Fire extinguishing bomb dry powder filling device and method

A technology for filling device and bomb dry powder, which is applied to the device for filling fire extinguishing bomb dry powder and the field of filling, can solve the problems of unenvironmental filling and low filling efficiency of fire extinguishing bomb dry powder, etc., so as to reduce dust scattering, and the assembly process is environmentally friendly and efficient. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

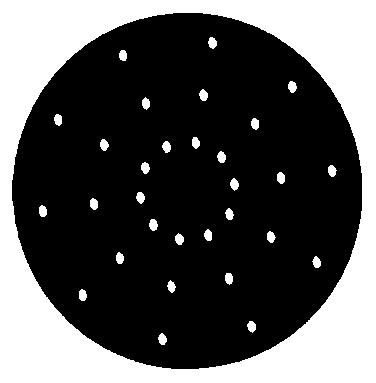

[0061] A dry powder filling device for fire extinguishing bombs includes a support cylinder, a filling bag, a vacuum pump and a dry powder filling machine. The supporting cylinder adopts an integral structure, the main body is a cylindrical structure, the lower end of the supporting cylinder is provided with an adapter, the adapter is designed in a funnel shape, and the small-diameter end of the adapter is connected to the vacuum pump. A rectifying plate is arranged in the radial air passage of the adapter, and the rectifying plate and the adapter are integrated; the surface of the rectifying plate is provided with air holes.

[0062] Using the above-mentioned fire-extinguishing bomb dry powder filling device, the present invention provides a fire-extinguishing bomb dry powder filling method, which includes the following steps:

[0063] Step 1: Prepare the dry powder filling bag of fire extinguishing bomb;

[0064] Filling bags use PVC bags. The outer diameter of the filling bag is ...

Embodiment 2

[0074] The invention provides a dry powder filling device for fire extinguishing bombs, which comprises a support cylinder, a filling bag, a vacuum pump and a dry powder filling machine. The support cylinder adopts a split structure, and the support cylinder includes an upper cylinder and a lower adapter. The large diameter end of the adapter is radially provided with a rectifier plate, the surface of the rectifier plate is provided with air holes, and the rectifier plate is fixedly connected to the adapter or movably connected. When the rectifier plate and the adapter are fixedly connected, the rectifier plate and the adapter can be an integrated structure; When the rectifier plate is movably connected with the adapter, a certain height of outer edge protruding upward is provided around the rectifier plate, which is convenient for disassembly, installation, replacement or maintenance of the rectifier plate.

[0075] The upper cylinder and the lower adapter are connected by threa...

Embodiment 3

[0088] The invention provides a dry powder filling device for fire extinguishing bombs, which comprises a support cylinder, a filling bag, a vacuum pump and a dry powder filling machine. The support cylinder includes an upper cylinder and a lower adapter. The upper cylinder and the lower adapter are connected by threads; the adapter is designed in a funnel shape, and the large-diameter end is connected with the upper cylinder, and the small-diameter end is connected with the vacuum pump. The rectifying plate is placed at the lower position of the support cylinder.

[0089] Using the above-mentioned fire-extinguishing bomb dry powder filling device, the present invention provides a fire-extinguishing bomb dry powder filling method, which includes the following steps:

[0090] Step 1: Prepare the dry powder filling bag of fire extinguishing bomb;

[0091] Filling bags use PVC bags. The outer diameter of the filling bag is 5mm-10mm smaller than the inner diameter of the fire extinguish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com