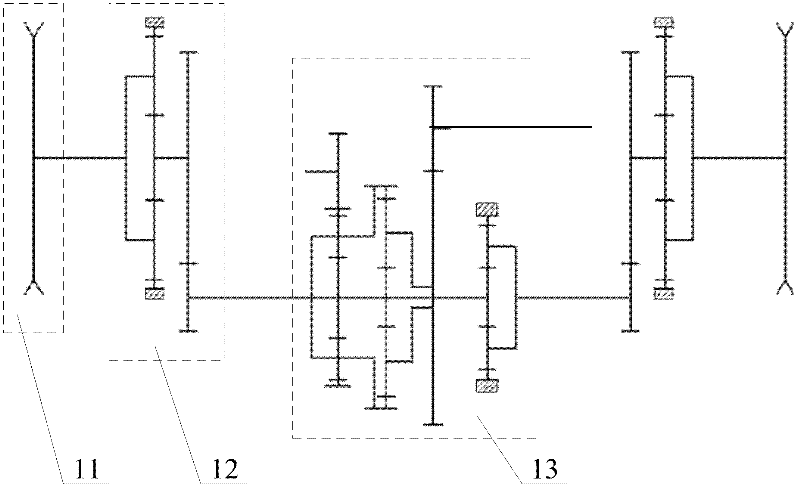

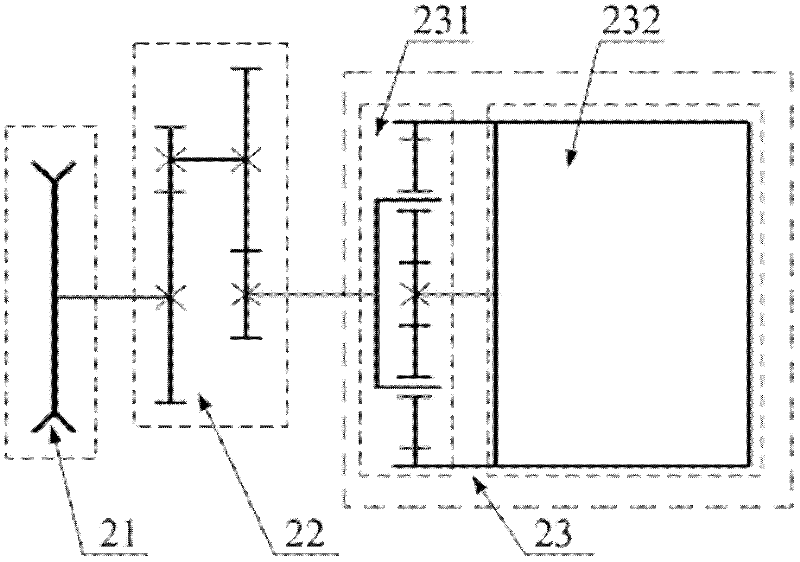

Hybrid bulldozer and power system thereof

A hybrid and power system technology, applied in hybrid vehicles, mechanically driven excavators/dredgers, motor vehicles, etc., can solve the problems of large occupied space, complex structure, complex structure of bulldozer power system, etc. The use of components, the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

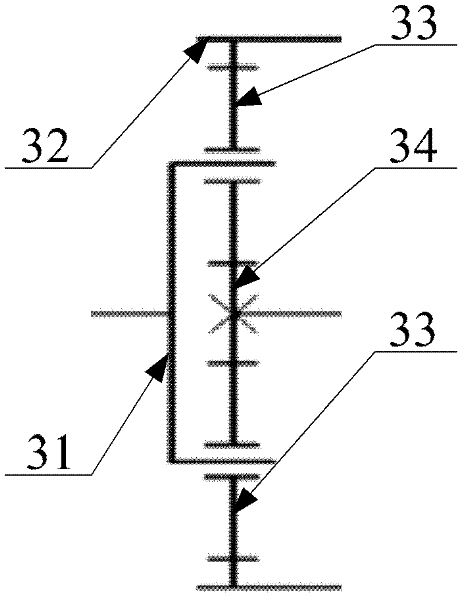

Embodiment Construction

[0040] For reference and clarity, the technical terms involved in the present invention are now explained as follows:

[0041] Hybrid Bulldozer: A new type of energy-saving bulldozer whose travel is driven by a motor rather than directly from an engine. The electrical energy required for the motor to work comes from the power generation system of the onboard engine.

[0042] Traveling device: It is composed of drive sprocket, guide wheel, supporting wheel, support sprocket and track, and converts the drive torque and rotational motion transmitted from the transmission system to the drive sprocket into the driving force required for the vehicle to work and travel and speed.

[0043] Final drive: It is an important part of the traditional bulldozer transmission system. It integrates the two-stage reduction mechanism and the bulldozer drive sprocket to realize the function of deceleration and torque increase to meet the needs of walking and various operating conditions.

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com