Low-formaldehyde-emission abrasion-resistant and moisture-proof laminate wood flooring and production and laying method for laminate wood flooring

A technology for strengthening wood flooring and formaldehyde emission, which is applied in chemical instruments and methods, paper/cardboard layered products, layered products, etc., can solve the problems of large formaldehyde emission, reduce emission, and improve moisture-proof and waterproof performance , Improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

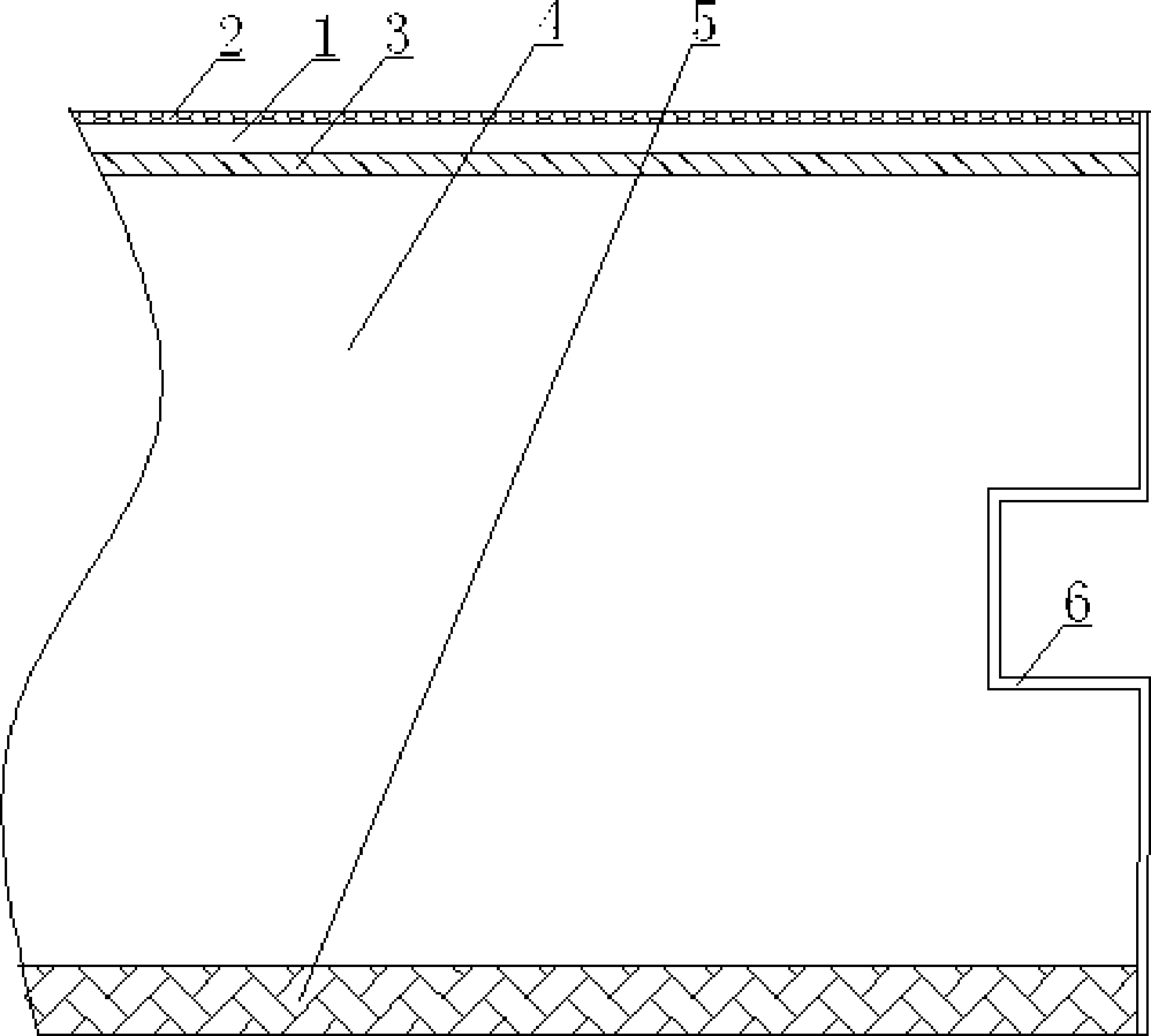

[0033] Embodiment 1: The production process of wear-resistant and moisture-proof laminate flooring with low formaldehyde emission includes the following contents:

[0034] 1. Made of high-density fiberboard. The method includes the following steps: 1) preparing urea-melamine-formaldehyde co-condensation resin according to the molar ratio of formaldehyde 1.35, urea 1, and melamine 0.35; the preparation process includes: adding formaldehyde into the reaction kettle, and using sodium hydroxide to adjust the pH value of the solution to 8.2 Add urea and melamine, heat up to 87°C within 43 minutes, and keep warm at 87°C for 30 minutes; adjust the pH value to 4.8 with ammonium chloride solution, and keep it warm for 50 minutes; adjust the pH value to 7.3 with sodium hydroxide solution, and cool to no Over 40°C; 2) Put 100 parts by weight of the urea-melamine formaldehyde co-condensation resin obtained in the previous step into the glue mixer; NH 4 Cl solution, 12 parts by weight of...

Embodiment 2

[0038] Embodiment 2: The production process of wear-resistant and moisture-proof laminate flooring with low formaldehyde emission includes the following contents:

[0039] 1. Made of high-density fiberboard. The method includes the following steps: 1) preparing urea-melamine-formaldehyde co-condensation resin according to the molar ratio of formaldehyde 1.3, urea 1, and melamine 0.39; the preparation process includes: adding formaldehyde into the reaction kettle, and using sodium hydroxide to adjust the pH value of the solution to 8 Add urea and melamine, heat up to 85°C within 45 minutes, and keep warm at 85°C for 35 minutes; adjust the pH value to 4.5 with ammonium chloride solution, and keep it warm for 40 minutes; adjust the pH value to 7 with sodium hydroxide solution, and cool to no Over 40°C; 2) Put 100 parts by weight of the urea-melamine formaldehyde co-condensation resin obtained in the previous step into the glue mixer; NH 4 Cl solution, 11 parts by weight of para...

Embodiment 3

[0043] Embodiment 3: The production process of wear-resistant and moisture-proof laminate flooring with low formaldehyde emission includes the following contents:

[0044] 1. Made of high-density fiberboard. The method includes the following steps: 1) preparing urea-melamine-formaldehyde co-condensation resin according to the molar ratio of formaldehyde 1.4, urea 1, and melamine 0.3; the preparation process includes: adding formaldehyde into the reaction kettle, and using sodium hydroxide to adjust the pH value of the solution to 8.5 Add urea and melamine, heat up to 90°C within 40 minutes, and keep warm at 90°C for 25 minutes; adjust the pH value to 5.0 with ammonium chloride solution, and keep it warm for 60 minutes; adjust the pH value to 7.5 with sodium hydroxide solution, and cool to no Over 40°C; 2) Put 100 parts by weight of the urea-melamine formaldehyde co-condensation resin obtained in the previous step into the glue mixer; NH 4 Cl solution, 15 parts by weight of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| dimensional stability | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com