Oil-electricity hybrid multi-mode automobile drive system

A vehicle drive system, multi-mode technology, applied to the layout of multiple different prime movers of hybrid vehicles, general power plants, motor vehicles, etc., can solve the problems of complex chassis structure and controllability, and improve fuel efficiency , Chassis structure is simple, the effect of system transmission efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

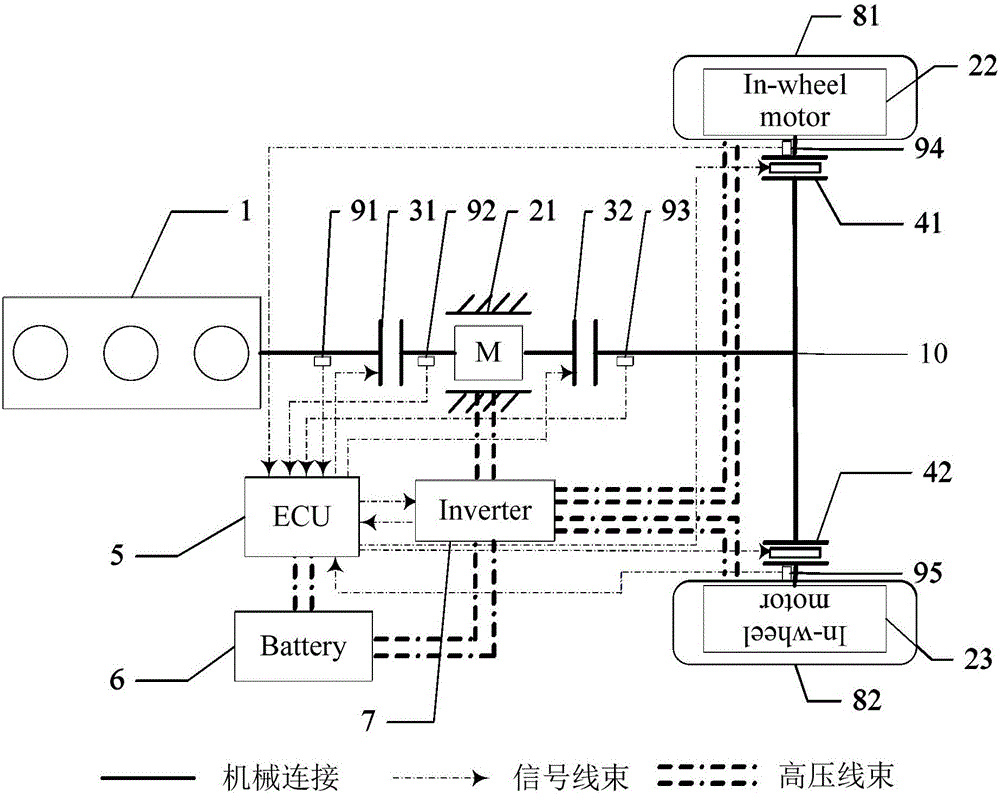

Embodiment 1

[0029] Such as figure 1 Shown, a kind of gasoline-electric hybrid multi-mode vehicle drive system, mainly by engine (1), ISG motor (21), hub motor (22) and (23), clutch (31) and (32), overrunning clutch (41 ) and (42), control unit ECU (5), battery pack (6), motor controller (7), wheels (81) and (82), multiple rotational speed sensors (91), (92), (93) , (94), (95) and power transmission shaft (10) etc. are formed.

[0030] One end of the rotor of the ISG motor (21) is connected to the output end of the engine (1) through the clutch (31), and the other end is respectively connected to one end of the overrunning clutches (41) and (42) through the clutch (32) and the transmission shaft (10). The other end of clutch (41), (42) is then connected with wheel (81), (82) respectively; Hub motor (22) and (23) are installed in the wheel (81), (82) respectively, can directly drive vehicle . The control unit ECU (5) sends instructions to clutches (31) and (32), overrunning clutches (41)...

Embodiment example 2

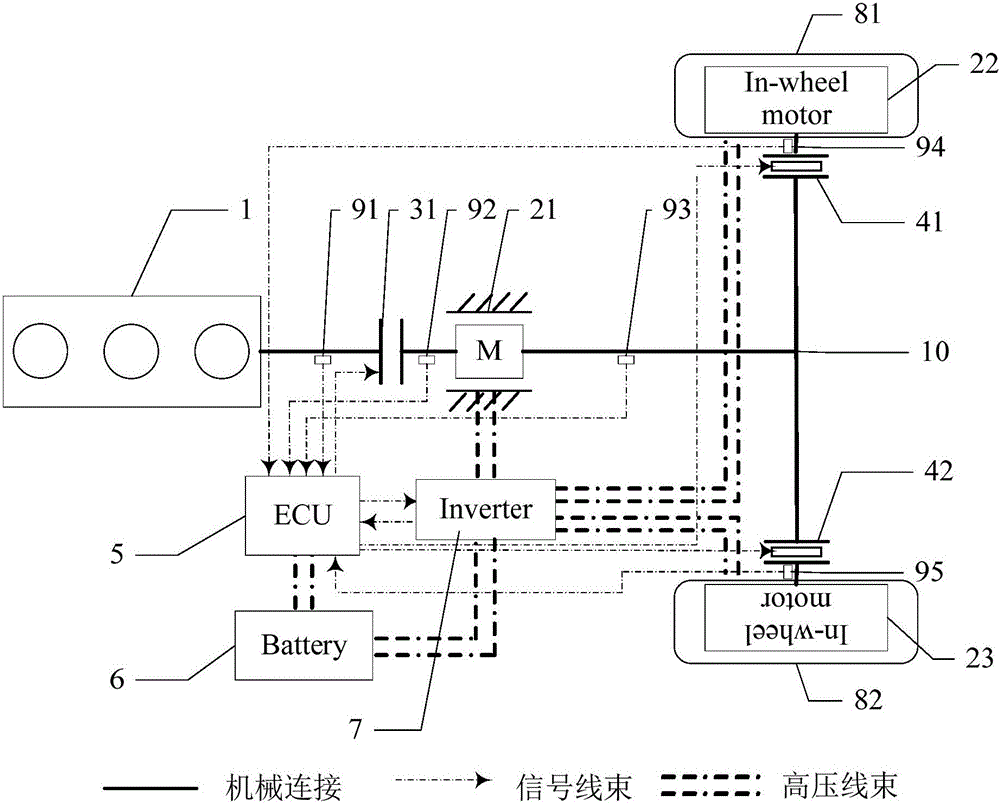

[0054] Such as figure 2 Shown, a kind of gasoline-electric hybrid multi-mode vehicle drive system, mainly by engine (1), ISG motor (21), hub motor (22) and (23), clutch (31), overrunning clutch (41) and (42 ), control unit ECU (5), battery pack (6), motor controller (7), wheels (81) and (82) and multiple rotational speed sensors (91), (92), (93), (94) , (95) and so on.

[0055] Its difference with Embodiment 1 is that the clutch (32) has been removed. The difference between the various working modes of the hybrid electric vehicle and Embodiment 1 lies in the electric starting mode: when the vehicle starts, the ISG motor (5) and the transmission shaft (10) omit the connection of the clutch, and the ISG motor (5) ) is directly connected with the drive shaft (10), and the ISG motor (5) no longer functions as a starter.

[0056] In the hybrid drive mode, the pure engine drive mode, the pure electric drive mode, the regenerative braking mode and the reverse mode, the working pr...

Embodiment approach 3

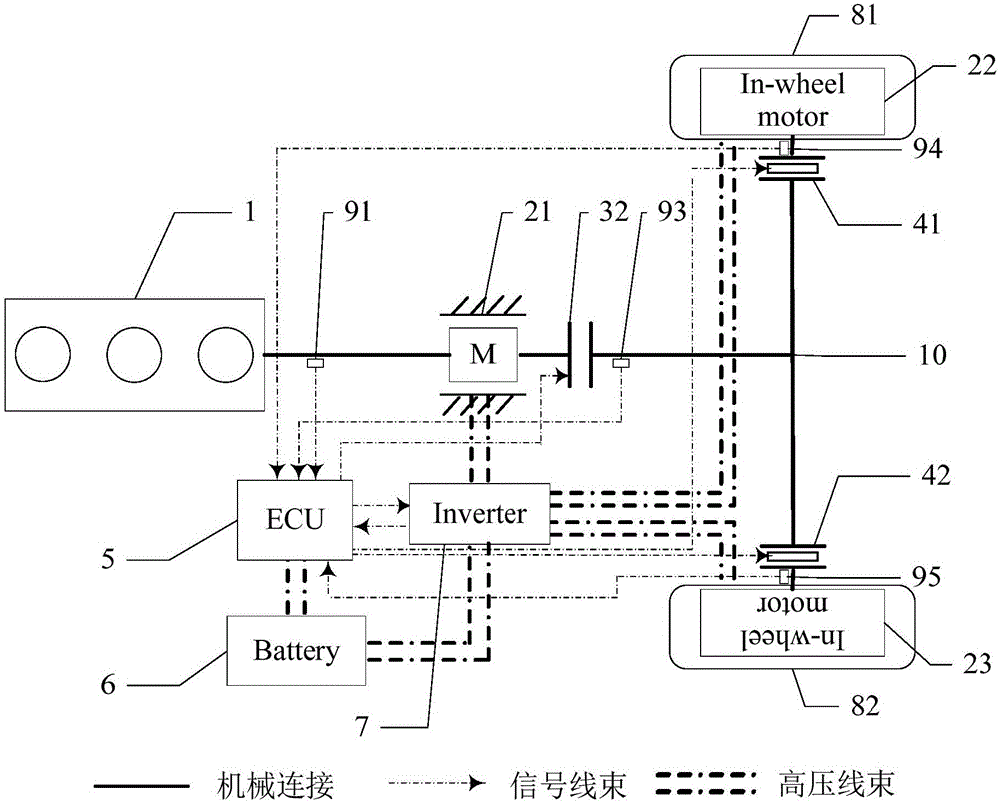

[0058] Such as image 3 Shown, a kind of gasoline-electric hybrid multi-mode vehicle drive system, mainly by engine (1), ISG motor (21), hub motor (22) and (23), clutch (32), overrunning clutch (41) and (42 ), control unit ECU (5), battery pack (6), motor controller (7), wheels (81) and (82) and multiple rotational speed sensors (91), (92), (93), (94) , (95) and so on.

[0059] It differs from Embodiment 1 in that the clutch (31) is removed, and the engine (1) is directly connected to the rotor shaft of the ISG motor (5). The various modes of operation of this scheme hybrid electric vehicle are different from embodiment 1 in that:

[0060] ●Pure electric drive mode

[0061] Since the engine (1) is directly connected to the ISG motor (5) rotor shaft, both always have the same rotational speed. Therefore, if the vehicle is to run in pure electric mode, the vehicle can only be powered by the hub motor (22) and the hub motor (23), and at this time, the clutch (32) is in a dise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com