Dynamic coupling pure-electric drive axle and control method thereof

A pure electric drive and power coupling technology, applied in the direction of control devices, power devices, electric power devices, etc., can solve the problem of discounting the life of the hub motor in the cruising range of the car, increasing the unsprung mass, affecting the ride comfort, ride comfort and Handling stability and other issues to achieve the effect of improving vehicle economy, improving ride comfort, and reducing unsprung mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

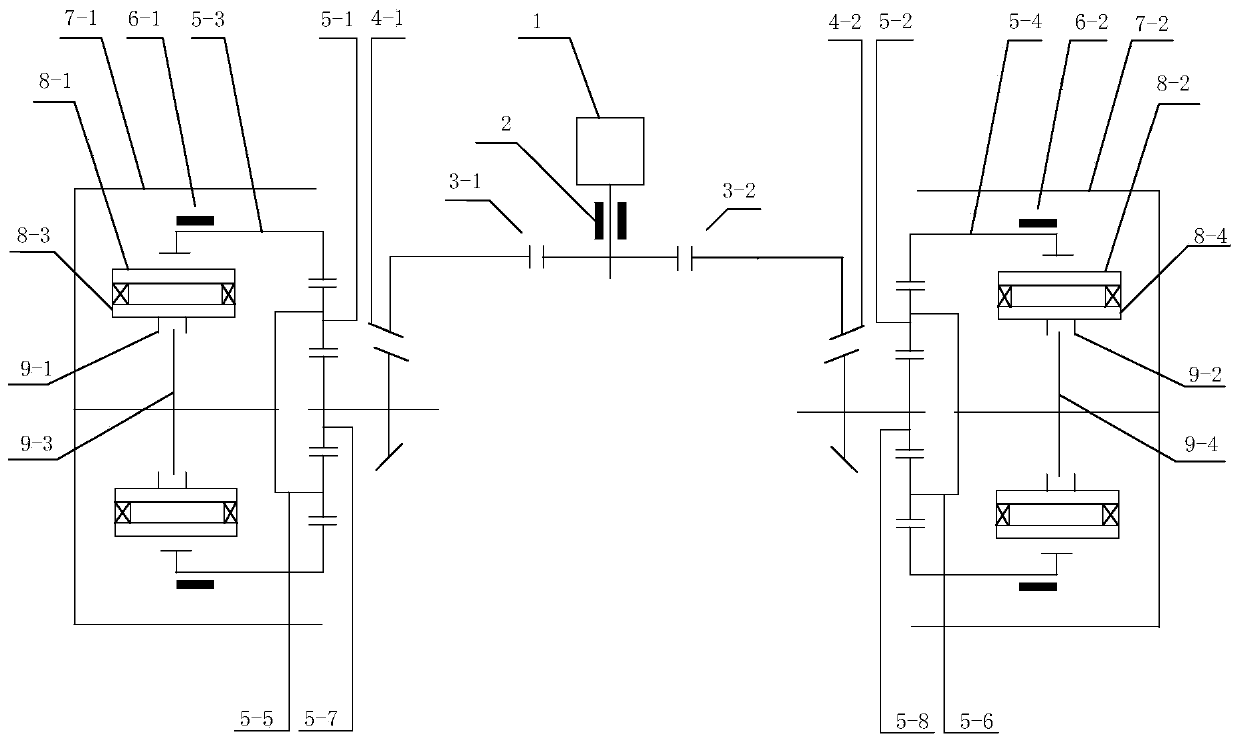

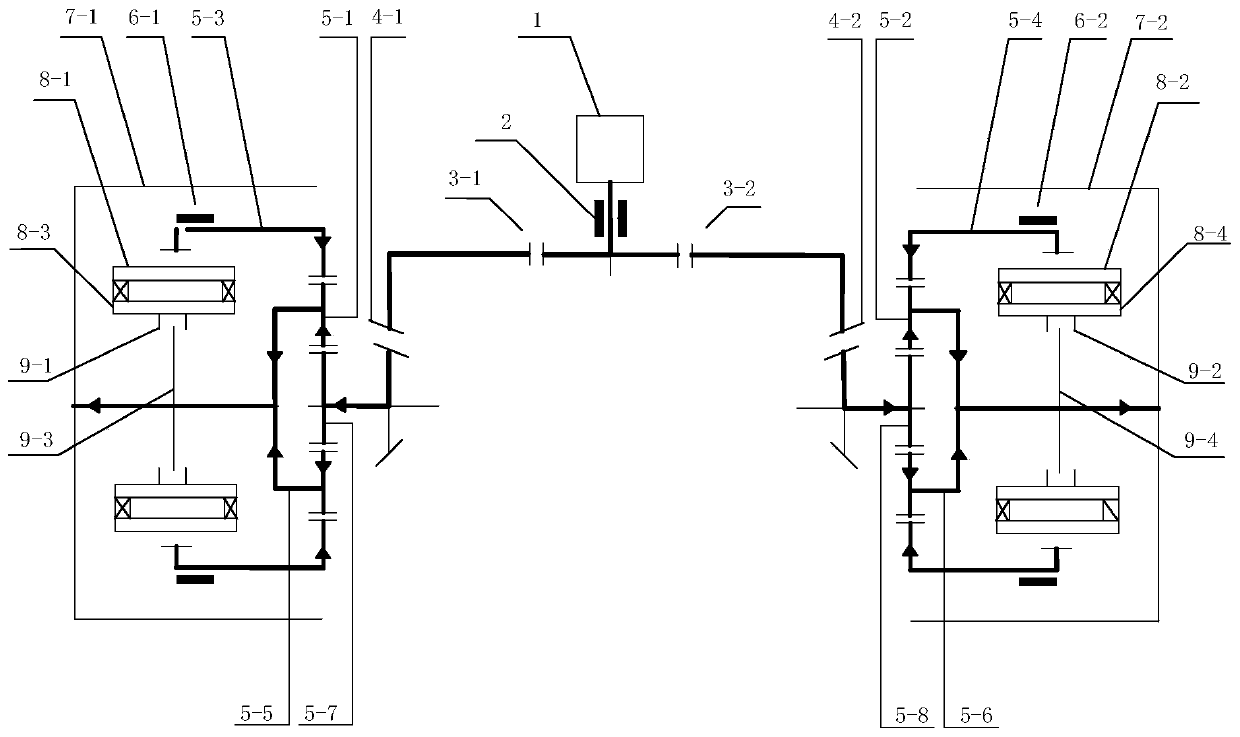

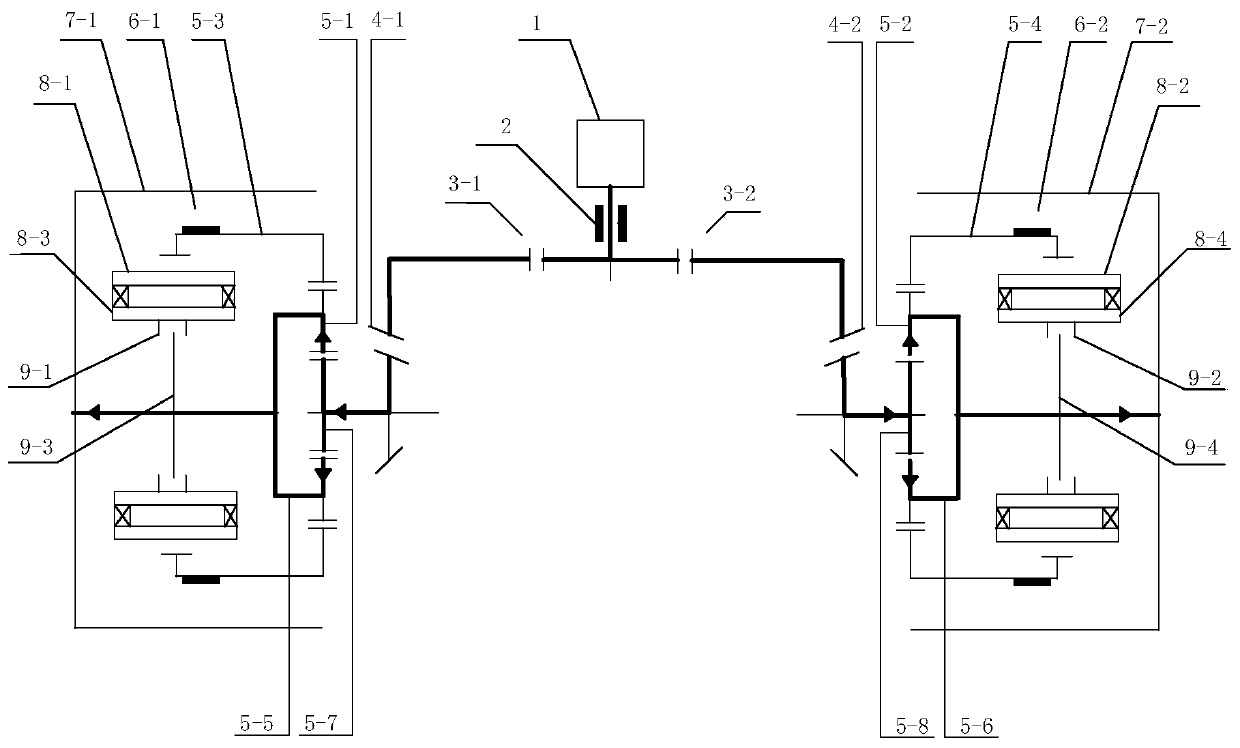

[0047] Left side: the output shaft of the central motor 1 is connected with the sun gear 5-7 of the left planetary mechanism 5 through the first brake 2, the fixed shaft transmission pair 3-1 and 4-1, and the rotor 8-1 of the left hub motor is connected with the The ring gear 5-3 of the left planetary mechanism 5 is connected, the second brake 6-1 can control the output of the ring gear 5-3 and the left hub motor, and the planet carrier 5-5 of the left planetary mechanism 5 passes through the left The power transmission shaft is connected with the rim 7-1, and the brake caliper 9-1 of the third brake 9 on the left is installed on the motor housing of the left hub motor 8, and the brake disc 9-3 is connected with the left power transmission shaft. Wherein the first brake can control the output of the central motor, the second brake 6-1 can control the output of the left ring gear and hub motor, and the third brake on the left can control the movement of the left wheel.

[0048] R...

Embodiment 2

[0114] Such as Figure 7 As shown: the difference between this embodiment and embodiment 1 is that the first brake 2 in embodiment 1 is removed, and at the transmission shaft between the sun gear of the planetary mechanism on the left and right sides and the fixed shaft gear transmission pair 4 A fourth brake 10 is added respectively. This embodiment can realize all the modes of Embodiment 1, and its specific working principle and speed ratio calculation are the same as those of Example 1, and will not be repeated here.

Embodiment 3

[0116] Such as Figure 8 Shown: this embodiment removes the structural principle diagram of the first brake 2 on the basis of embodiment 1.

[0117] In this embodiment, except that the in-wheel motor driving mode and the in-wheel motor regenerative braking mode in embodiment 1 cannot be realized, other modes in embodiment 1 can be realized by this mode, and its specific working principle and speed ratio calculation relationship are the same as Embodiment 1 is the same and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com