Automatic shoe polisher

A technology of automatic wiping and shoe machine, applied in the direction of cleaning boots and shoes, cleaning equipment, household appliances, etc., can solve the problem of open chassis structure and large dust, and achieve the effect of reducing dust scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

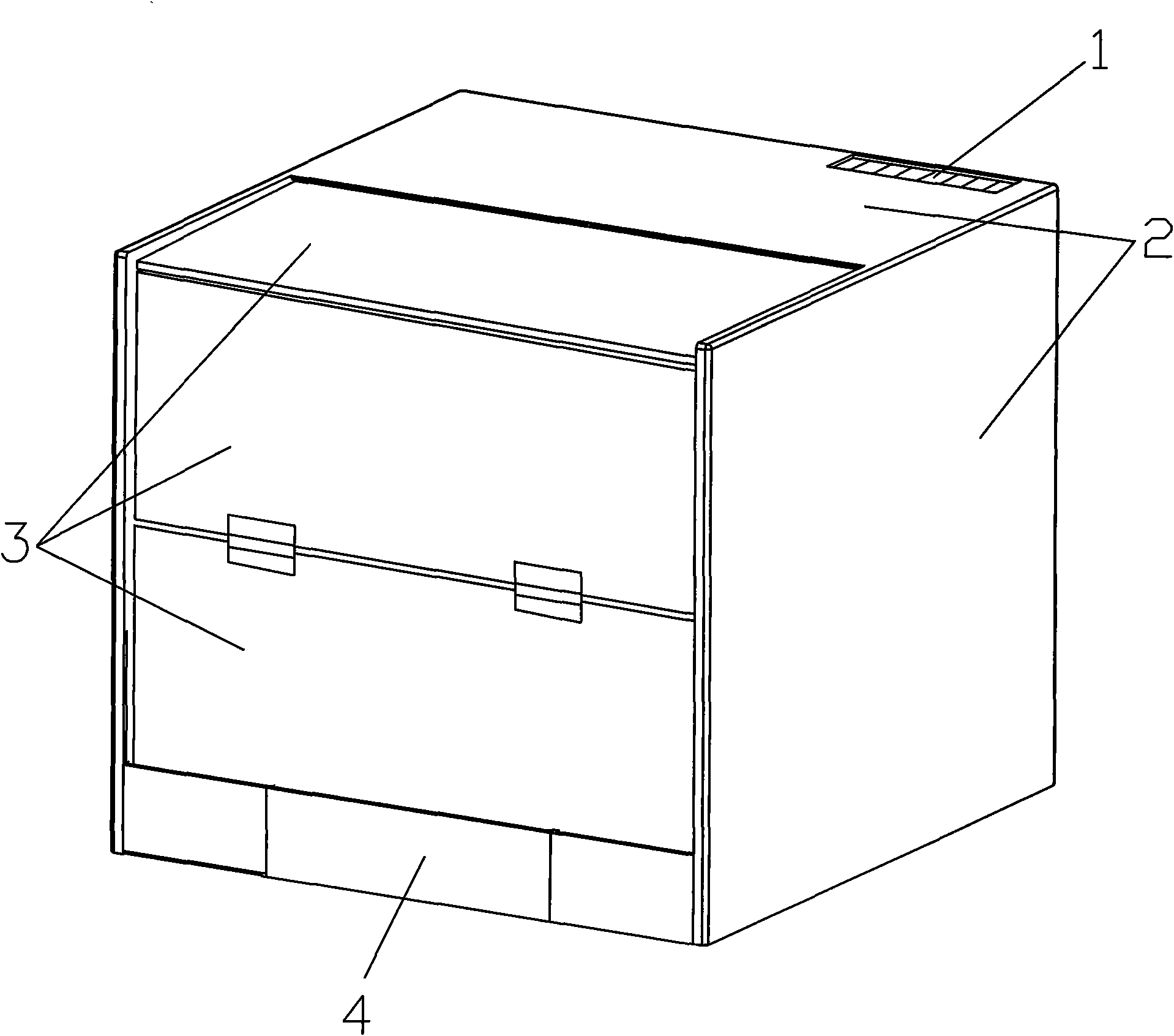

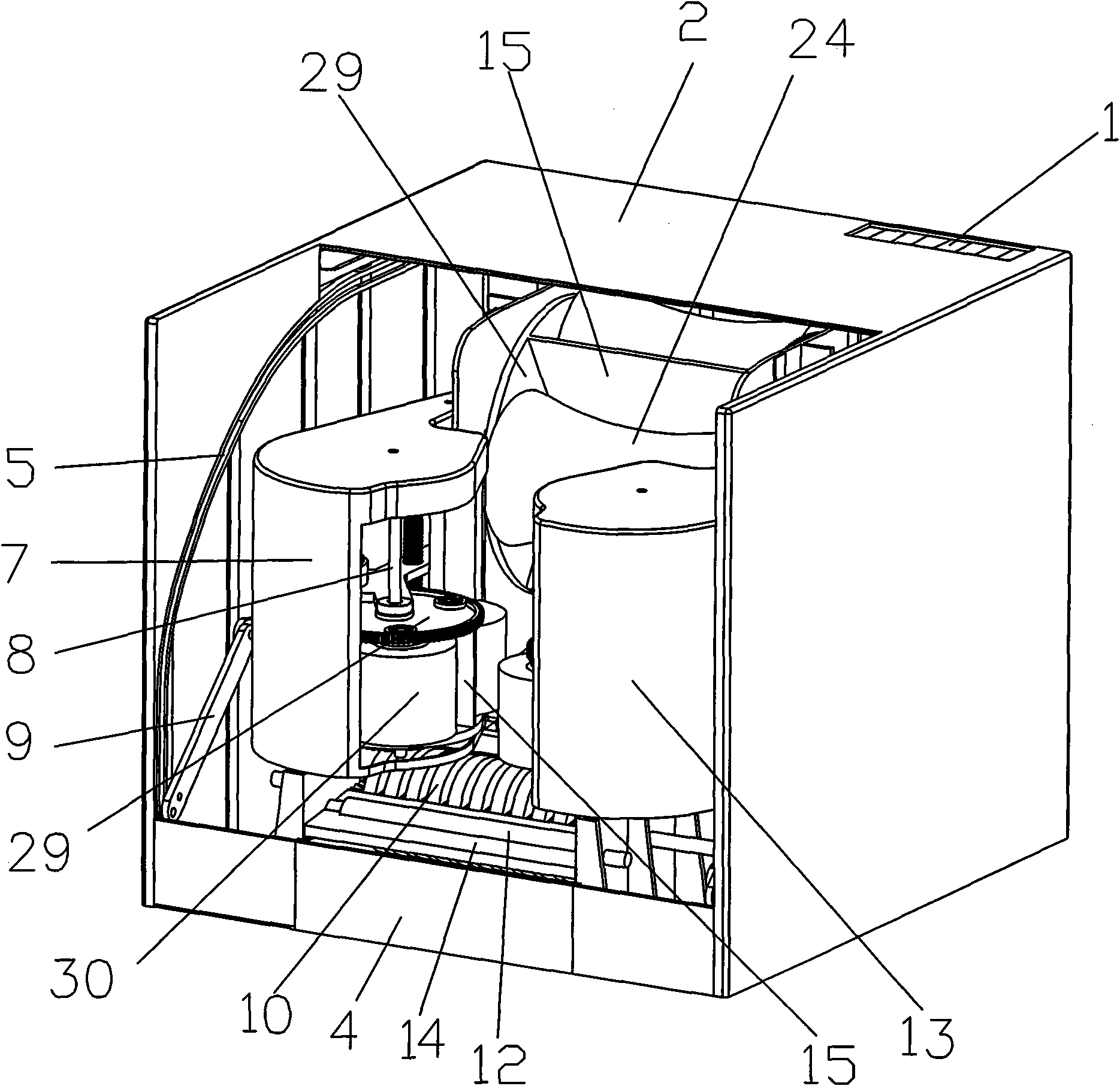

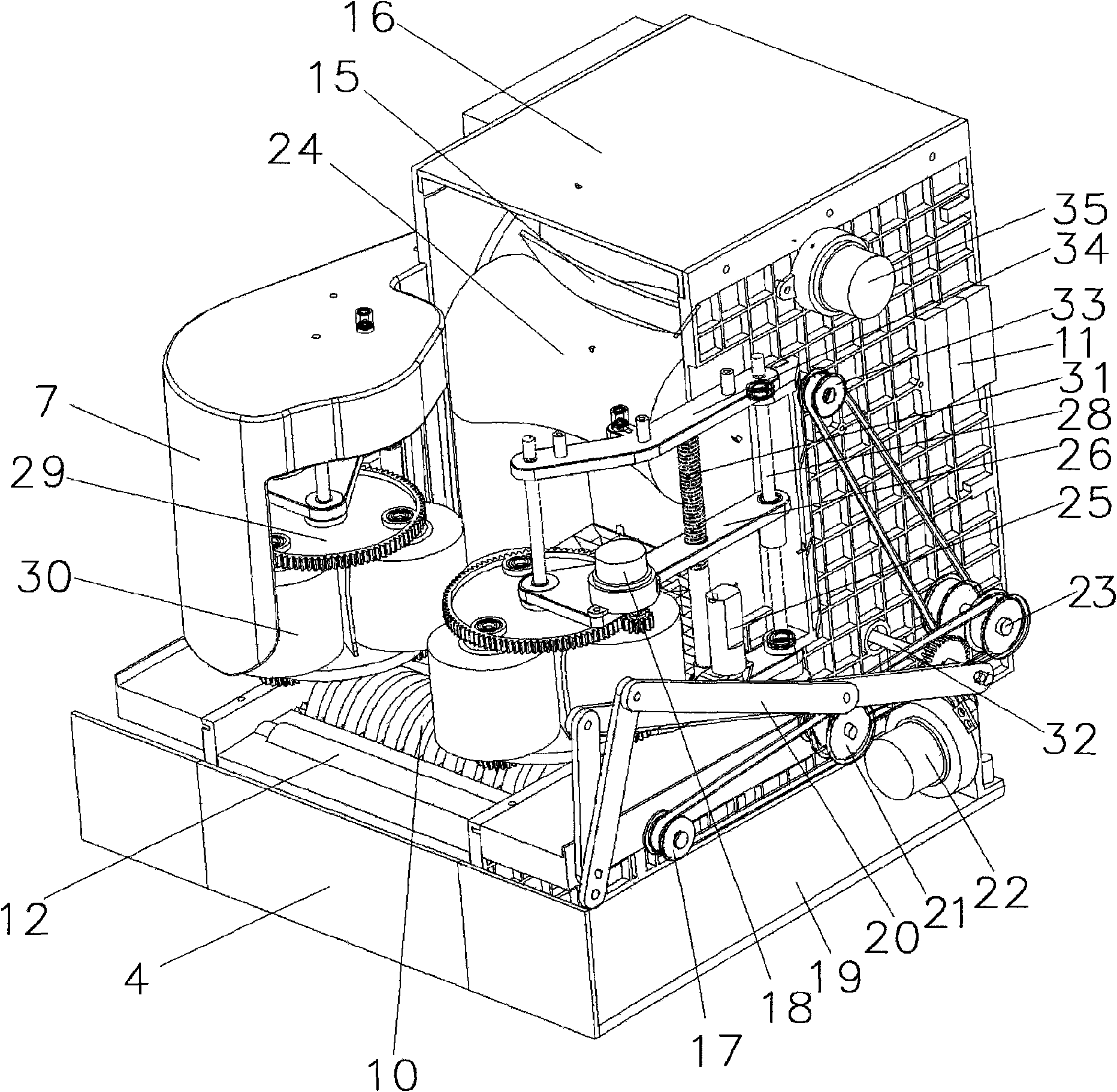

[0021] Such as Figure 1 to Figure 5Shown, a kind of automatic shoe polishing machine comprises base 19 and is connected on the chassis cover 2 of base 19 tops, and the front half side of chassis cover 2 front and top is provided with the opening that connects. The middle part of the base 19 is provided with a drawer-type dust collection box 4, the upper part of the dust collection box 4 is provided with a grid dust leakage protection layer 14 adapted to the shape of the opening, and the side of the dust collection box 4 near the front opening of the chassis cover 2 is provided with a The sole brush 10 that penetrates the grid dust leakage protection layer 14; the inner side of the base 19 is adjacent to the dust box 4 and is provided with an inner box 16 composed of two side plates and a top plate, and the position of the inner box 16 top plate is close to the top of the chassis cover 2 On the top of the inner box 16, there are three-color brush rollers 29 with upper brushes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com