Anti-theft gate rabbet, its production method and its special mould

A technology of anti-theft doors and molds, applied in the field of anti-theft doors, can solve the problems of multiple processes, rust, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

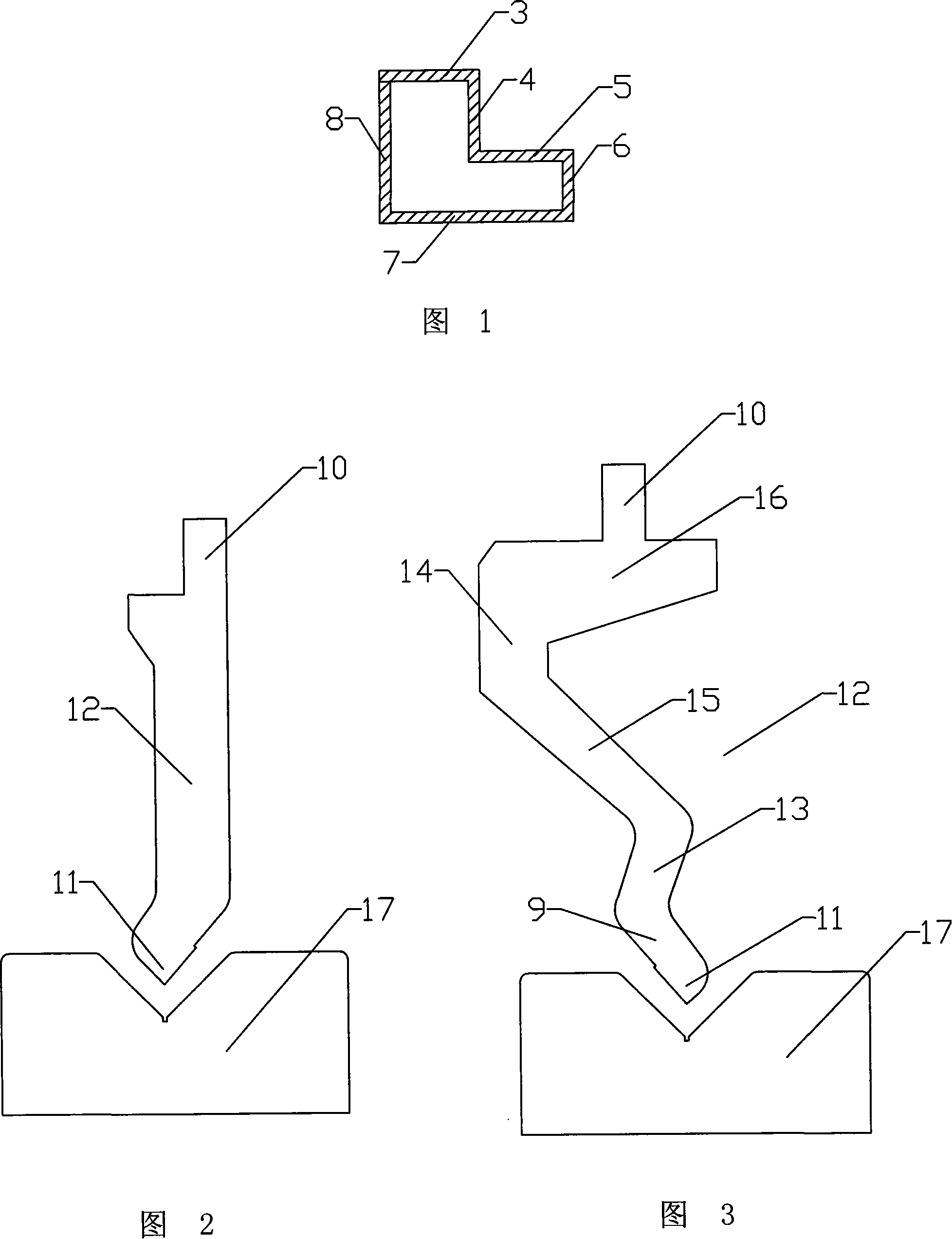

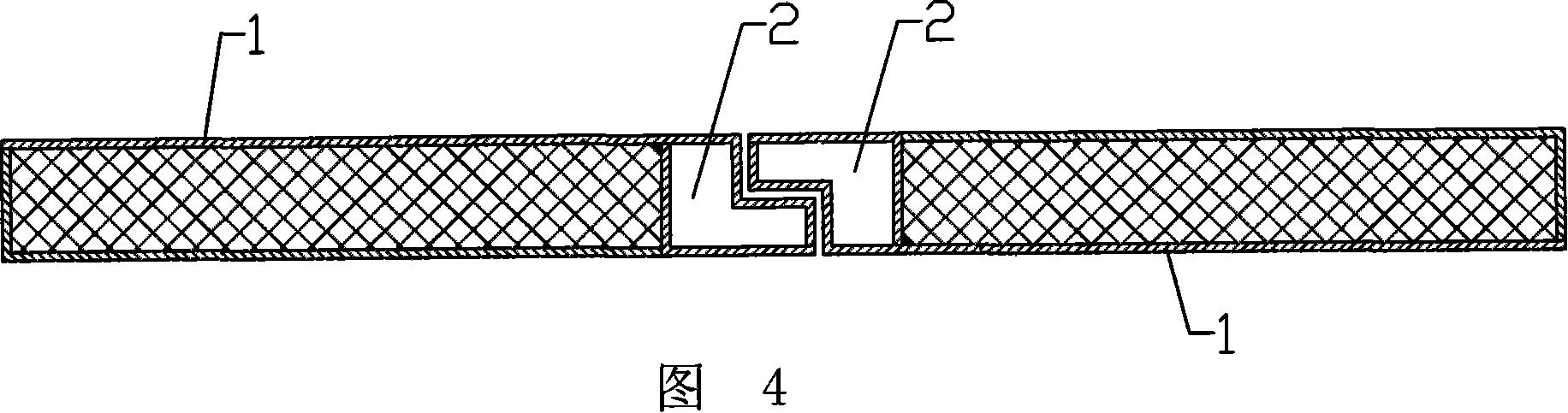

[0020] Embodiment, as shown in FIG. 1 , a security door cutout, the security door cutout is a structure with an L-shaped cavity inside which is integrally bent by a metal plate, and the metal plate includes a first frame 3 and a second frame 4 , the third frame 5, the fourth frame 6, the fifth frame 7 and the sixth frame 8, the adjacent frames are arranged vertically, and the sixth frame 8 is fixedly connected to the first frame 3.

[0021] In order to be able to integrally bend into a cutout with an L-shaped cavity inside, the manufacturing method of the present invention comprises the following steps:

[0022] 1. First cut the metal plate for cutting with a shearing machine;

[0023] 2. Bending 90° between the second frame 4 and the third frame 5 of the metal plate by a bending machine;

[0024] 3. Perform reverse 90° bending between the third frame 5 and the fourth frame 6 of the metal plate;

[0025] 4. Bending 90° between the fifth frame 7 and the sixth frame 8 of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com