Continuous granulator and granulating method by gravity method

A technology of granulation equipment and gravity method, which is applied in the field of spray granulation equipment, can solve the problems of high cost and high energy consumption of equipment, and achieve the effects of improving production efficiency, improving production efficiency, and reducing production sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

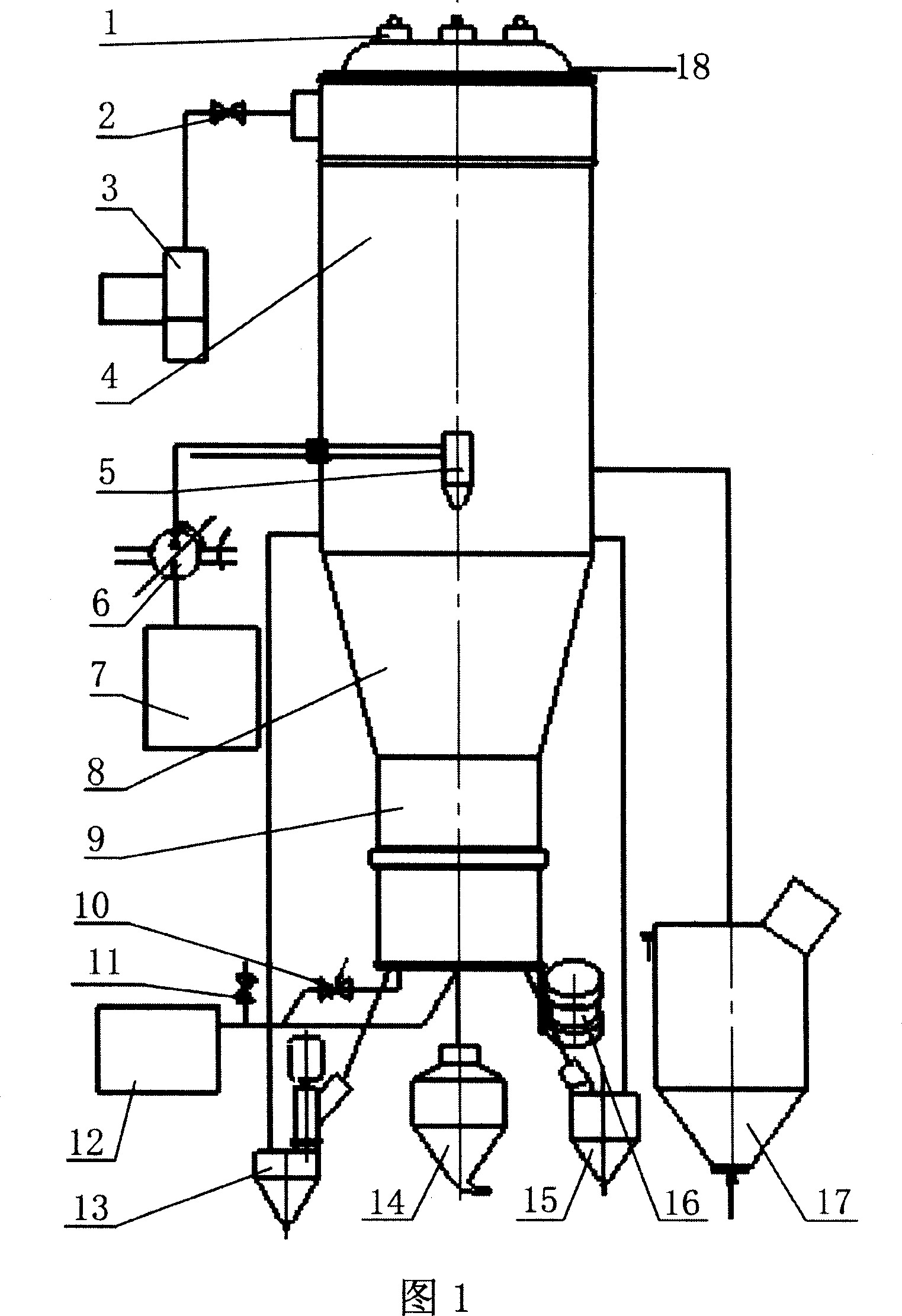

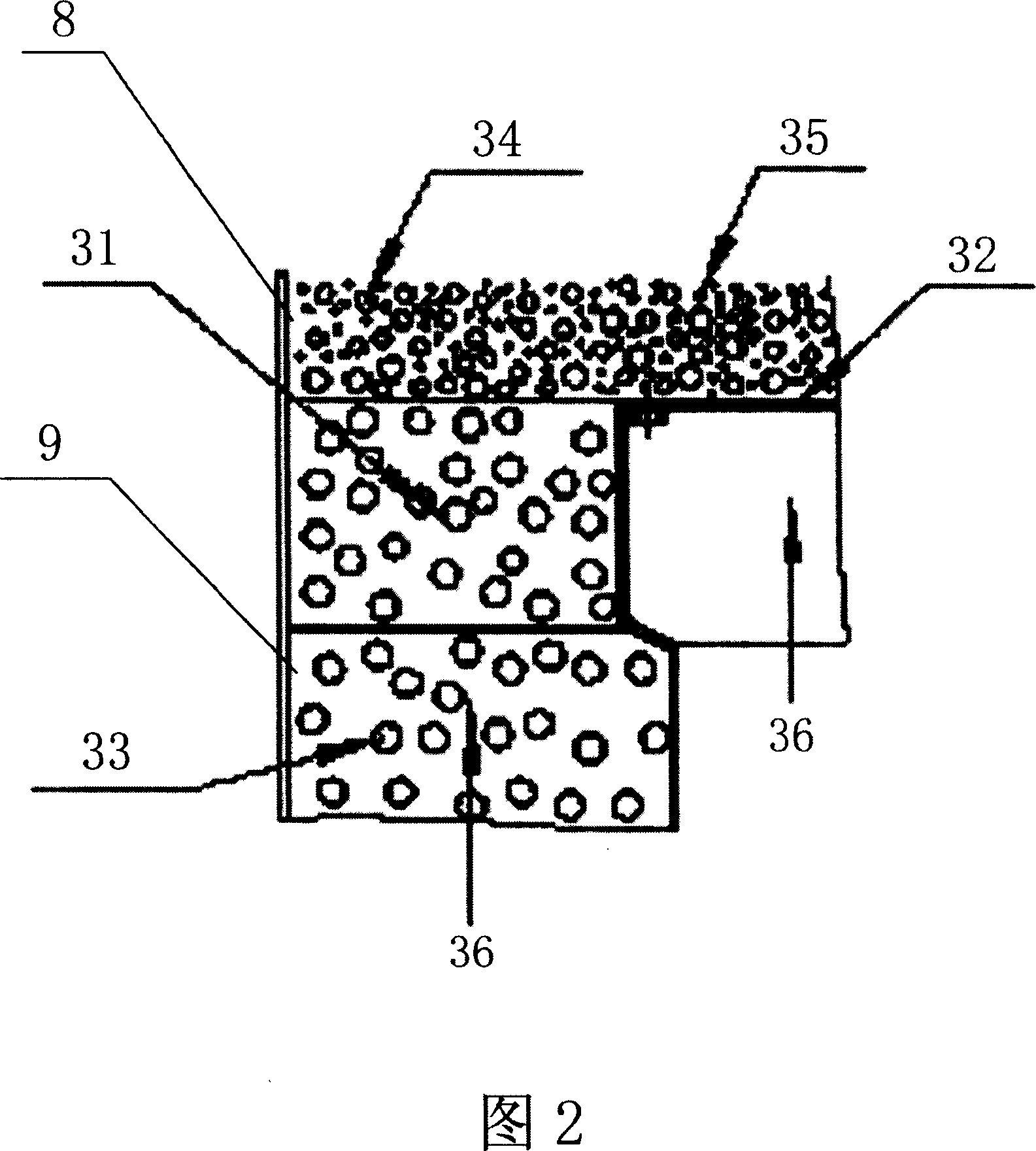

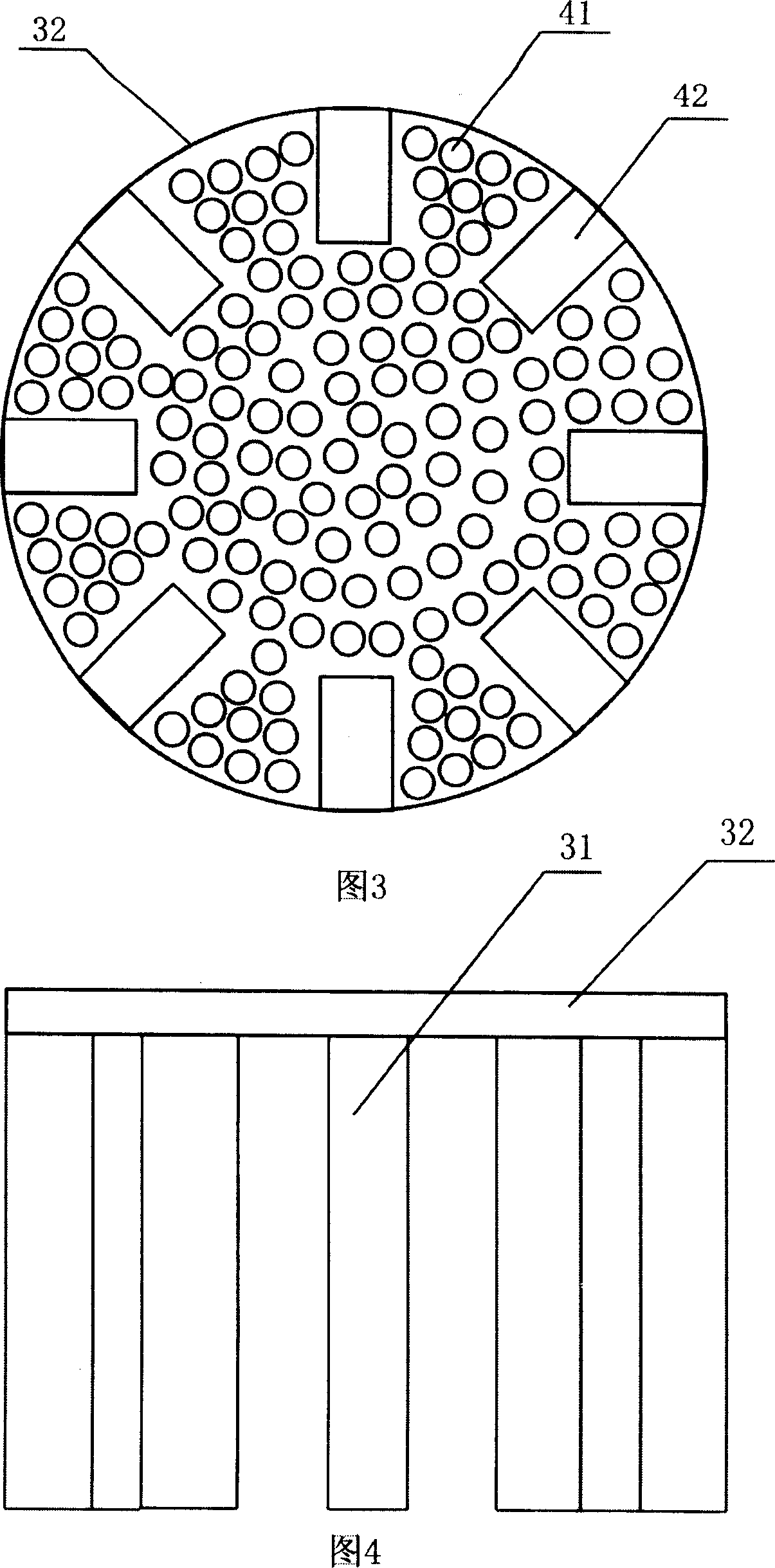

[0033] As shown in accompanying drawings 1 and 2, the present invention is a kind of gravity method continuous granulation equipment, and this granulation equipment comprises dust collection device 4, granulation chamber 8, by nozzle 5, peristaltic pump 6, binder liquid tank 7, a liquid spraying system consisting of a vibrating motor 16, a drying chamber 9, and a grading device, a hot air system consisting of a fan 3 and a heat exchanger 12, and a continuous feeding device 17, a discharger 14, and a return material devices, etc., the continuous feeding device 17 is connected with the granulation chamber 8 through pipelines; the granulation chamber 8 is connected with the drying chamber 9 through the ventilation plate 32 and the throat pipe 31, and the hot blast pipeline of the hot air system is connected with the ventilation plate 32 and the The throat pipe 31 is connected; the bottom of the drying chamber 9 is provided with a classification device with two layers of screens; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com