Modular integrated multi-stage and multi-drive chamber partially non-coaxial dry type vacuum single pump

一种驱动腔、多驱动的技术,应用在用于弹性流体旋转活塞式/摆动活塞式的泵组合、旋转活塞式/摆动活塞式的泵部件、旋转活塞式泵等方向,能够解决难以实现节能环保等问题,达到便于维护和洗涤、泵腔容积大、转子结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

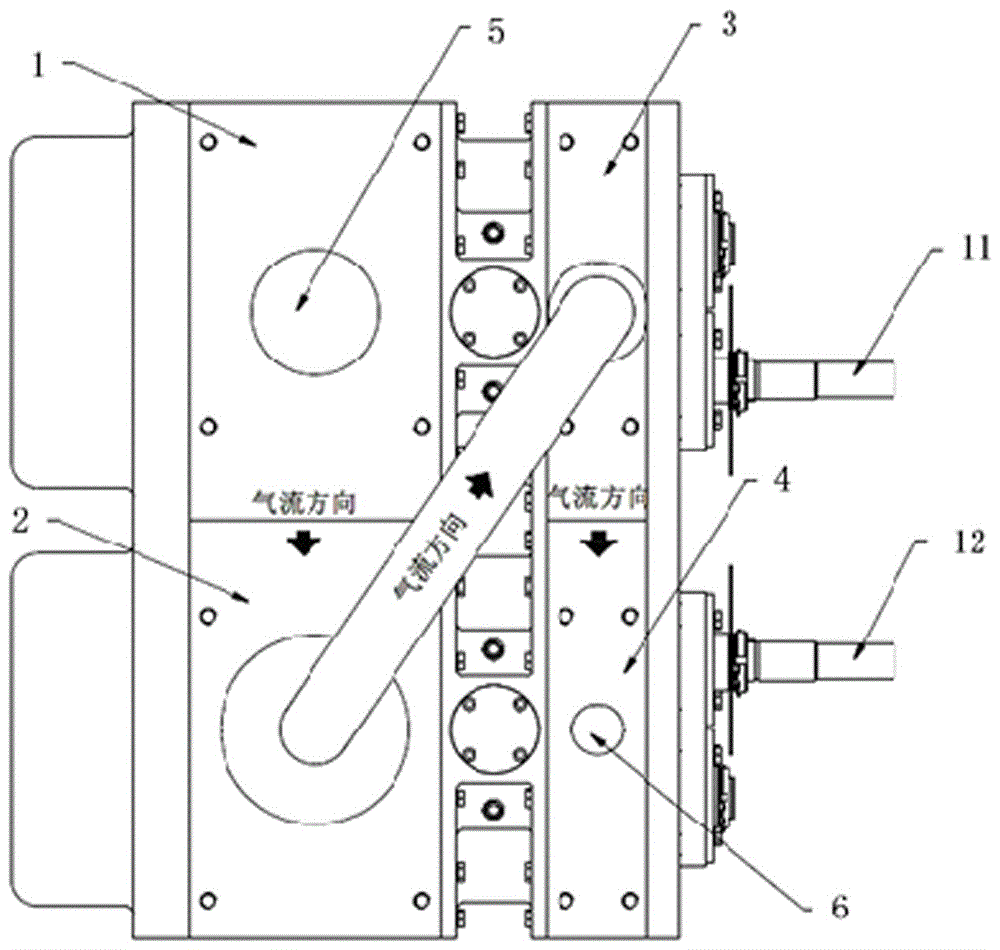

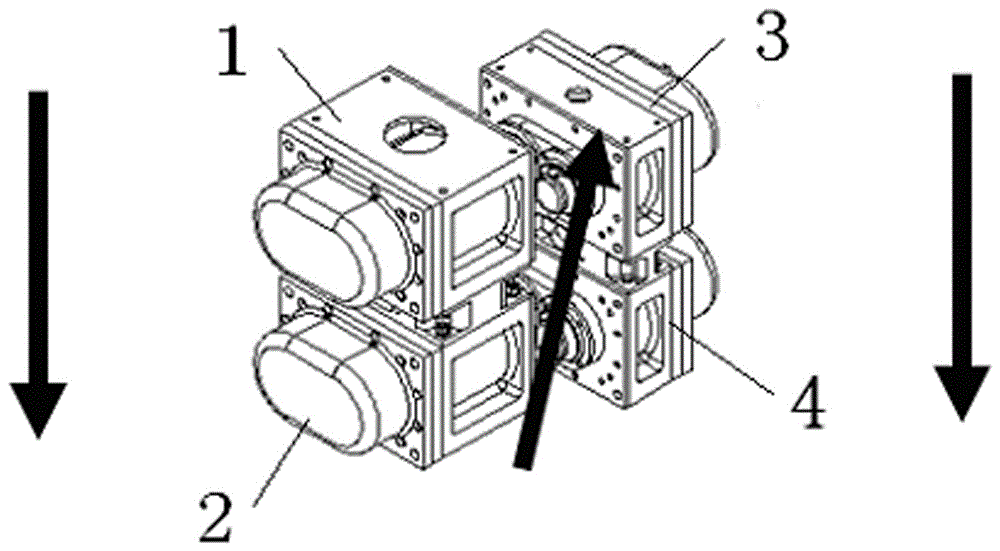

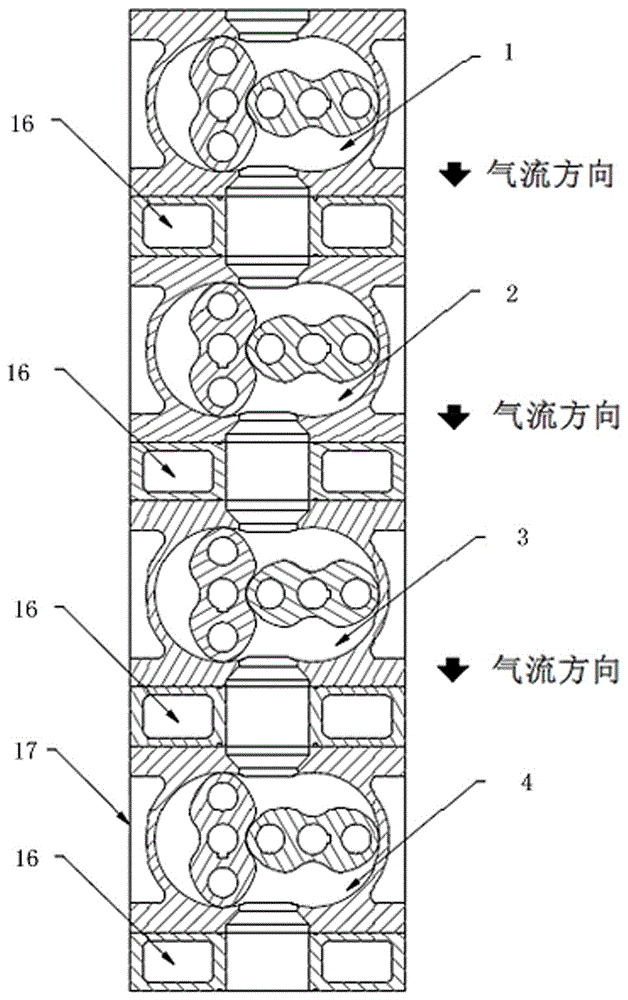

[0042] The present invention is a modular one-piece multi-drive chamber partial non-coaxial vacuum single pump (including multi-drive chamber incomplete coaxial vacuum pump, that is, some drive chambers may be coaxial, but not all drive chambers are coaxial). To achieve a higher vacuum, an independent vacuum pump must perform multi-stage continuous compression of the gas to achieve it. According to the gas balance equation, P 1 V 1 =P 2 V 2 =P 3 V 3 =P 4 V 4 , if at this time P 1 Represents the atmospheric pressure of 1013mbar, P 4 It is a high vacuum of 1mbar at the suction port. If it is realized by one-stage compression, the actual gas compression amount is about 1013 times, and then according to the formula of air compression temperature rise: T 1 = T 2 *(P 2 / P 1 ) 0.286 If calculated, the temperature rise may reach 7.2 times. At this time, the temperature of the exhaust port will reach 1800°, which is obviously not allowed. So like a dry screw pump with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com