Automatic paint spraying equipment for blank of elevator guide rail

A technology for automatic painting and elevator guide rails, applied in spraying devices, coatings, devices for coating liquids on surfaces, etc., it can solve problems such as the thickness of the dry paint film not meeting customer requirements, affecting the spraying efficiency and quality, etc. The effect of less ground, improving efficiency and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

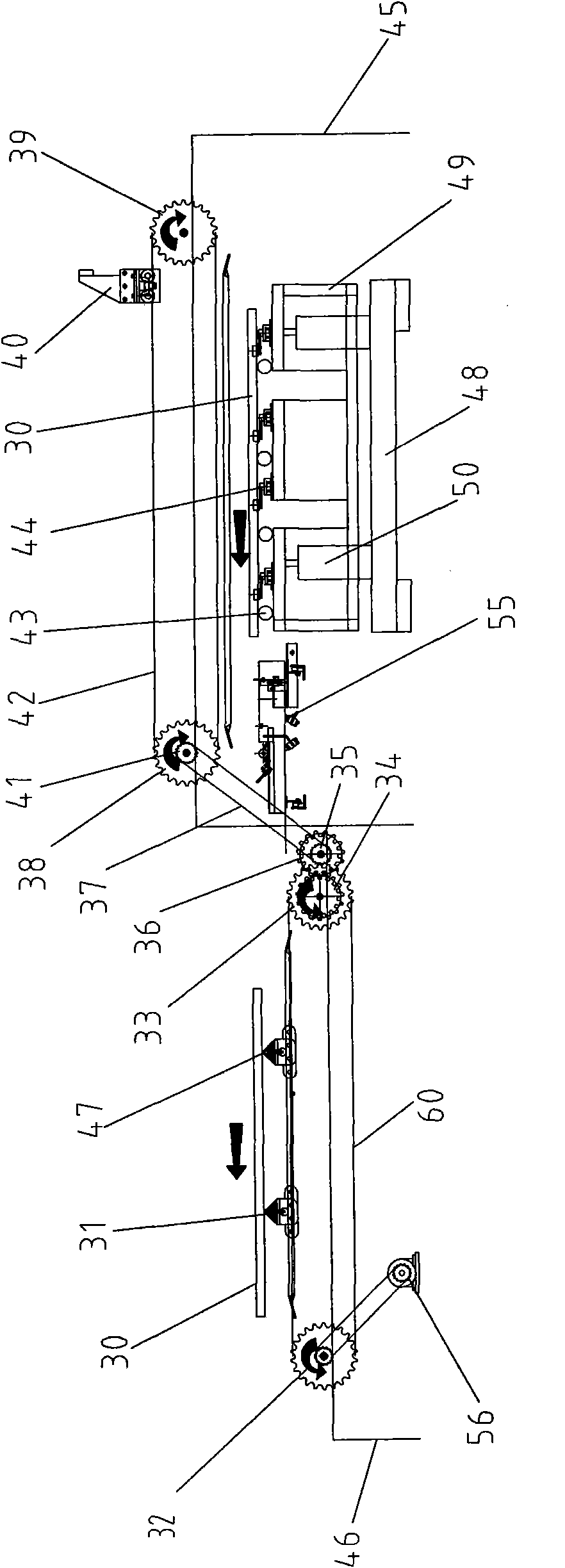

[0040] Such as Figure 3a , Figure 3b Shown, the transmission structure of the preferred embodiment of the present invention. The guide rail 30 is a blank before spraying, which can enter the lifting frame roller 43 arranged on the lifting frame 49 from the A direction (ie, the horizontal direction) or the B direction (ie, the longitudinal direction), and is guided by the flexible self-centering structure provided on the lifting frame 49. The mechanism 44 is clamped and centered (three flexible self-centering guide mechanisms 44 are provided in this embodiment). The push rod of the lifting frame cylinder 50 is fixedly connected with the lifting frame 49 with screws, and the bottom of the cylinder body of the lifting frame cylinder 50 is connected with the fixed frame 48 with hinges. Frame 49 is in descending state. To facilitate A to be hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com