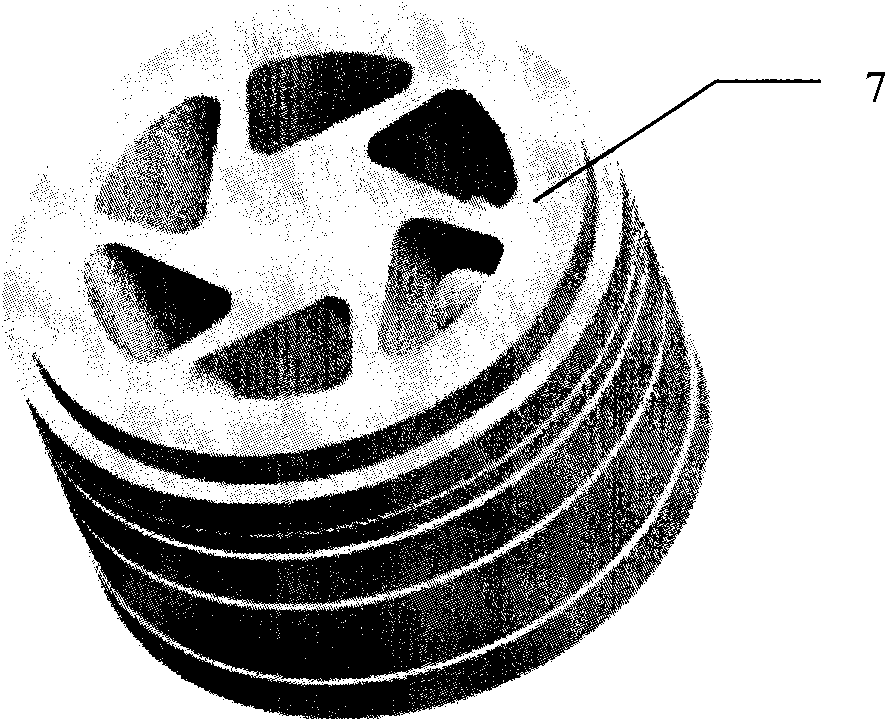

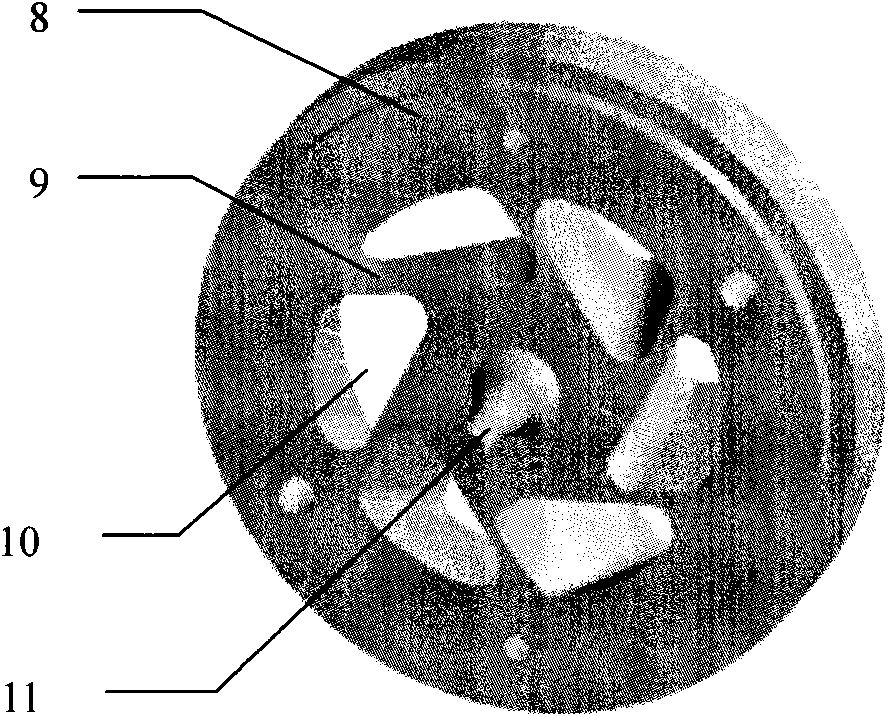

[0030] Such as figure 2 and image 3 As shown, the upper mold 1 includes an upper feeding end surface 7 and an upper discharging end surface 8 opposite thereto, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com