Patents

Literature

35results about How to "Realize the differential function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

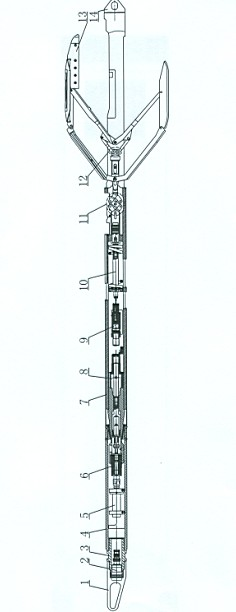

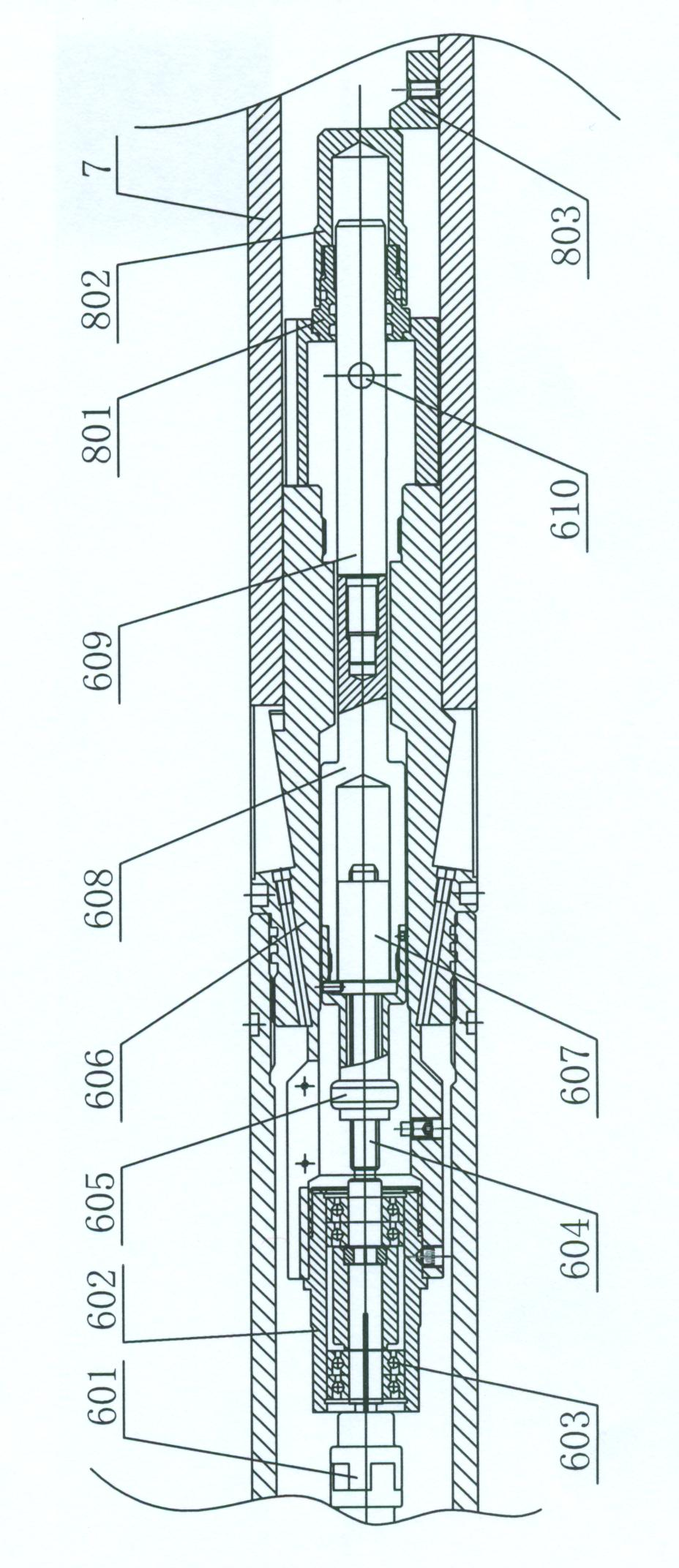

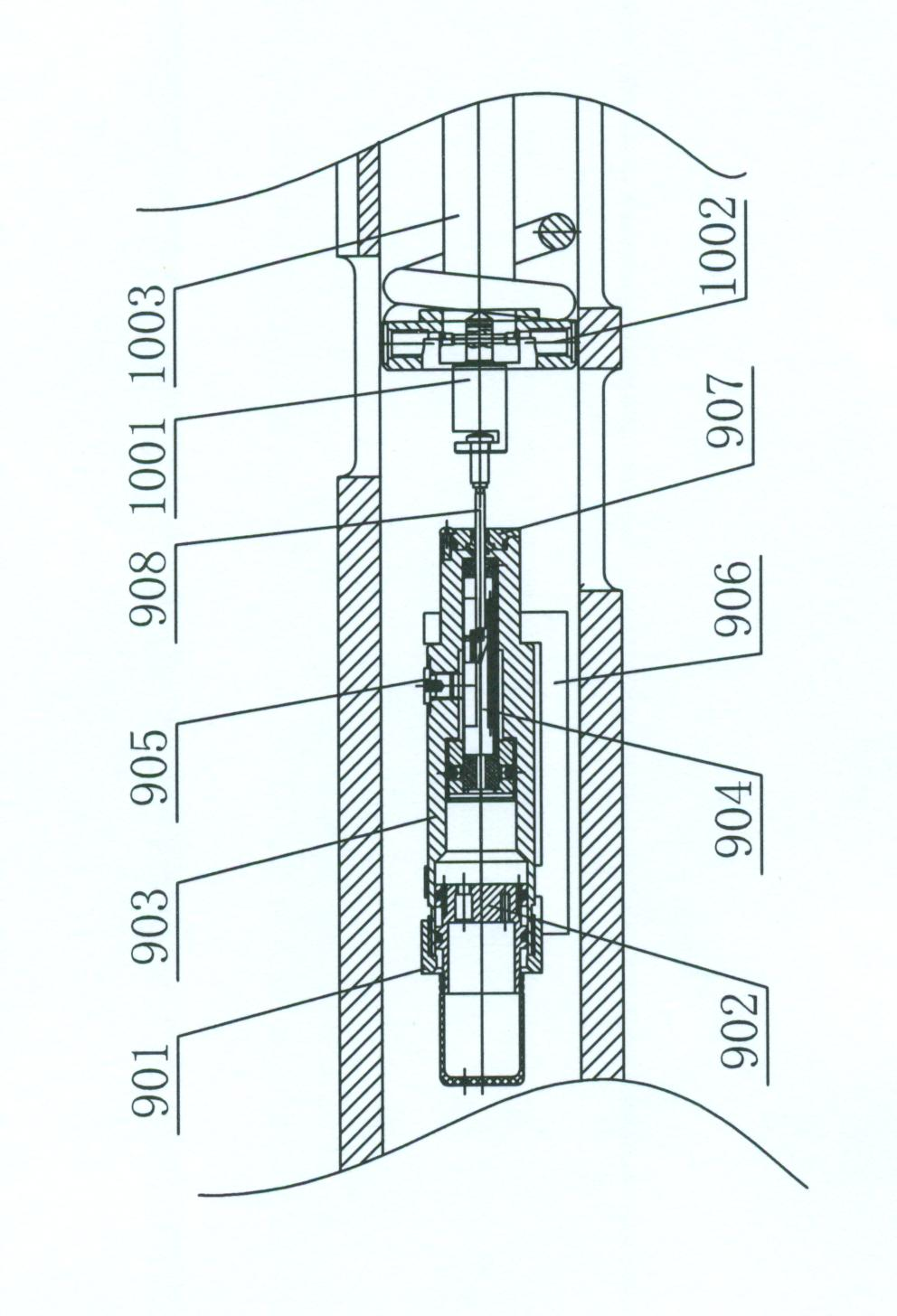

Microsphere logging instrument sidewall contact device

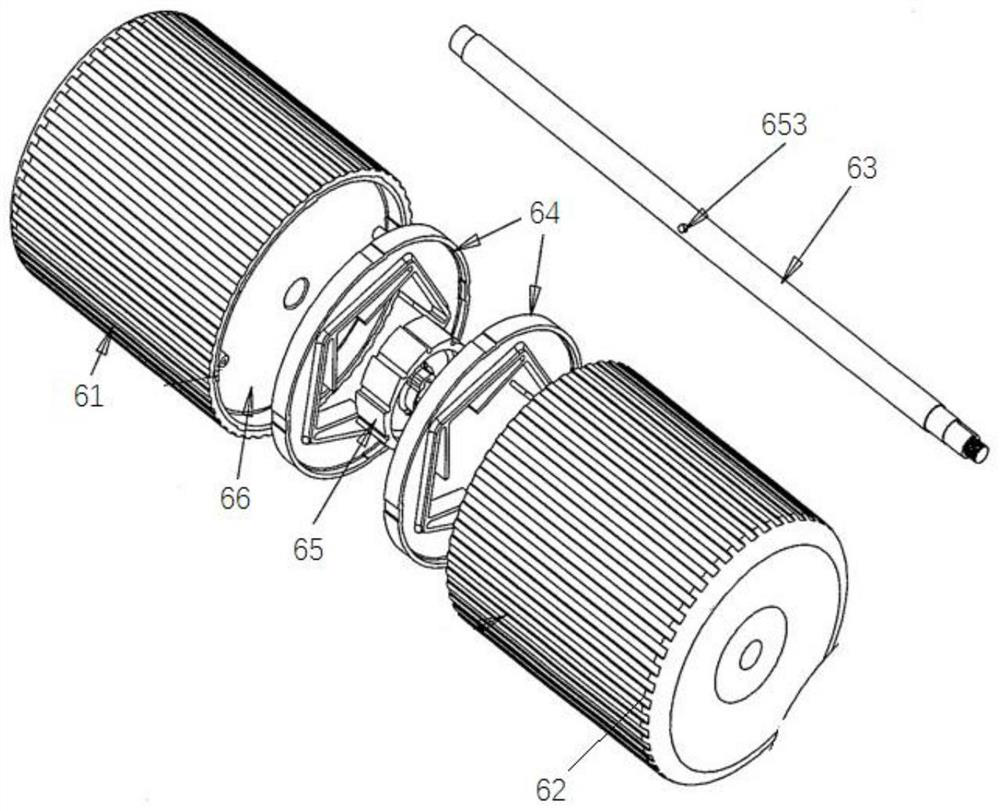

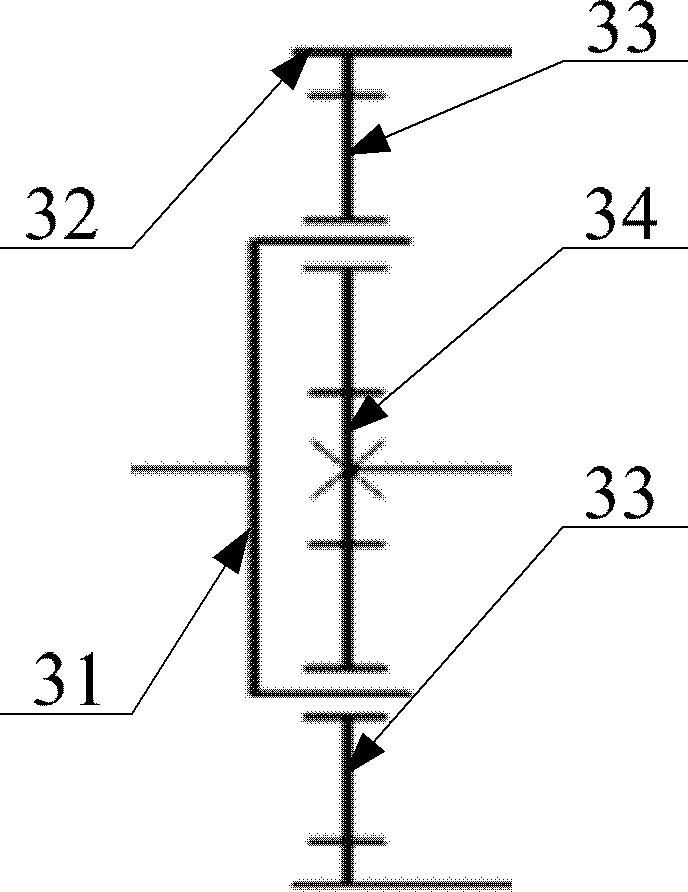

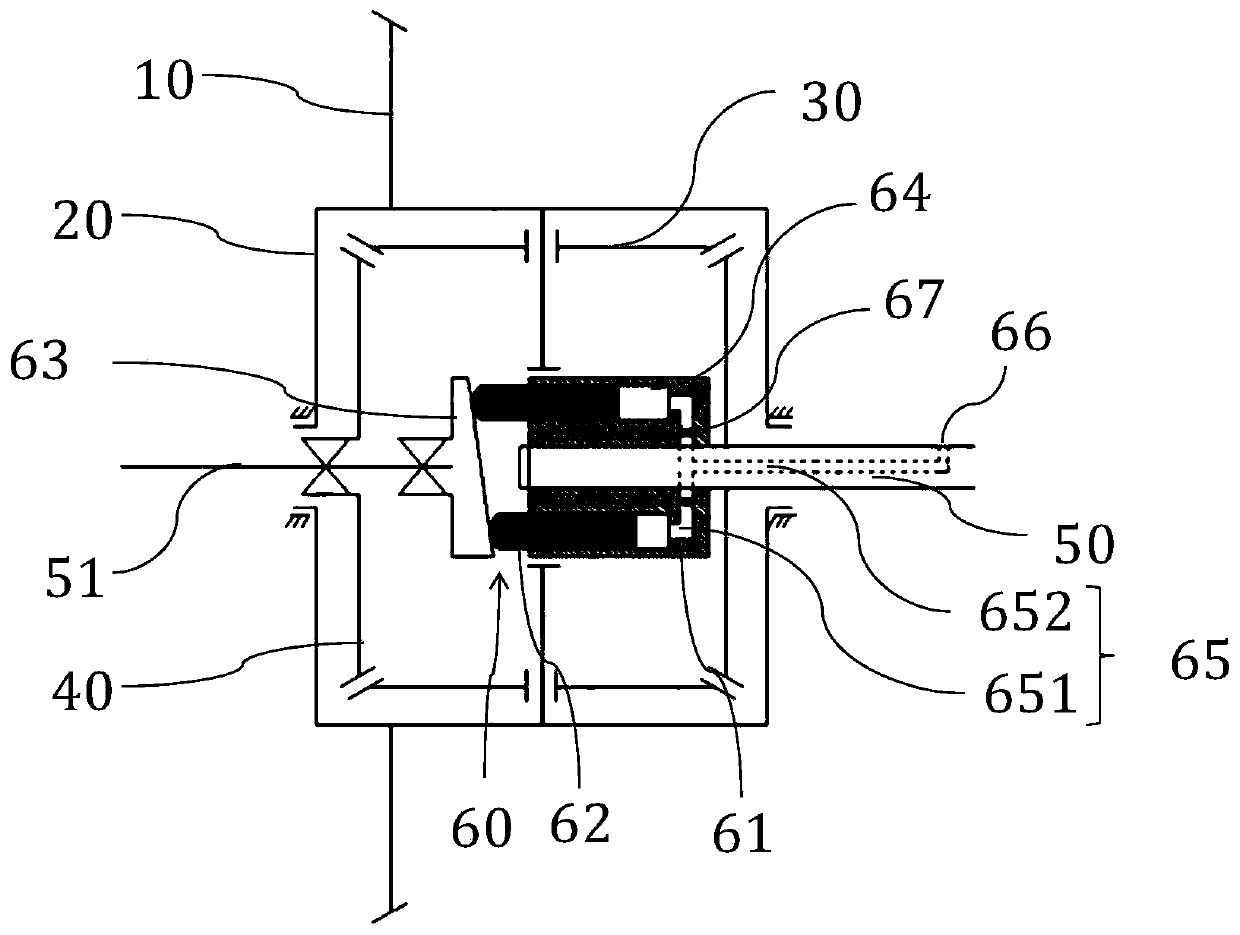

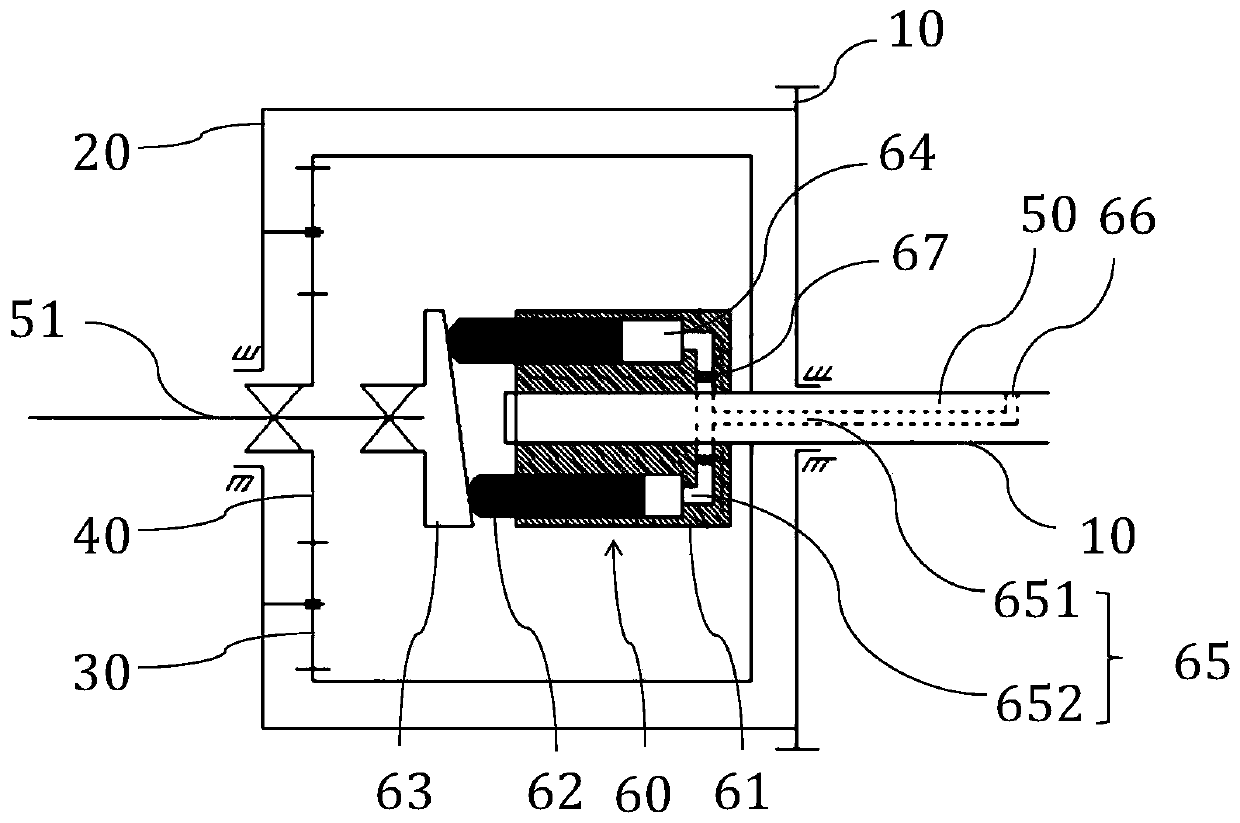

The invention discloses a microsphere logging instrument sidewall contact device, which solves the problems that a logging instrument sidewall contact device used in a conventional oil field limits the detection and influences a detection result of an irregular detected well wall fundamentally. The microsphere logging instrument sidewall contact device comprises a shell, a motor, a drive assembly, a pressure balance assembly, a borehole diameter potentiometer assembly, a spring assembly, a hinge assembly and a pushing end, wherein the motor, the drive assembly, the pressure balance assembly, the borehole diameter potentiometer assembly, the spring assembly and the hinge assembly are arranged in the shell in turn; and the pushing end is connected with the hinge assembly. The technical points of the microsphere logging instrument sidewall contact device are that: the hinge assembly comprises a connecting frame and a hinge connecting rod group connected with the spring assembly; the hinge rod group is a dual-hinge four-connecting-rod mechanism for realizing reverse movement; the front hinge four-connecting-rod mechanism and the back hinge four-connecting-rod mechanism of the dual-hinge four-connecting-rod mechanism use two intermediate connecting rods commonly and are fixed with the shell at a hinge position of the two intermediate connecting rods; the front end of the front hinge four-connecting-rod mechanism is connected with the connecting frame; and the back end of the back hinge four-connecting-rod mechanism is connected with the pushing end. The microsphere logging instrument sidewall contact device changes a linkage working mode of the conventional sidewall contact device, and realizes a working state of the sidewall contact device by fully utilizing a spring tension of the spring assembly.

Owner:SHENYANG XINJIN GASOLINEEUM EQUIP

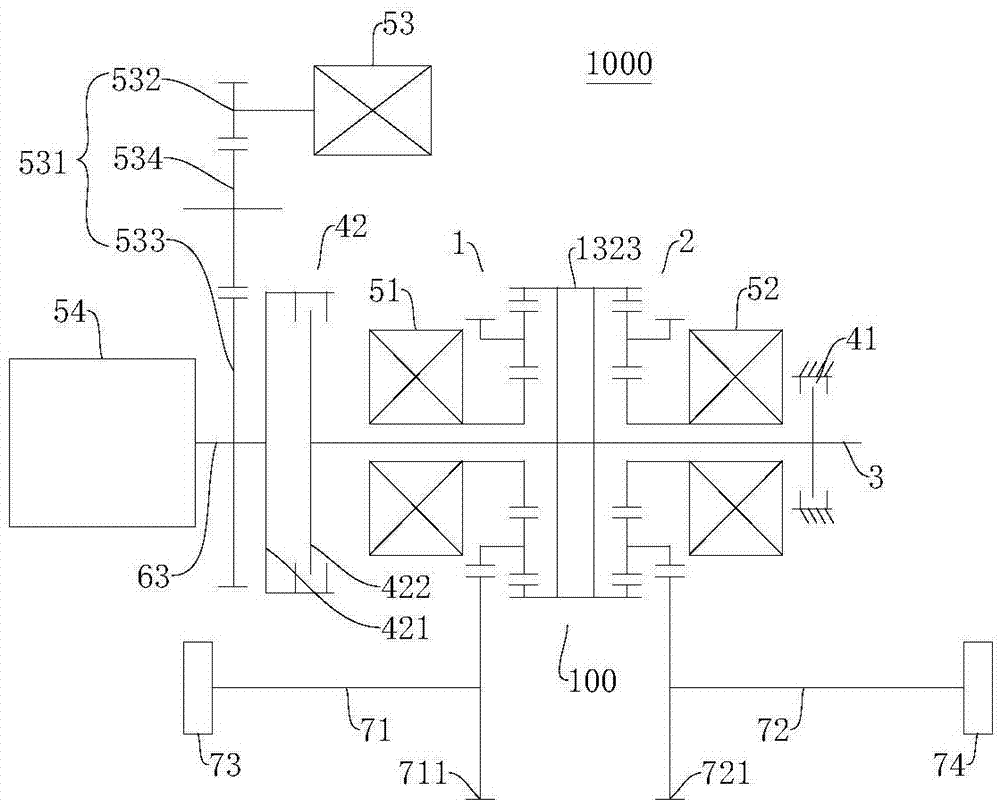

Power driving system and vehicle with same

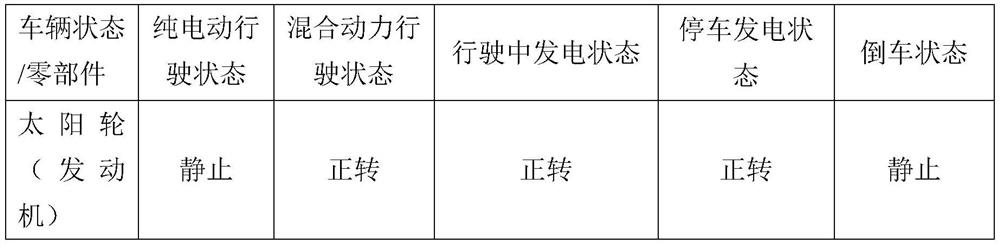

InactiveCN106915236ARealize the differential functionRich transmission modeHybrid vehiclesGas pressure propulsion mountingPower couplingDifferential function

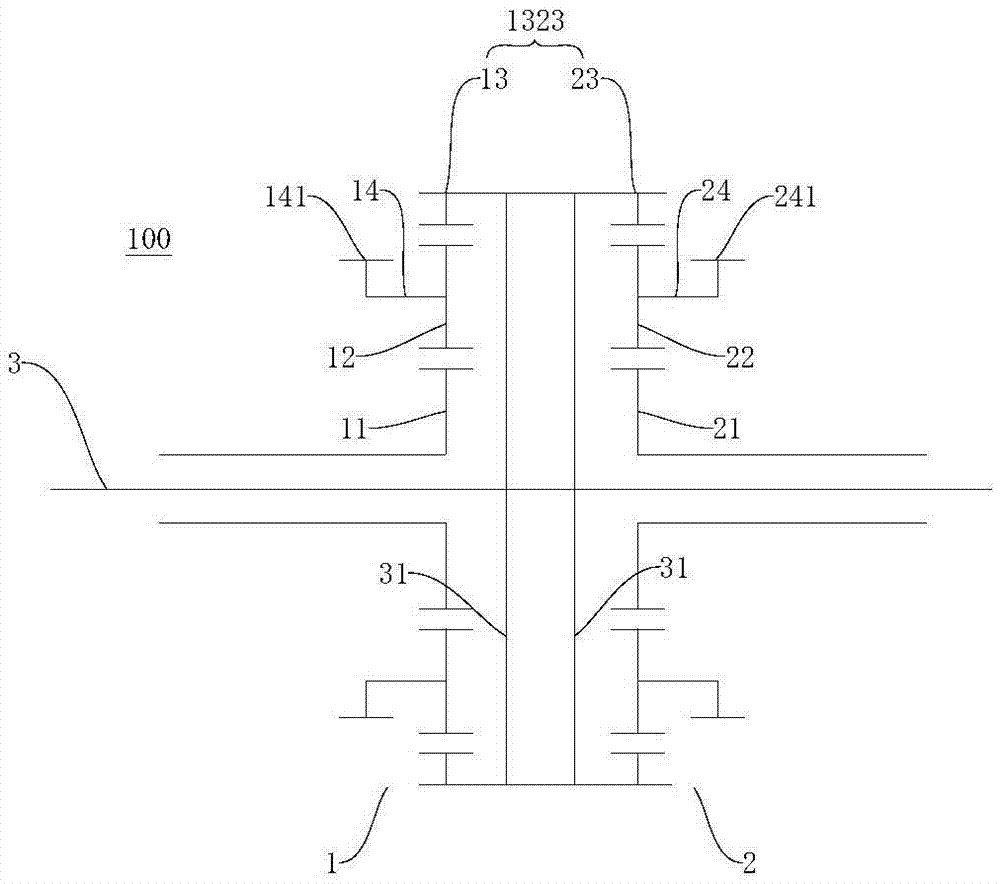

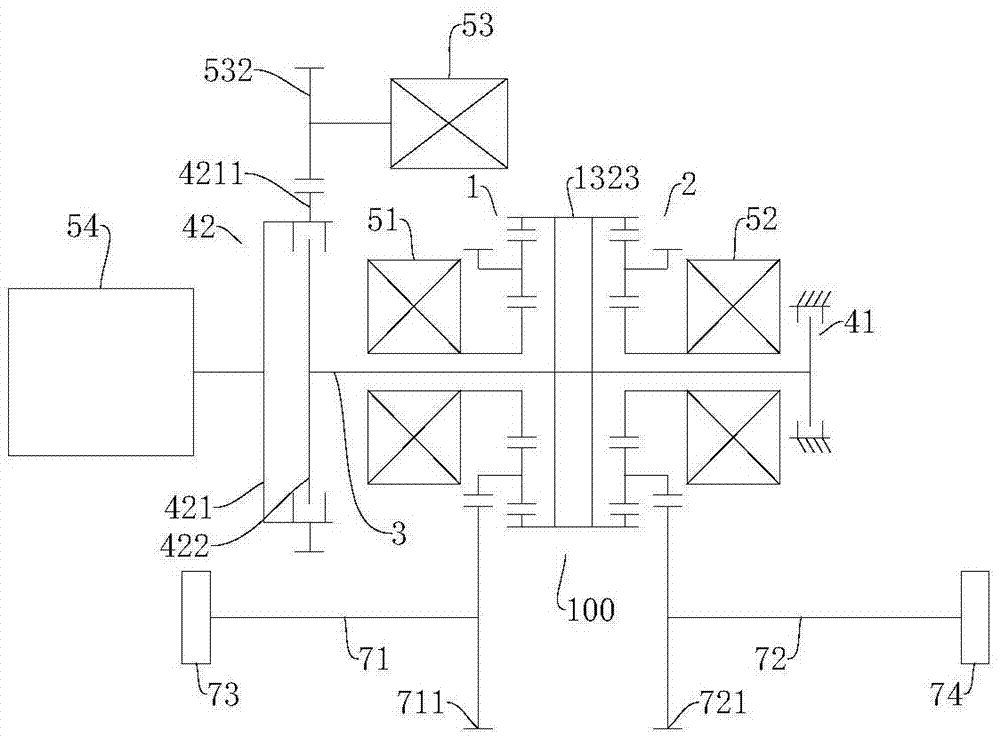

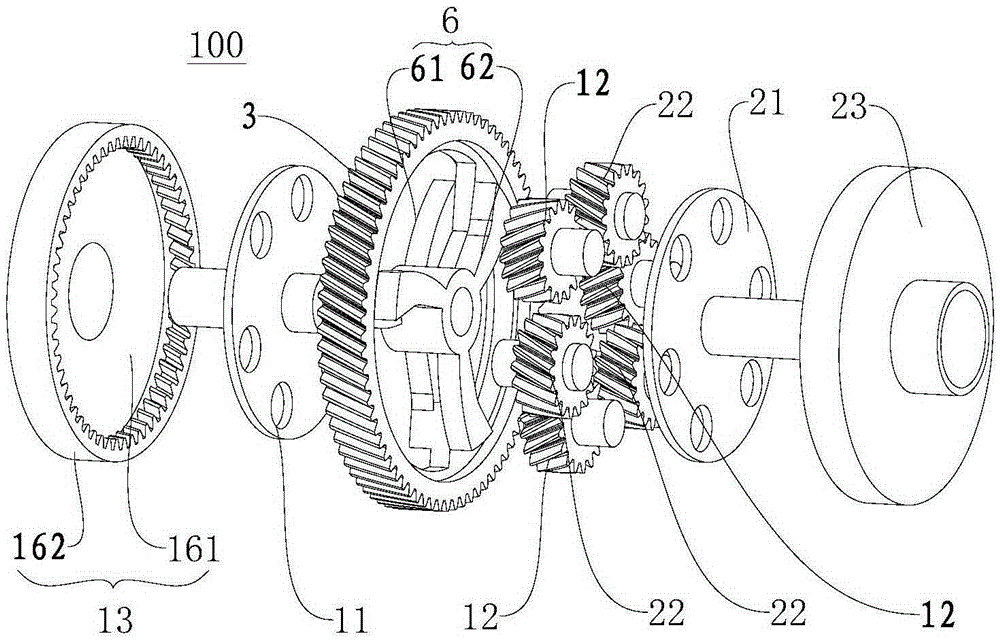

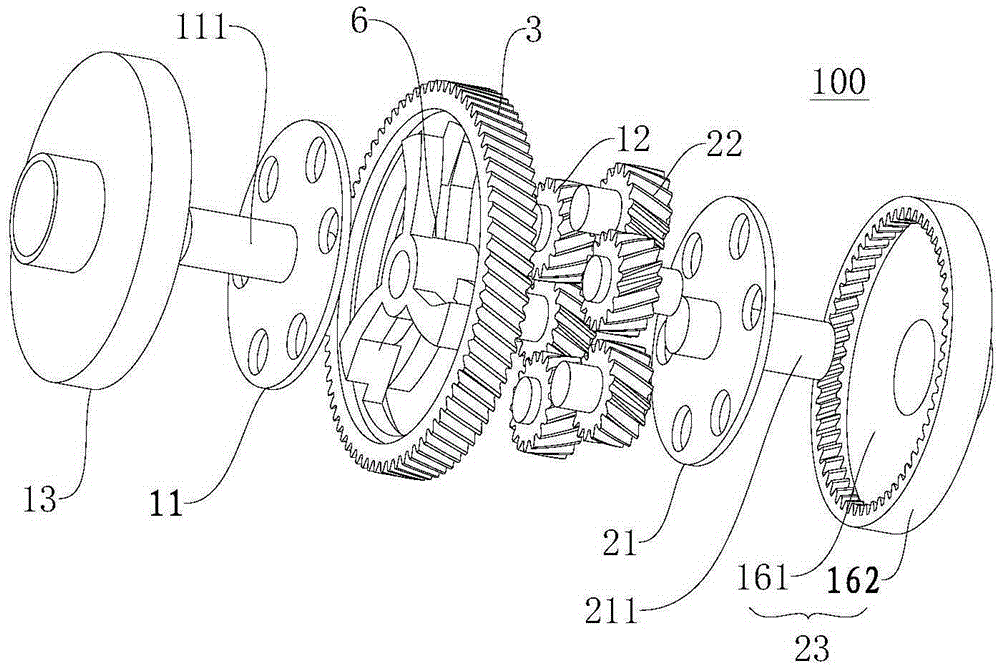

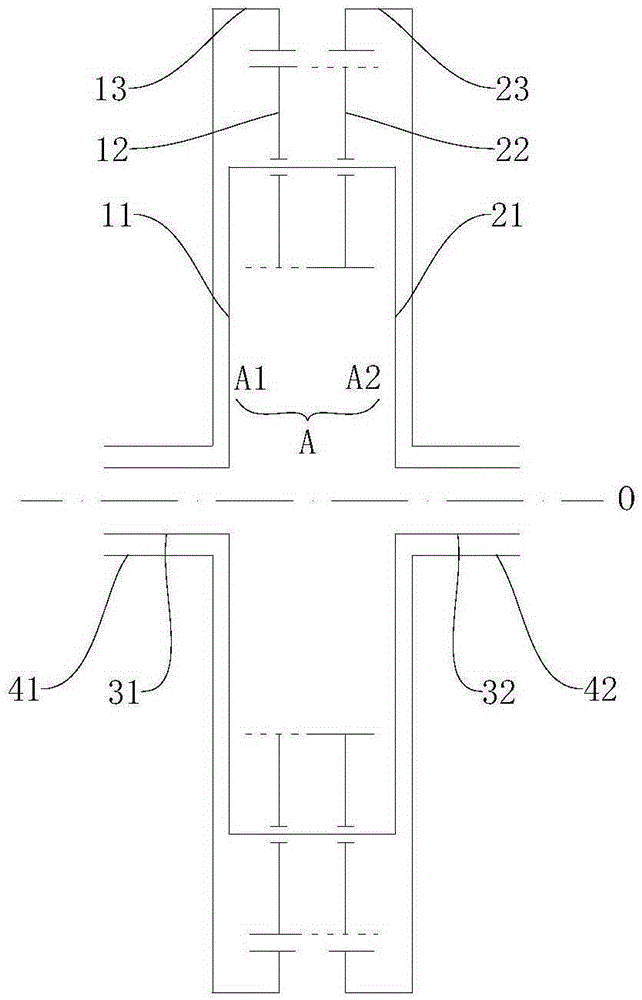

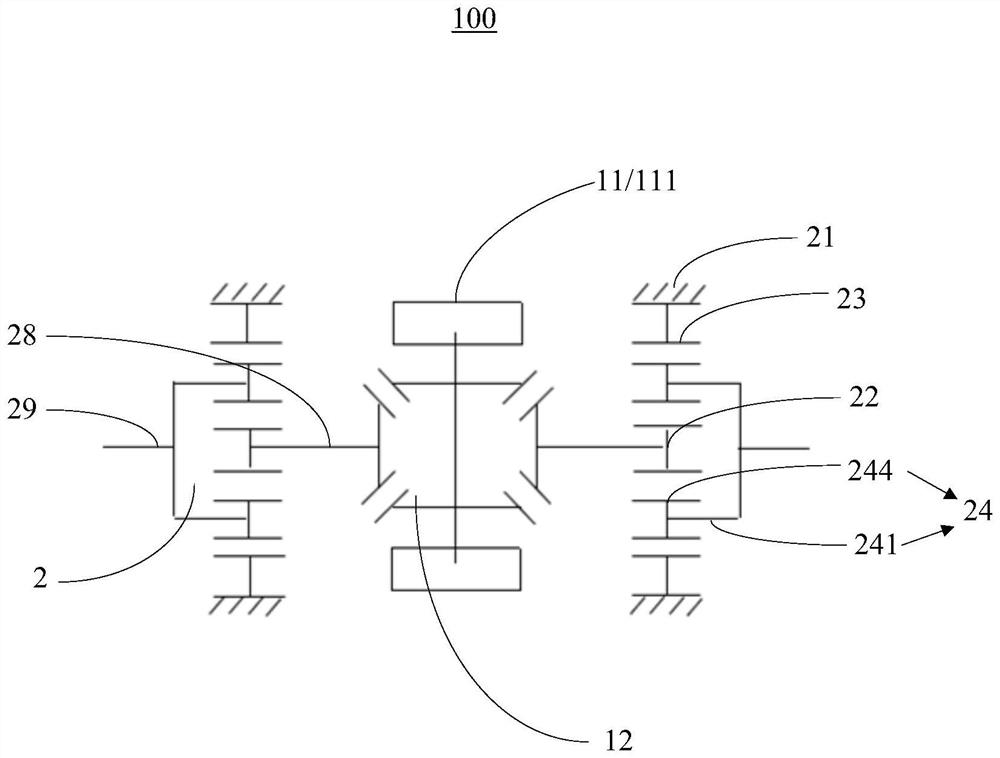

The invention discloses a power driving system. The power driving system comprises a power coupling device, a power source, a first electric power generator, a second electric power generator and a first brake device, wherein the power coupling device comprises a first sun gear, a first planet carrier, a first gear ring, a second sun gear, a second planet carrier and a second gear ring, wherein the first gear ring is coaxially connected with the second gear ring; the power source is arranged to be selectively linked with the first gear ring and the second gear ring; the first electric power generator is linked with the first sun gear; the second electric power generator is linked with second sun gear; and the first brake device is used for directly or indirectly braking the first gear ring and the second gear ring. The power driving system has the advantages that a differential function is realized on the premise of eliminating the traditional mechanical differential mechanism and rich transmission modes are also realized.

Owner:BYD CO LTD

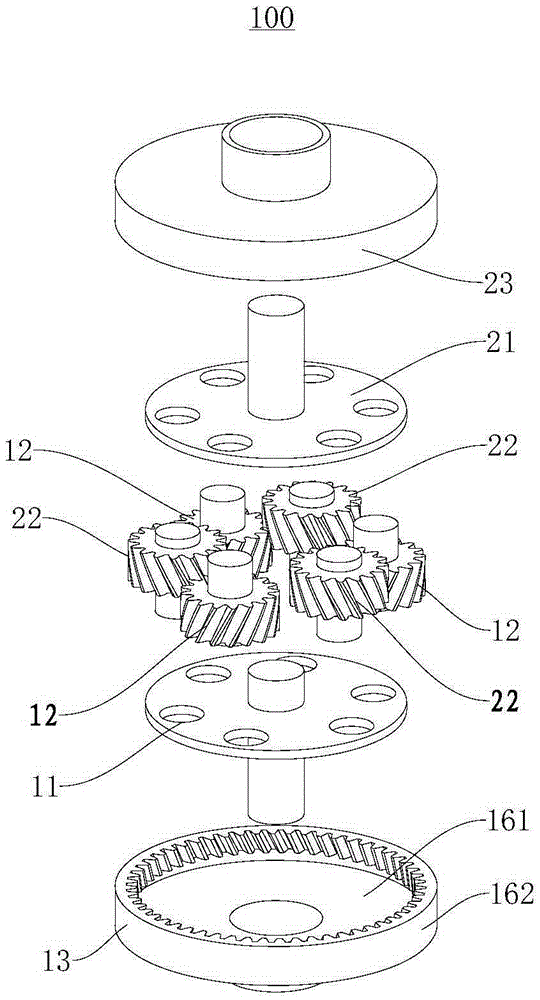

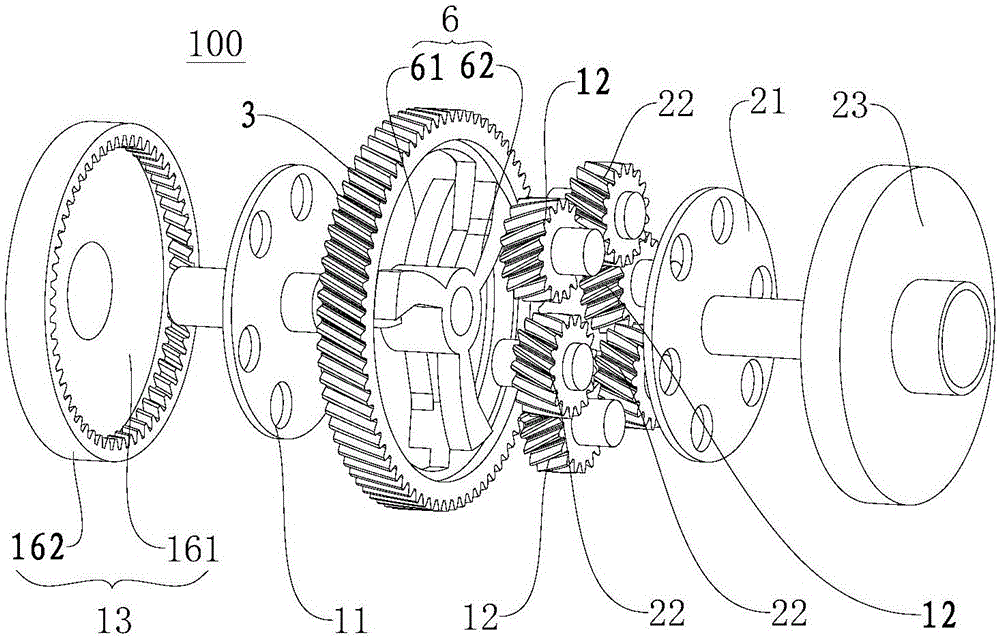

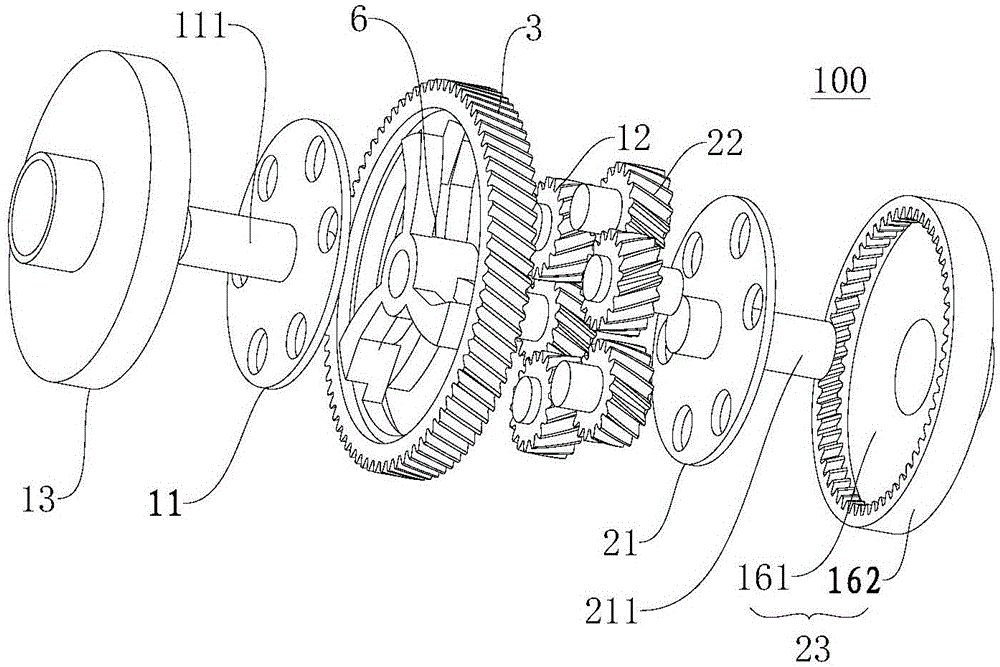

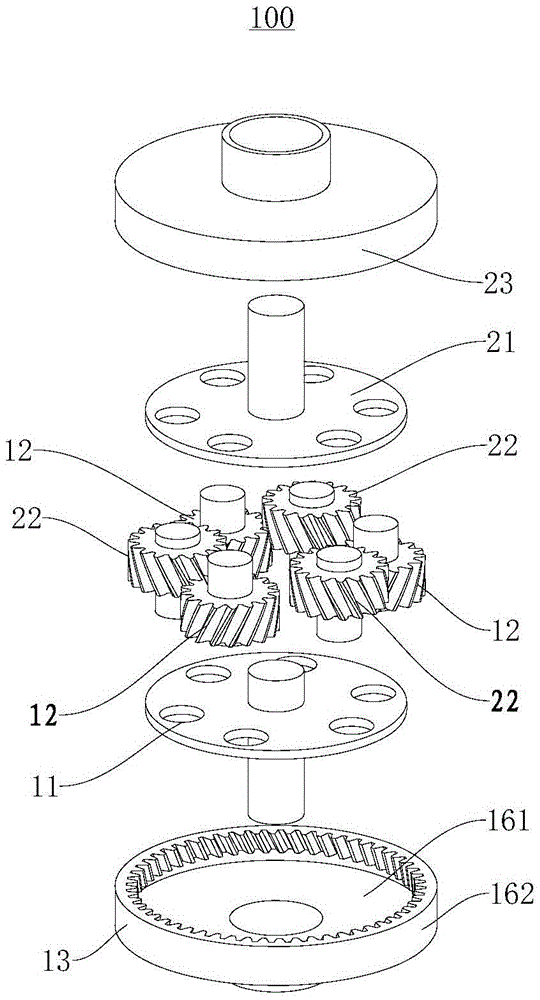

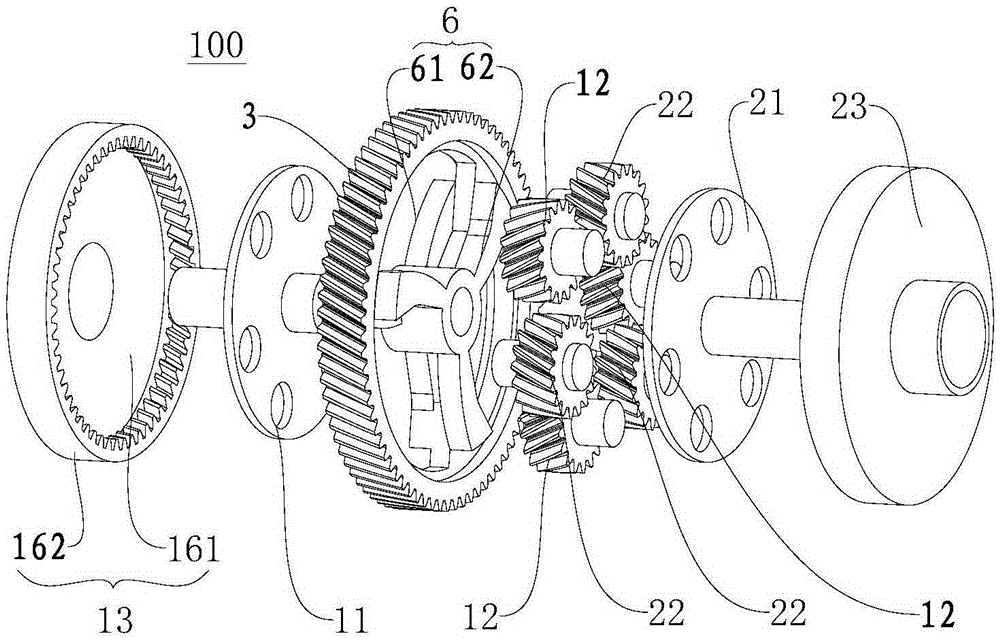

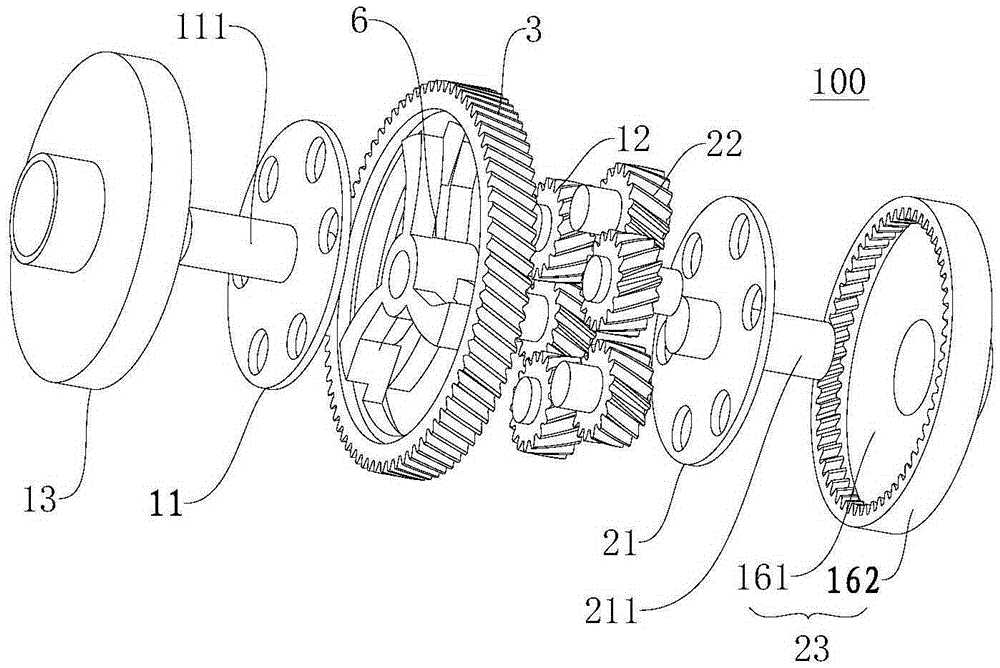

Power-driven system and vehicle comprising power-driven system

ActiveCN106555858ARealize the differential functionCompact structureDifferential gearingsControl devicesDifferential functionControl theory

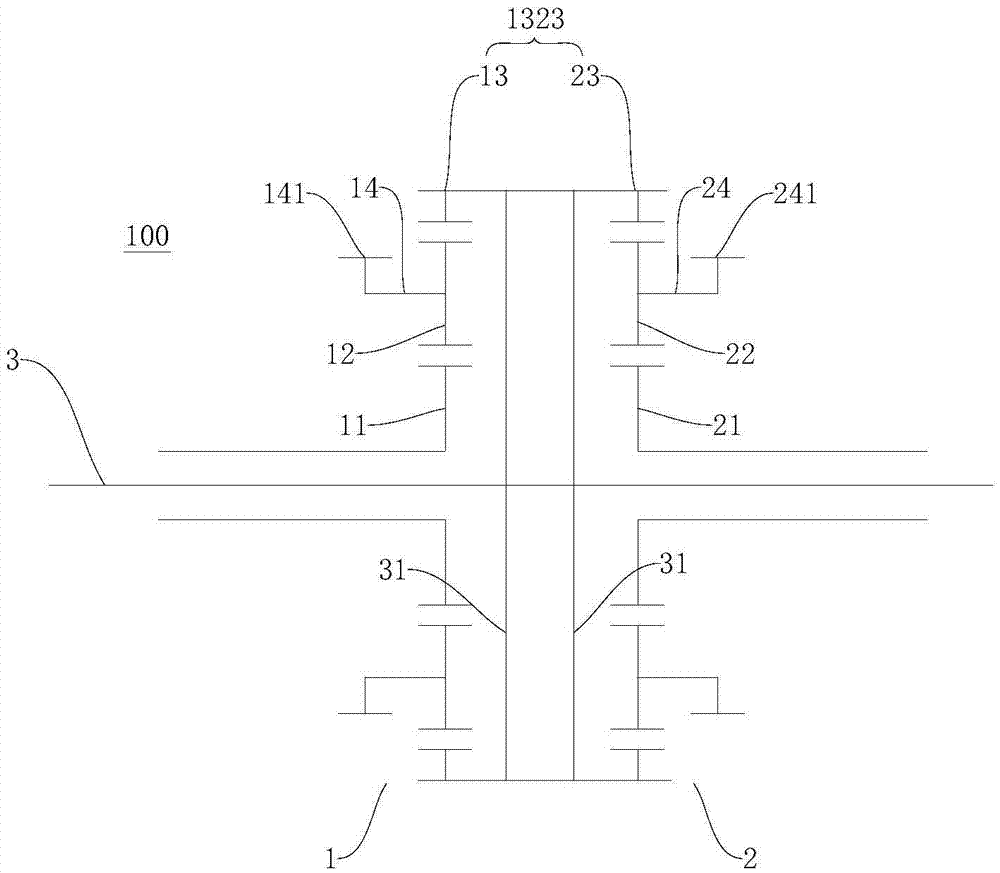

The invention discloses a power-driven system and a vehicle. The power-driven system comprises a differential mechanism, a power output shaft, multiple input shafts, a first motor generator and a second motor generator. The differential mechanism is composed of an input part, a first planet carrier, a second planet carrier, first planet wheels, second planet wheels, a first gear ring and a second gear ring. The first planet wheels and the second planet wheels are connected with the first planet carrier and the second planet carrier correspondingly. The first planet wheels and the second planet wheels are engaged with the first gear ring and the second gear ring correspondingly. The second planet wheels are further engaged with the first planet wheels, and the input part, the first planet carrier and the second planet carrier are coaxially linked. The power output shaft is arranged to be linked with the input part. Each input shaft is arranged to be linked with the power output shaft. The first motor generator is linked with the first gear ring, and the second motor generator is linked with the second gear ring. The differential mechanism of the power-driven system achieves the differential function based on the planet differential principle, and the structure is compact and simple.

Owner:BYD CO LTD

Power drive system and vehicle with same

ActiveCN106555844ARealize the differential functionCompact structureHybrid vehiclesElectric propulsion mountingDifferential functionEngineering

The invention discloses a power drive system and a vehicle. The power drive system comprises a differential, a power output shaft, a plurality of input shafts and a first electric motor generator; the differential comprises a first planet carrier, a second planet carrier, a first planet wheel, a second planet wheel, a first gear ring and a second gear ring, the first planet wheel is arranged on the first planet carrier, the second planet wheel is arranged on the second planet carrier, the first planet wheel is engaged with the first gear ring, the second planet wheel is engaged with the second gear ring, and the second planet wheel is further engaged with the first planet wheel; the power output shaft is arranged to be linked with the power input end of the differential; one input shaft of the multiple input shafts is arranged to be selectively linked with the power output shaft, and the remaining input shafts are arranged to be linked with the power output shaft; the first electric motor generator is arranged to be linked with one input shaft. According to the differential of the power drive system, the planet differential principle is used for achieving the differential function, and the structure is compact and simple.

Owner:BYD CO LTD

Power drive system and vehicle with power drive system

ActiveCN106553536ARealize the differential functionCompact structureControl devicesDifferential functionElectric generator

The invention discloses a power drive system and a vehicle. The power drive system comprises a differential mechanism, an input part, a transmission, an engine, a first electric generator and a second electric generator. The differential mechanism comprises a first planet carrier, a second planet carrier, first planet gears, second planet gears, a first gear ring and a second gear ring. The first planet gears and the second planet gears are connected with the first planet carrier and the second planet carrier correspondingly and engaged with the first gear ring and the second gear ring correspondingly. The second planet gears are further engaged with the first planet gears. The input part is in coaxial linkage with the first planet carrier and the second planet carrier. The transmission is connected with the engine and the differential mechanism, and generated power can be output to the input part through the engine after passing through the transmission. The first electric generator is in linkage with the first gear ring, and the second electric generator is in linkage with the second gear ring. The differential mechanism of the power drive system utilizes the planet differential principle for achieving the differential function, and the structure is compact and simple.

Owner:BYD CO LTD

Oil-electricity hybrid multi-mode automobile drive system

ActiveCN106394230AImprove fuel efficiencyAvoid high fuel consumption at idle speedHybrid vehiclesGas pressure propulsion mountingElectricityDifferential function

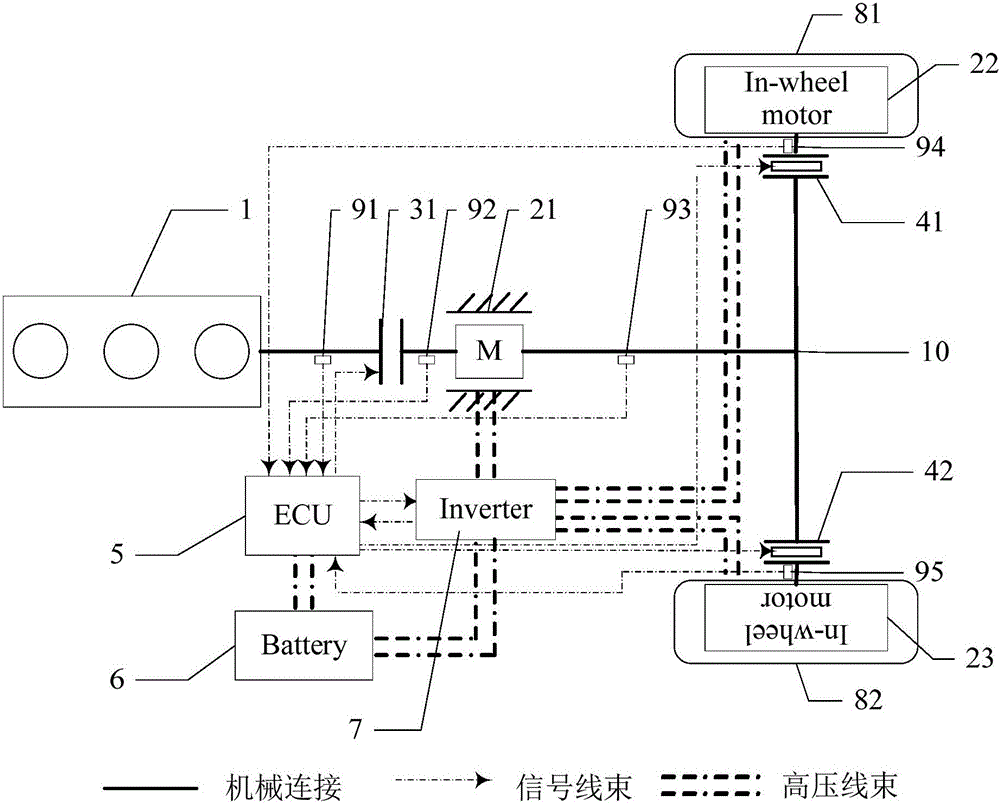

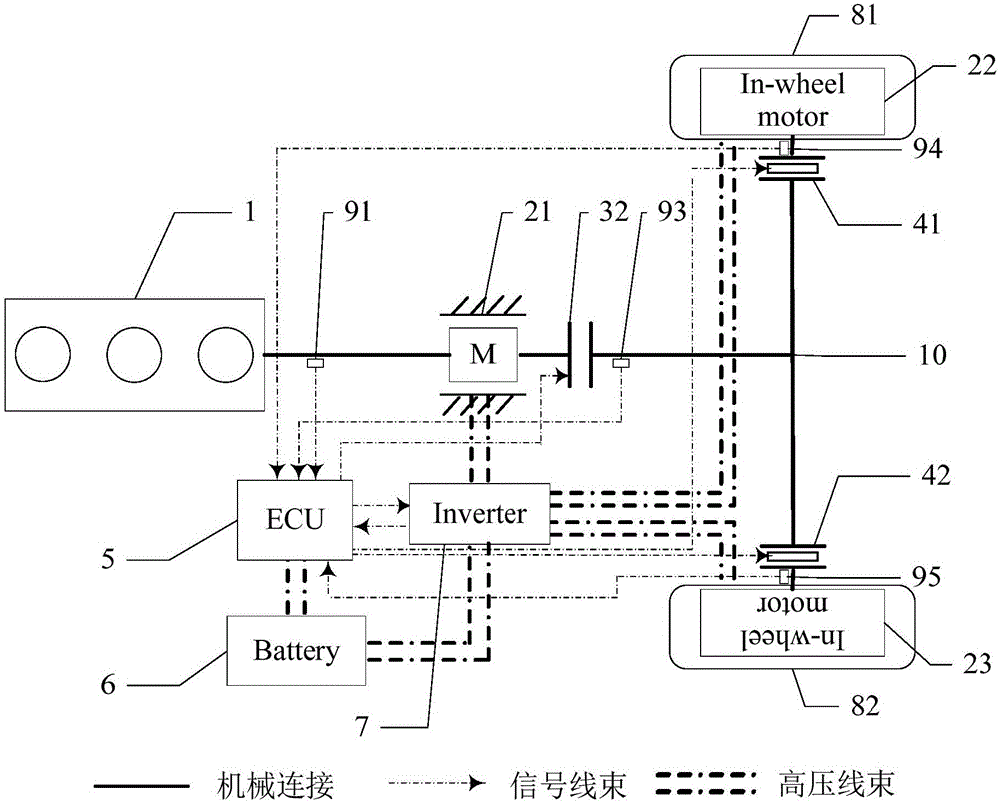

The invention discloses an oil-electricity hybrid multi-mode automobile drive system. The system is mainly composed of an engine, two clutches, an ISG motor, two overrun clutches, two hub motors, a control unit ECU, a motor controller, a storage battery group and the like. The two ends of an ISG motor rotor are connected with the output end of the engine and a transmission shaft through the first clutch and the second clutch respectively. The two ends of each overrun clutch are connected with the transmission shaft and a corresponding wheel. The wheels are internally provided with the hub motors which can directly drive a vehicle to run. The control unit ECU sends an instruction to the clutches and the motor controller according to signals fed back by a sensor so that the combining / separating of the clutches and power output of the motor can be controlled and the purpose of work mode switching can be achieved. By means of the multi-mode character of the system, the opportunity of working at an efficient range is increased for the engine; and by means of the overrun clutches, the differential function under certain modes can be achieved, the energy consumption of additional loads can also be reduced, and the system efficiency can be improved.

Owner:SHANDONG UNIV OF TECH

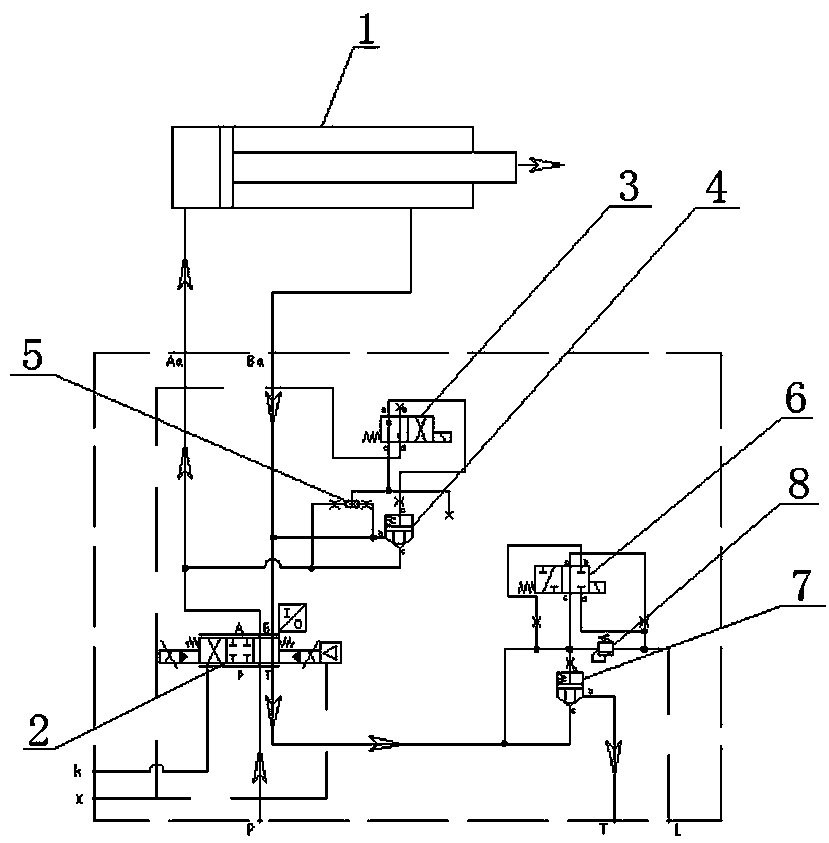

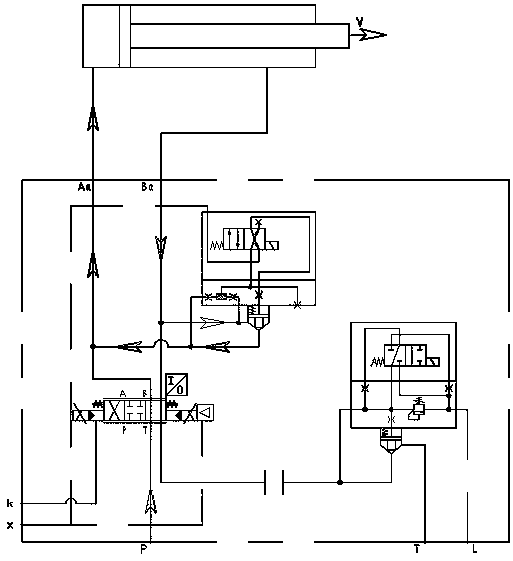

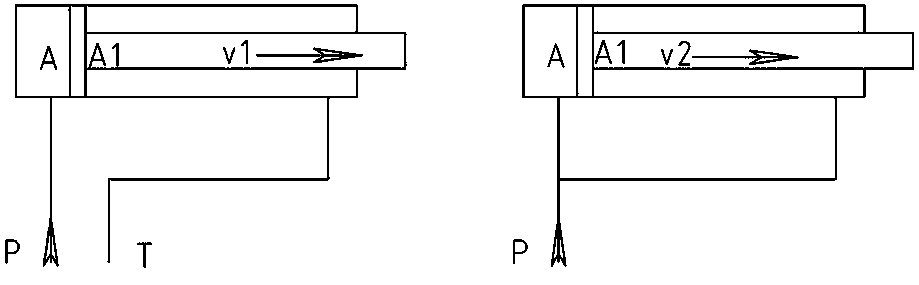

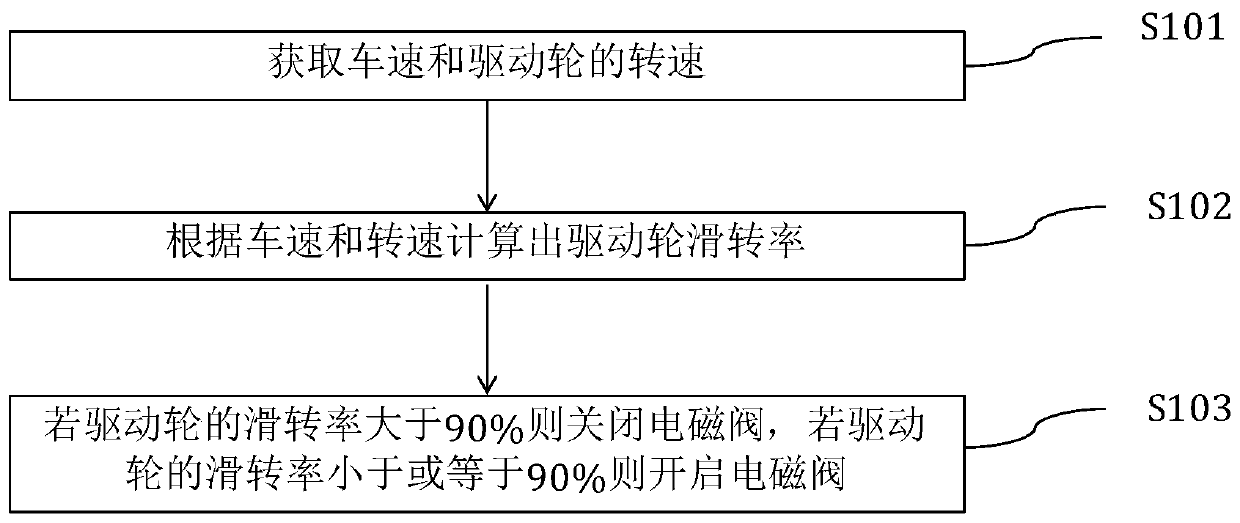

Differential circuit of high-flow hydraulic system and control method thereof

ActiveCN108488112ARealize the differential functionServomotor componentsServomotorsProportional controlSolenoid valve

The invention discloses a differential circuit of a high-flow hydraulic system and a control method of the differential circuit. The differential circuit comprises an oil cylinder, an electric-hydraulic proportional control valve, a first differential control valve and a second differential control valve. An external control opening k of the electric-hydraulic proportional control valve is connected with a pilot control oil source, and an external control opening x of the electric-hydraulic proportional control valve is connected with an oil tank. The first differential control valve comprisesa first solenoid valve, a first cartridge valve and an or gate shuttle valve. The second differential control valve comprises a second solenoid valve, a second cartridge valve and a deceleration valve. According to the differential circuit of the high-flow hydraulic system and the control method of the differential circuit, a hydraulic main oil circuit and a control network are formed through selection and usage of a series of standard serial valve blocks according to the stretching hydraulic principle of a differential oil cylinder, and the function of differential motion of the oil cylinderunder the condition of the high flow is fulfilled.

Owner:NANTONG RAINBOW HEAVY MACHINERIES

Power drive system and vehicle equipped with power drive system

ActiveCN106555849ARealize the differential functionCompact structureHybrid vehiclesGas pressure propulsion mountingEngineeringControl theory

The invention discloses a power drive system and a vehicle equipped with the power drive system. The power drive system comprises a differential mechanism, wherein the differential mechanism comprises a first planet carrier and a second planet carrier, a first planet gear and a second planet gear, a first gear ring and a second gear ring, at least one power output shaft, a plurality of input shafts, and a first motor generator; the first and second planet gears are respectively arranged on the first and second planet carriers; the first and second planet gears are respectively meshed with the first and second gear rings; the second planet gear is also meshed with the first planet gear; the power output shaft is designed to be linked with the power input end of the differential mechanism; each input shaft is designed to be linked with the power output shaft; and the first motor generator is linked with one of the power input shafts. The differential speed function of the differential mechanism in the power drive system disclosed by the embodiment of the invention is achieved by utilizing the planetary differential principle; and the power drive system is compact and simple in structure.

Owner:BYD CO LTD

Dynamic coupling pure-electric drive axle and control method thereof

InactiveCN109866590AImprove economyFor higher demands on dynamicsElectric propulsion mountingMotor depositionPower couplingElectricity

The invention discloses a dynamic coupling pure-electric drive axle and a control method thereof. The drive axle mainly comprises a central motor, two hub motors, two planet mechanisms, five brakes and four dead axle gear pairs. A sun gear and a gear ring of three elements of each planet mechanism serve as two input ends or one element serves as an input end, and a planet carrier of each planet mechanism serves as an output end. The central motor is connected with the sun gears of the planet mechanisms on the corresponding sides through two corresponding dead axle gear pairs, the two hub motors are connected with the gear rings of the planet mechanisms on the corresponding sides, the planet carriers on the two sides are connected with rims on the corresponding sides through transmission shafts to serve as output ends, power is finally transmitted to the rims through the planet carriers, and a vehicle is driven to run. By the adoption of the structural scheme, different working modes can be achieved according to the actual road condition requirements, the high requirement of the vehicle for the dynamic property can be met, a power source works in an efficient area, and the economical efficiency of the vehicle is improved. Meanwhile, the unsprung mass of the vehicle is reduced, and the riding comfort and control stability of the vehicle are improved.

Owner:SHANDONG UNIV OF TECH

Power driving system and vehicle with same

InactiveCN106915243ARealize the differential functionRich transmission modeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDynamoDifferential function

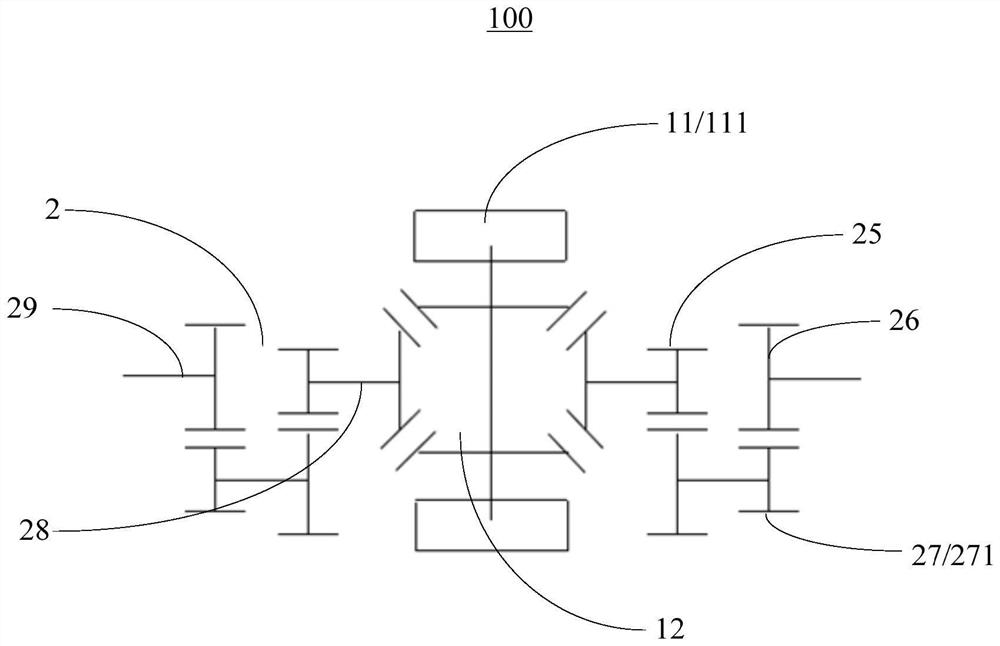

The invention discloses a power driving system and a vehicle. The power driving system comprises a power coupling device, a power transmission part, an immediate shaft, a first electric power generator, a second electric power generator, a third electric power generator and a first brake device, wherein the power coupling device comprises a first sun gear, a first planet carrier, a first gear ring, a second sun gear, a second planet carrier and a second gear ring; the power transmission part is coaxially linked with the first sun gear and the second sun gear; the immediate shaft is arranged to be linked with the power transmission part; the first electric power generator is linked with the first gear ring; the second electric power generator is linked with the second gear ring; the third electric power generator is arranged to be selectively linked with the immediate shaft; and the first brake device is used for directly or indirectly braking the immediate shaft. The power driving system has the advantages that a differential function is realized on the premise of eliminating the traditional mechanical differential mechanism and rich transmission modes are also realized.

Owner:BYD CO LTD

Power-driven system and vehicle with same

ActiveCN106555853ARealize the differential functionCompact structureDifferential gearingsControl devicesDifferential functionControl theory

The invention discloses a power-driven system and a vehicle. The power-driven system comprises a differential mechanism, a power output shaft, a plurality of input shafts, a first output part, a second output part, a first motor generator and a second motor generator; the differential mechanism comprises a first planet carrier, a second planet carrier, a first planet wheel, a second planet wheel, a first gear ring and a second gear ring, the first planet wheel and the second planet wheel are arranged on the first planet carrier and the second planet carrier correspondingly and are meshed with the first gear ring and the second gear ring correspondingly, and the second planet wheel is further meshed with the first planet wheel; the power output shaft is arranged to be in linkage with the power input end of the differential mechanism; each input shaft is arranged to be in linkage with the power output shaft; the first output part and the second output part are linked with the first gear ring and the second gear ring correspondingly; and the first motor generator and the second motor generator are linked with the first output part and the second output part correspondingly. The differential mechanism of the power-driven system achieves the differential function on the basis of the planet differential principle, and the structure is compact and simple.

Owner:BYD CO LTD

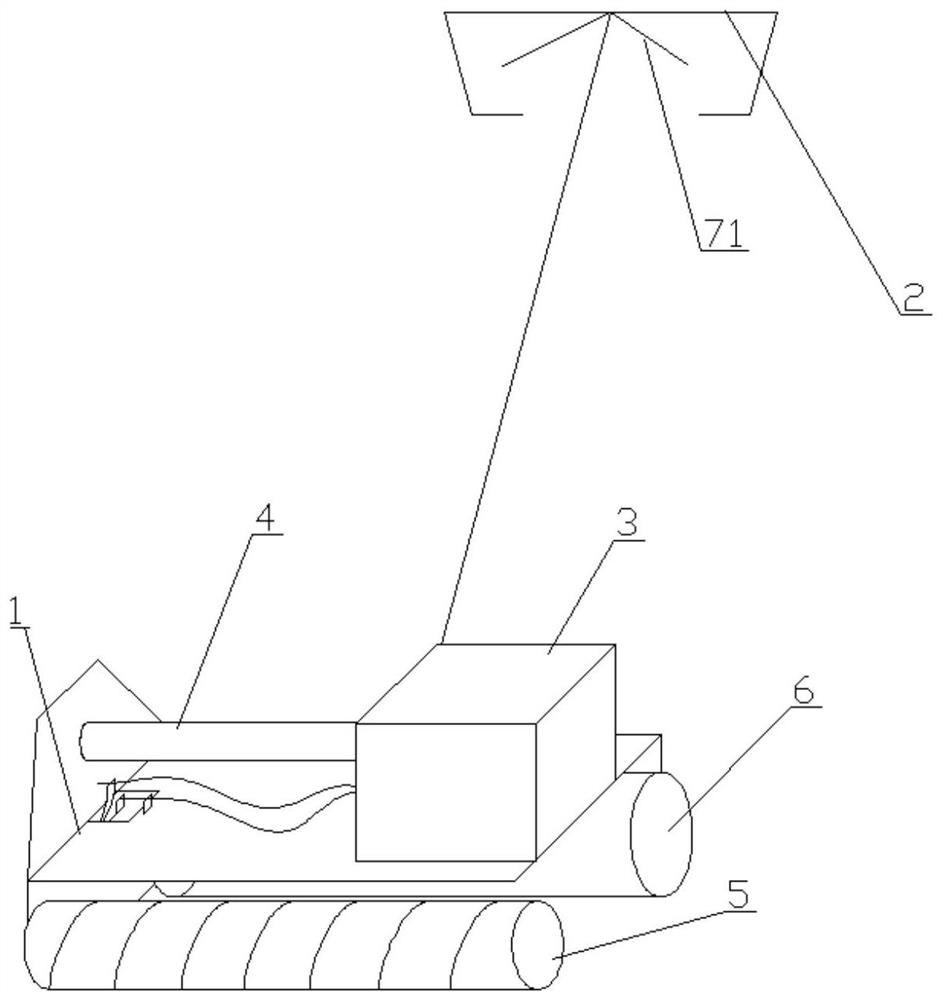

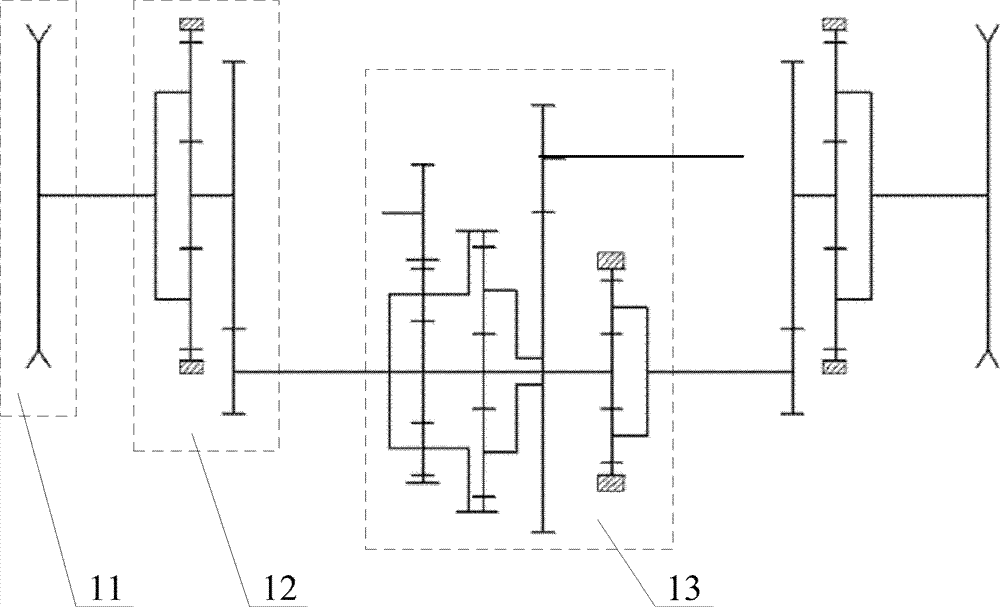

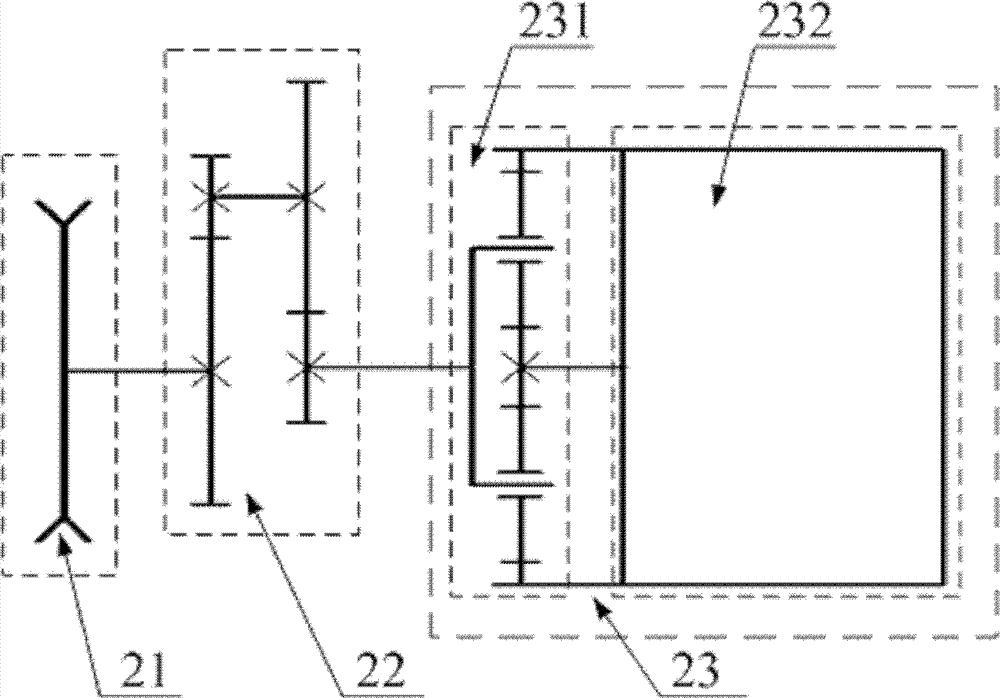

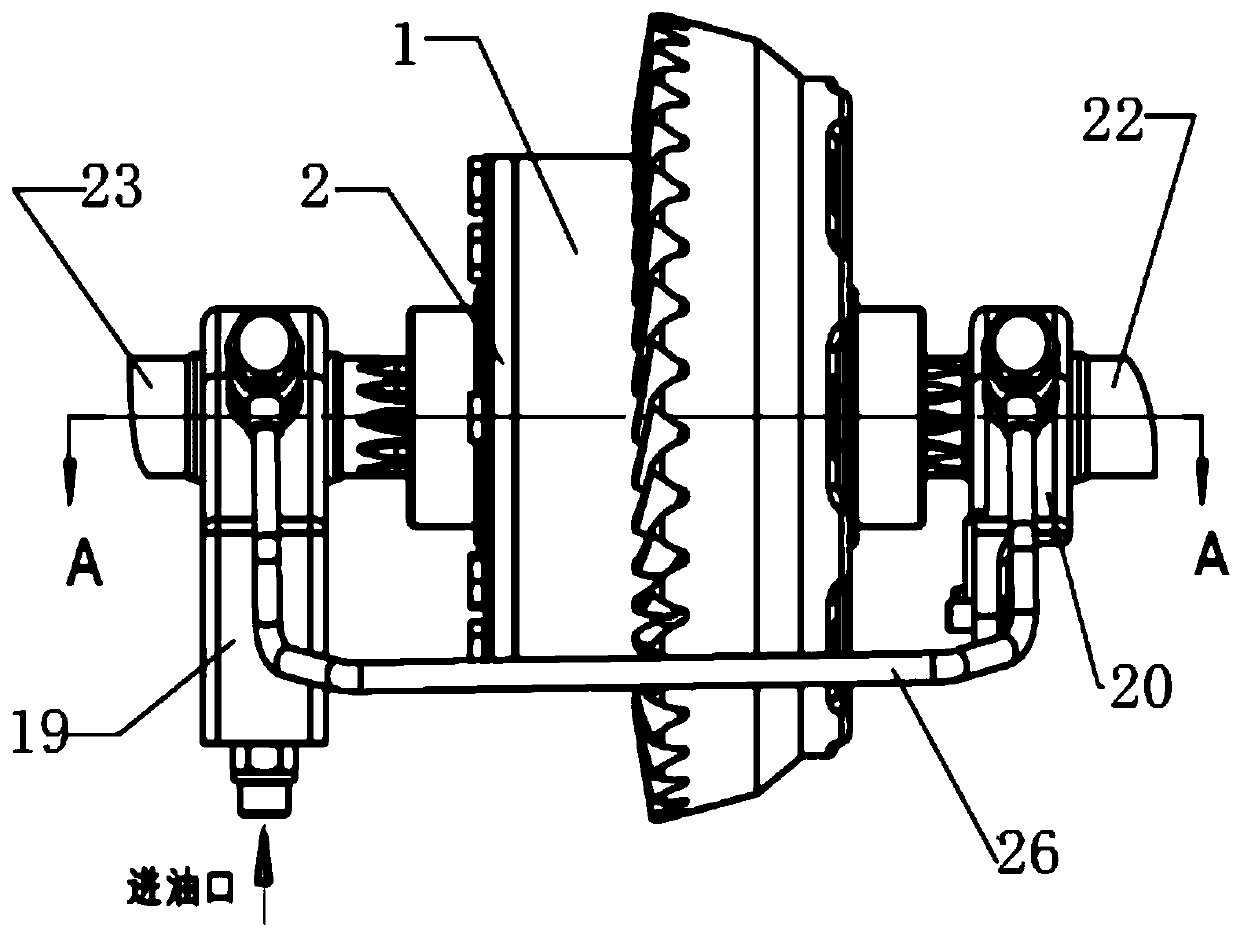

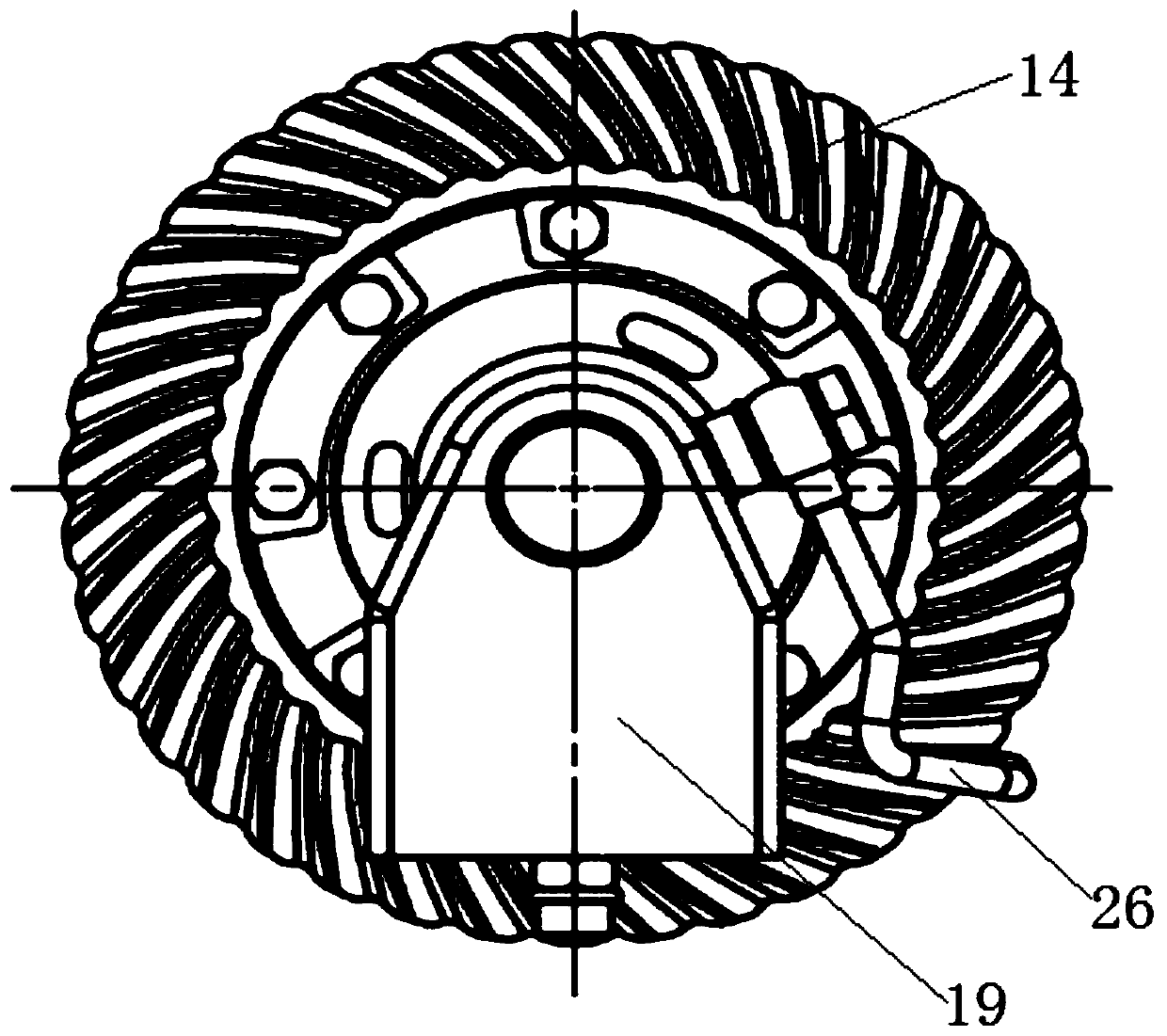

Hybrid bulldozer and power system thereof

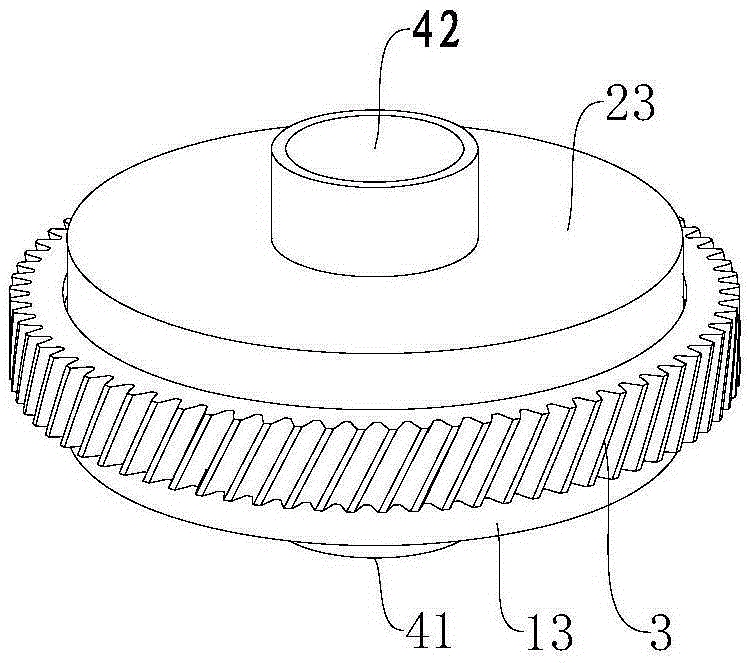

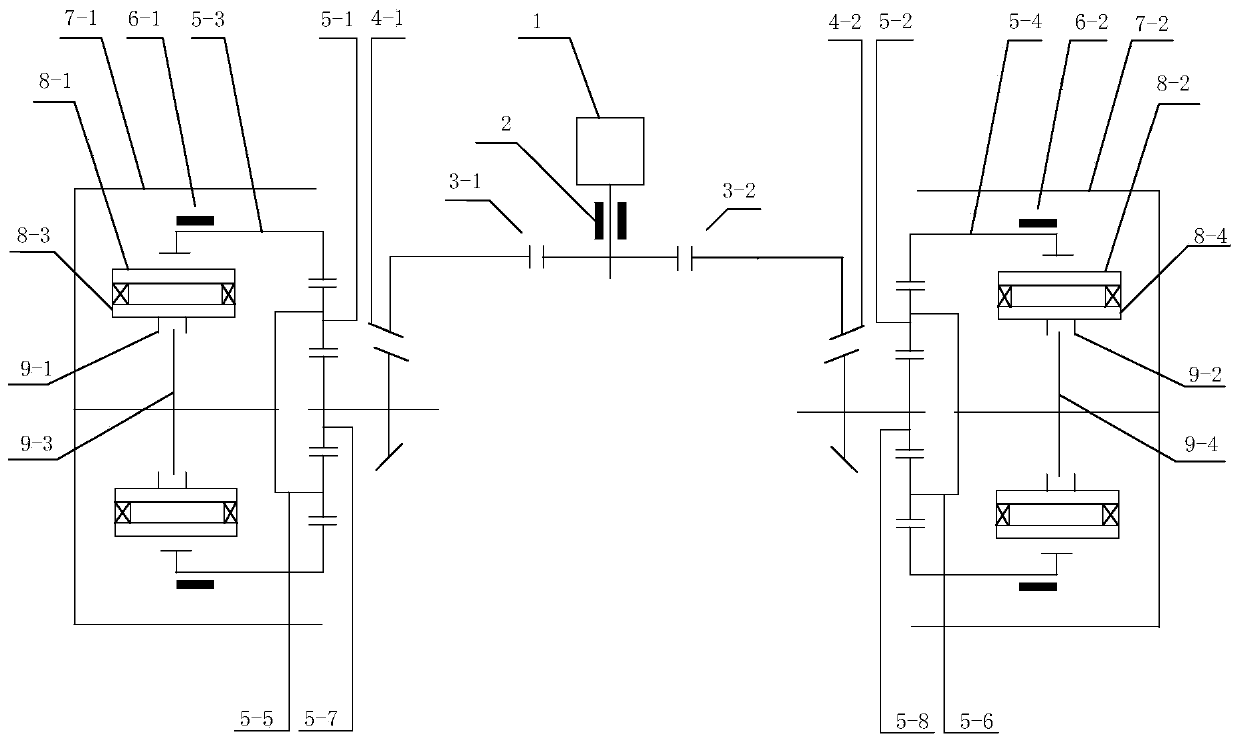

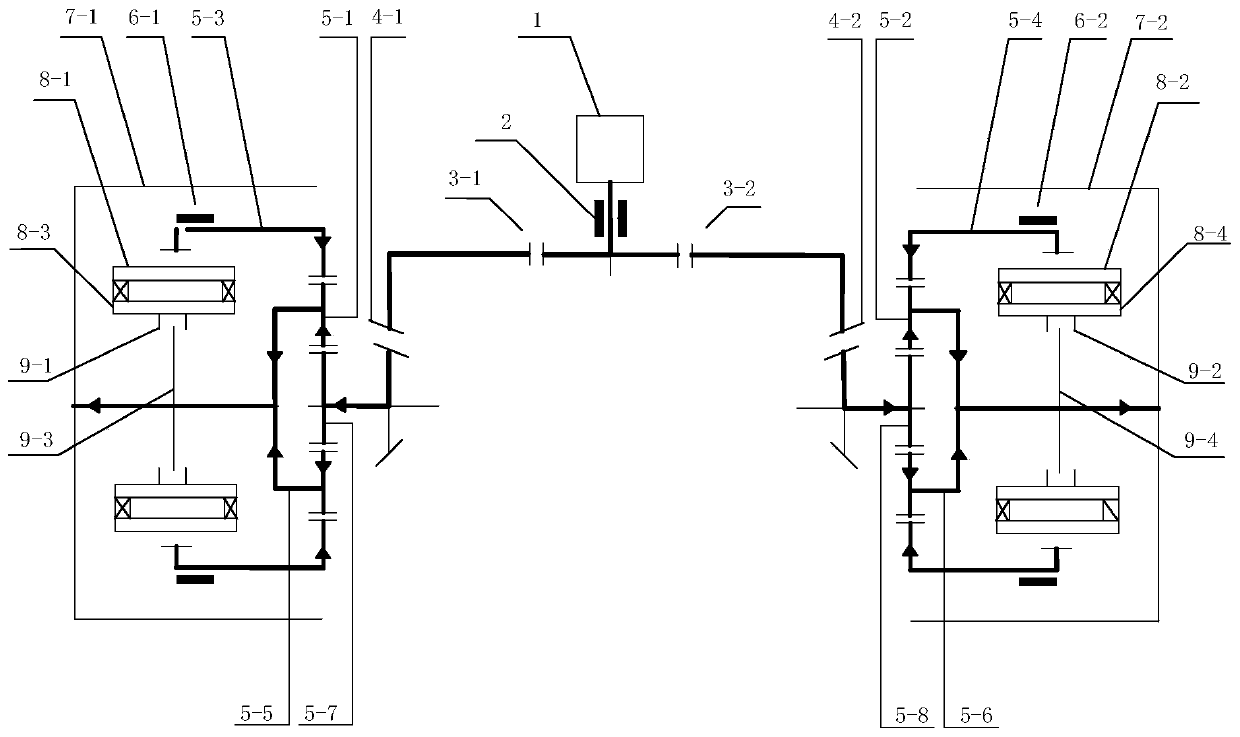

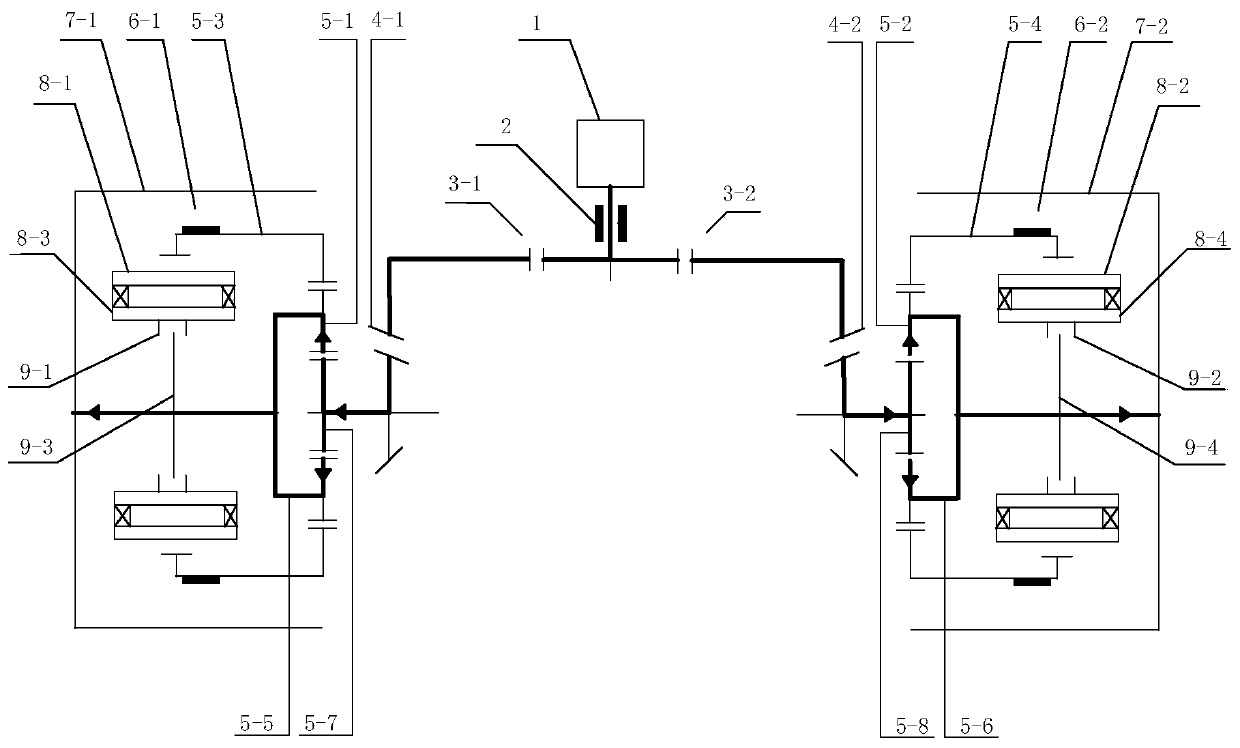

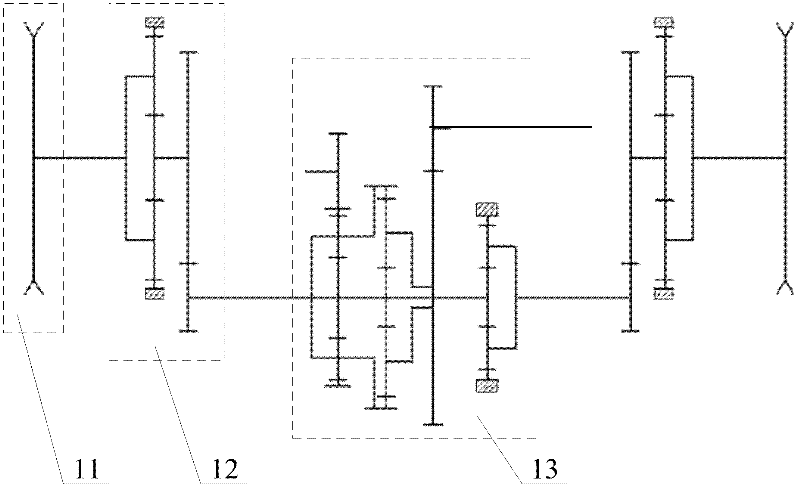

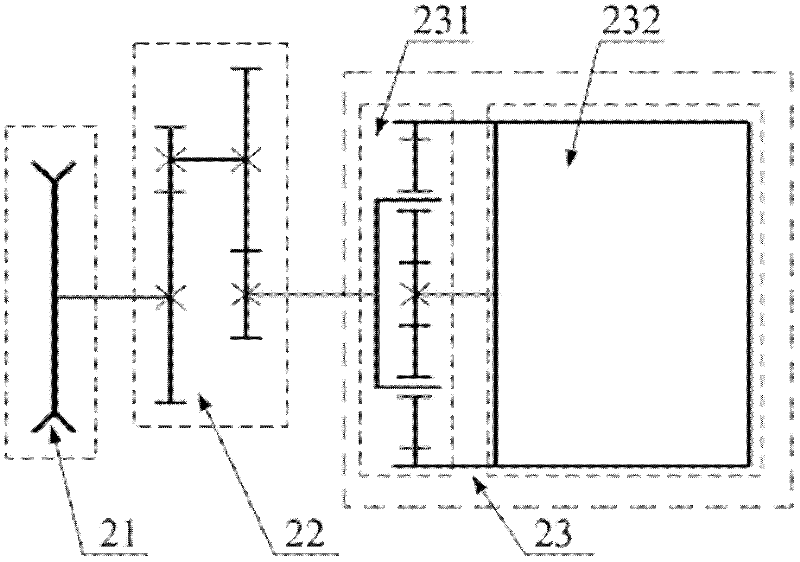

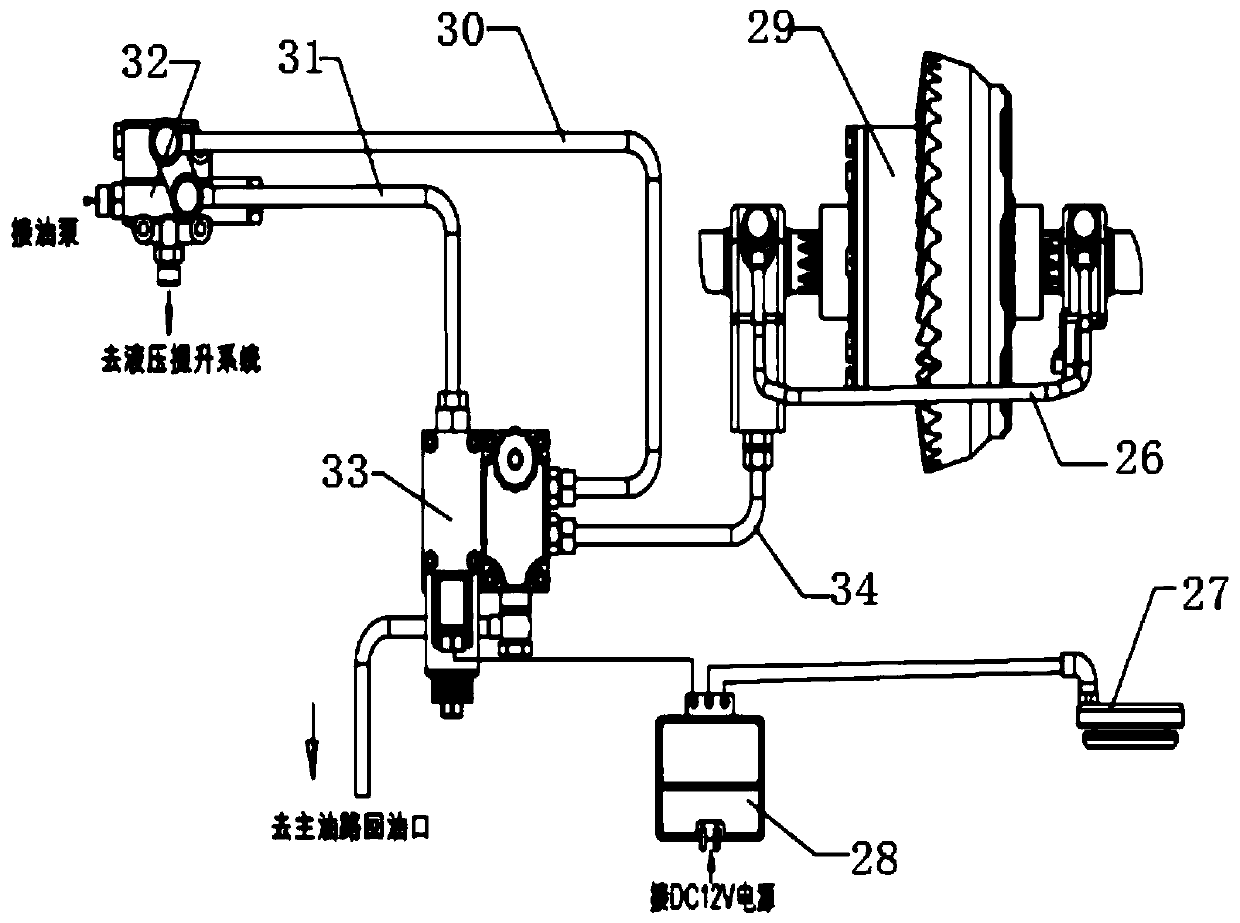

ActiveCN102505716ASmall footprintRealize the differential functionHybrid vehiclesMechanical machines/dredgersThree levelReduction drive

The invention provides a power system of a hybrid bulldozer. The power system comprises two symmetrically distributed subsystems which are same in structure, and each subsystem comprises a final drive unit (22) and a motor deceleration integration device (23), wherein each final drive unit (22) is provided with a secondary speed reducer, the output end of each secondary speed reducer is connected with a walking device (21) of the power system of the hybrid bulldozer, and each motor deceleration integration device (23) is connected with each final drive unit (22) and comprises a primary speed reducer and a motor (232). The power system of the hybrid bulldozer, disclosed by the invention, utilizes three-level deceleration and simultaneously avoids utilization of a differential. Compared with the power system, employing four-level deceleration and provided with the differential, of the hybrid bulldozer in the prior art, the power system of the hybrid bulldozer, disclosed by the invention, can be used for reducing the number of used parts and components so as to reduce a space occupied by the power system of the hybrid bulldozer. The invention further provides a hybrid bulldozer with the power system.

Owner:WEICHAI POWER CO LTD

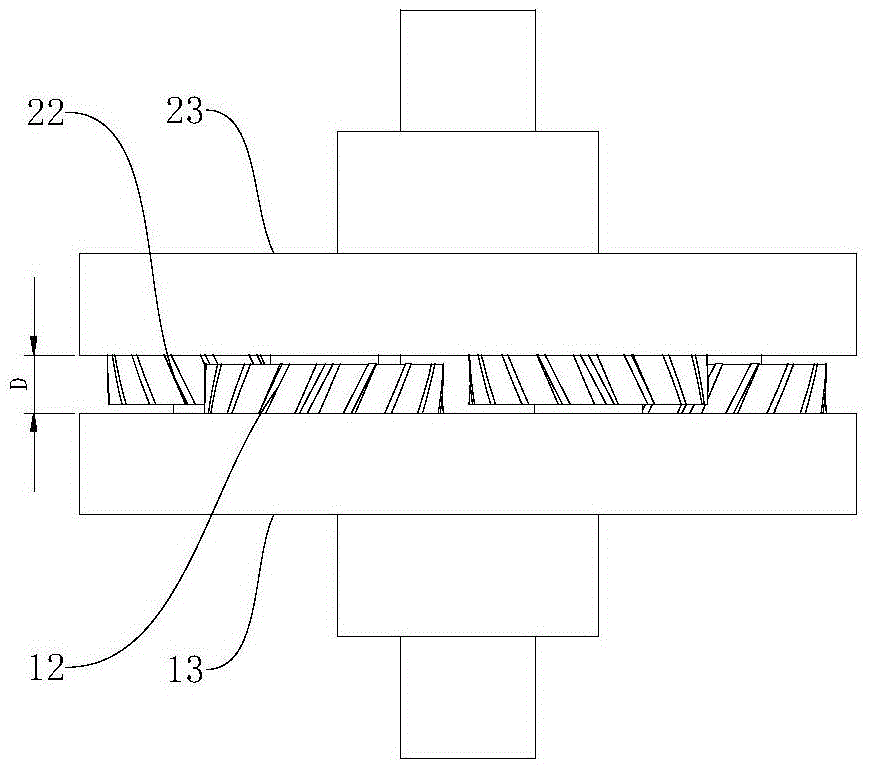

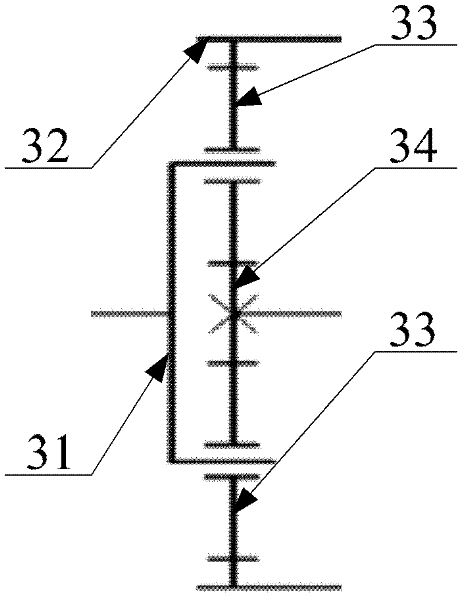

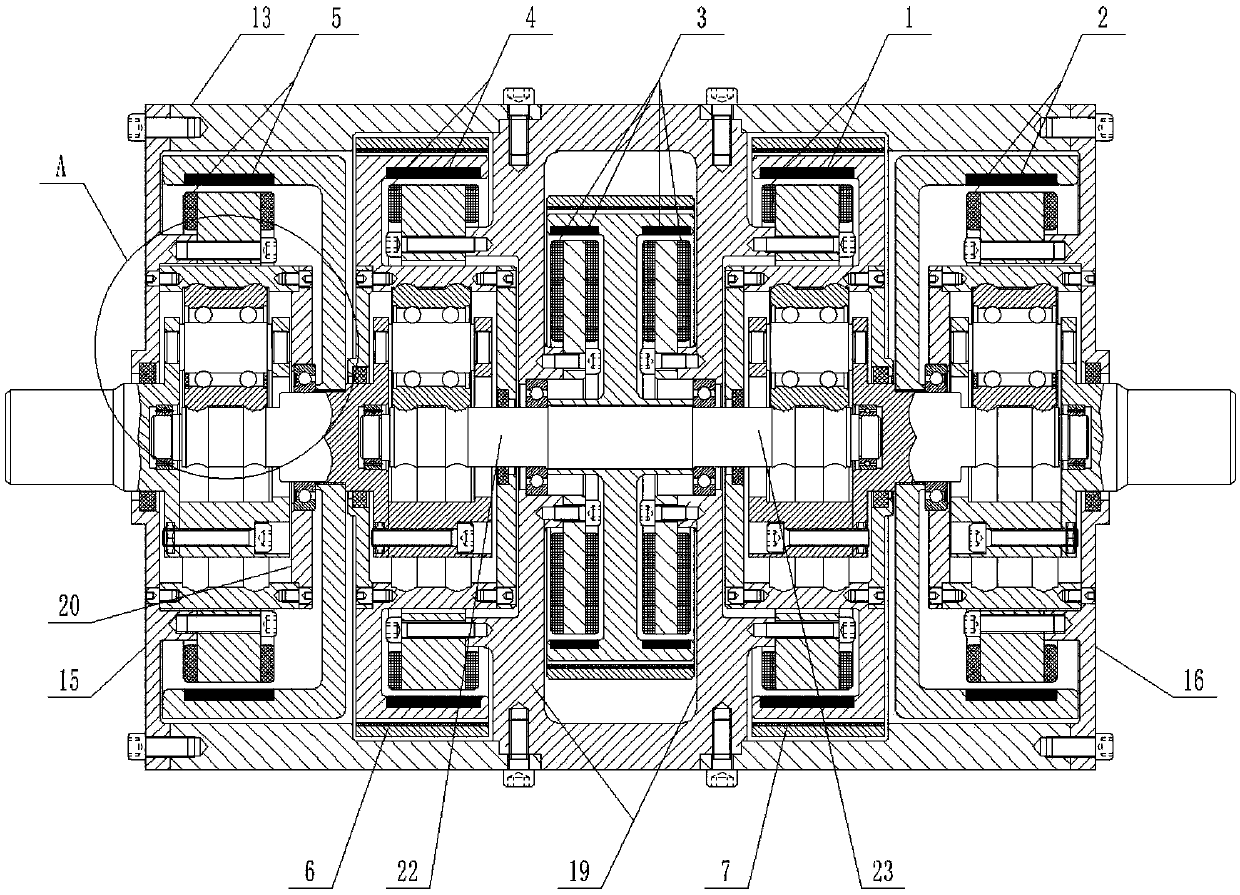

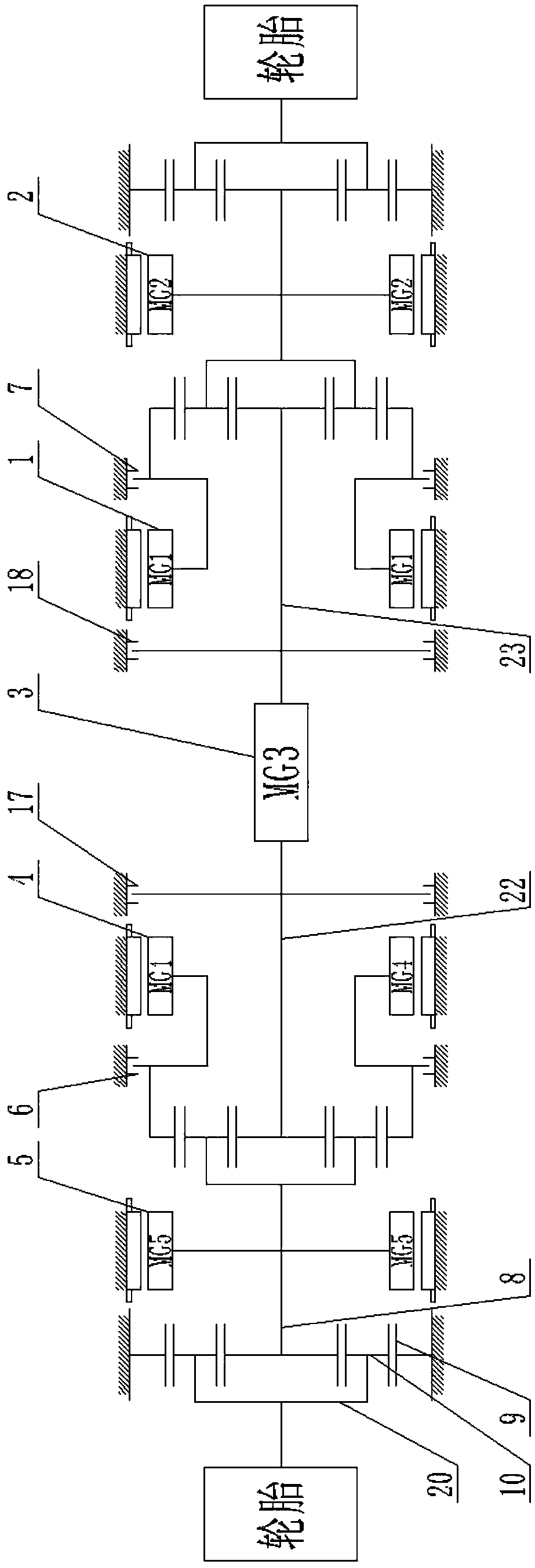

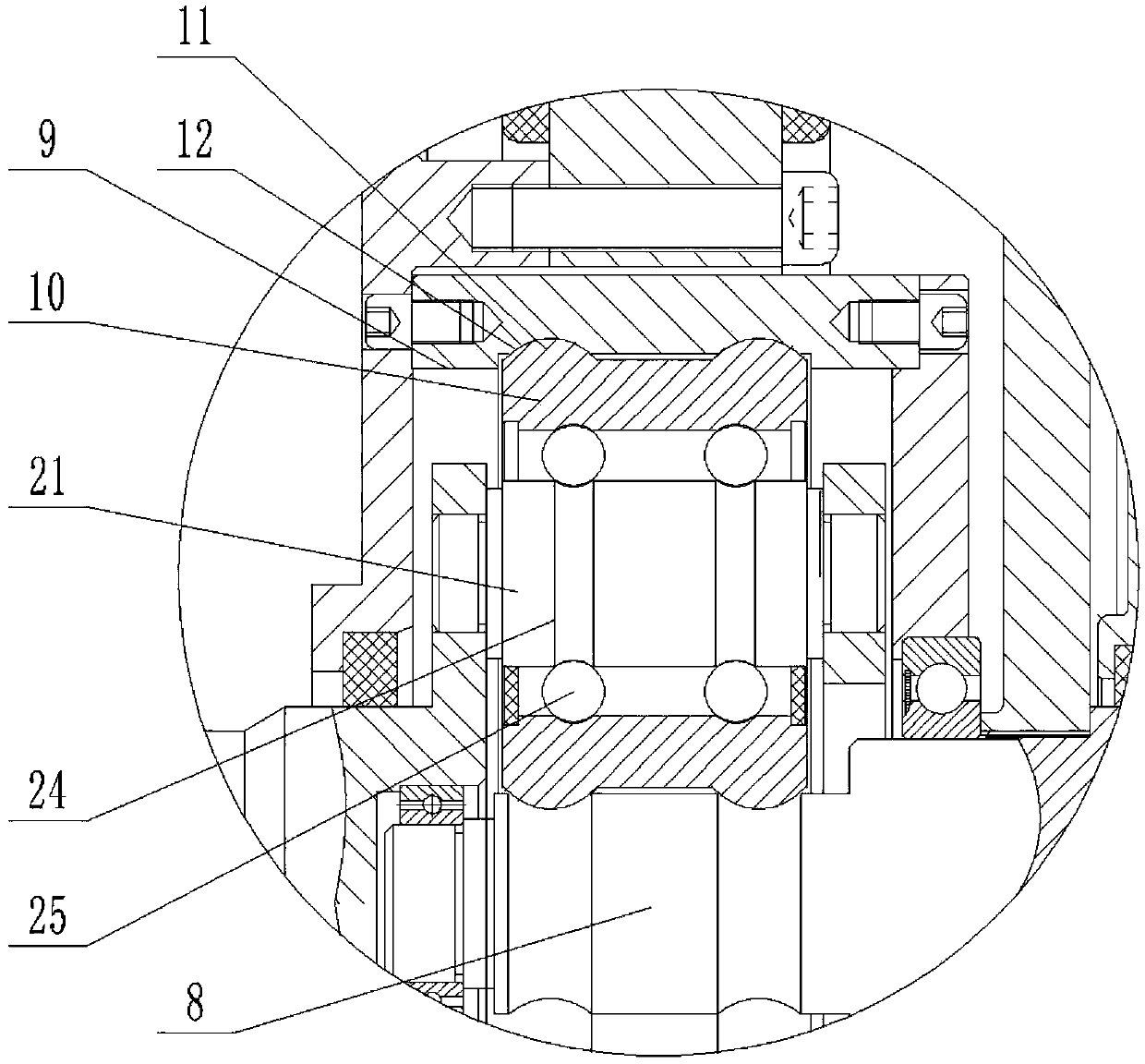

Multi-sub-motor coupling planet traction drive bearing type speed reduction driving system

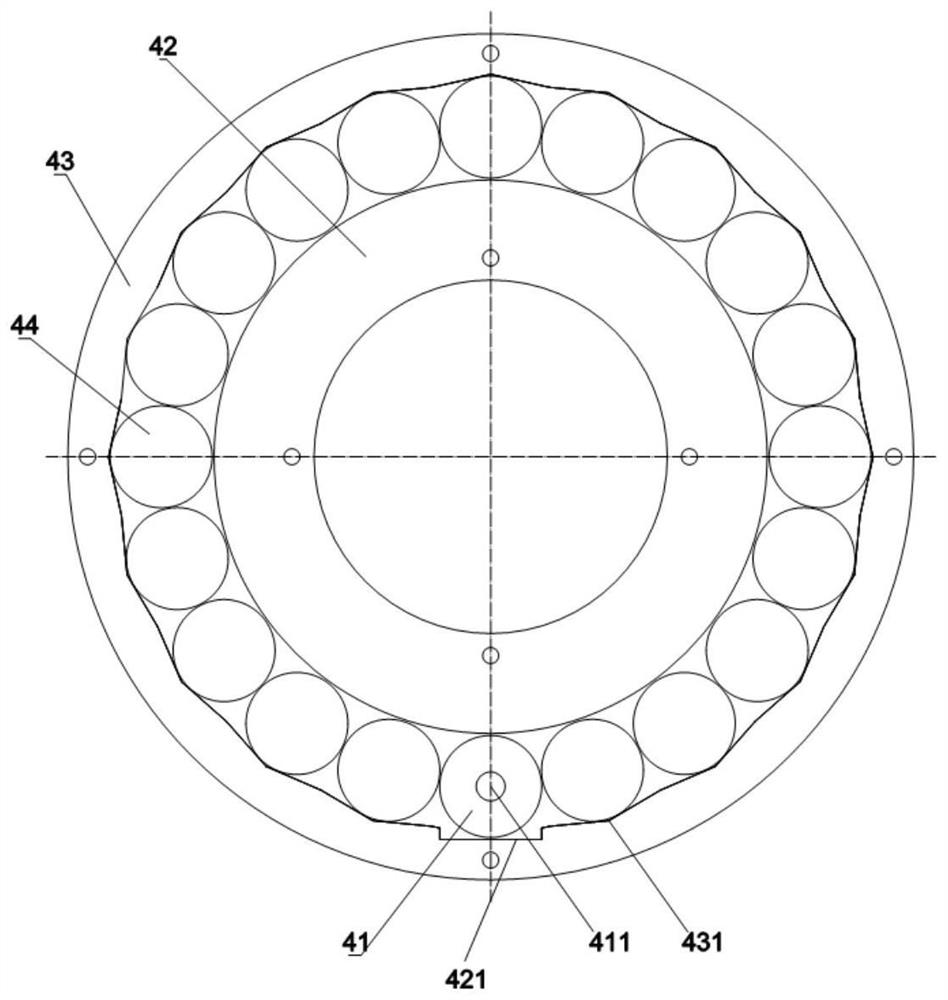

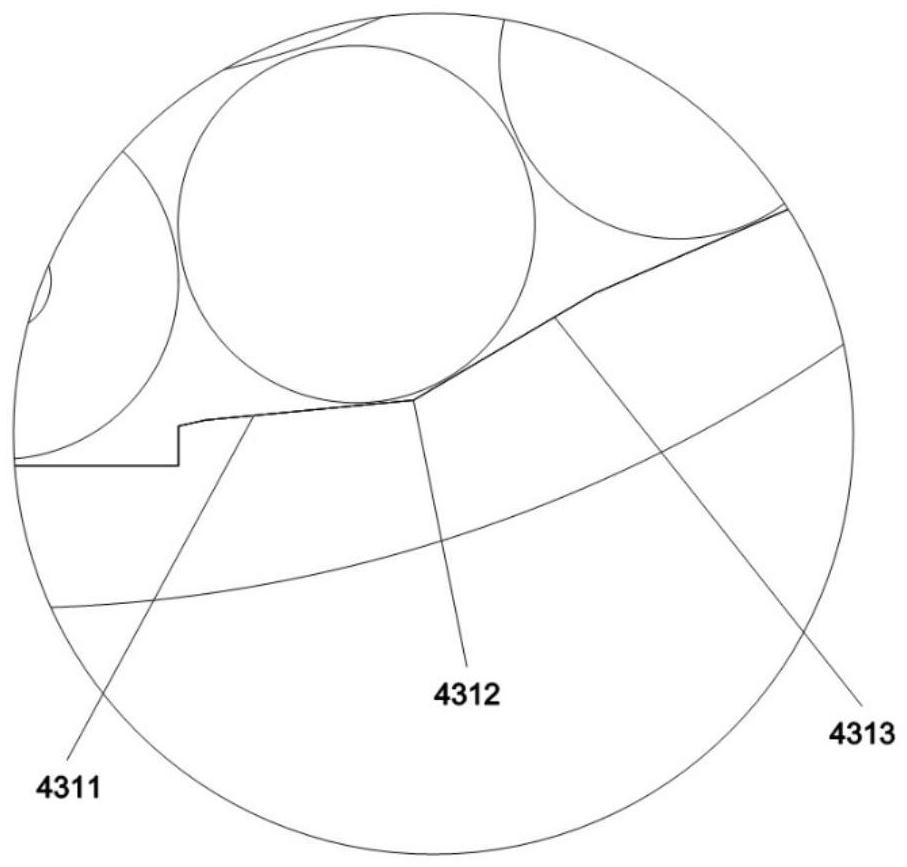

PendingCN109624679AImprove work efficiencyImprove battery lifeElectric propulsion mountingControl devicesReduction driveCoupling

The invention discloses a multi-sub-motor coupling planet traction drive bearing type speed reduction driving system which comprises a left planet traction drive bearing type speed reducer, a right planet traction drive bearing type speed reducer, a number one motor, a number two motor, a number three motor, a number four motor and a number five motor; random order combination of a sun wheel, a planet carrier and an outer ring in the speed reducer is corresponding to a power input end, a power output end and a middle transmission part in the speed reducer respectively, the number three motor is used for providing power, the number one motor and the number four motor are used for speed coupling, and the number two motor and the number five motor are used for torque coupling; according to the multi-sub-motor coupling planet traction drive bearing type speed reduction driving system, through the cooperative working of the four motors, the speed can be coupled so that the wheel high rotation speed or differential speed requirement of two-wheel-drive during turning during vehicle high speed driving can be met, a differential speed device structure is not required to be equipped, the driving system structure is simplified, the structure is compact, and the cost of the driving system is reduced.

Owner:CHONGQING UNIV

Automobile power system and automobile

PendingCN114454712AReduce weightReduce volumeElectric propulsion mountingControl devicesGear wheelElectric machinery

The invention discloses an automobile power system and an automobile, the automobile power system comprises an integrated power structure, and the integrated power structure comprises a driving motor and a differential mechanism; the driving motor comprises a rotor which is rotationally mounted; the differential mechanism comprises a planetary gear shaft connected with the rotor, two planetary gears arranged oppositely and two half axle gears arranged oppositely, the planetary gear shaft is sleeved with the two planetary gears, and each half axle gear is meshed with the two planetary gears; and the axis of each half axle gear and the axis of the rotor are coaxially arranged. The problems that an existing automobile power system is large in size and weight and not compact in structure are solved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Power driving system and vehicle with same

ActiveCN106915240ARich transmission modeRealize the differential functionHybrid vehiclesGas pressure propulsion mountingDynamoDifferential function

Owner:BYD CO LTD

Differential system for vehicle

ActiveCN112196968ASimple structureRealize the differential functionDifferential gearingsFreewheel clutchesDrive wheelDrive shaft

The invention discloses a differential system for a vehicle. The differential system comprises a driving device, a two-direction overrunning clutch and a driving wheel, wherein an output shaft of thedriving device is connected with a driving shaft connected to the driving wheel in a matched mode, the two-direction overrunning clutch comprises a driving piece and a driven piece, the driving pieceis connected with the driving shaft, the driven piece is connected with the driving wheel, and the two-direction overrunning clutch is used for transmitting two-direction torque output from the driving device to the driving shaft. The differential function of the differential system is achieved through the two-direction overrunning clutch, and the structure of the vehicle differential system is greatly simplified.

Owner:TRANF TECH XIAMEN CO LTD

Power drive system and vehicle with power drive system

ActiveCN106553533ARealize the differential functionCompact structureControl devicesDifferential functionMultiple input

The invention discloses a power drive system and a vehicle. The power drive system comprises a differential mechanism, an input part, a power output shaft, a plurality of input shafts and a first electric generator. The differential mechanism comprises a first planet carrier, a second planet carrier, first planet gears, second planet gears, a first gear ring and a second gear ring. The first planet gears and the second planet gears are connected with the first planet carrier and the second planet carrier correspondingly and engaged with the first gear ring and the second gear ring correspondingly. The second planet gears are further engaged with the first planet gears. The input part is in coaxial linkage with the first planet carrier and the second planet carrier. The power output shaft is arranged to be in linkage with the input part. Each input shaft is arranged to be in linkage with the power output shaft. The first electric generator is in linkage with one input shaft in the multiple input shafts. The differential mechanism of the power drive system utilizes the planet differential principle for achieving the differential function, and the structure is compact and simple.

Owner:BYD CO LTD

Power drive system and vehicle with the power drive system

ActiveCN106915245BRealize the differential functionRich transmission modeHybrid vehiclesElectric propulsion mountingPower couplingControl theory

The invention discloses a power drive system and a vehicle. The power drive system includes: a power coupling device, the power coupling device includes: a first sun gear, a first planet carrier and a first ring gear, a second sun gear, a second planet carrier and a second ring gear; and a power transmission part, The power transmission is coaxially coupled with the first sun gear and the second sun gear; a power source, the power source is arranged to selectively engage the power transmission; the first motor generator, the second motor generator, the first motor generator The second motor generator is linked with the first ring gear, and the second motor generator is linked with the second ring gear; and the first brake device directly or indirectly brakes the power transmission part. The power drive system of the present invention realizes the differential function on the premise of canceling the traditional mechanical differential, and has abundant transmission modes at the same time.

Owner:BYD CO LTD

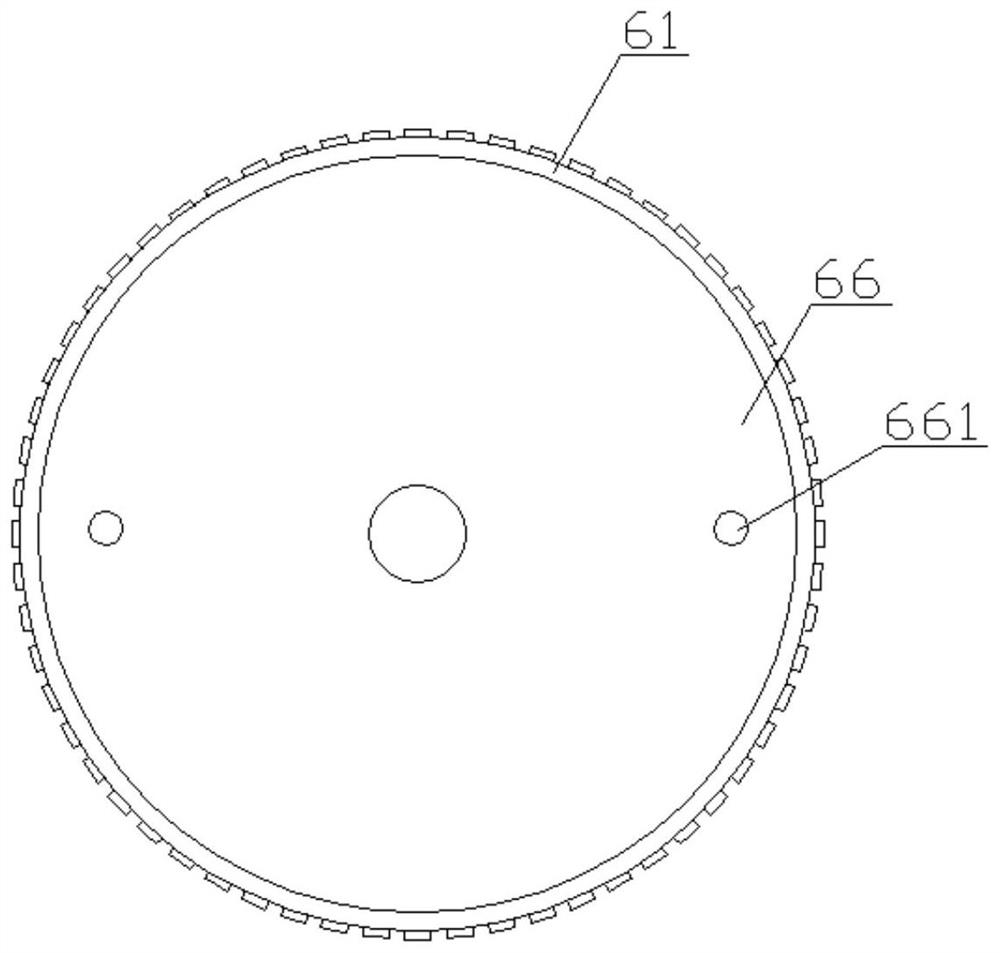

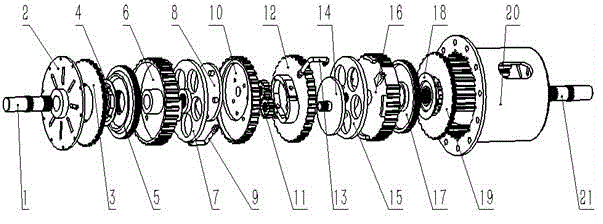

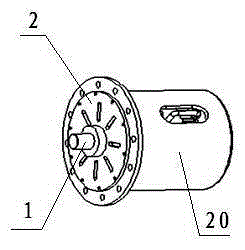

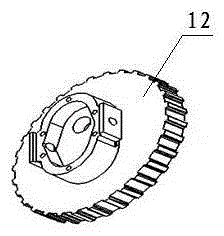

A self-propelled lawn mower

The invention discloses a self-propelled lawn mower, which comprises a machine body, a push handle, a power device, a power output shaft, a lawn mowing wheel and a driving wheel. The driving wheel includes a left driving wheel, a right driving wheel and a Drive shaft, one end of the drive shaft is connected to the power take-off shaft, and a differential is arranged between the two drive wheels; the differential includes two ring gears, a ratchet, and the opposite ends of the left drive wheel and the right drive wheel Ring gear seats are respectively formed, and the ring gears are respectively arranged in the ring gear seats of the left drive wheel and the right drive wheel. The center of the ring gear is provided with a regular polygonal through hole, and each inner corner of the through hole is provided with a Elastic racks facing the same side; the ratchet is fixedly arranged in the middle of the drive shaft, and the two ring gears are respectively arranged at both ends of the ratchet with the same orientation. The differential gear of the present invention has a simple and compact structure and is suitable for small domestic lawnmowers.

Owner:HUAIAN ZHONGLU GARDEN MACHINERY CO LTD

Straight pin hole hydraulic automatic limited slip differential

InactiveCN103697139BGreat driving forceAvoid deadlockDifferential gearingsHydraulic cylinderLeft half

The invention discloses a straight-toothed hole pin type hydraulic automatic limited slip differential, which comprises a differential shell, a left half shaft, a right half shaft, a differential mechanism and a hydraulic slip limiting mechanism. According to the differential, hydraulic oil in a hydraulic cylinder on one side is pressed into a hydraulic cylinder on the other side by virtue of the tooth space volume change of two gears so as to increase oil pressure in the hydraulic cylinder on one side, and thus a friction plate group on the side can be pressed closely; meanwhile, the torque of the differential shell is transmitted to non-slip wheels through the friction plate group to increase the driving force of the non-slip wheels so as to achieve a slip limiting function, so that the slip limiting function can be independently and autonomously realized without an independent hydraulic execution mechanism and an auxiliary mechanism. The differential is simple and reasonable in structure and low in manufacturing cost; in addition, the highest oil pressure can be controlled by setting the amount of oil injected into the hydraulic cylinders, thereby avoiding the condition that the differential is locked when excessive pressing force is applied to the friction plate groups; moreover, the left and right hydraulic cylinders serve as oil tanks of each other, so that the shortcoming of size enlargement caused by an independent oil tank can be overcome.

Owner:CHONGQING UNIV OF TECH

Power drive system and vehicle having the power drive system

ActiveCN106915238BRealize the differential functionRich transmission modeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingPower couplingEngineering

The invention discloses a power driving system and a vehicle. The power driving system comprises a power coupling device, a first electric power generator, a second electric power generator, a third electric power generator, and a first brake device, wherein the power coupling device comprises a first sun gear, a first planet carrier, a first gear ring, a second sun gear, a second planet carrier and a second gear ring, wherein the first gear ring is coaxially connected with the second gear ring; the first electric power generator is linked with the first sun gear and the second electric power generator is linked with second sun gear; the third electric power generator is linked with a power transmission part; and the first brake device is used for directly or indirectly braking the gear rings. The power driving system disclosed by the embodiment of the invention has the advantages that a differential function is realized on the premise of eliminating the traditional mechanical differential mechanism and rich transmission modes are also realized.

Owner:BYD CO LTD

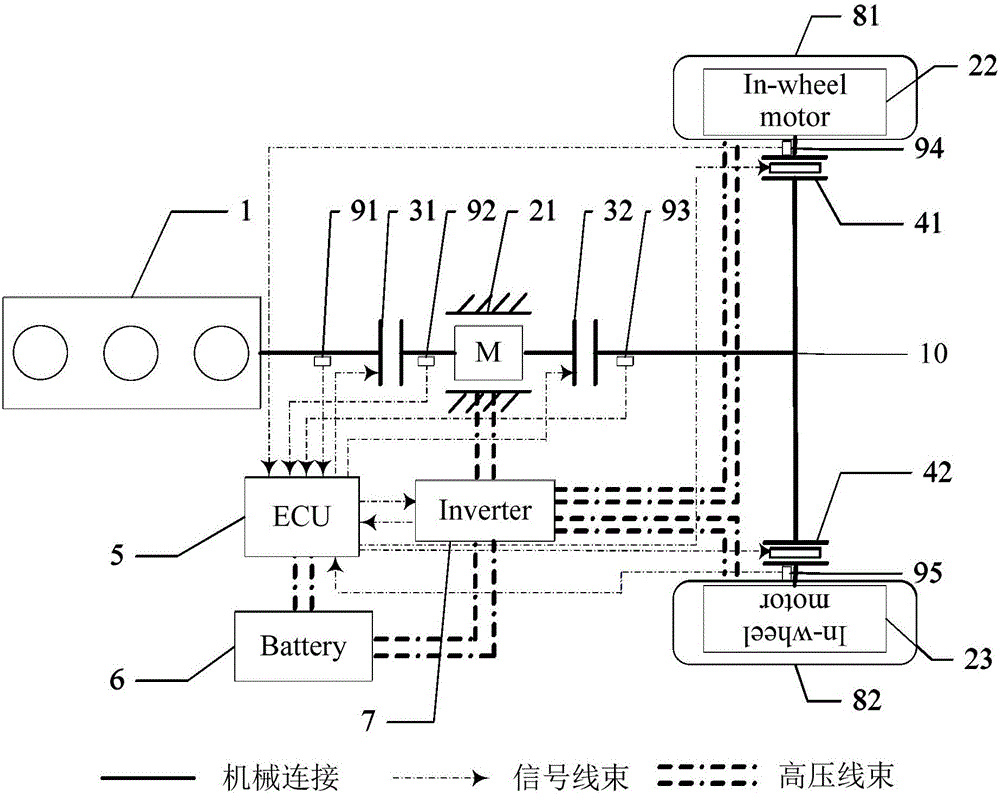

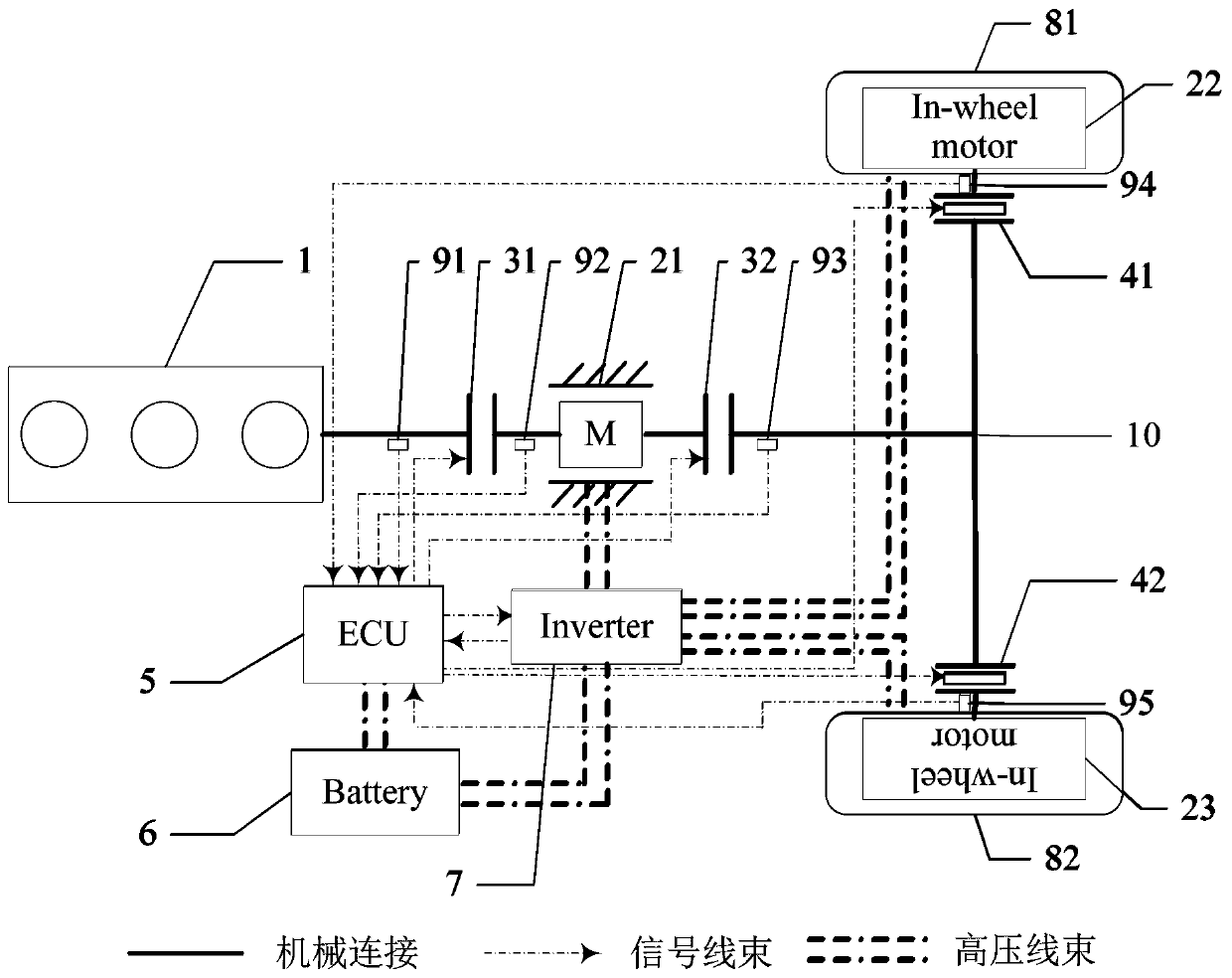

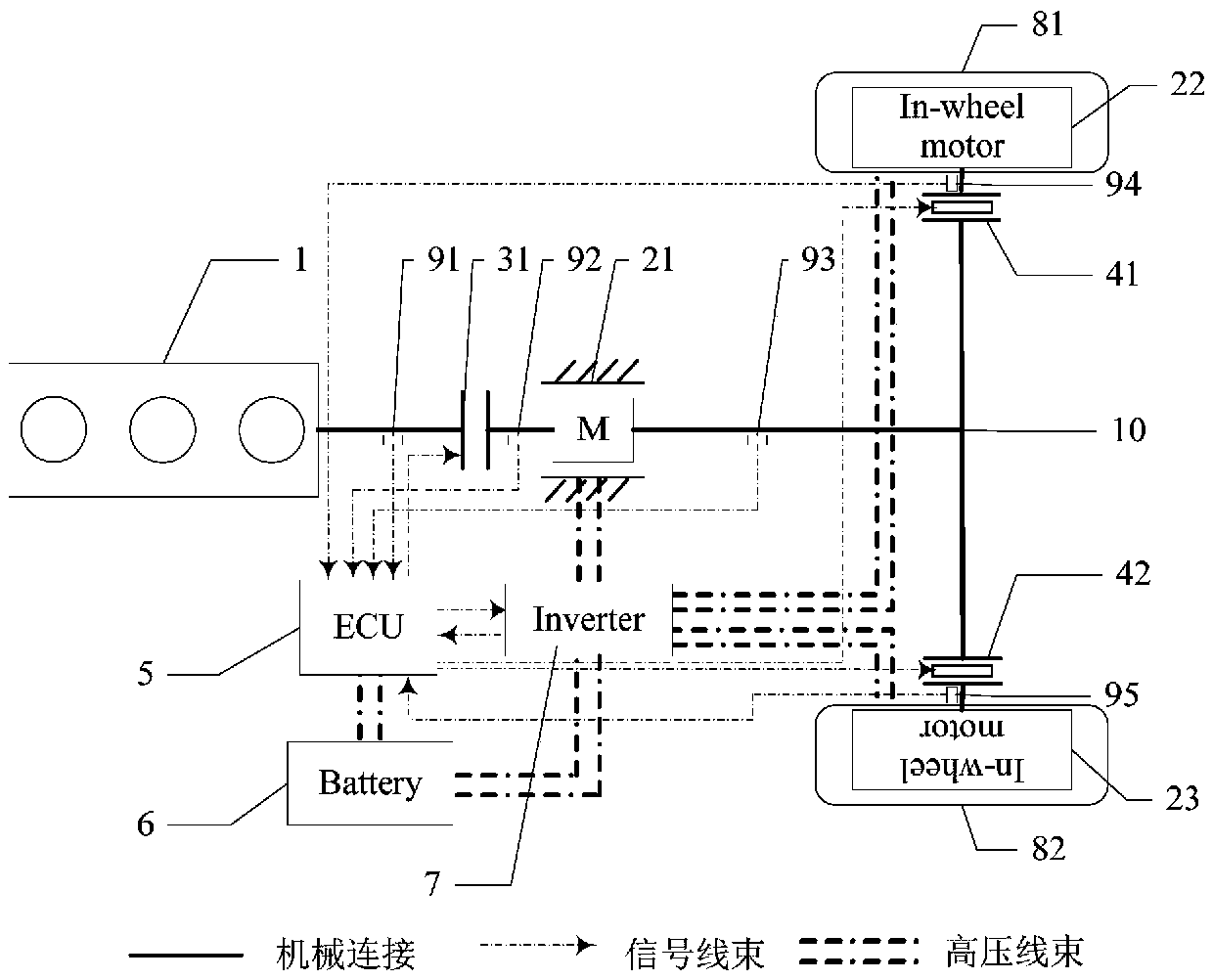

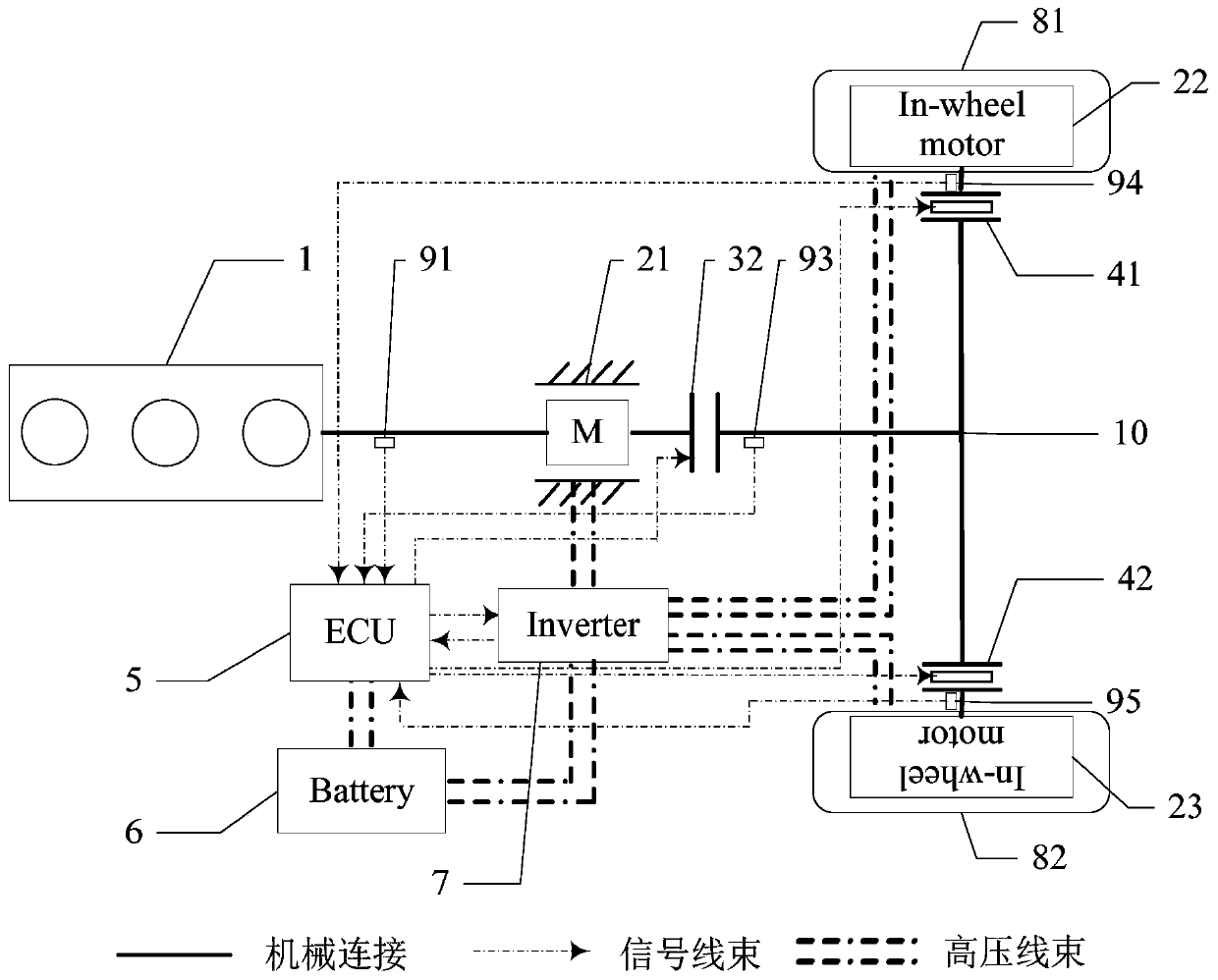

A gasoline-electric hybrid multi-mode vehicle drive system and control method

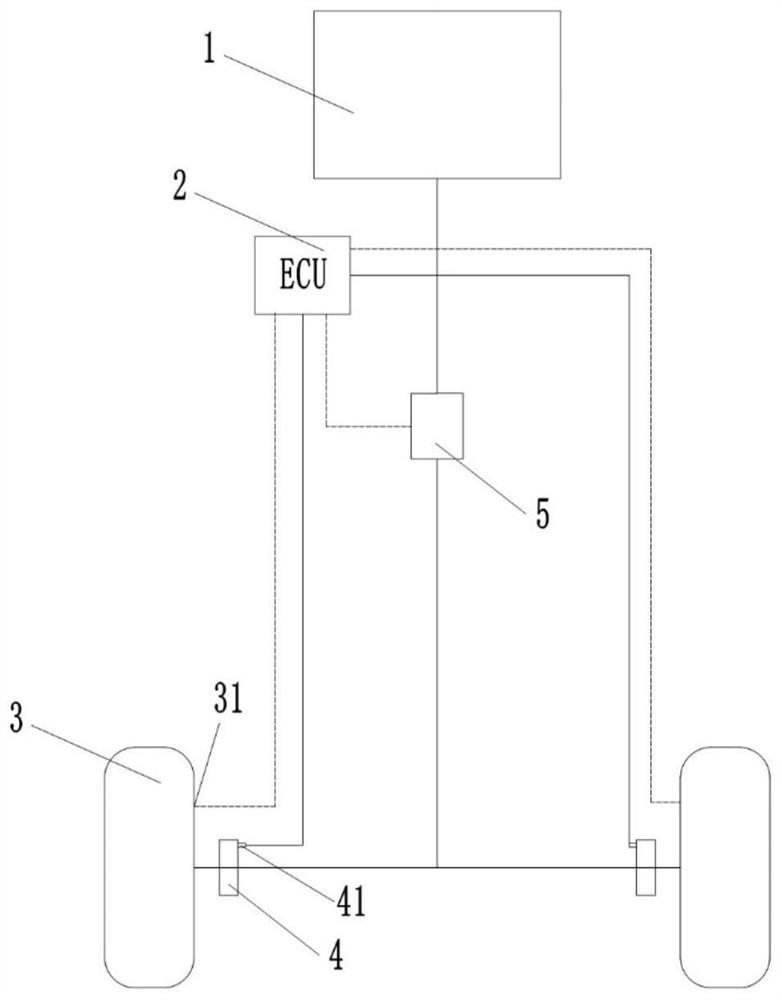

ActiveCN106394230BReduce consumptionRealize the differential functionHybrid vehiclesGas pressure propulsion mountingElectricityDifferential function

The invention discloses a gasoline-electric hybrid multi-mode vehicle drive system, which is mainly composed of an engine, two clutches, an ISG motor, two overrunning clutches, two wheel hub motors, a control unit ECU, a motor controller, a battery pack and the like. The two ends of the ISG motor rotor are respectively connected to the engine output end and the transmission shaft through the first and second clutches, and the two ends of each overrunning clutch are respectively connected to the transmission shaft and the corresponding wheel; the hub motor is installed in the wheel, which can directly drive the vehicle run. The control unit ECU sends instructions to each clutch and motor controller according to the signal fed back by the sensor to control the coupling / disengagement of the clutch and the power output of the motor, and achieve the purpose of switching the working mode. The multi-mode feature of the system increases the chances of the engine working in the high-efficiency zone; the setting of the overrunning clutch can not only realize the differential function in certain modes, but also reduce the energy consumption of the additional load and improve the system efficiency.

Owner:SHANDONG UNIV OF TECH

Hybrid bulldozer and power system thereof

ActiveCN102505716BSmall footprintRealize the differential functionHybrid vehiclesMechanical machines/dredgersThree levelReduction drive

The invention provides a power system of a hybrid bulldozer. The power system comprises two symmetrically distributed subsystems which are same in structure, and each subsystem comprises a final drive unit (22) and a motor deceleration integration device (23), wherein each final drive unit (22) is provided with a secondary speed reducer, the output end of each secondary speed reducer is connected with a walking device (21) of the power system of the hybrid bulldozer, and each motor deceleration integration device (23) is connected with each final drive unit (22) and comprises a primary speed reducer and a motor (232). The power system of the hybrid bulldozer, disclosed by the invention, utilizes three-level deceleration and simultaneously avoids utilization of a differential. Compared with the power system, employing four-level deceleration and provided with the differential, of the hybrid bulldozer in the prior art, the power system of the hybrid bulldozer, disclosed by the invention, can be used for reducing the number of used parts and components so as to reduce a space occupied by the power system of the hybrid bulldozer. The invention further provides a hybrid bulldozer with the power system.

Owner:WEICHAI POWER CO LTD

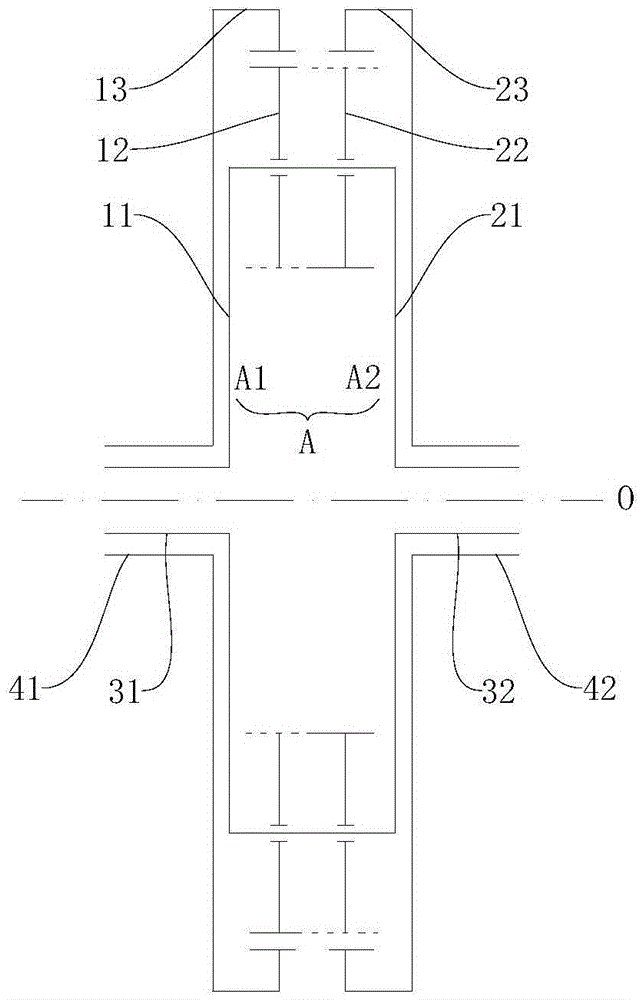

Differential mechanism, control method thereof and vehicle with differential mechanism

InactiveCN111043273ARealize the differential functionReduce loadDifferential gearingsGear wheelEngineering

The invention belongs to the technical field of vehicles, and particularly relates to a differential mechanism, a control method thereof and a vehicle with the differential mechanism. The differentialmechanism comprises a power input gear, a differential mechanism shell, two planet gears, two side gears, two half shafts and a hydraulic locking device, wherein the power input gear is connected tothe outer side of the differential mechanism shell, the differential mechanism shell and the power input gear coaxially rotate, the two planet gears are connected to the inner side of the differentialmechanism shell, the two planet gears are located between the two side gears, the two side gears mesh with the two planet gears correspondingly, the two side gears are coaxial with the power input gear, the two side gears are connected to the two half shafts correspondingly, the two half shafts penetrate through the differential mechanism shell in the mode of being capable of rotating relative tothe differential mechanism shell, and the hydraulic locking device is arranged on the two half shafts.

Owner:WEICHAI POWER CO LTD

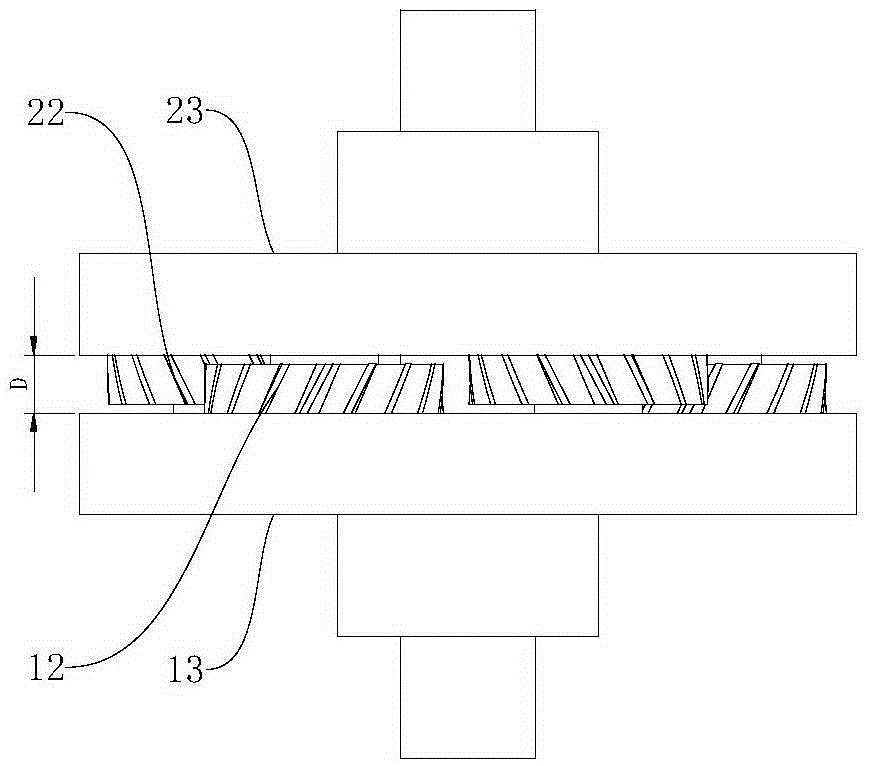

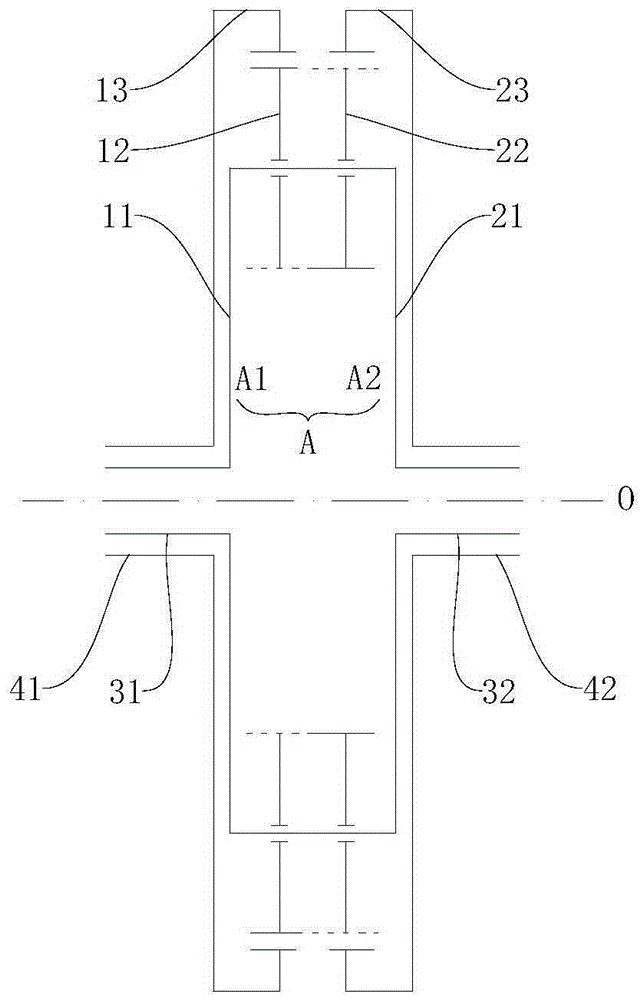

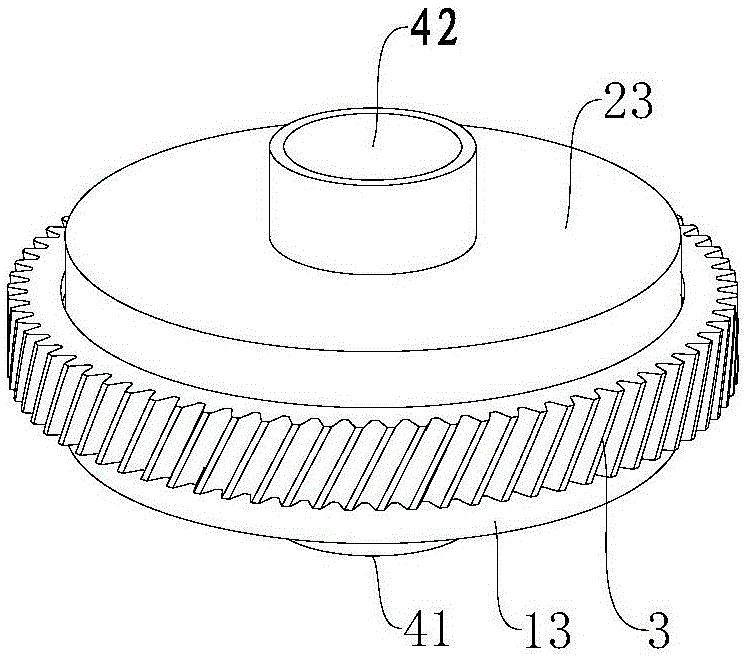

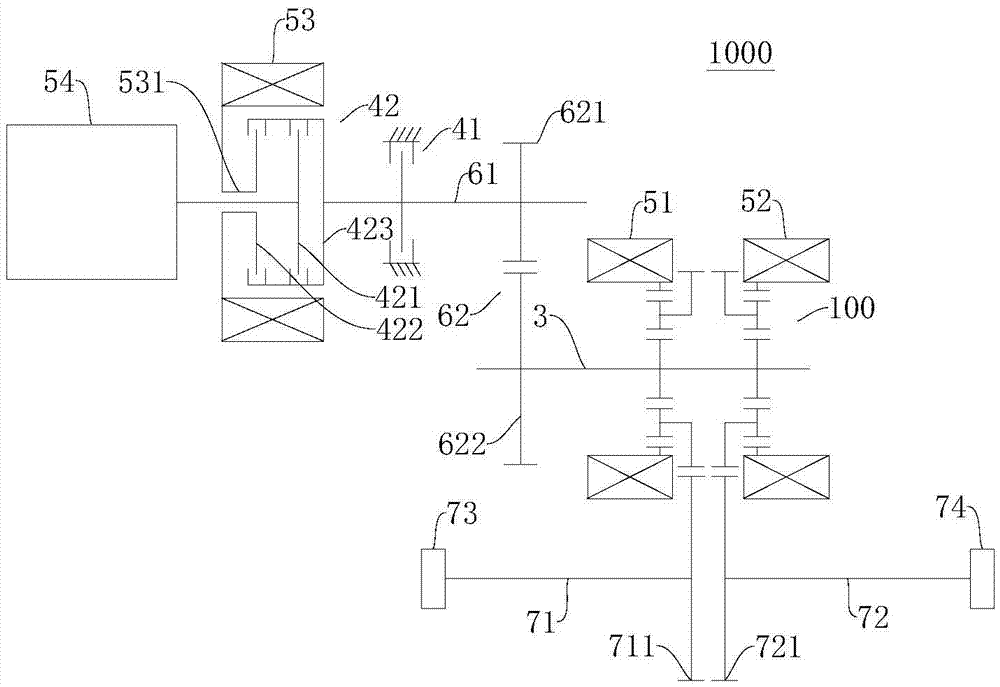

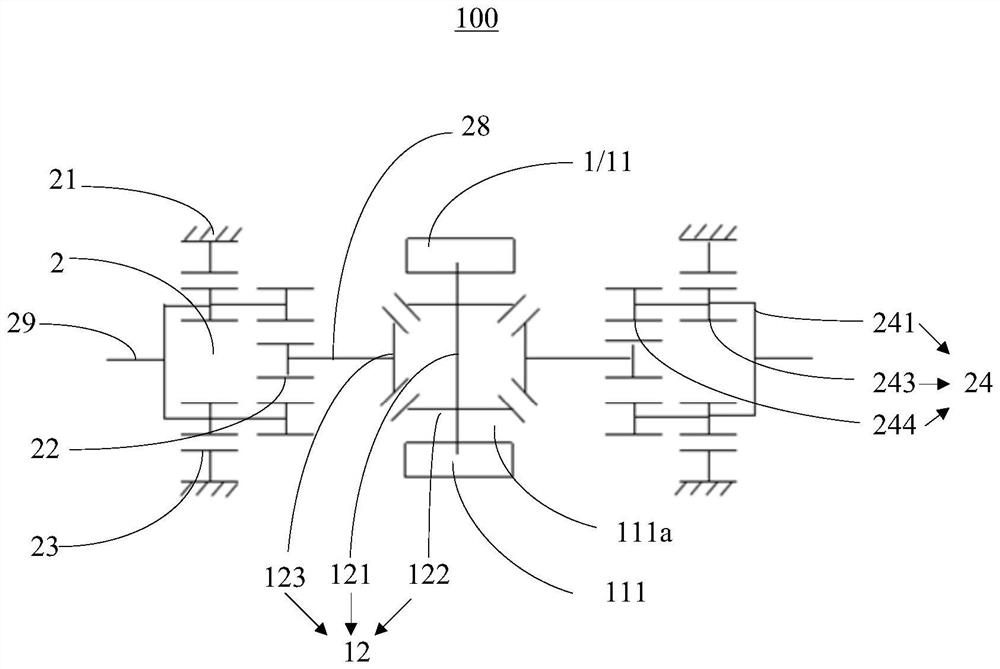

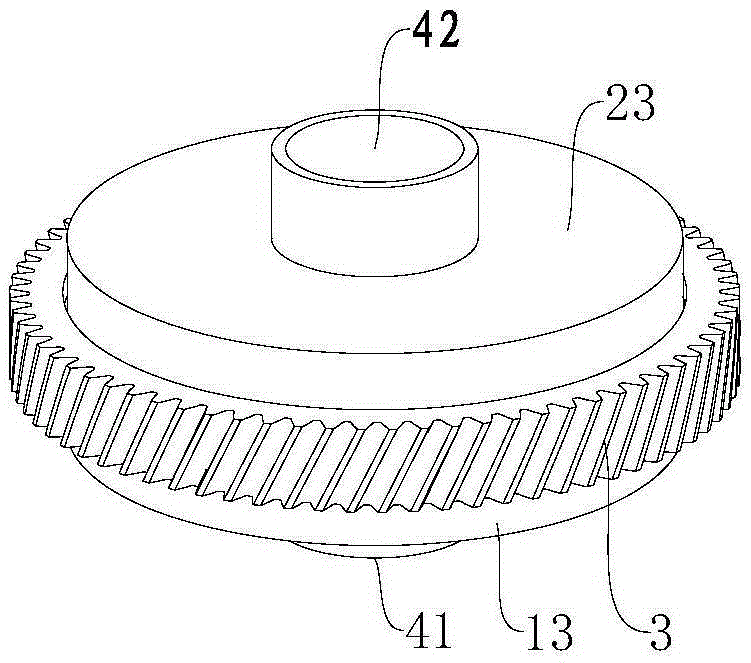

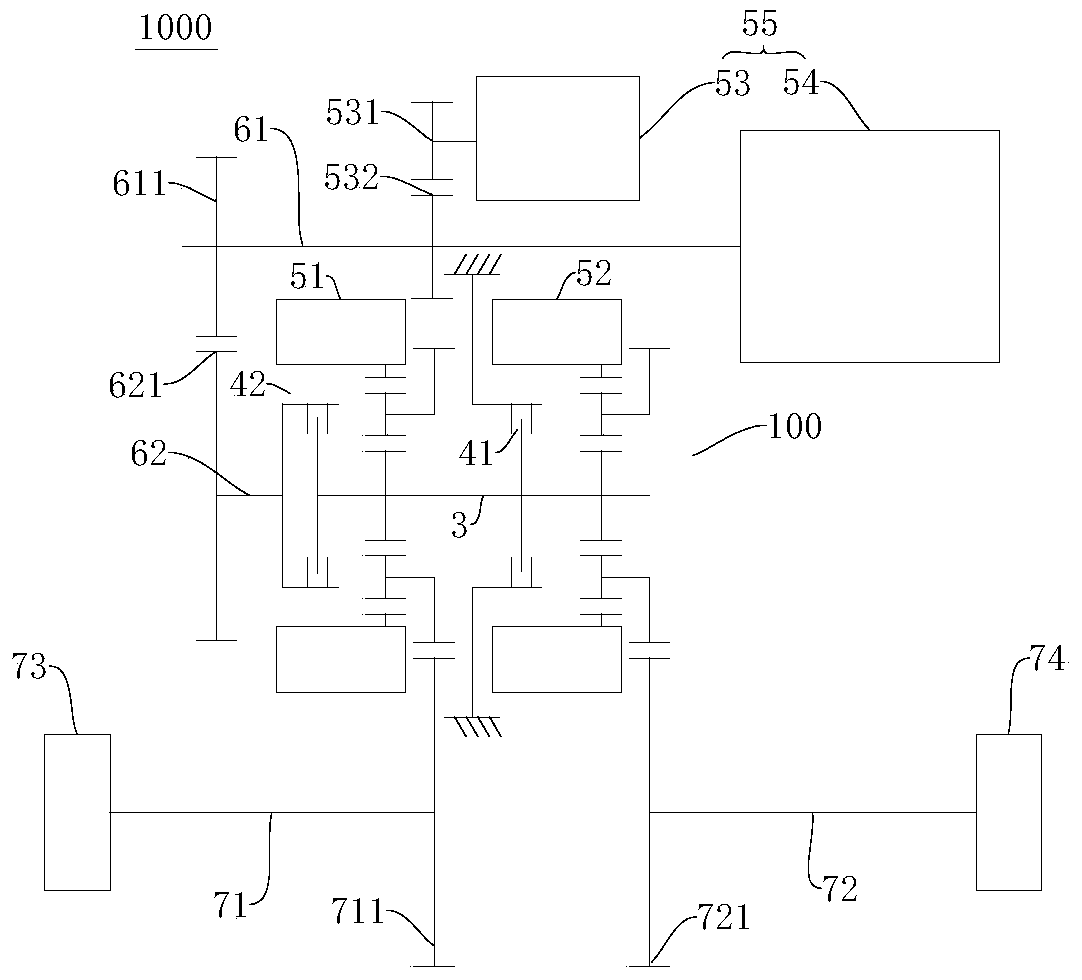

Power drive system and vehicle with the power drive system

ActiveCN106915240BRealize the differential functionRich transmission modeHybrid vehiclesGas pressure propulsion mountingPower couplingEngineering

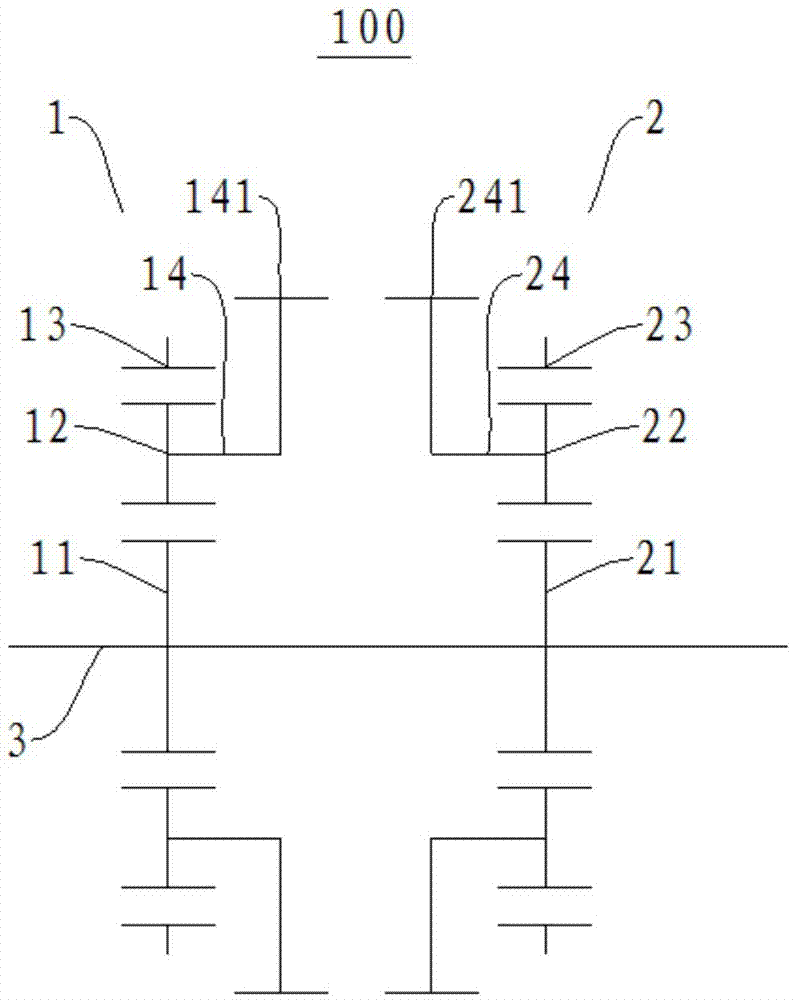

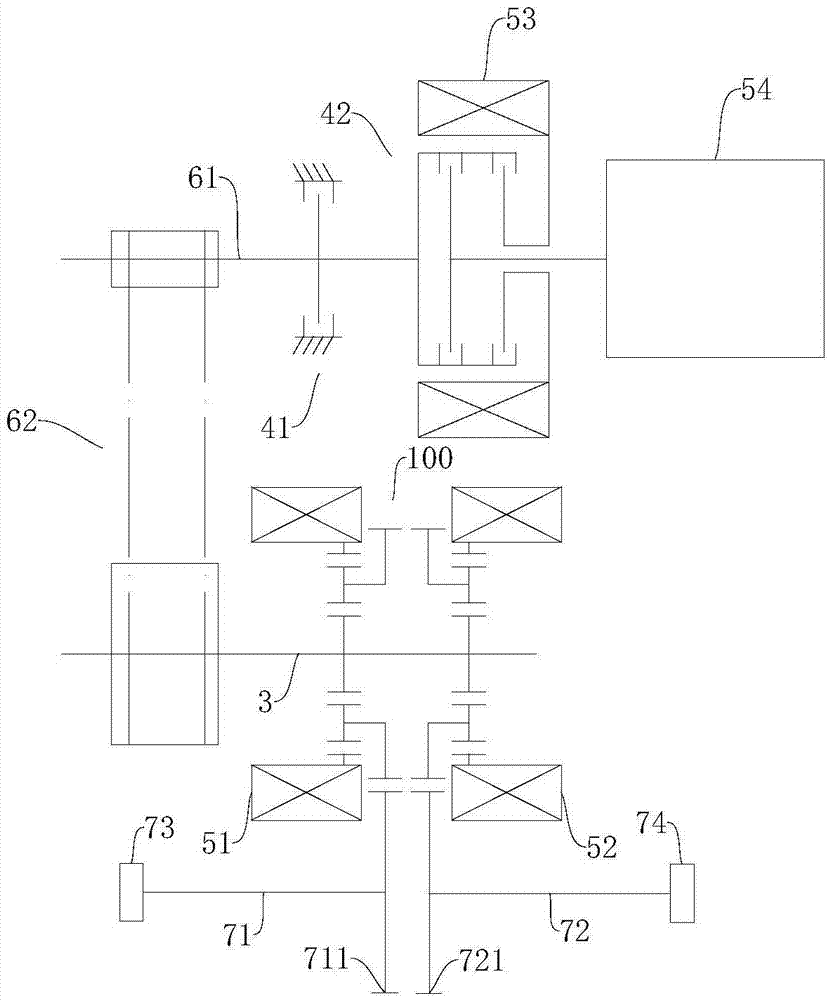

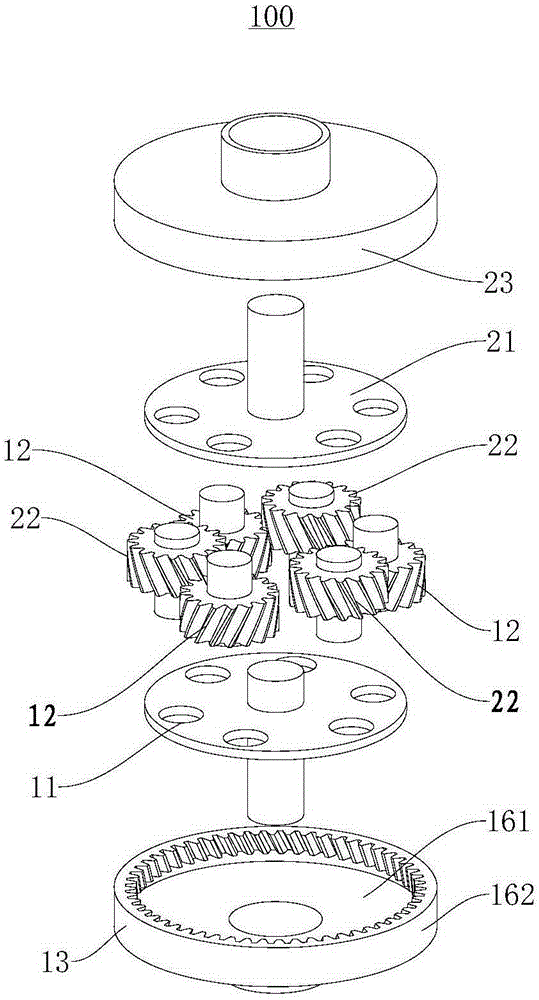

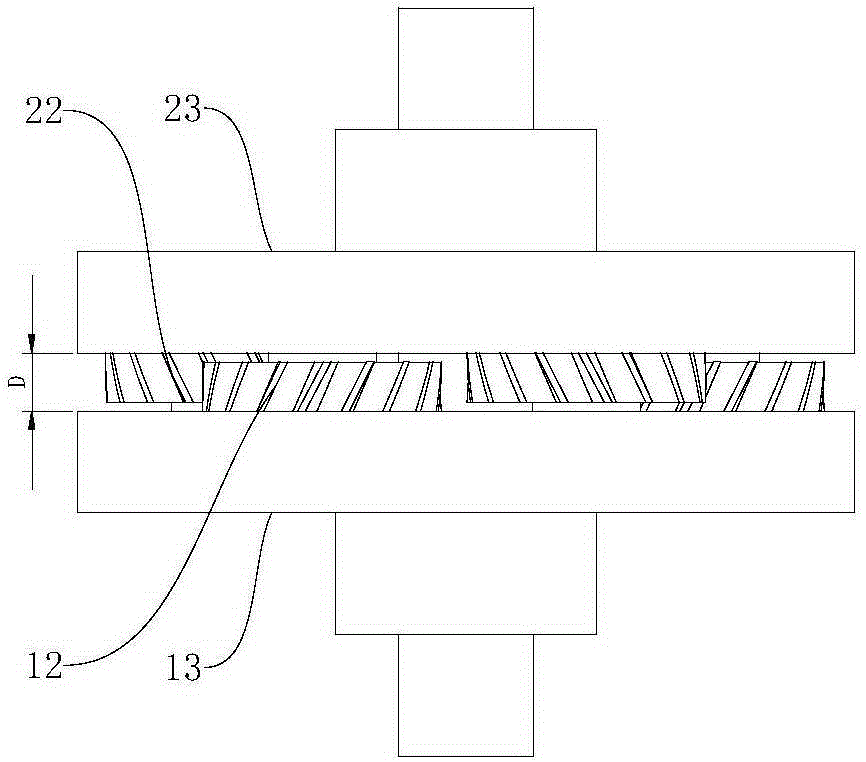

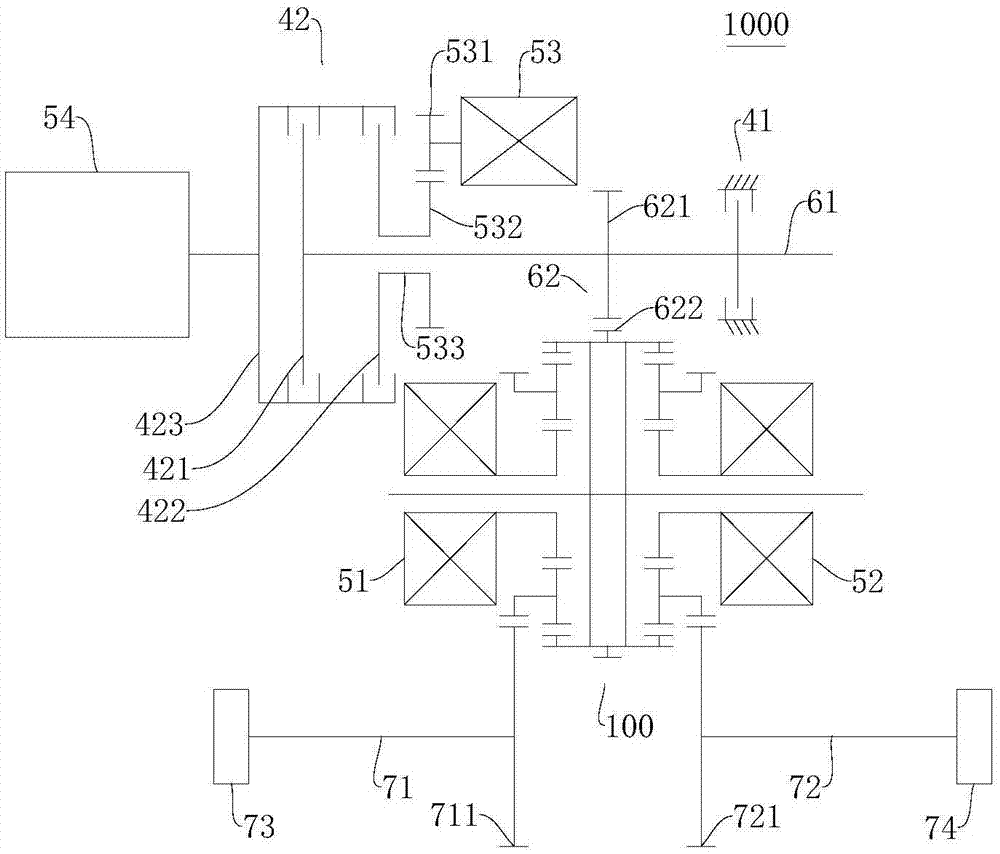

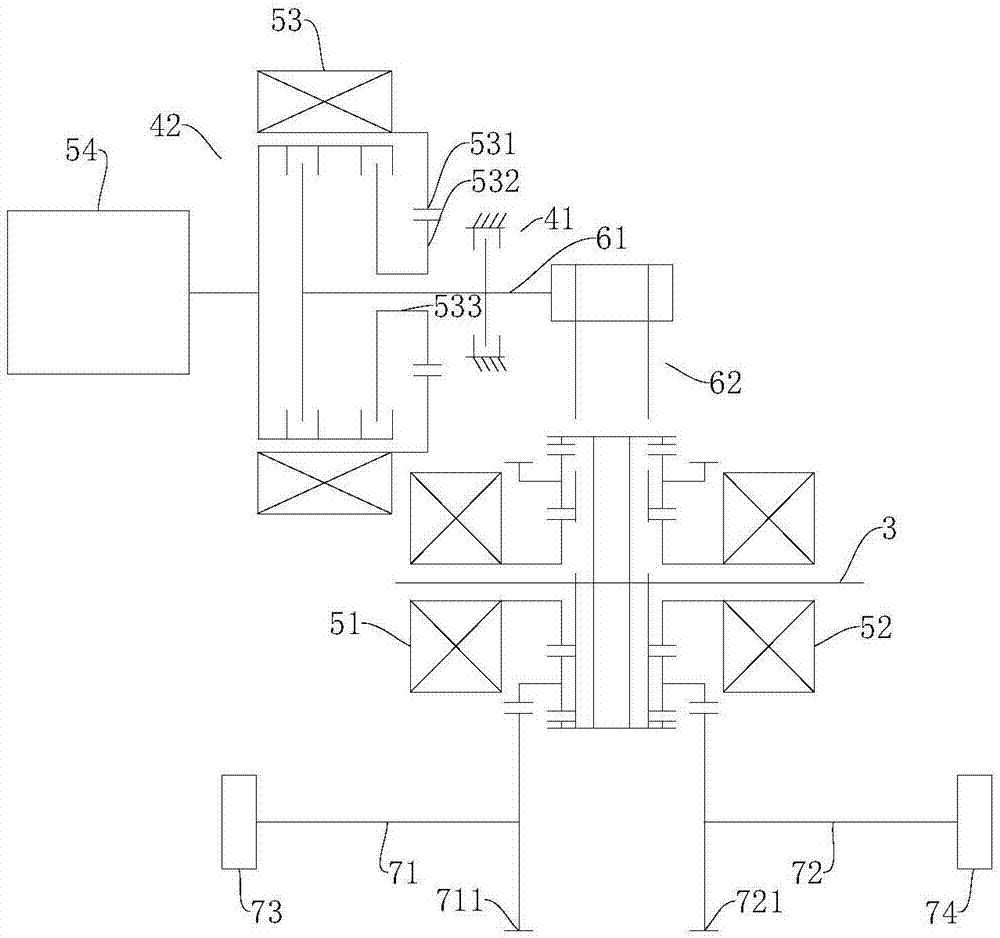

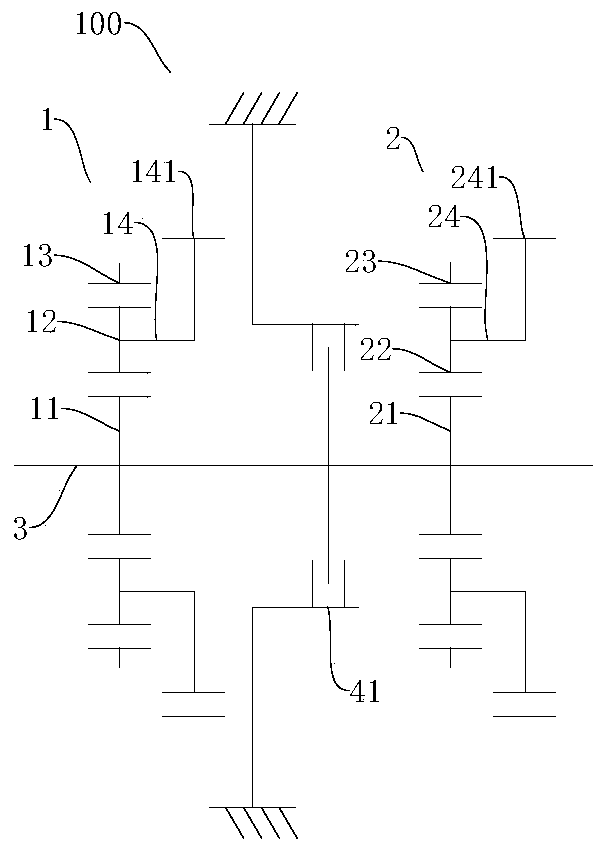

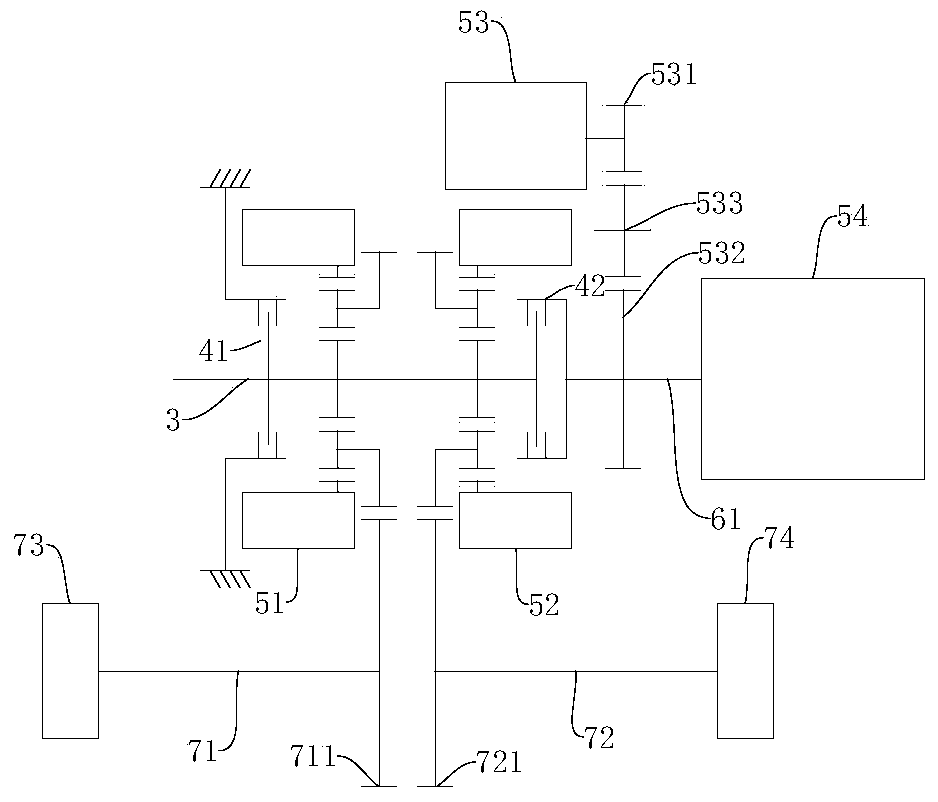

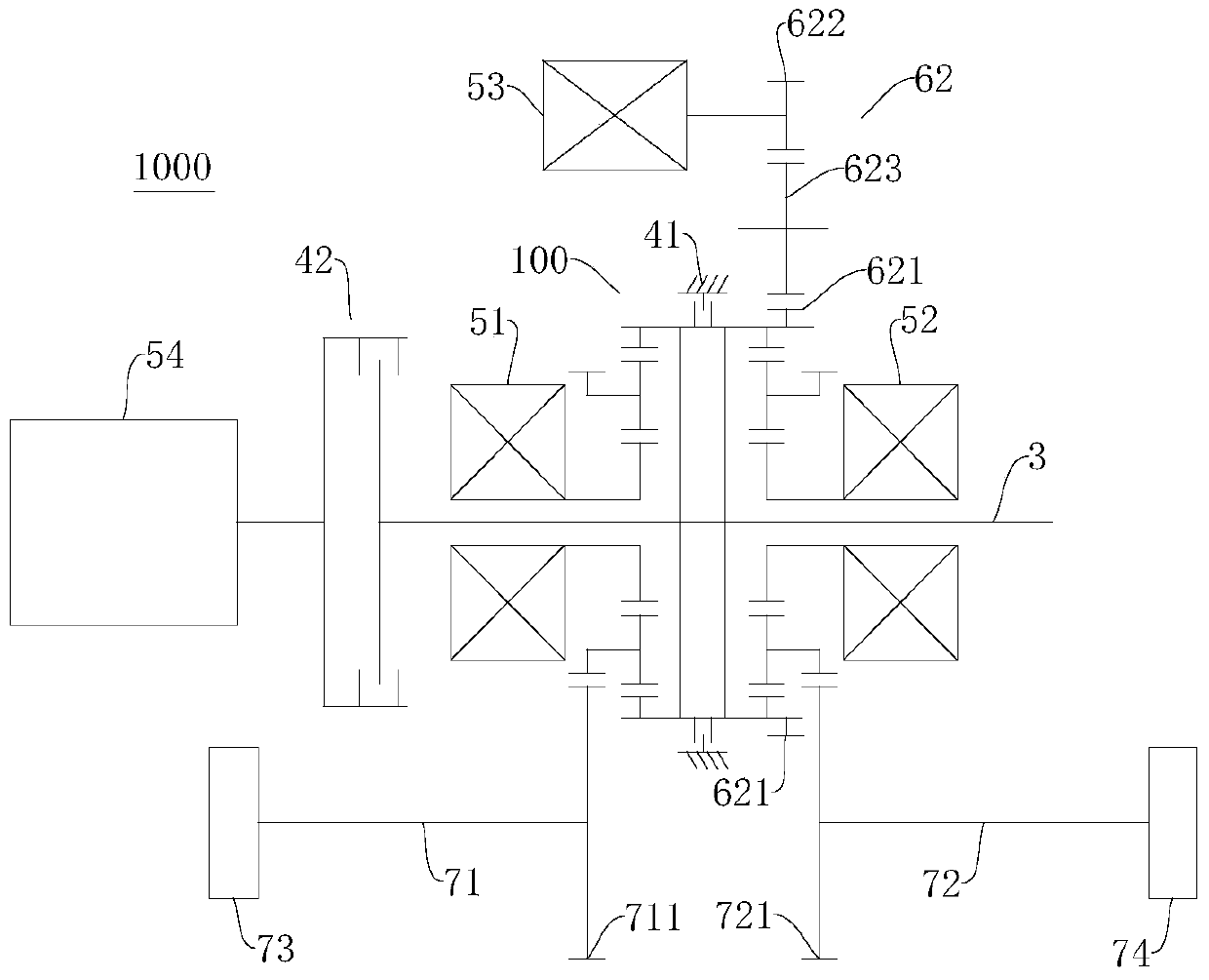

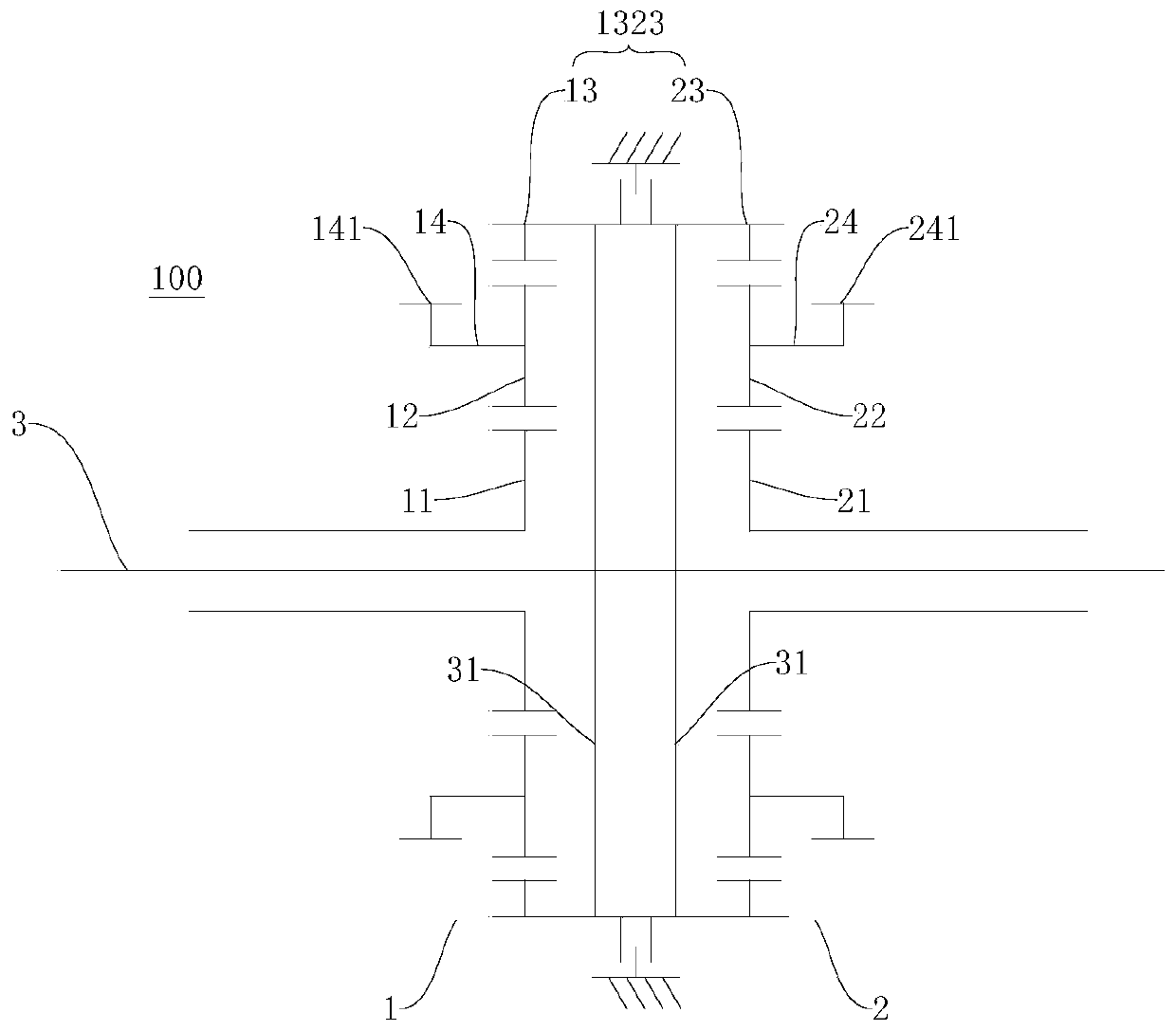

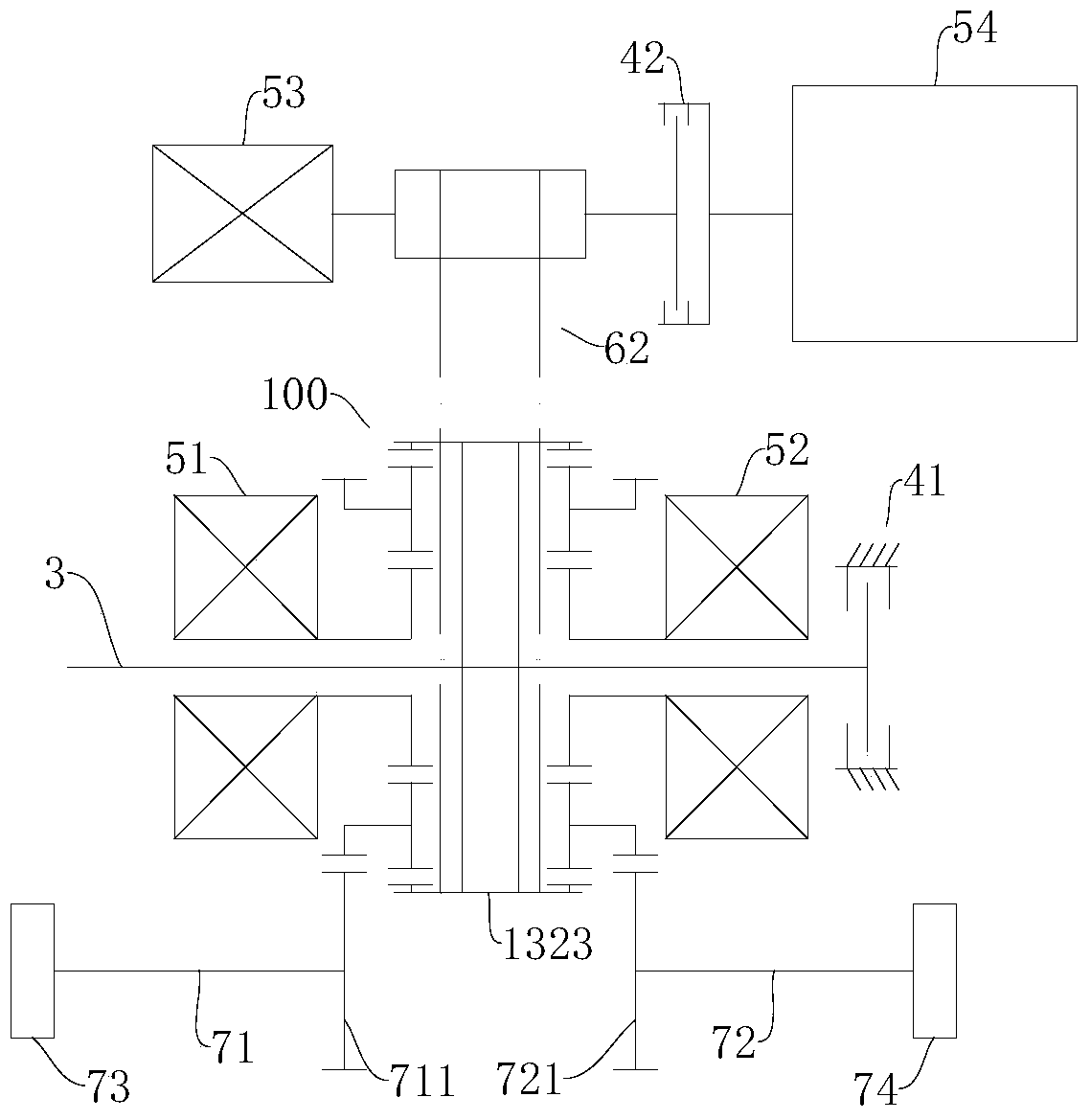

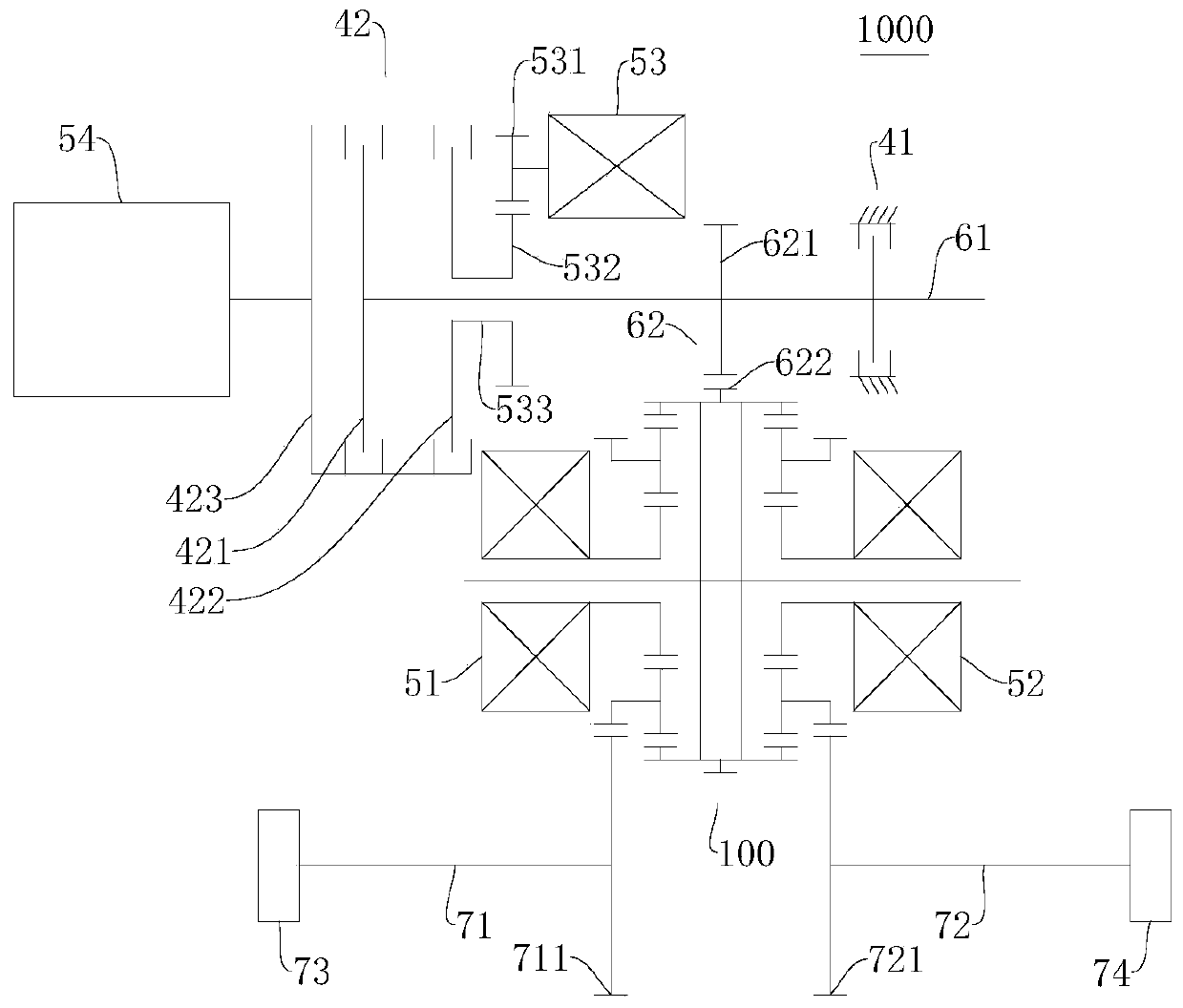

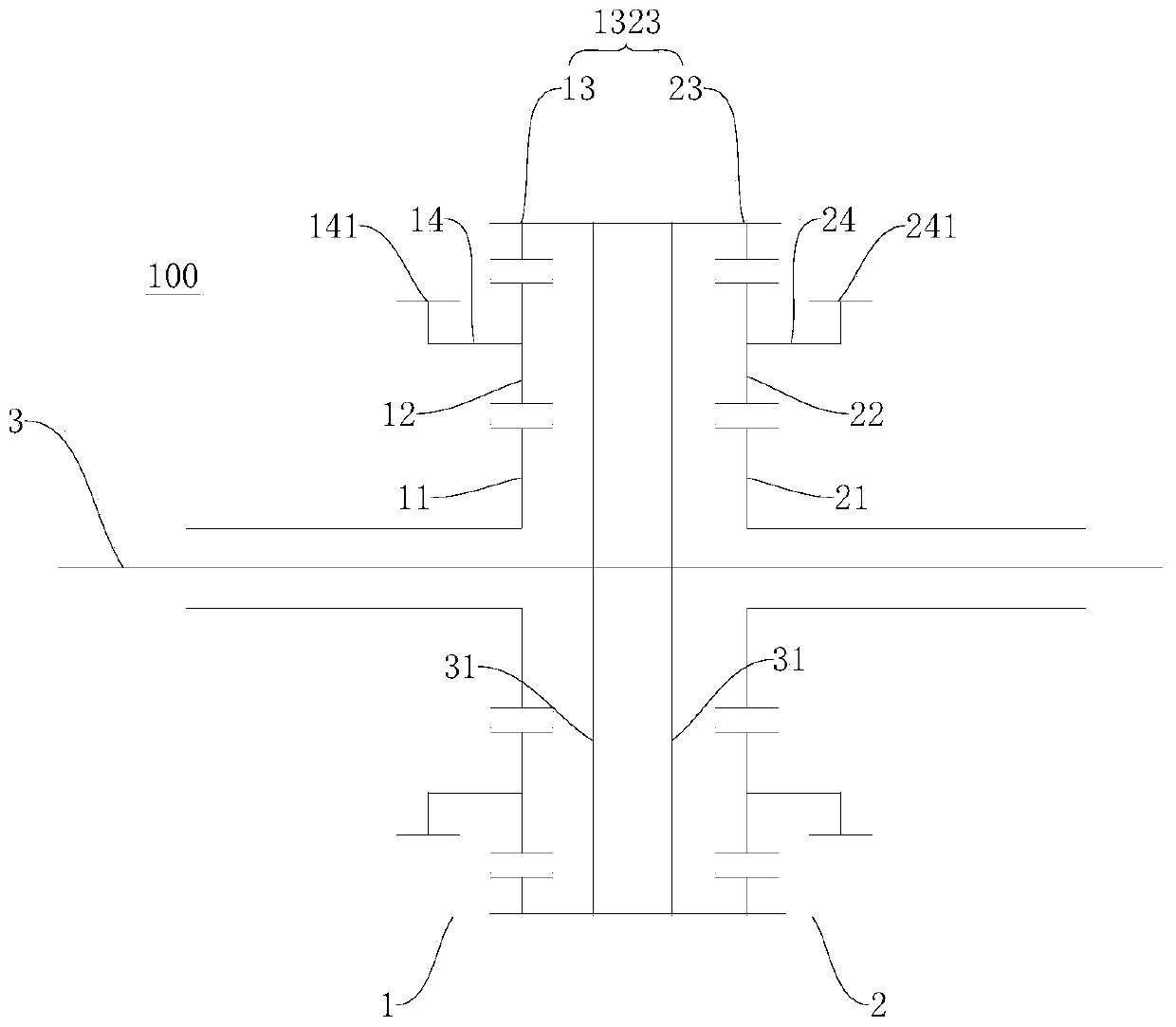

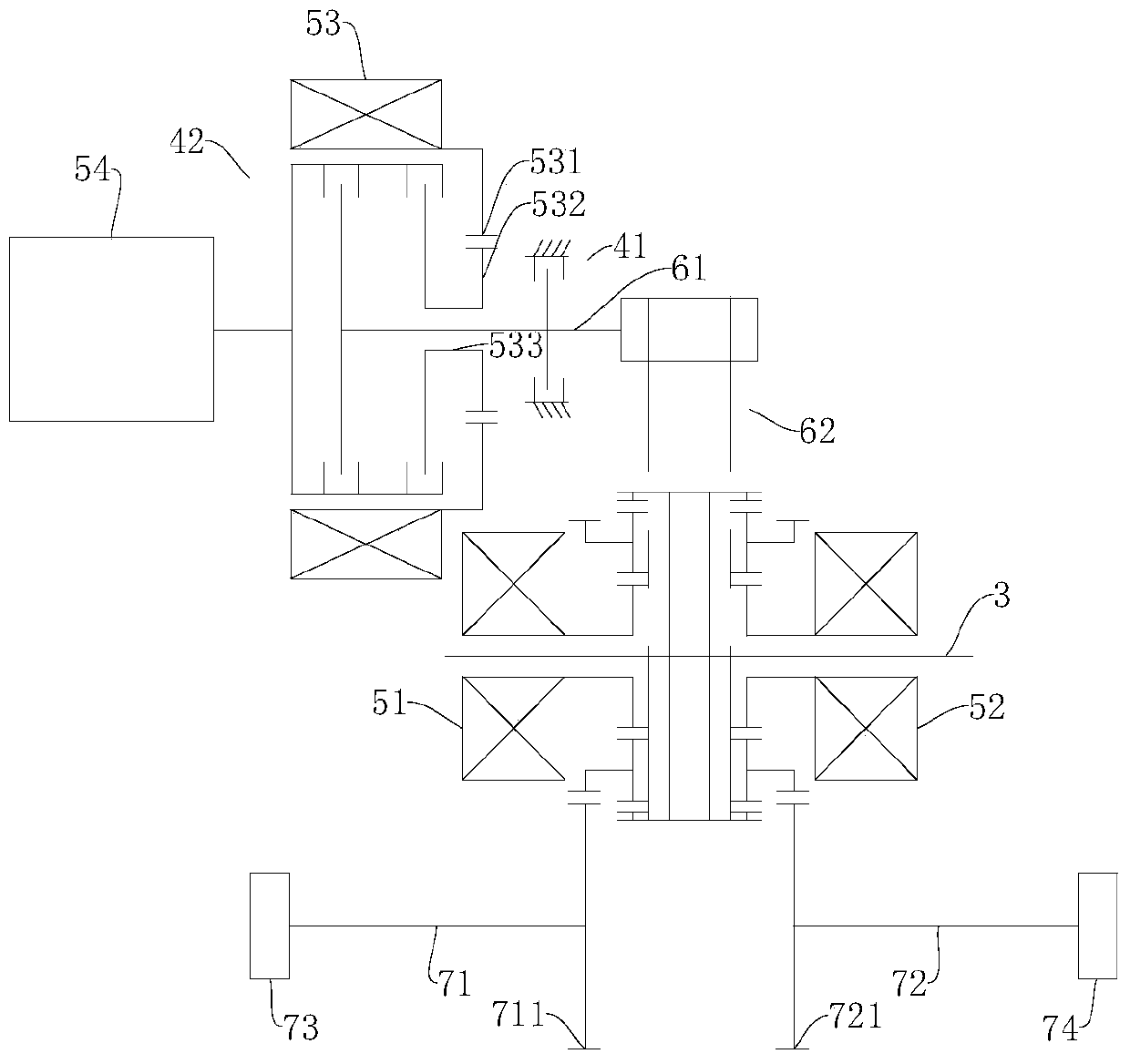

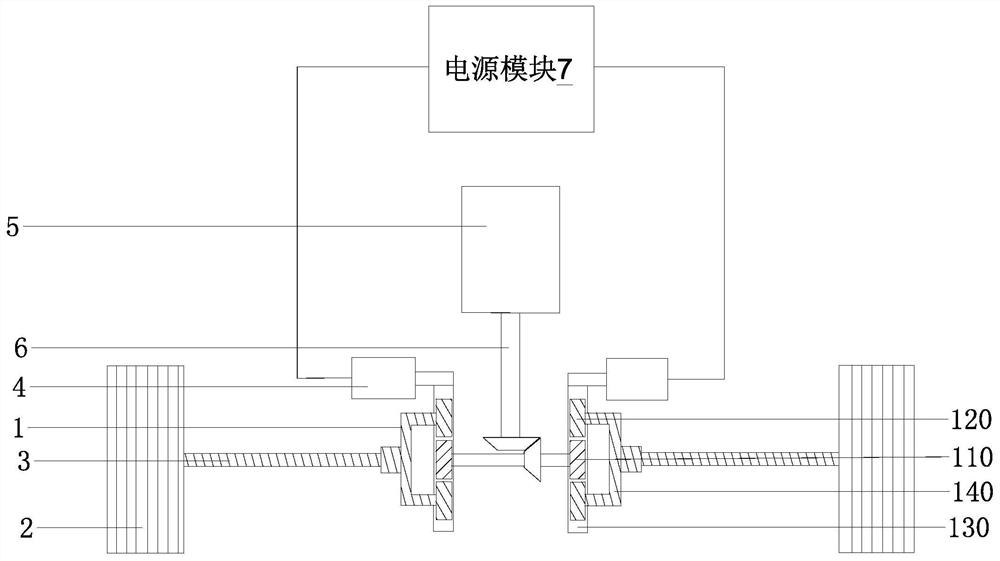

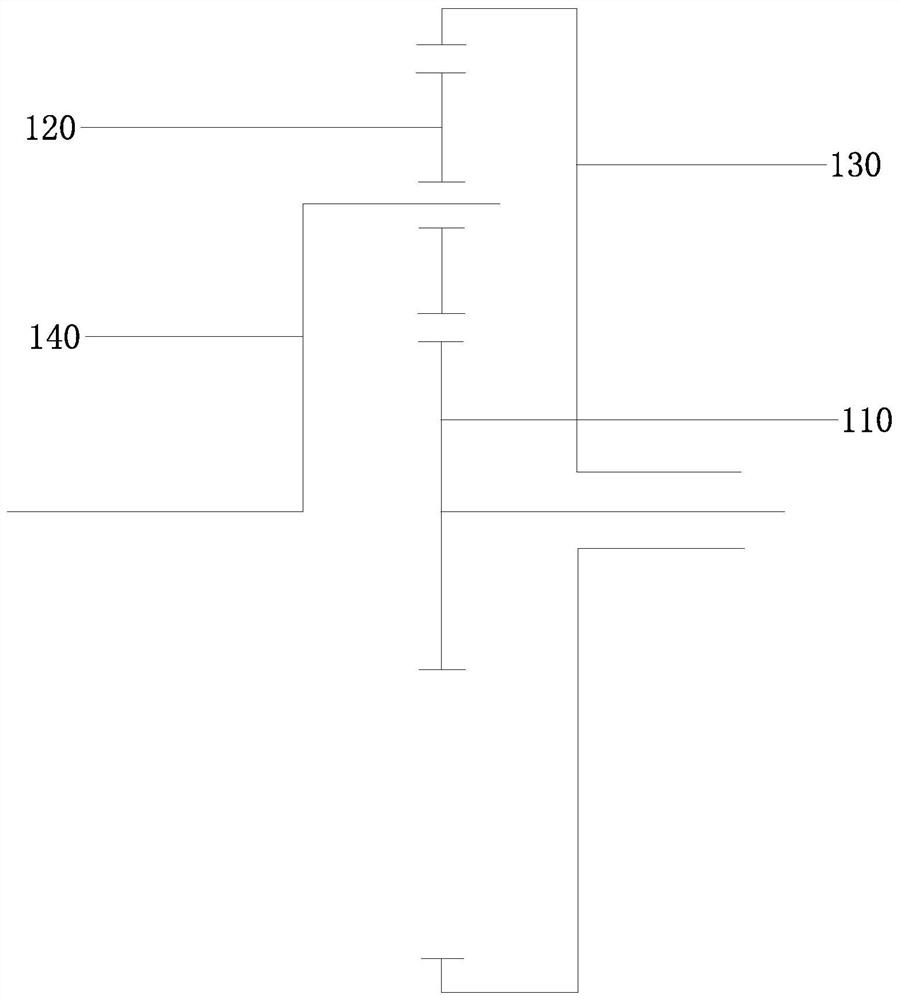

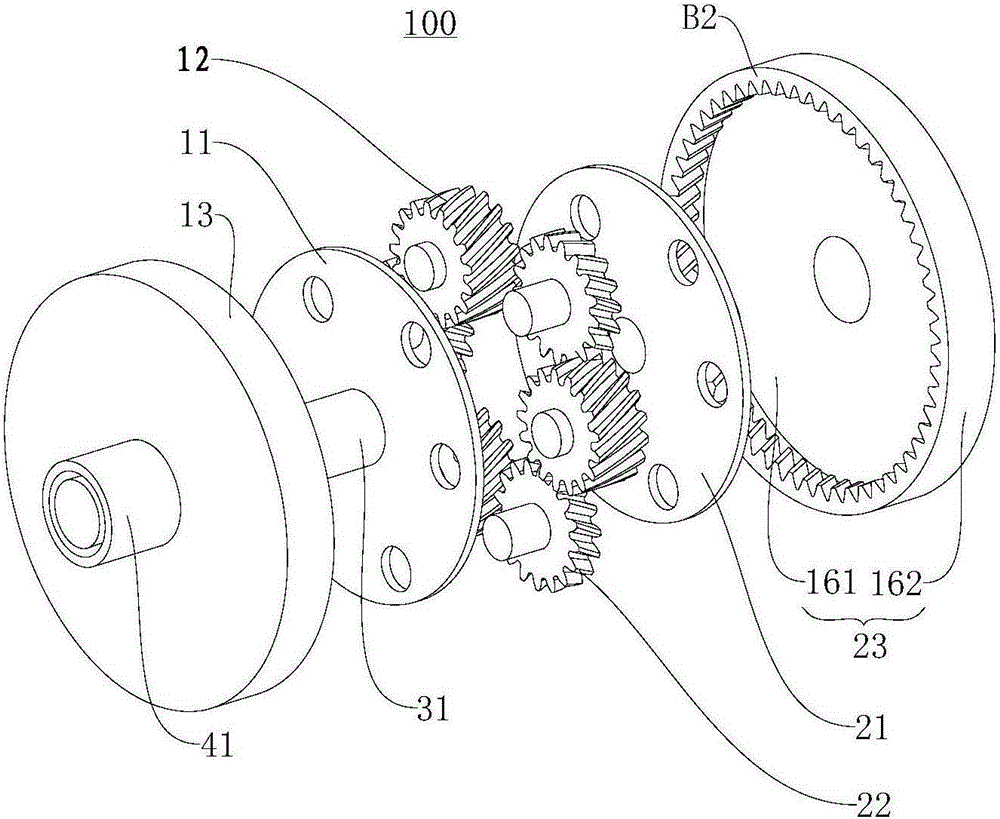

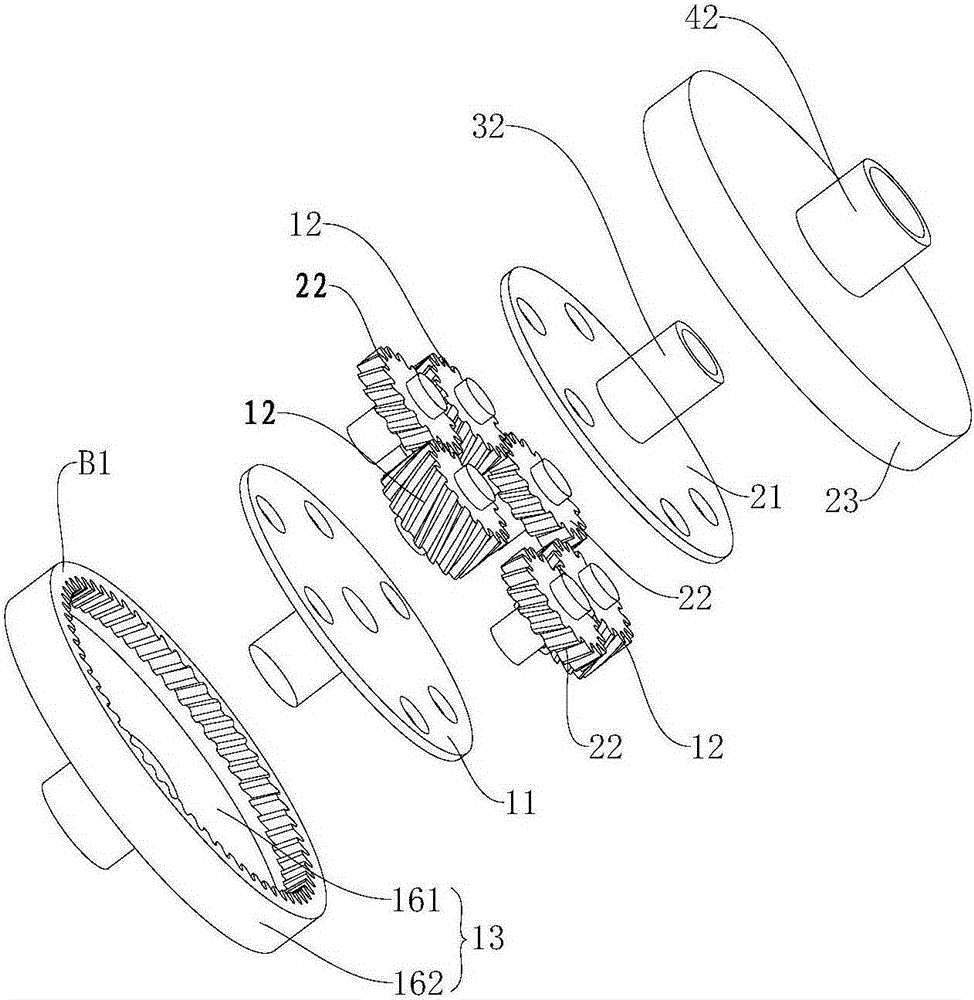

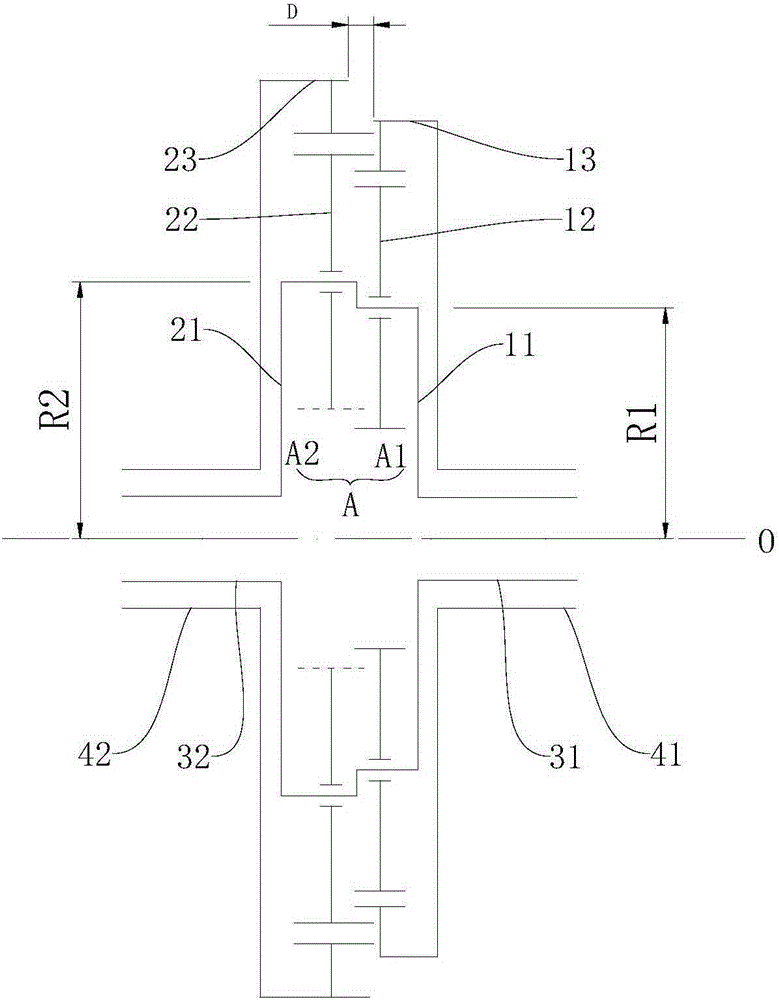

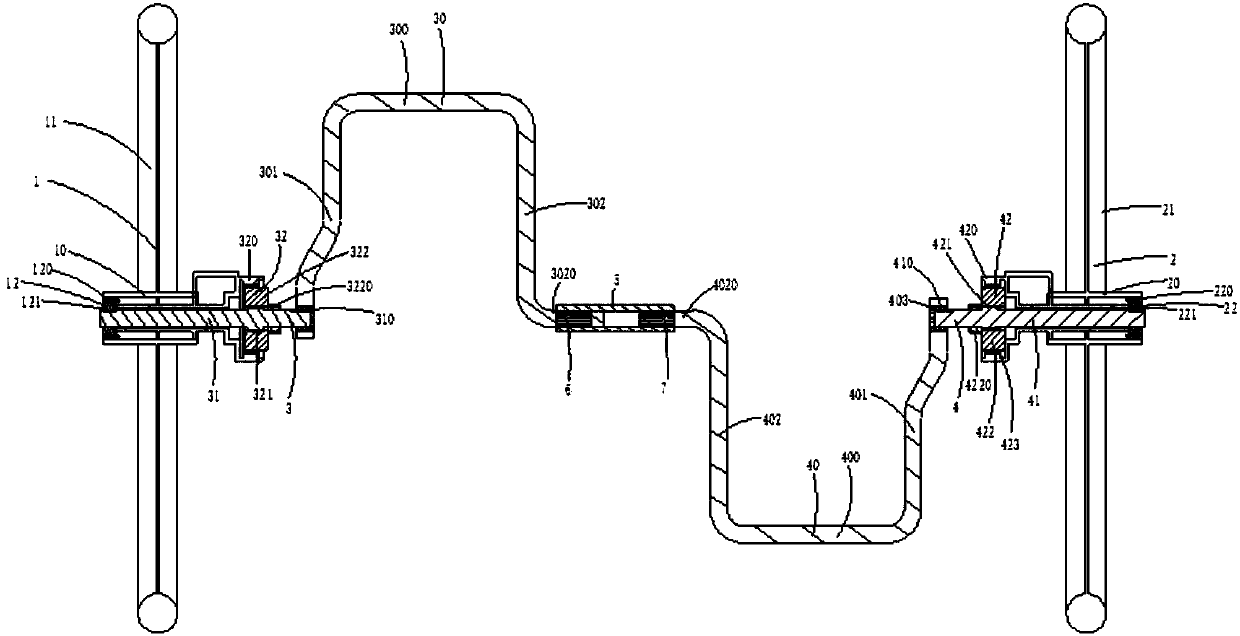

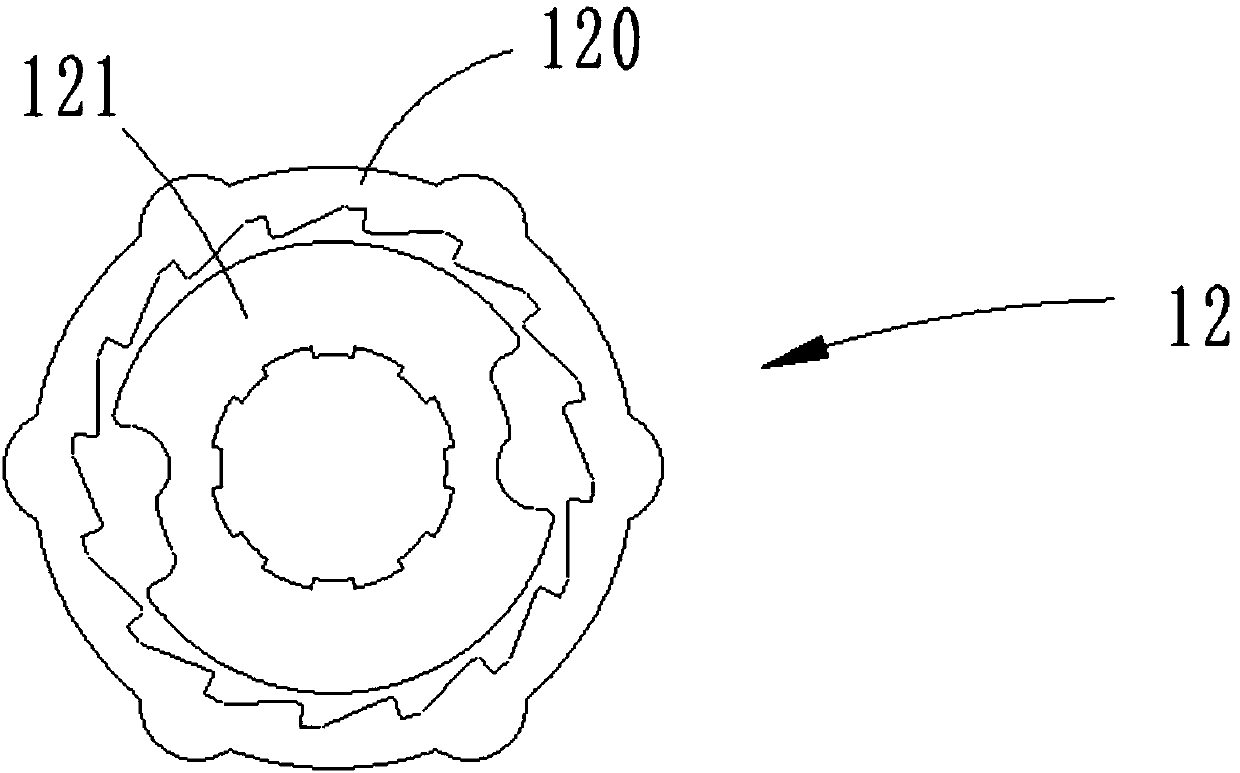

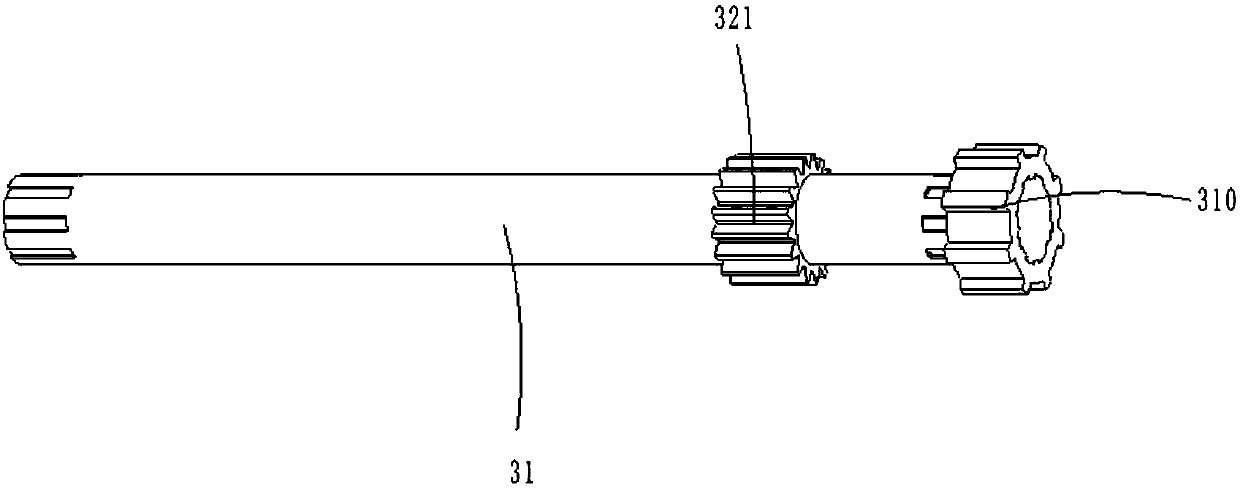

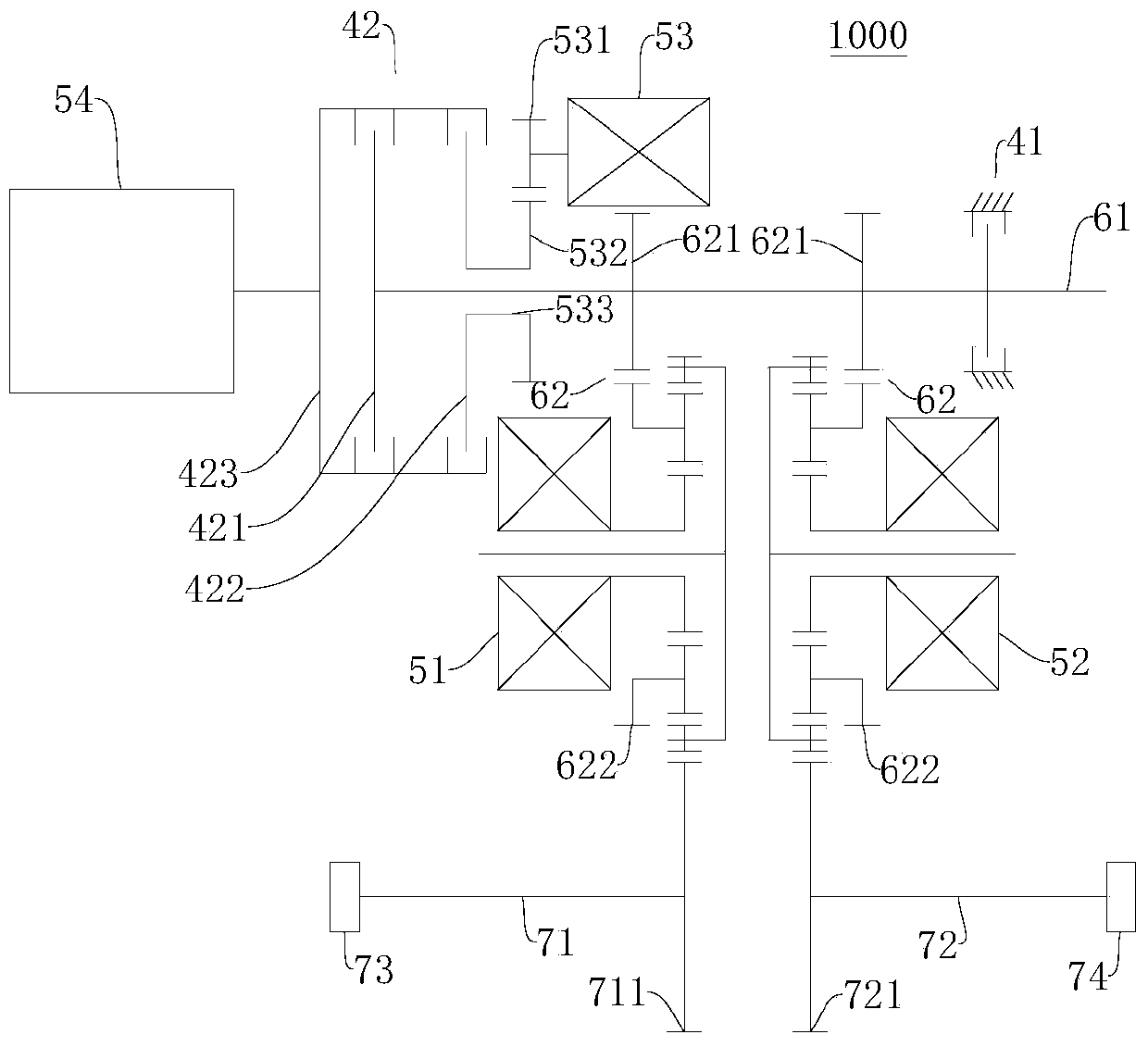

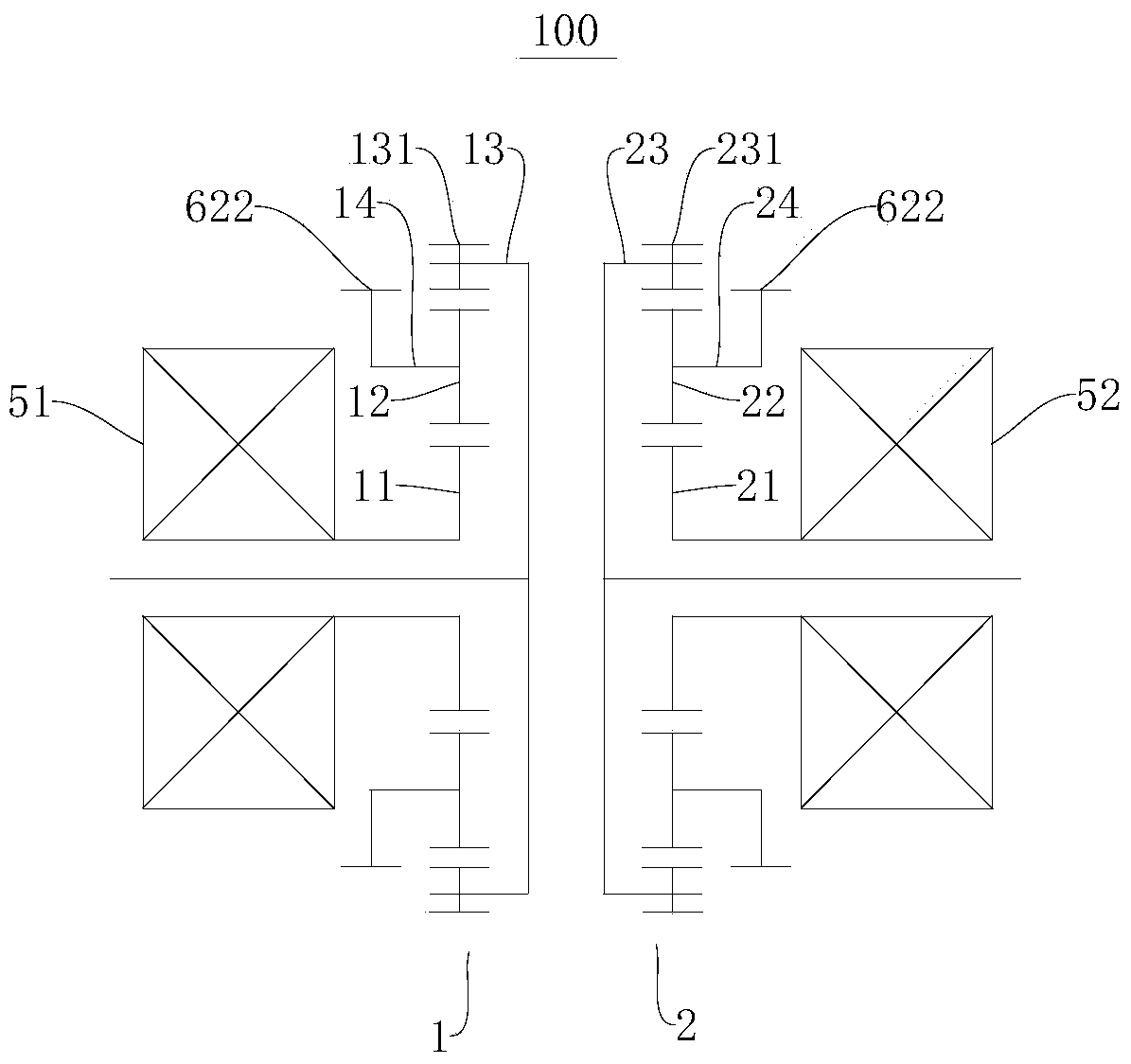

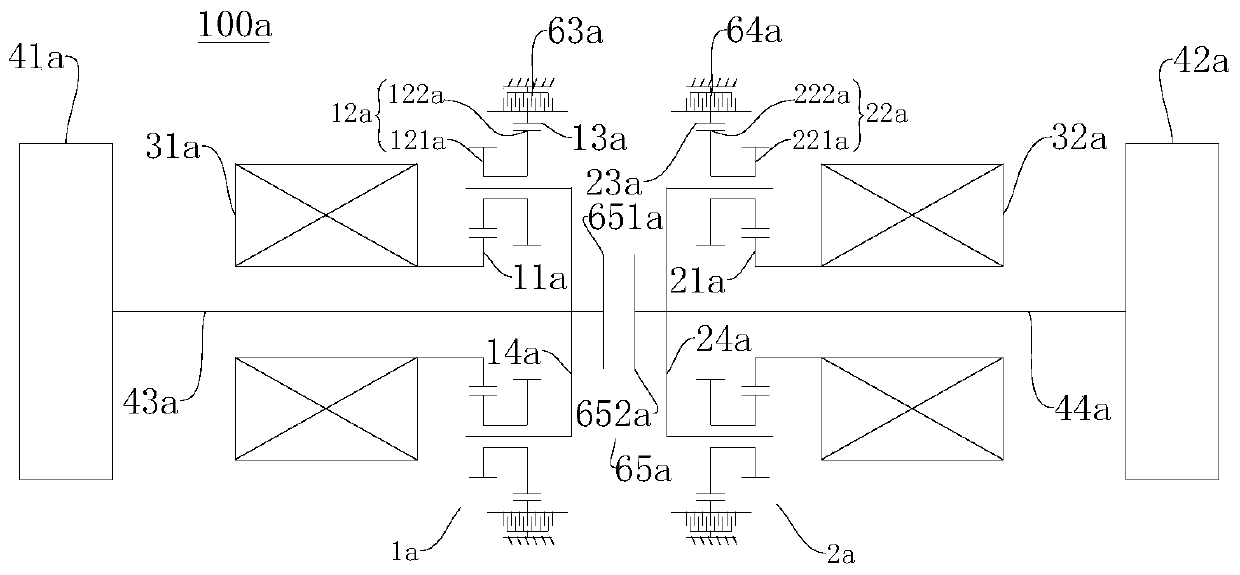

Provided are a power drive system (1000) and a vehicle (10000); the power drive system (1000) comprises: a power coupling device (100), said power coupling device (100) comprising: a first sun gear (11), first planetary carrier (14), and first ring gear (13), and a second sun gear (21), second planetary carrier (24), and second ring gear (23); the first ring gear (13) and second ring gear (23) are coaxially connected; an intermediate shaft (61), said intermediate shaft (61) being configured to move concomitantly with the first ring gear (13) and second ring gear (23); an engine (54), said engine (54) being configured to selectably engage with the intermediate shaft (61); a first electric motor generator (51), second electric motor generator (52), and third electric motor generator (53); the first electric motor generator (51) moves concomitantly with the first sun gear (11), the second electric motor generator (52) moves concomitantly with the second sun gear (21), and the third electric motor generator (53) is configured to selectably move concomitantly with the engine (54); a first braking device (41) which directly or indirectly brakes the intermediate shaft (61). The power drive system (1000) achieves a differential function in a situation without a conventional mechanical differential, and also has an abundance of drive modes.

Owner:BYD CO LTD

Hybrid power transmission system of vehicle

PendingCN112124065AFew partsCompact structurePropulsion using engine-driven generatorsGas pressure propulsion mountingEpicyclic gearingNew energy

The invention discloses a hybrid power transmission system of a vehicle, and relates to the technical field of automobile new energy. A main body of the hybrid power transmission system is equipped with an input component, wherein the input component is equipped with two groups of planetary gear sets and two groups of wheels; and two groups of the planetary gear sets are separately connected ontotwo wheels to realize independent drive control, on the wheels, of the planetary gear sets and a differential travelling process of the two wheels without mounting a differential; and therefore, partsare relatively reduced, production cost is relatively reduced, and economic benefits are higher.

Owner:花潍

Power driving system and vehicle with same

ActiveCN106555850ARealize the differential functionCompact structureDifferential gearingsDifferential functionControl theory

The invention discloses a power driving system and a vehicle with the same. The power driving system comprises a differential, a power output shaft, multiple input shafts, and a first electric generator, wherein the differential includes first and second planet racks, first and second planet gears, and first and second gear rings; the first and second planet gears are respectively arranged on the first and second planet rack, and are respectively engaged with the first and second gear rings; the second planet gear is engaged with the first planet gear; the first planet gear and the second planet gear are different in revolving radius; the power output shaft is linked with a power input end of the differential; each input shaft is linked with a power output shaft; and the first electric generator is linked with one of the multiple input shafts. The differential of the power driving system uses a planet differential principle for realizing a differential function, and is compact and simple in structure.

Owner:BYD CO LTD

Bicycle double front wheel drive device

ActiveCN106005214BCompact structureEasy to installWheel based transmissionRider propulsionDrive shaftFront-wheel drive

The invention relates to a dual front wheel driving device for a bicycle. The dual front wheel driving device comprises a left-front wheel mechanism, a right-front wheel mechanism, a left-front wheel driving device and a right-front wheel driving device, wherein the left-front wheel driving device is connected with the right-front wheel driving device through an intermediate shaft sleeve; the left-front wheel driving device comprises a left treading crank and a left driving shaft; a planetary transmission is arranged on the left driving shaft; the left treading crank comprises a left treading shaft, a first crank and a second crank; a first spline is arranged at the free tail end of the first crank; a second spline matched with the first spline is arranged at one end of the left driving shaft; a third spline matched with the first spline is arranged at one end of a planet frame; the structure of the right-front wheel driving device is identical with that of the left-front wheel driving device. According to the dual front wheel driving device for the bicycle, disclosed by the invention, the structure is compact, the convenience in mounting is realized, and variable speed and differential speed can be realized.

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

Power drive system and vehicle with the power drive system

ActiveCN106915249BRealize the differential functionRich transmission modeHybrid vehiclesGas pressure propulsion mountingPower couplingControl theory

The invention discloses a power driving system and a vehicle. The power driving system comprises a power coupling device, an immediate shaft, an engine, a first electric power generator, a second electric power generator, a third electric power generator and a first brake device, wherein the power coupling device comprises a first sun gear, a first planet carrier, a first gear ring, a second sun gear, a second planet carrier and a second gear ring; the immediate shaft is arranged to be linked with the first planet carrier and the second planet carrier; the engine is arranged to be selectively jointed with the immediate shaft; the first electric power generator is linked with the first sun gear; the second electric power generator is linked with the second sun gear; the third electric power generator is arranged to be selectively linked with the engine; and the first brake device is used for directly or indirectly braking the immediate shaft. The power driving system has the advantages that a differential function is realized on the premise of eliminating the traditional mechanical differential mechanism and rich transmission modes are also realized.

Owner:BYD CO LTD

Limited slip differential, control system and control method

PendingCN110081143AImprove powerImprove passabilityGearing controlDifferential gearingsFriction torqueLimited-slip differential

The invention discloses a limited slip differential, a control system and a control method. The problem that the performance of steering drive axles is limited by differentials in the prior art is solved, and the beneficial effect of improving the vehicle power performance and passing capability is achieved. According to the following technical scheme, the limited slip differential comprises a differential mechanism comprising a half shaft of which the end is matched with a planetary gear through a half shaft gear, and a limited slip mechanism comprising a compression piston arranged on the half shaft gear; the compression piston is telescopically arranged; the other end of the compression piston is fixed; a limited slip friction plate is arranged on one side of the compression piston; anoil hole is formed in the half shaft; and pressure oil can be supplied to the compression piston and pushes the compression piston to move, the limited slip friction plate is pressed, and then limitedslip friction moment is generated.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com