A self-propelled lawn mower

A lawn shearing and self-propelled technology, which is applied in the field of machinery, can solve the problems of large structural space, low operating performance, and increased weight, and achieve the effect of simple and compact structure, high operating stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The invention will now be described in further detail with reference to the drawings. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

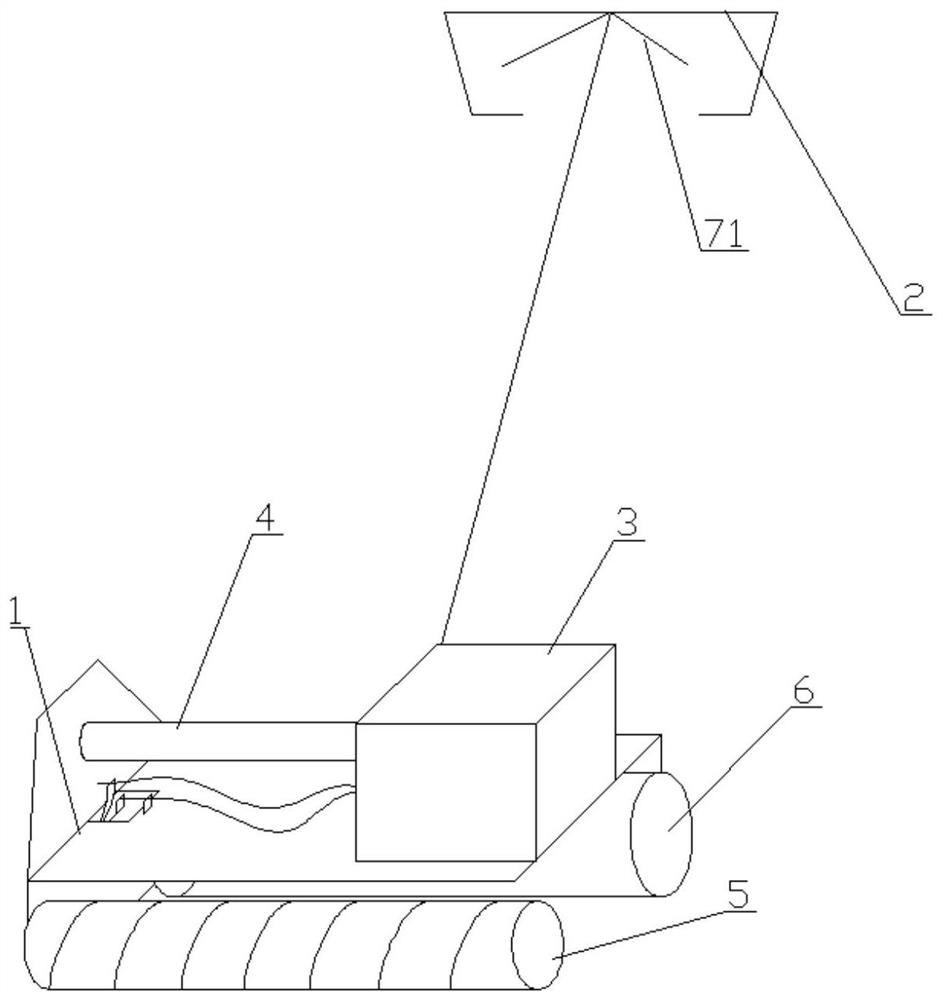

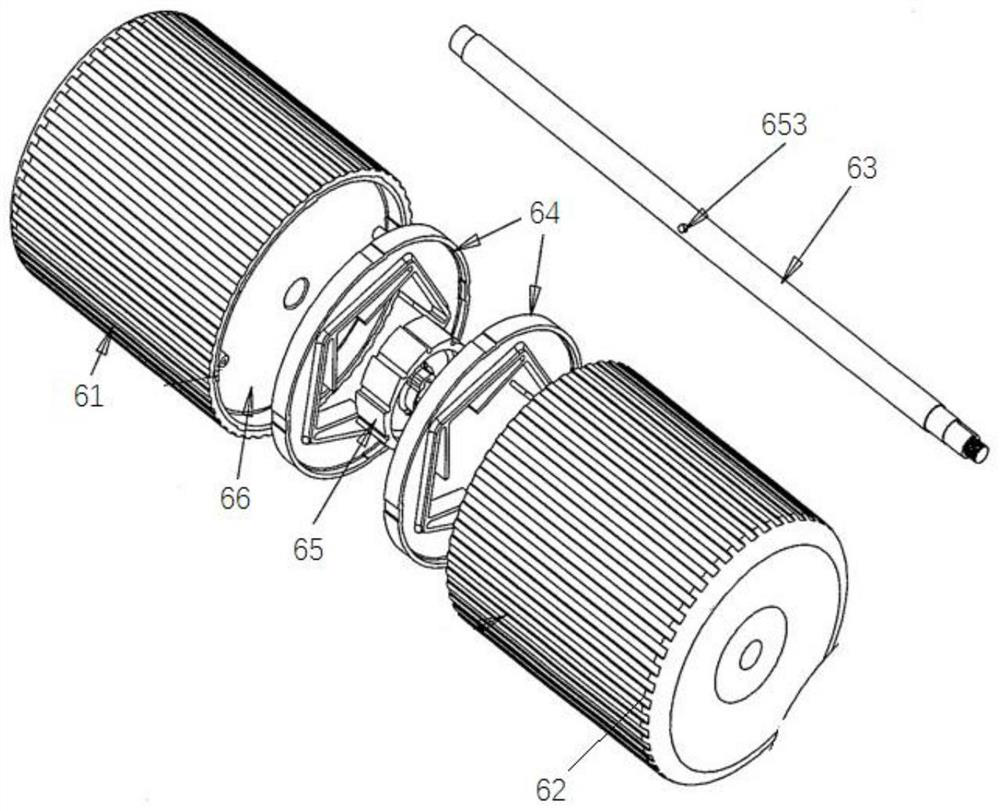

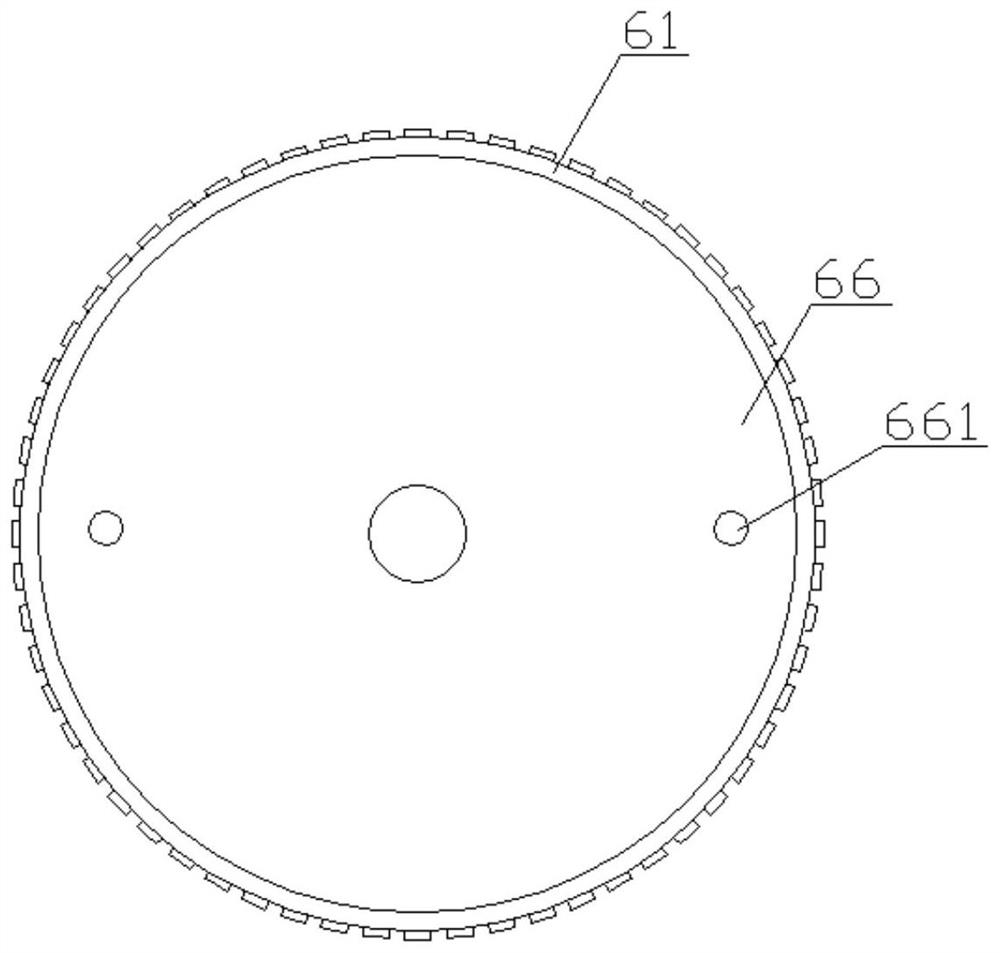

[0035]Such asfigure 1 ,figure 2 ,image 3 andFigure 4 As shown, a self-propelled lawn shear machine, including body 1, push hand 2, power device 3, power output shaft 4, shear wheel 5, and drive wheel 6, the power device 3 will power the power output shaft 4 Transmitted to the power control system, thereby driving the shear wheel 5 and the drive wheel 6, the drive wheel 6 includes a left drive wheel 61, a right drive wheel 62, and a drive shaft 63 through which the drive shaft 63 are connected to the power output. A differential is provided between the axis 4, and the two drive wheels; the differential includes two ring gear 64, the ratchet 65, the opposite end of the left drive wheel 61 and the right drive wheel 62 forming a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com