Heat dissipation device

A radiator and heat dissipation hole technology, which is applied to lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of low heat dissipation efficiency, affecting the service life of LED lamps, and high temperature of LED light sources and power supplies. Achieve the effect of large heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

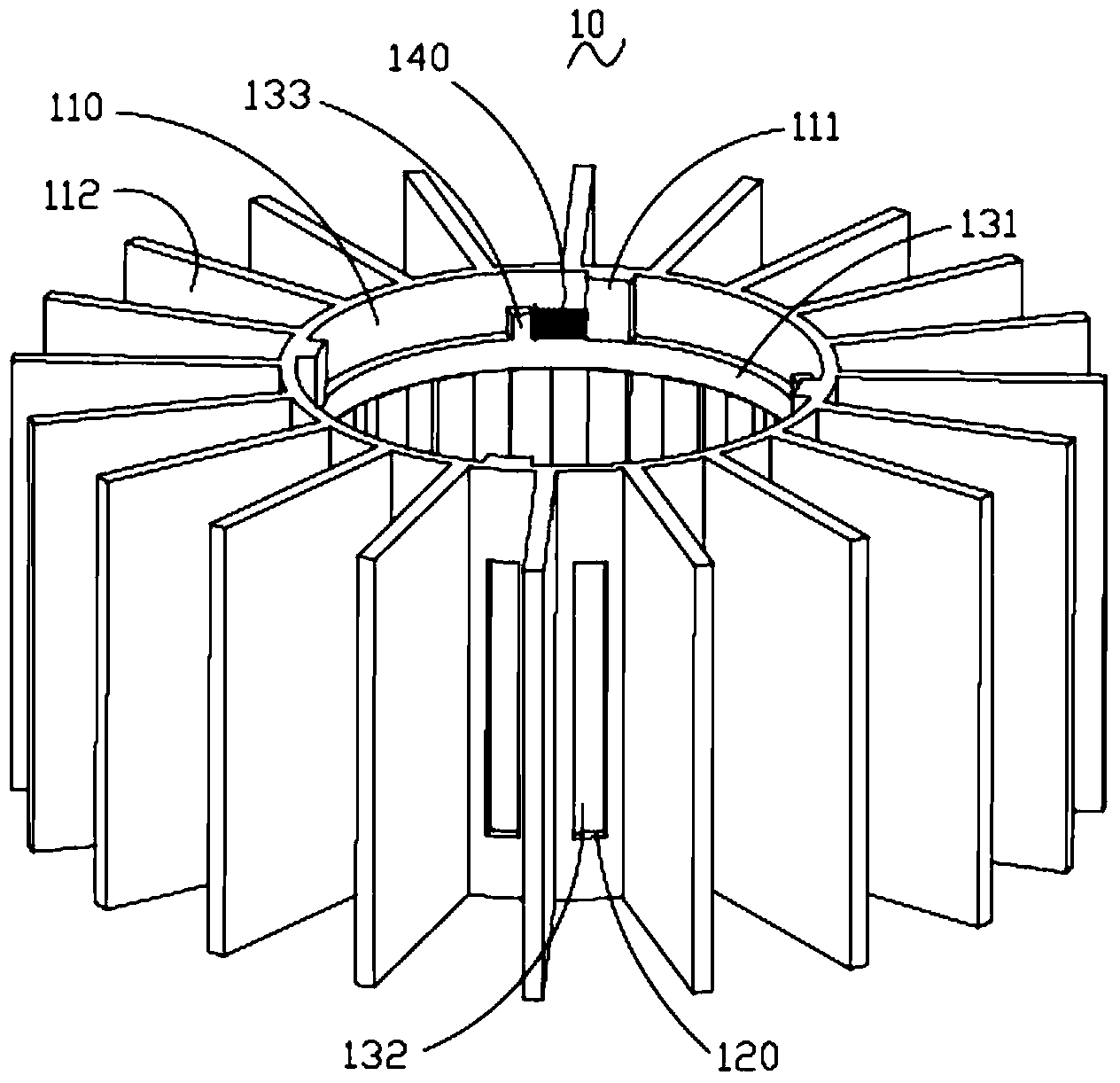

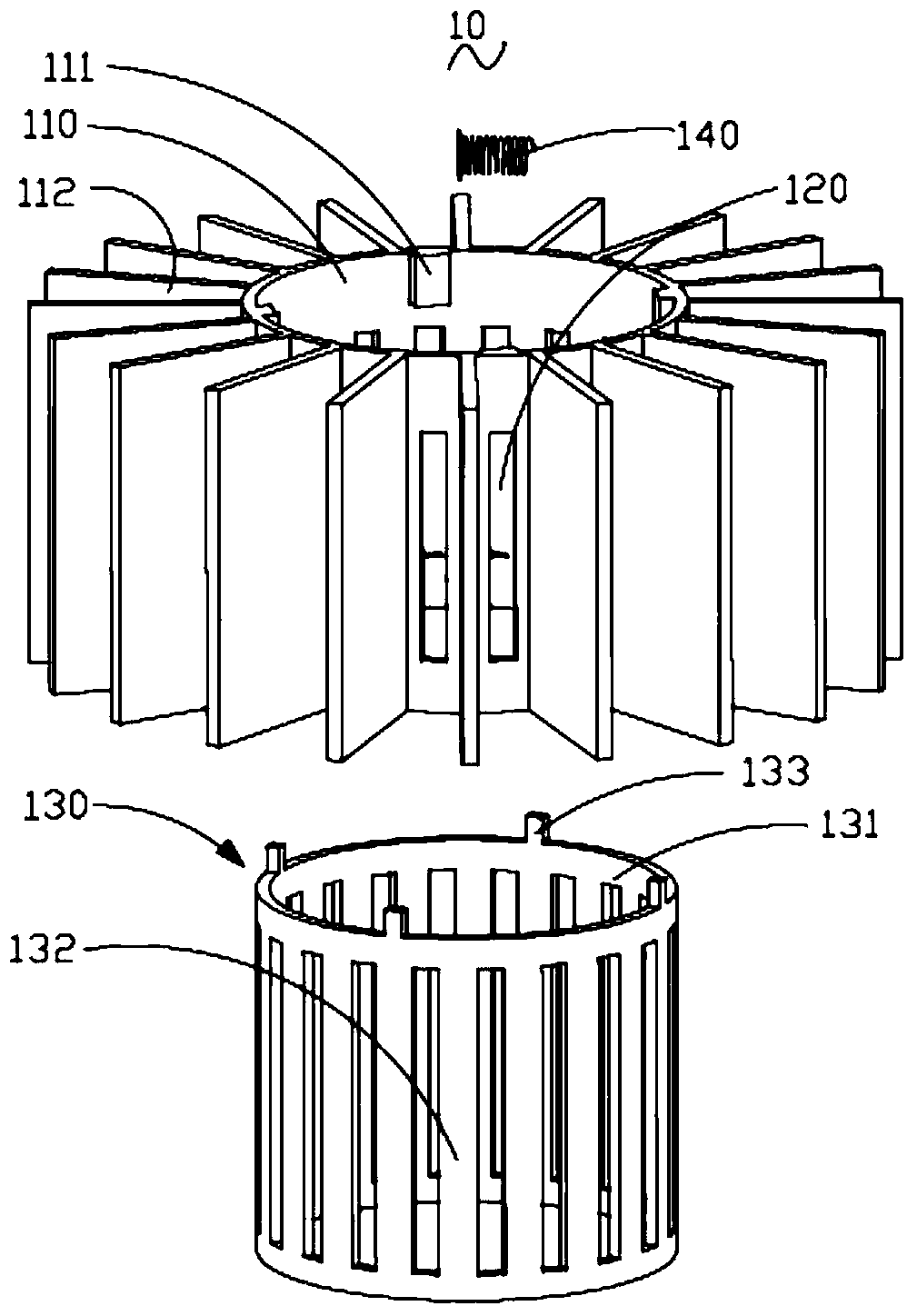

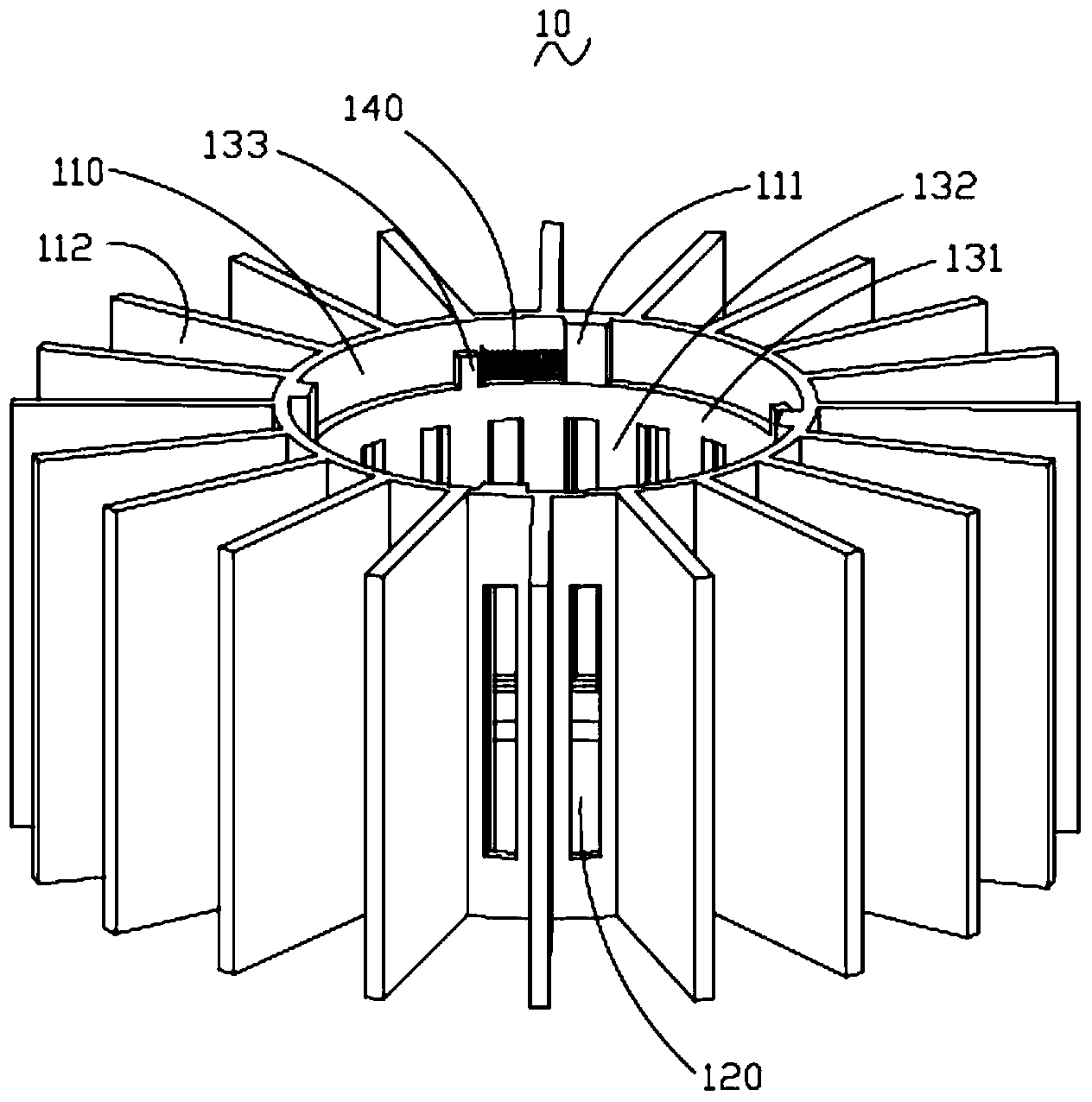

[0023] Such as figure 1 with figure 2 , which are respectively a structural schematic diagram of a radiator 10 in an embodiment of the present invention and an explosion schematic diagram of a radiator 10 of the present invention, wherein the default figure 1 The structural diagram showing the closed state of the cooling hole 120 of the radiator 10 is a general state.

[0024] The radiator 10 includes: a radiator body 110 , a plurality of cooling holes 120 arranged on the radiator body 110 , a baffle 130 closely attached to the radiator body 110 , and a baffle 130 connected between the baffle 130 and the radiator body 110 drive 140 . The radiator body 110 may be cylindrical, elliptical or square, preferably cylindrical. The blocking piece 130 is closely attached to the inner wall of the radiator body 110 . Wherein, the cooling hole 120 may be in any shape, preferably a square. The outer wall of the radiator body 110 can also be connected with a plurality of cooling fins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com