Clean vacuum system used for engine plume test research and vacuumizing and repressing method thereof

A vacuum system and engine technology, used in engine testing, aerodynamic testing, machine/structural component testing, etc., to achieve the effect of diverse working modes and full-scale high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below with reference to the accompanying drawings.

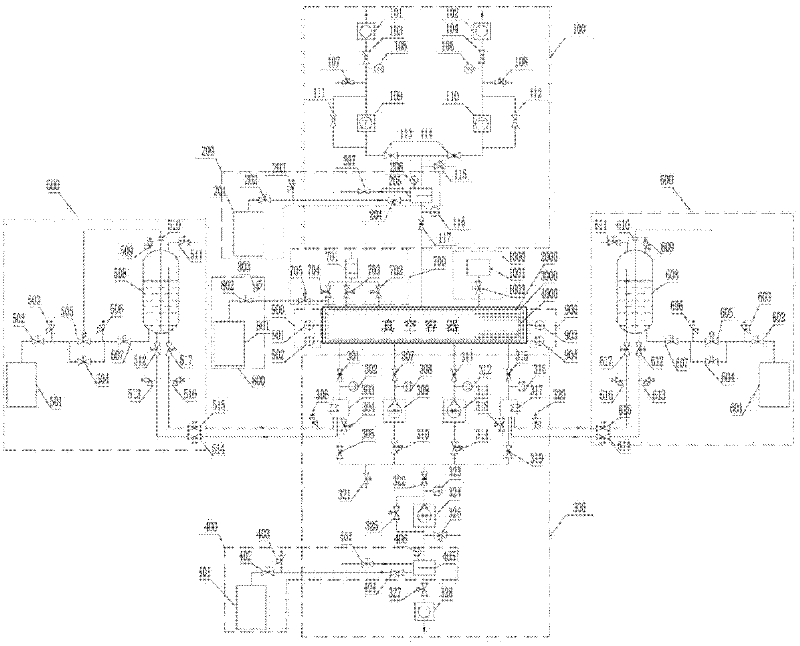

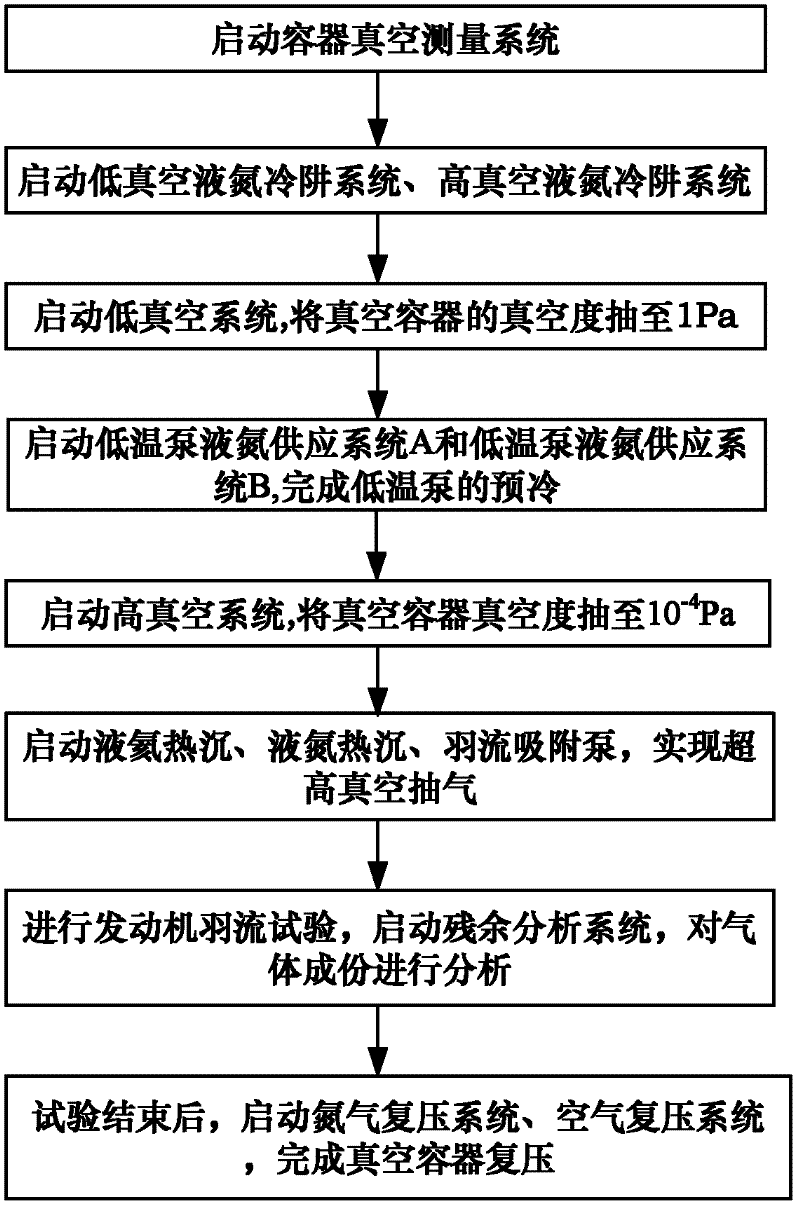

[0052] A clean vacuum system of the present invention is used for the research of the engine plume flow test, such as figure 1 As shown, including low vacuum system 100, low vacuum liquid nitrogen cold trap system 200, high vacuum system 300, high vacuum liquid nitrogen cold trap system 400, cryopump liquid nitrogen supply system A500, cryopump liquid nitrogen supply system B600, air recovery system Pressure system 700, nitrogen recompression system 800, container vacuum measurement system 900, residual gas analysis system 1000, liquid helium heat sink 2000, liquid nitrogen heat sink 3000, plume adsorption pump 4000.

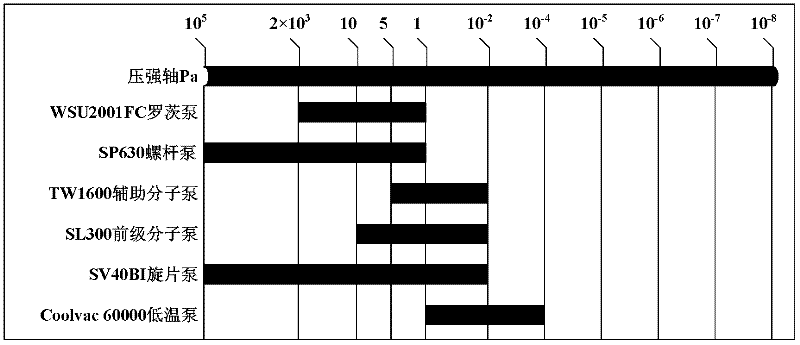

[0053] The low vacuum system 100 includes a Roots pump unit A and a Roots pump unit B. Roots pump unit A includes screw pump A101, butterfly valve A103, resistance gauge A105, solenoid valve A107, Roots pump A109, butterfly valve C111 and flappe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com