Device and method for recovery and reliquefaction of boil-off gas of liquefied natural gas

A technology of liquefied natural gas and boil-off gas, applied in gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problems of surrounding environmental pollution, waste of energy economy, loss, etc., to achieve good operation reliability and eliminate energy waste , the effect of simplifying the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

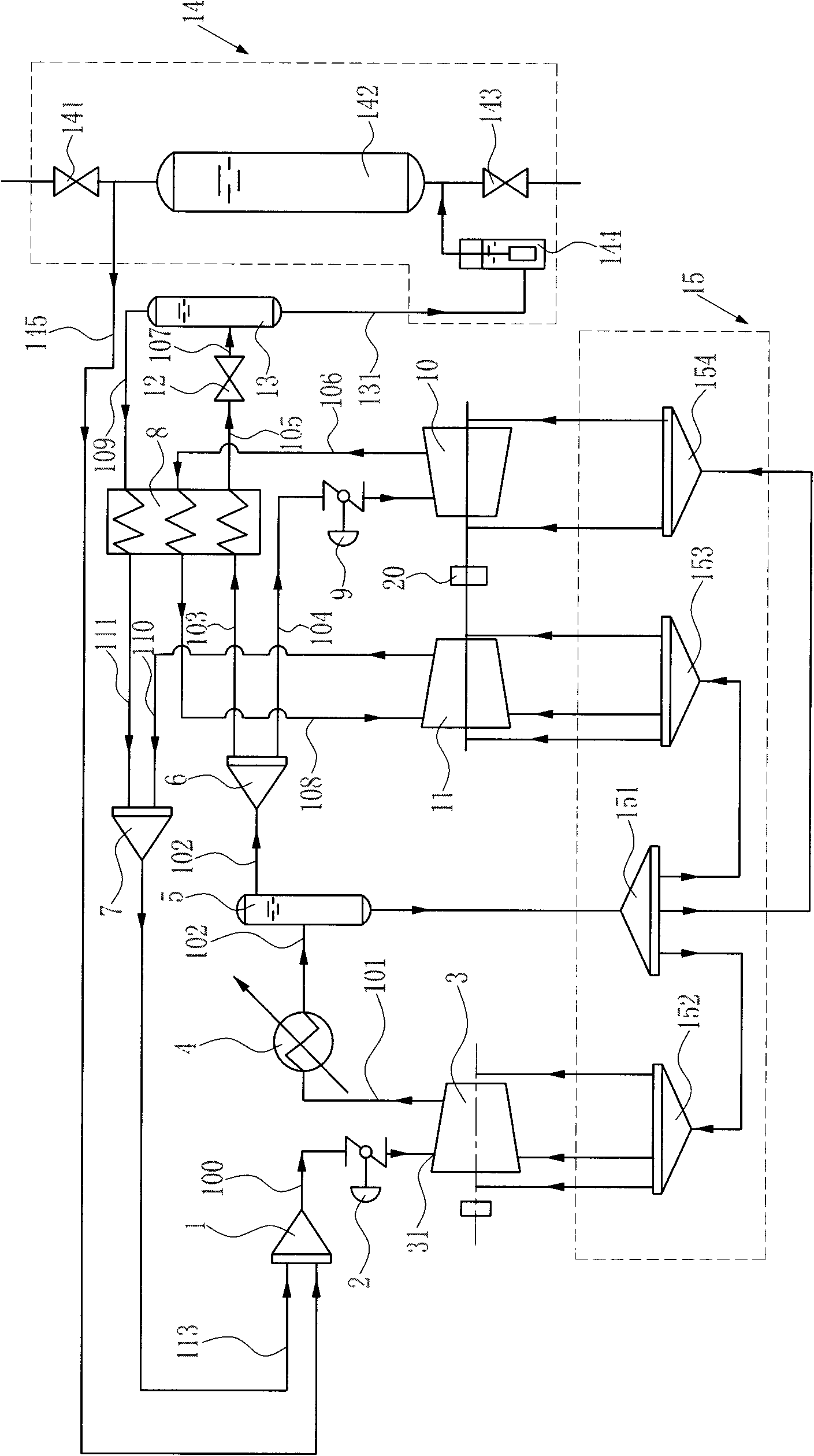

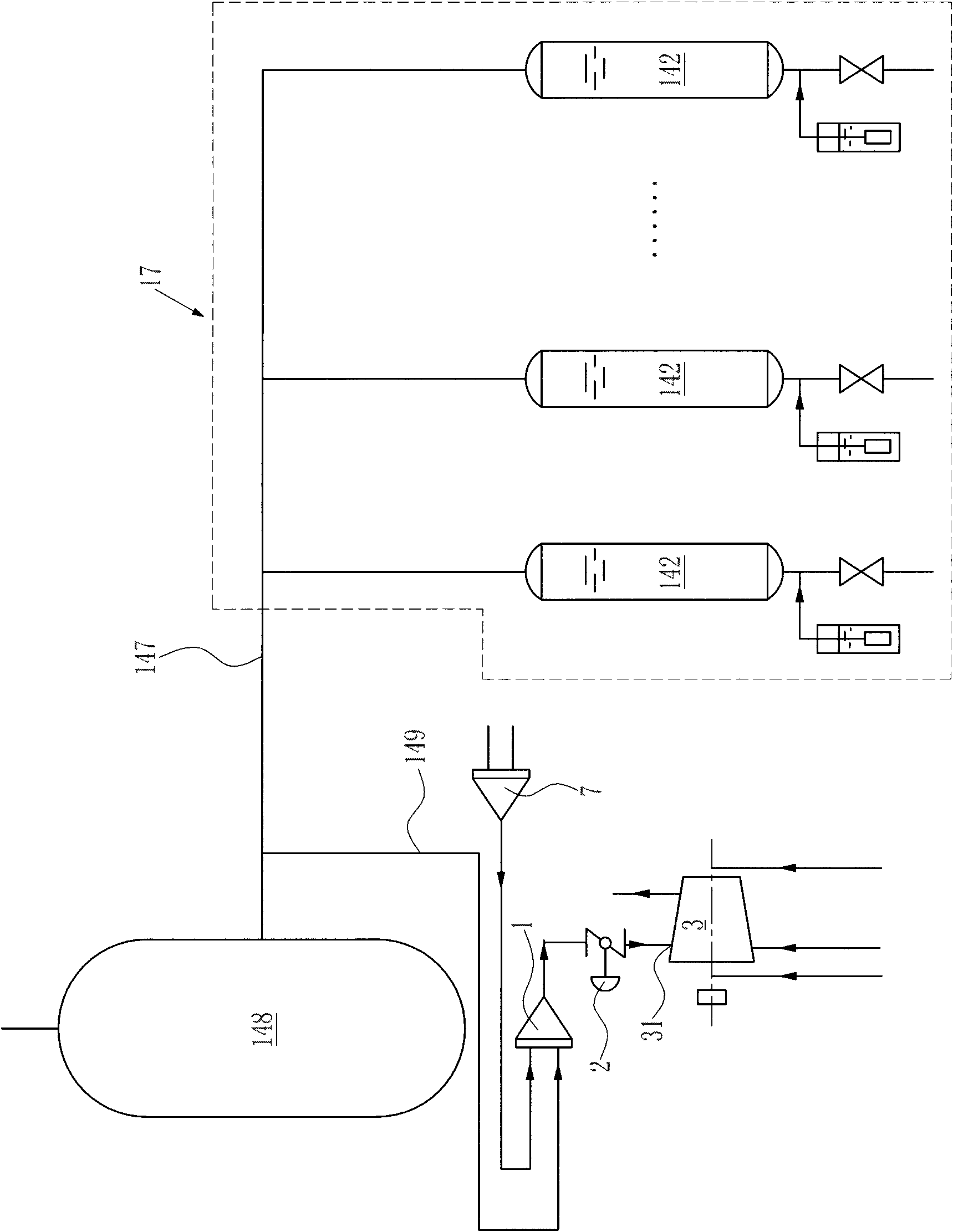

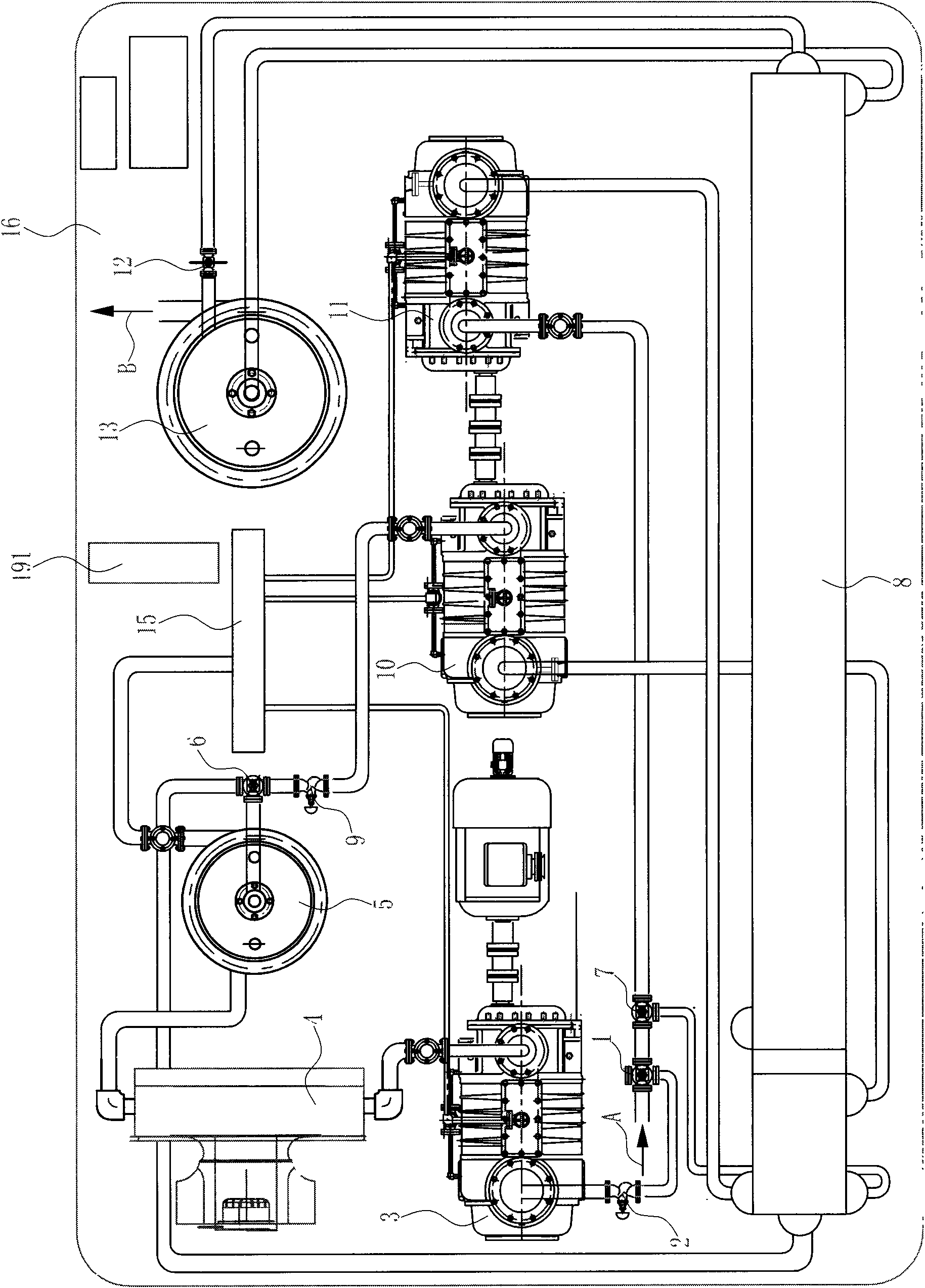

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] Figure 1 to Figure 3 Two embodiments of the present invention are shown, which include a LNG storage tank device 14 (or a LNG storage tank area device 17), a first boil-off gas (BOG) combiner 1, and a recovery compressor with a pressure control valve 2 3. The recovery compressor is a single-stage screw compressor, cooler 4, oil-gas separator 5, boil-off gas (BOG) distributor 6, second boil-off gas (BOG) confluence 7, plate-fin heat exchanger 8, Butterfly speed control valve 9, a refrigeration unit coaxially linked by a screw expander 10 and a second screw compressor 11, a throttle valve 12, a gas-liquid separator 13, and a cooling and lubricating system 15; a complete set of components composed of the above components Except for the liquefied natural gas storage tank device 14, they are all installed on a common skid-mounted frame bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com