Special claw type rotor profile

A rotor profile and special claw technology, applied in the direction of rotary piston pump, rotary piston machine, rotary piston/oscillating piston pump components, etc., can solve the problem of low pumping speed, poor practical performance and low volume utilization coefficient And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

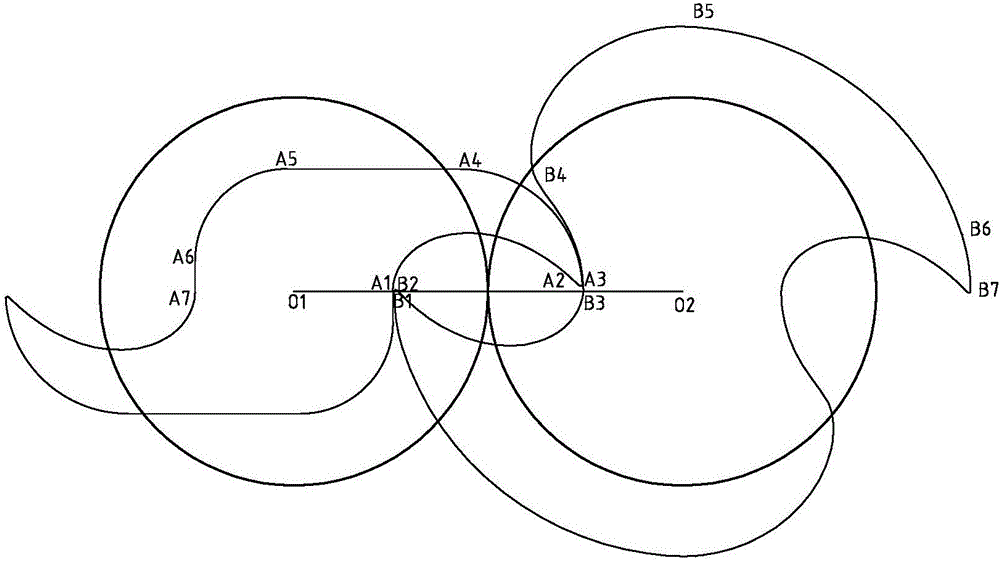

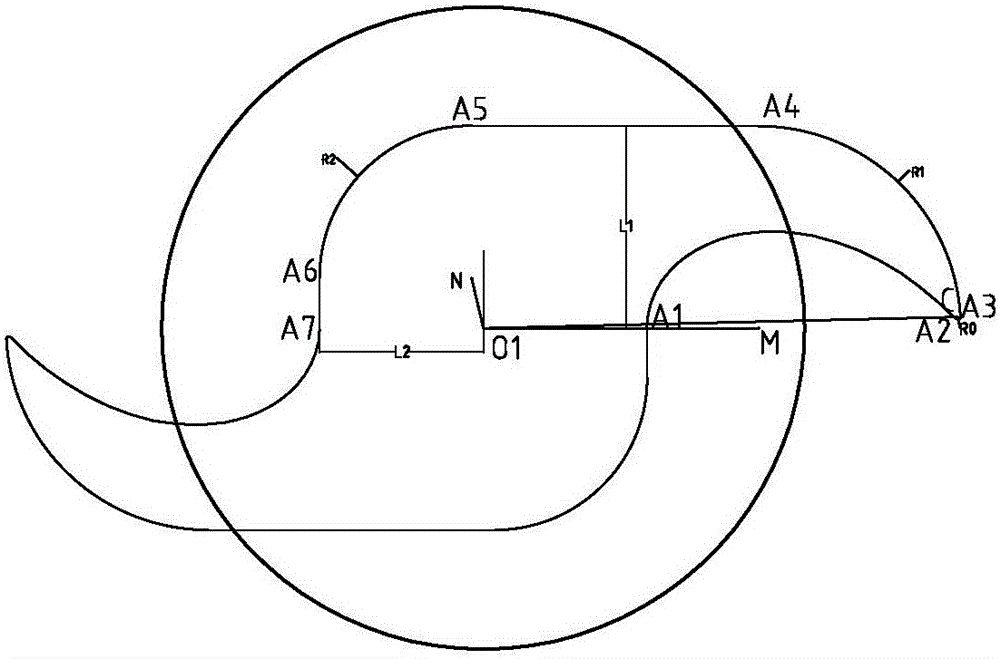

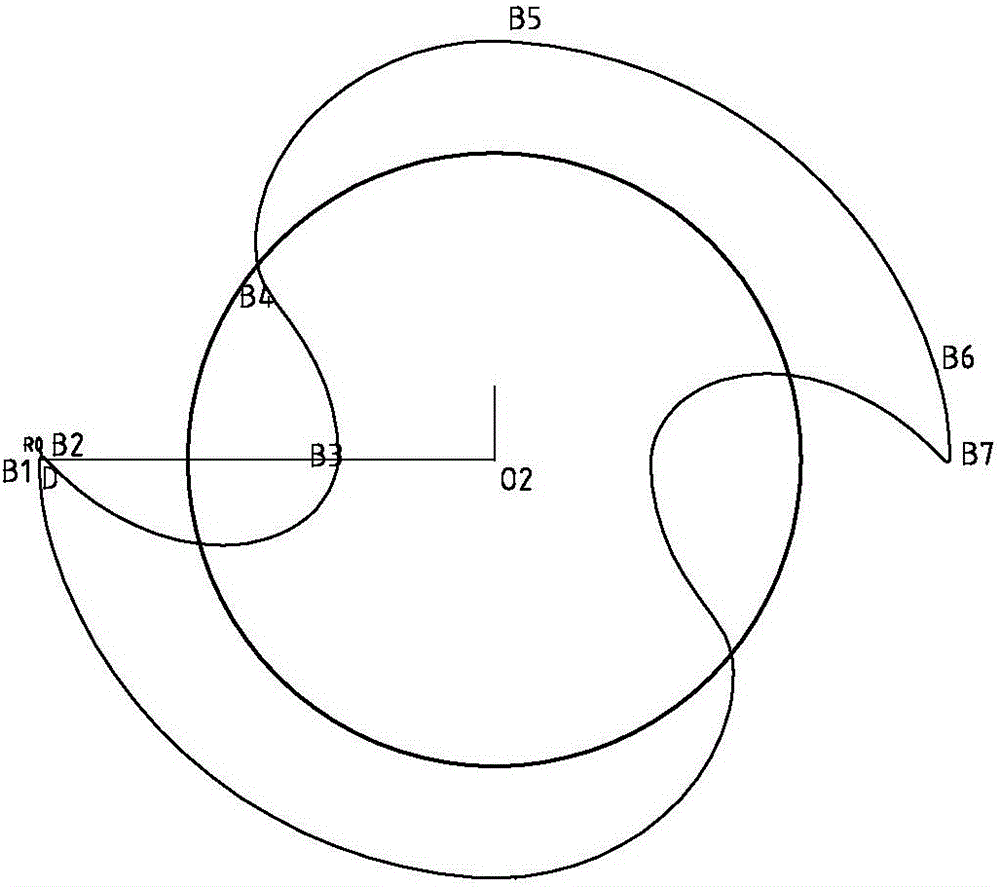

[0056] like Figure 1-Figure 4 As shown, the profile of the special claw rotor in the present invention is characterized in that it includes a special claw rotor A and a special claw rotor B that are meshed, and both the special claw rotor A and the special claw rotor B are centrally symmetrical structure; the special claw rotor A described by the arc R 0 Curve conjugate curve A1A2, arc one A2A3, arc two A3A4, straight line A4A5, arc three A5A6 and straight line two A6A7 six-segment lines; the special claw rotor B is composed of arc R 0 Curve B1B2, arc-conjugate curve B2B3, arc-two-conjugate curve B3B4, straight-line-conjugate curve B4B5, arc-three-conjugate curve B5B6 and straight-line two-conjugate curve B6B7 six-segment line.

[0057] The arc R 0 Curve conjugate curve A1A2 is centered on the center point of the special claw rotor A, and the arc R of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com