Gear rotating grinding device for automobile steering gear

A technology for automotive steering gears and gears, which is applied in grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, grinding machines, etc., which can solve the problems of no grinding dust treatment channels, unfavorable fast grinding, long installation and fixed time, etc. problem, to achieve the effect of convenient and firm grinding, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

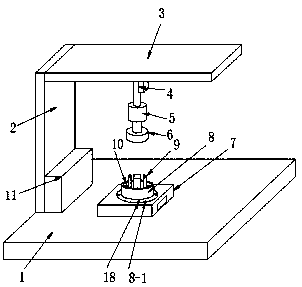

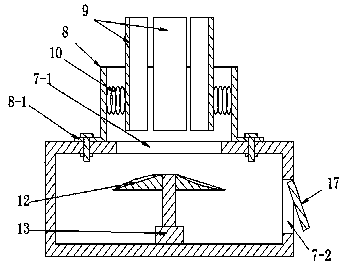

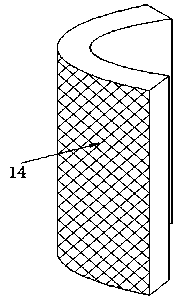

[0023] see as Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a bottom plate 1, a vertical plate 2, a top plate 3, an electric lifting rod 4, a grinding motor 5, a grinding wheel 6, a dust collection box 7, a positioning piece fixing ring 8, a positioning Sheet 9, tension spring 10, electric control box 11, turbine 12, turbine rotating motor 13; one side of the bottom plate 1 is welded with a vertical plate 2, and the upper part of the vertical plate 2 is welded with a top plate 3 at the top of the bottom plate 1, and the top plate 3 The lower surface of the lower surface is connected and fixed with the electric control end of the electric lifting rod 4 by bolts, and the output shaft of the electric lifting rod 4 is welded and fixed on the electric control end shell of the grinding motor 5, and the output shaft of the grinding motor 5 is connected with a grinding wheel 6; The upper surface of the bottom plate 1 is welded ...

specific Embodiment approach 2

[0029] see Figure 4 and Figure 5The difference between this specific embodiment and the specific embodiment one is that the fixed bolt 18 is replaced by a buffer spring 16, the upper end of the buffer spring 16 is welded and fixed on the bottom surface of the fixed flange 8-1, and the buffer spring 16 is The lower ends are all welded and fixed on the spring mounting seat 15, the spring mounting seat 15 is an annular structure, and its upper edge is welded and fixed on the upper surface of the dust collection box 7, and is located below the opening 7-1. The side 8-1 is movably embedded in the opening 7-1; the symmetrical bolts on the left and right sides of the lower surface of the top plate 3 are fixed with a Y-direction slide rail 19, and a Y-direction slider 20 is movable on the Y-direction slide rail 19. An X-direction slide rail 23 is welded between the left and right Y-direction sliders 20, and an X-direction slider 24 is movable on the X-direction slide rail 23. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com