Device for filtering cutting fluid

A technology of filtering device and cutting fluid, applied in the direction of filtering circuit, filtering separation, maintenance and safety accessories, etc., can solve the problems of inability to increase the height, inability to increase the total length of the fluid passage, etc., and achieve the effect of simple cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

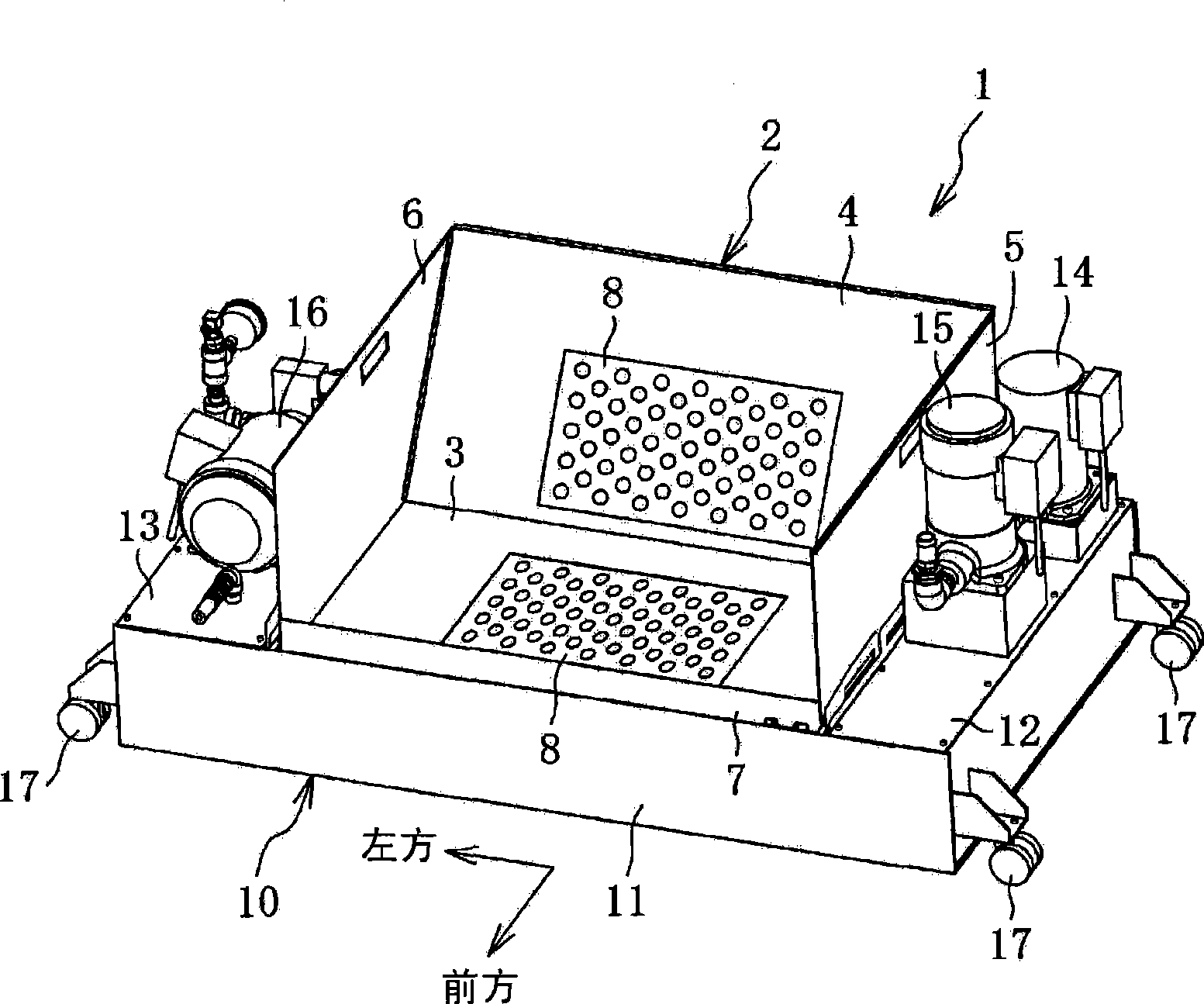

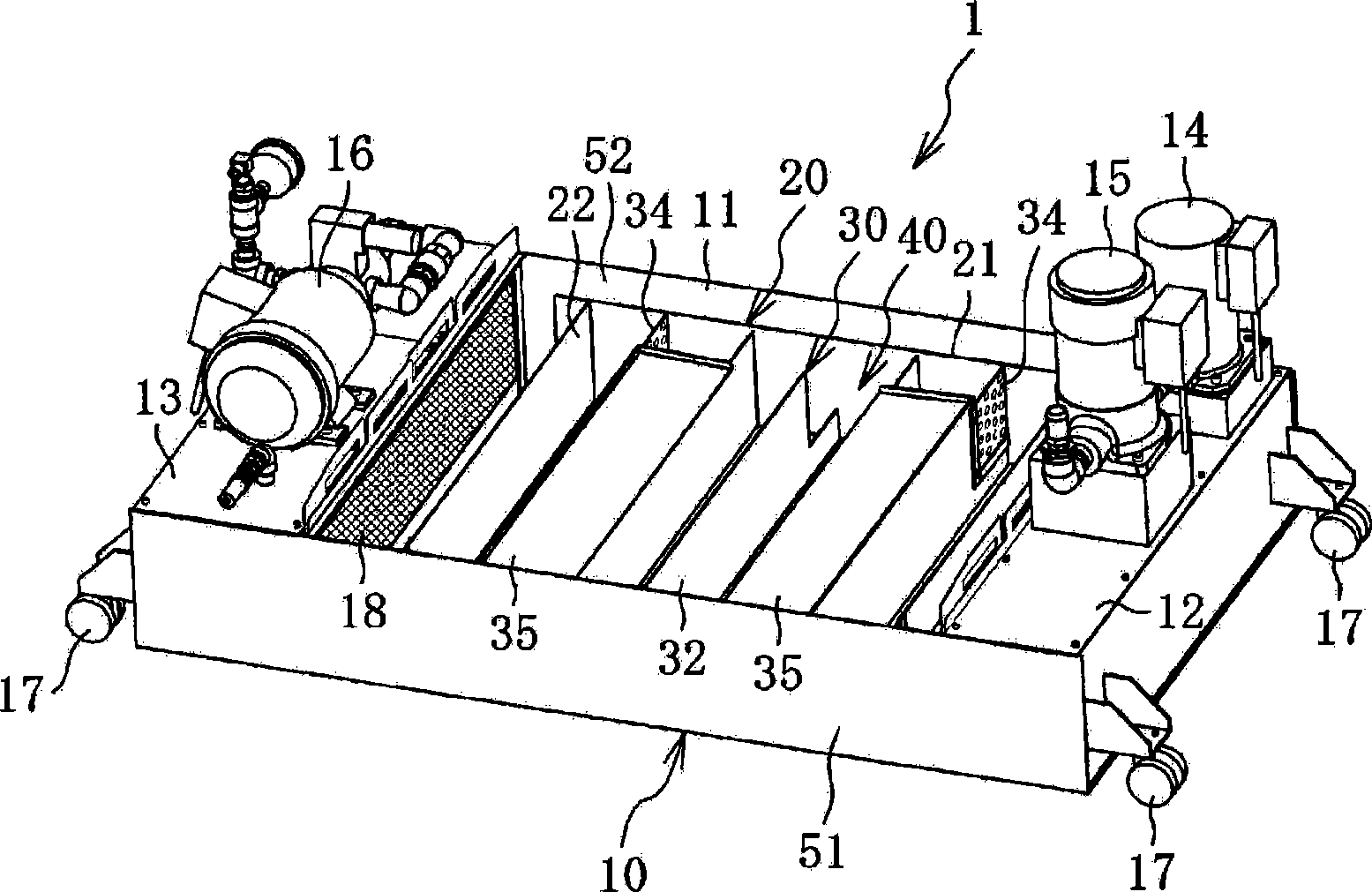

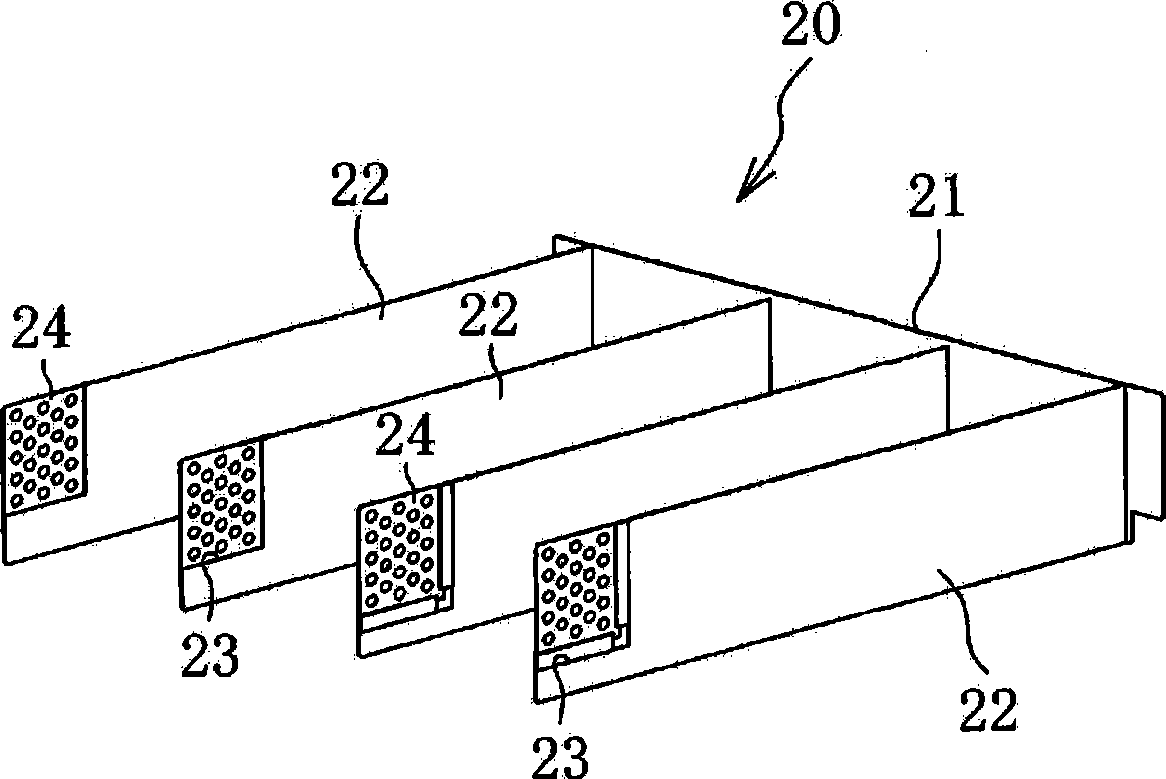

[0027] Embodiments of the present invention will be described below with reference to the drawings. like figure 1 , figure 2 As shown, the cutting fluid filter device 1 includes a guide housing 2 and a cutting fluid tank 10 .

[0028] like figure 1 As shown, the guide housing 2 includes a bottom wall portion 3 , a rear wall portion 4 , a right side wall portion 5 , a left side wall portion 6 and a mounting portion 7 . The upper surface and the front surface of the guide case 2 are open. The bottom wall portion 3 is inclined downward toward the rear. The cutting fluid flowing into the guide housing 2 flows toward the rear of the bottom wall portion 3 due to the inclination of the bottom wall portion 3 . The bottom wall portion 3 has a chip receiving plate 8 which will be described later in its central portion. The chip receiving plate 8 has many through holes (for example, a diameter of about 3.0 mm). The cutting fluid discharge part 41 of the machine tool (refer to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com