Limited slip differential, control system and control method

A limited-slip differential and limited-slip technology, applied in the transmission field to achieve the effect of improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

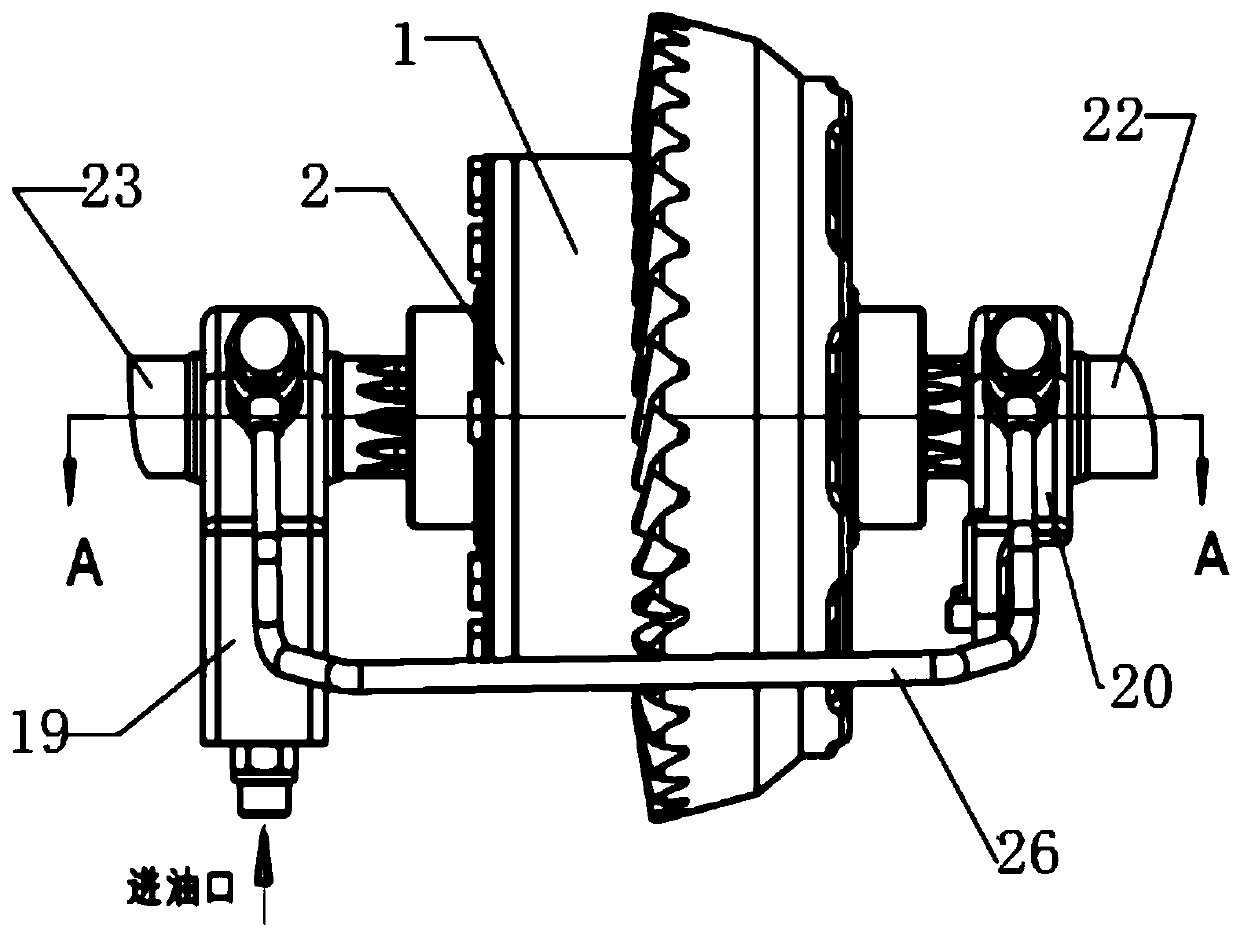

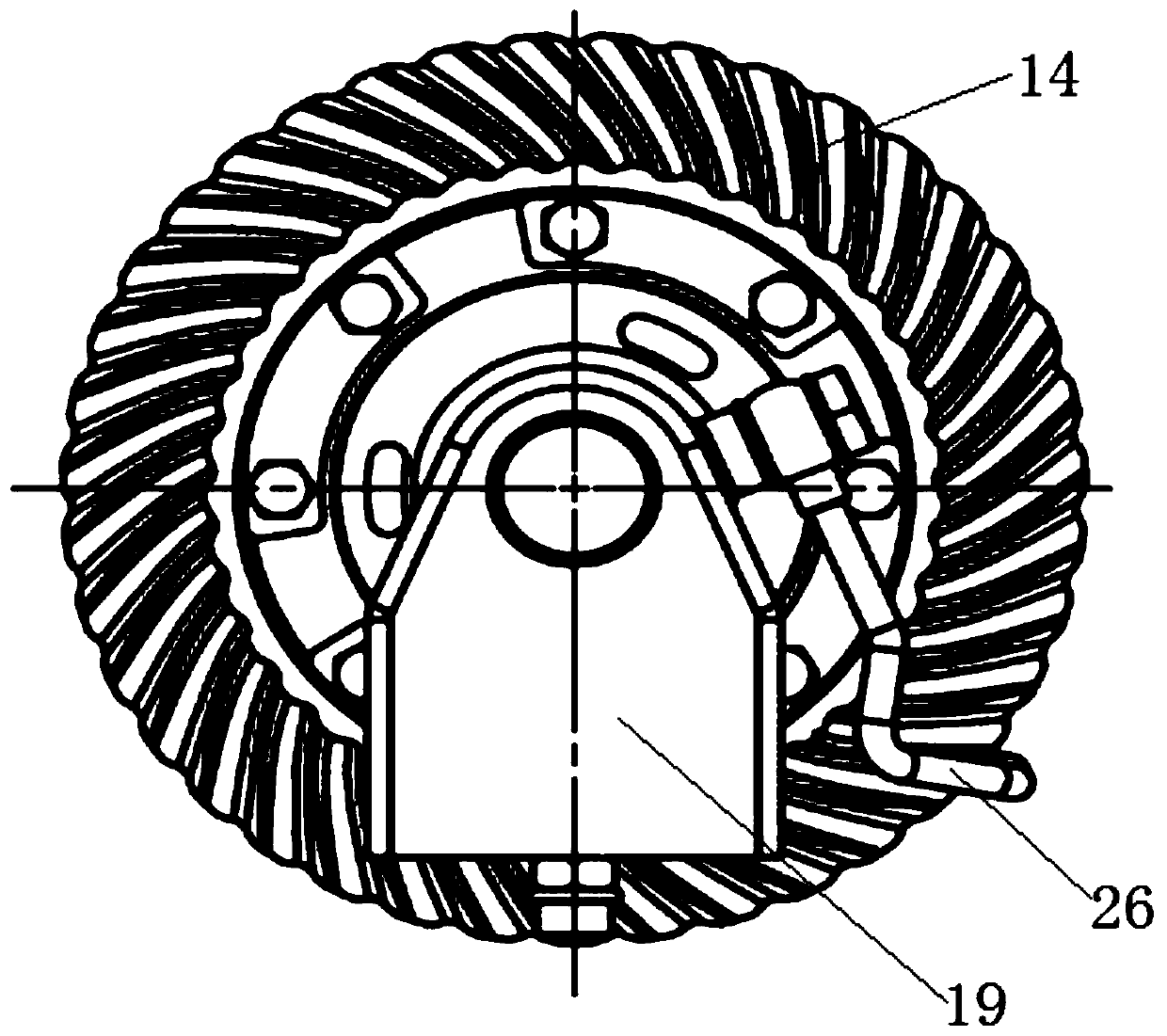

[0039] In a typical implementation of the present application, such as Figure 2-Figure 5 As shown, a limited-slip differential includes a differential mechanism, including a half shaft, and the end of the half shaft cooperates with the planetary gear 6 through the side gear 5, and the side gear 5 passes through the side shaft and the side gear thrust pad 4 Installed in the side gear mounting hole of the differential housing, the planetary gear 6 is installed in the planetary gear mounting hole of the differential housing through the planetary gear shaft and the star gear thrust pad 3; The compression piston 9 of the half shaft gear is telescopically arranged, and the other end of the compression piston 9 is fixed, and a limited-slip friction plate 10 is arranged on one side of the compression piston, and an oil hole is arranged in the half shaft, which can discharge the pressure oil It is supplied to the compression piston 9, and the pressure oil pushes the compression piston...

Embodiment 2

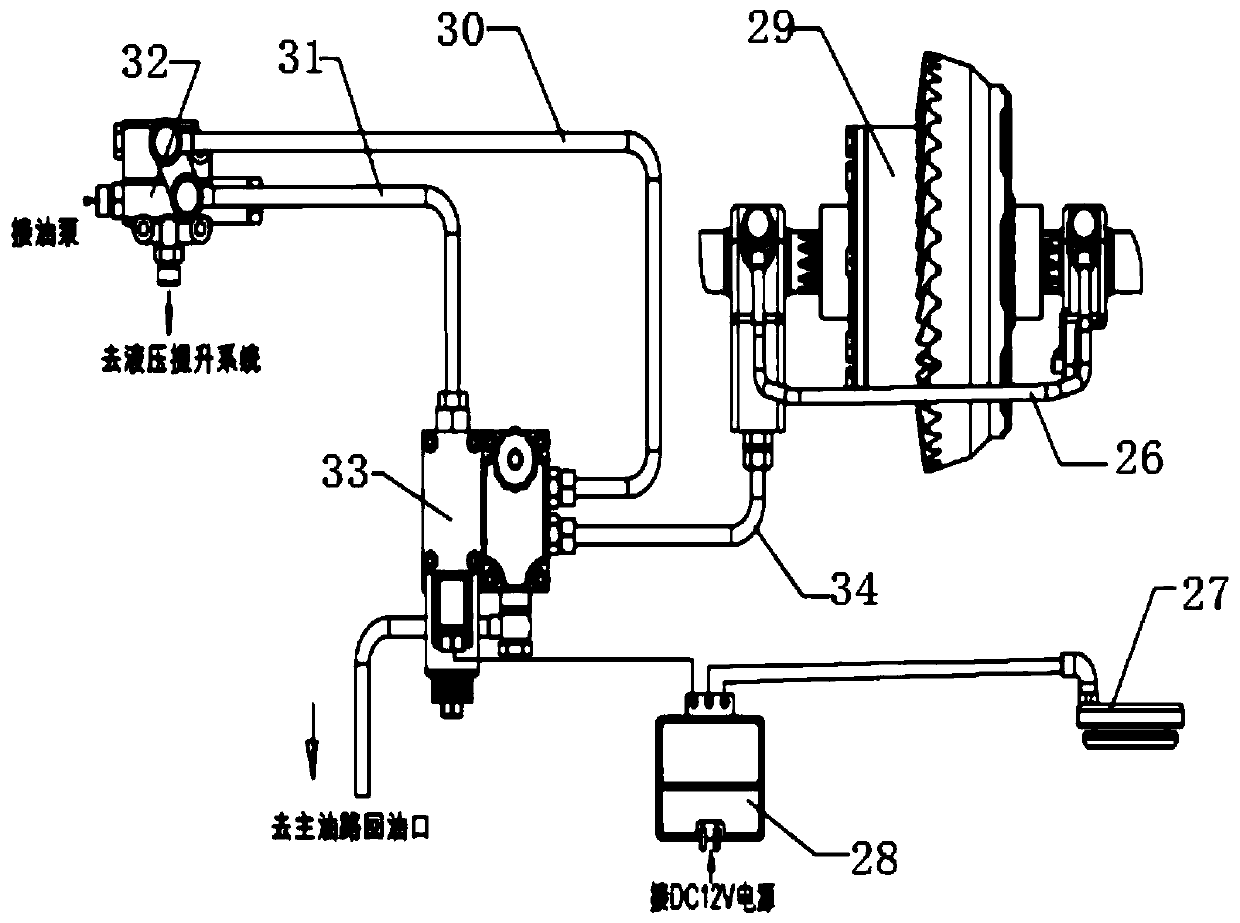

[0049] A limited slip differential control system such as figure 1 shown, including:

[0050] A limited-slip differential 29 described in Embodiment 1;

[0051] The controller is connected with the steering sensor provided on the vehicle, and the controller is connected with the oil pump, and the oil pump is connected with the oil hole of the half shaft.

[0052] The above-mentioned control system realizes the electro-hydraulic control of the differential. The controller is a PLC controller 28, an electro-hydraulic control combination valve 33 and a load-sensing priority valve 32. The load-sensing priority valve 32 is separately connected to the oil pump and the hydraulic lifting mechanism. And through the preferential distribution oil pipe 31 and the pressure feedback oil pipe 30, the electro-hydraulic control combination valve 33 is connected, the driver 28 controls the electro-hydraulic control combination valve 33, and the electro-hydraulic control combination valve 33 is...

Embodiment 3

[0054] A control method for a limited-slip differential control system, comprising the following content:

[0055] When the steering sensor detects that the vehicle has turned over a valid angle, it sends a signal to the controller;

[0056] The controller controls the pressure oil to be sent into the main oil circuit through the oil pump, and the differential mechanism realizes the differential speed. When the steering knuckle turns over the effective angle, the steering sensor sends a signal to the drive controller, and the drive controller sends an instruction to disconnect the control circuit, so that the electric Hydraulic control combined valve reversing, so as to control the flow of hydraulic oil.

[0057] When the steering sensor does not detect that the vehicle has turned over an effective angle, the controller controls the oil pump to send pressure oil to the limited slip mechanism, and the pressure oil from the electro-hydraulic control combination valve is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com