Method for preparing nanometer magnesium oxide and active light calcium carbonate

A nano-magnesium oxide, active lightweight technology, applied in the field of preparation of inorganic non-metallic materials, can solve the problems of difficult to realize industrialized production, expensive equipment, complicated process, etc., and achieve the effects of improving utilization rate, improving digestion efficiency, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

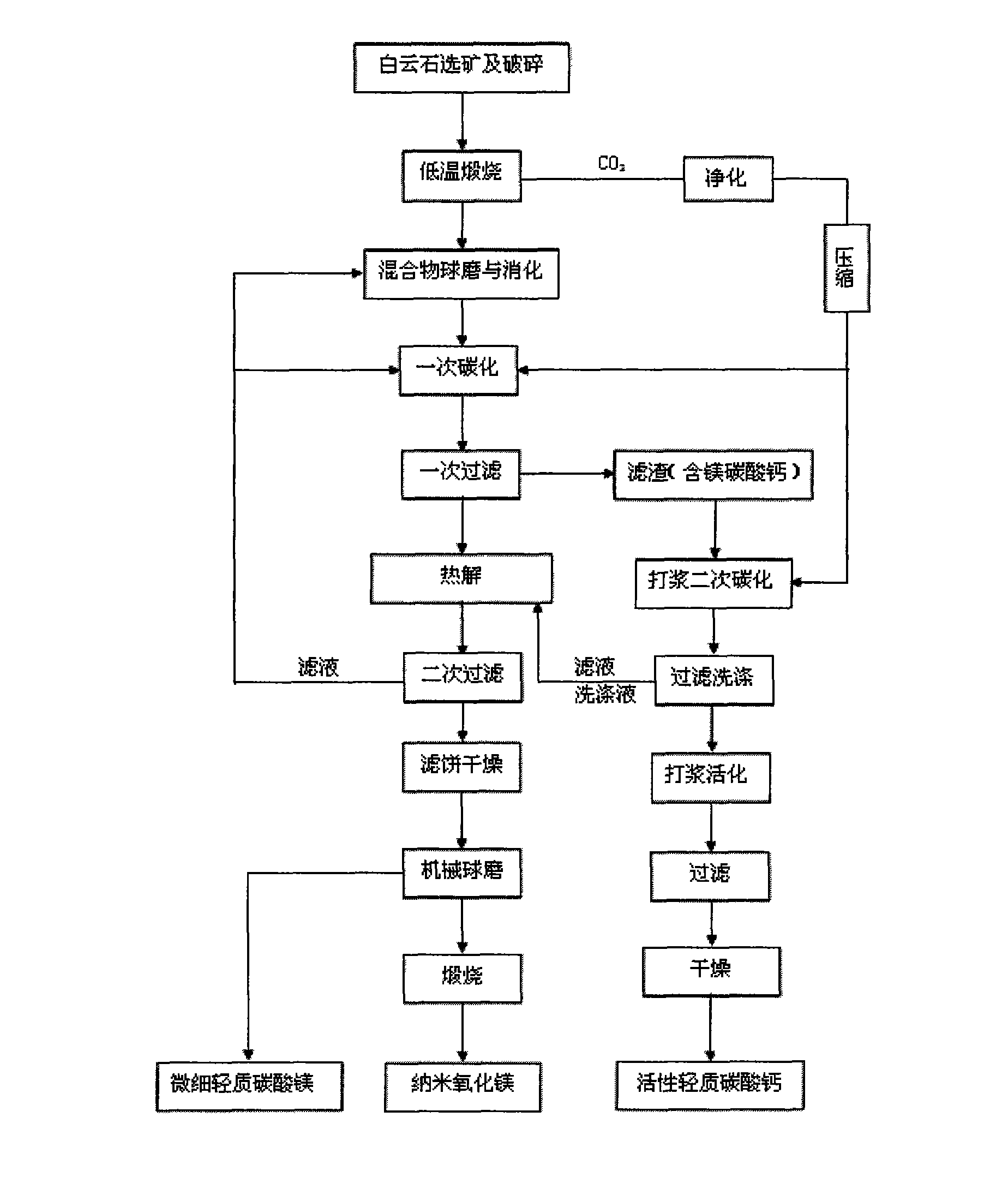

[0087] The method for preparing nano magnesium oxide comprises the following steps:

[0088] 1. Crushing the dolomite to a particle size of 2 mm;

[0089] 2. Calcining the dolomite crushed to a particle size of 2mm in a heating furnace at 810°C for 3 hours, a chemical reaction occurs, and the chemical reaction formula is: CaMg(CO 3 ) 2 =CaCO 3 +MgO+CO 2 ↑, obtain the mixture of magnesium oxide and calcium carbonate;

[0090] 3. Take 60 grams of magnesium oxide and calcium carbonate mixture, 1200 milliliters of 85 ℃ deionized water and 900 grams of stainless steel balls and put them into the ball mill tank for digestion reaction. The speed of the ball mill is controlled at 500 rpm, and the reaction is completed after 75 minutes. The chemical reaction The formula is: MgO+H 2 O=Mg(OH) 2 , remove the residue to obtain a suspension;

[0091] 4. Add secondary filtrate to the suspension to lower the temperature. After the suspension is cooled to 20°C, inject CO into the suspen...

Embodiment 2

[0102] The method for preparing nano magnesium oxide comprises the following steps:

[0103] 1. Crushing the dolomite to a particle size of 5mm;

[0104] 2. Calcining the dolomite crushed to a particle size of 5mm in a heating furnace at 830°C for 2.5 hours, a chemical reaction occurs, and the chemical reaction formula is: CaMg(CO 3 ) 2 =CaCO 3 +MgO+CO 2 ↑, obtain the mixture of magnesium oxide and calcium carbonate;

[0105] 3. Take 60 grams of magnesium oxide and calcium carbonate mixture, 1500 milliliters of 90 ℃ deionized water and 1800 grams of stainless steel balls and put them into a ball mill tank for digestion reaction. The speed of the ball mill is controlled at 300 rpm, and the reaction is completed after 50 minutes. The chemical reaction The formula is: MgO+H 2 O=Mg(OH) 2 , remove the residue to obtain a suspension;

[0106] 4. Add deionized water to the suspension, wait for it to cool to 30°C, and pass CO into the suspension 2 The furnace gas with a volume...

Embodiment 3

[0117] 1. Crushing the dolomite to a particle size of 0.6mm;

[0118] 2. Calcining the dolomite crushed to 0.6mm in a heating furnace at 870°C for 1.5 hours to obtain a mixture of magnesium oxide and calcium carbonate,

[0119] 3. Take a mixture of 60 grams of magnesium oxide and calcium carbonate, 2100 milliliters of 87 ° C deionized water and 1200 grams of stainless steel balls and put them into a ball mill tank for digestion reaction. The speed of the ball mill is controlled at 400 rpm, and the reaction is completed after 60 minutes. The chemical reaction The formula is: MgO+H 2 O=Mg(OH) 2 , remove the residue to obtain a suspension;

[0120] 4. Add deionized water to the suspension, wait for it to cool to 45°C, and pass CO into the suspension 2 The furnace gas with a volume percentage of 32% is carbonized once, the gas pressure is controlled at 0.8MPa, and it is stirred while passing through. When the pH of the solution reaches 6.8, the carbonized solution is filtered, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com