Space strontium optical clock built-in vacuum high-temperature evaporation source device

A high-temperature evaporation, strontium optical clock technology, applied in electric furnace heating, furnace type, furnace and other directions, can solve the problems of large volume, poor thermal insulation performance, high power consumption, and achieve the effect of small size, improved thermal insulation performance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

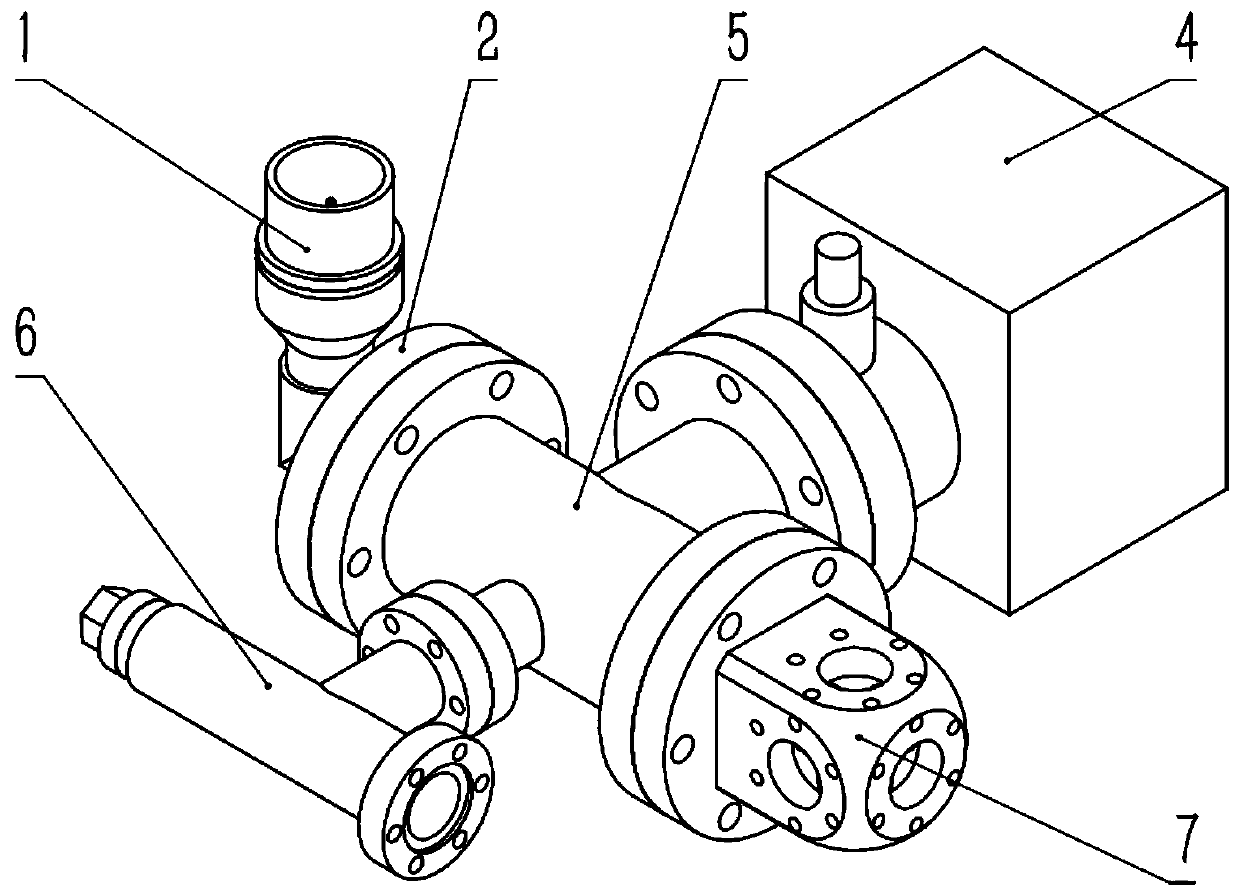

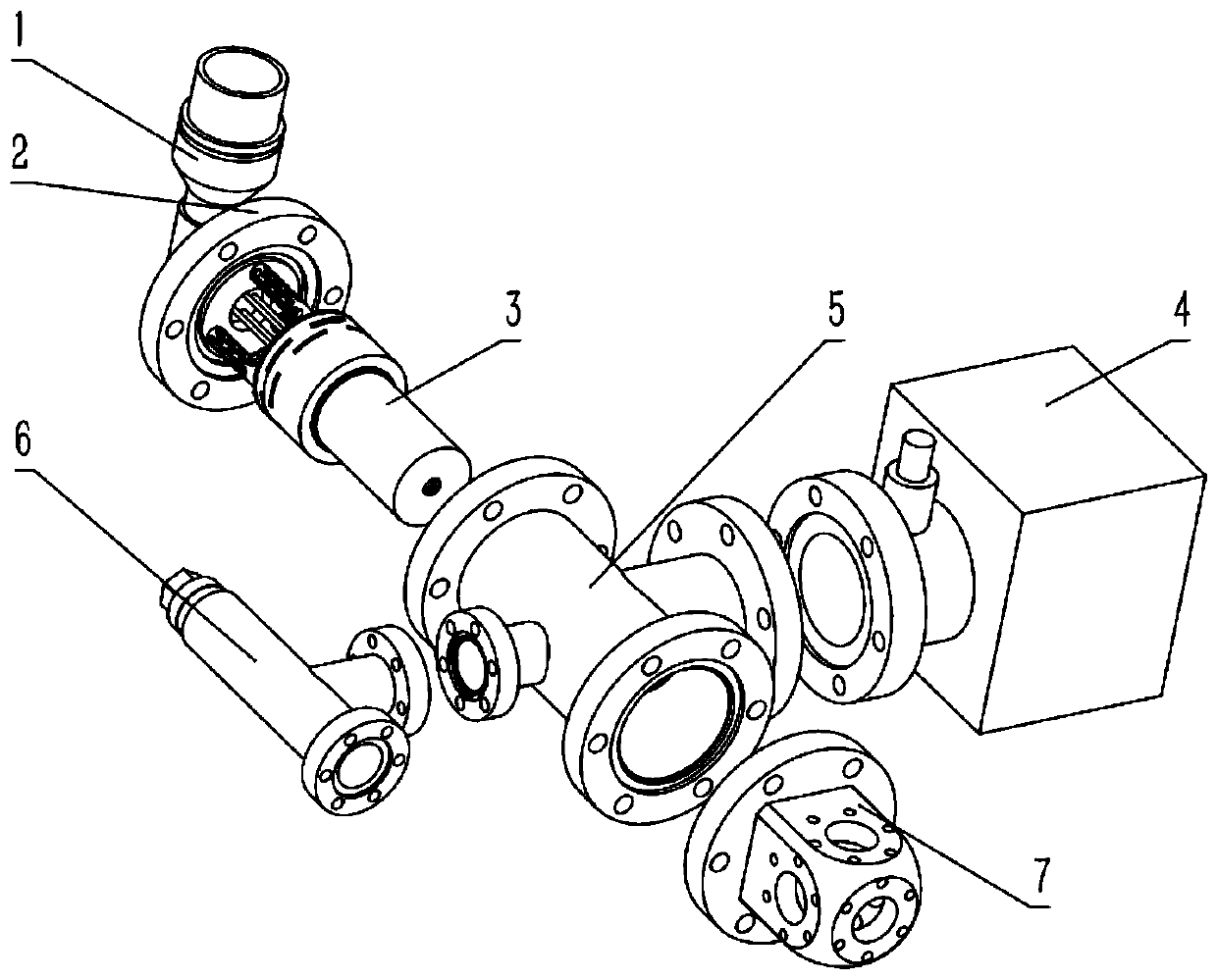

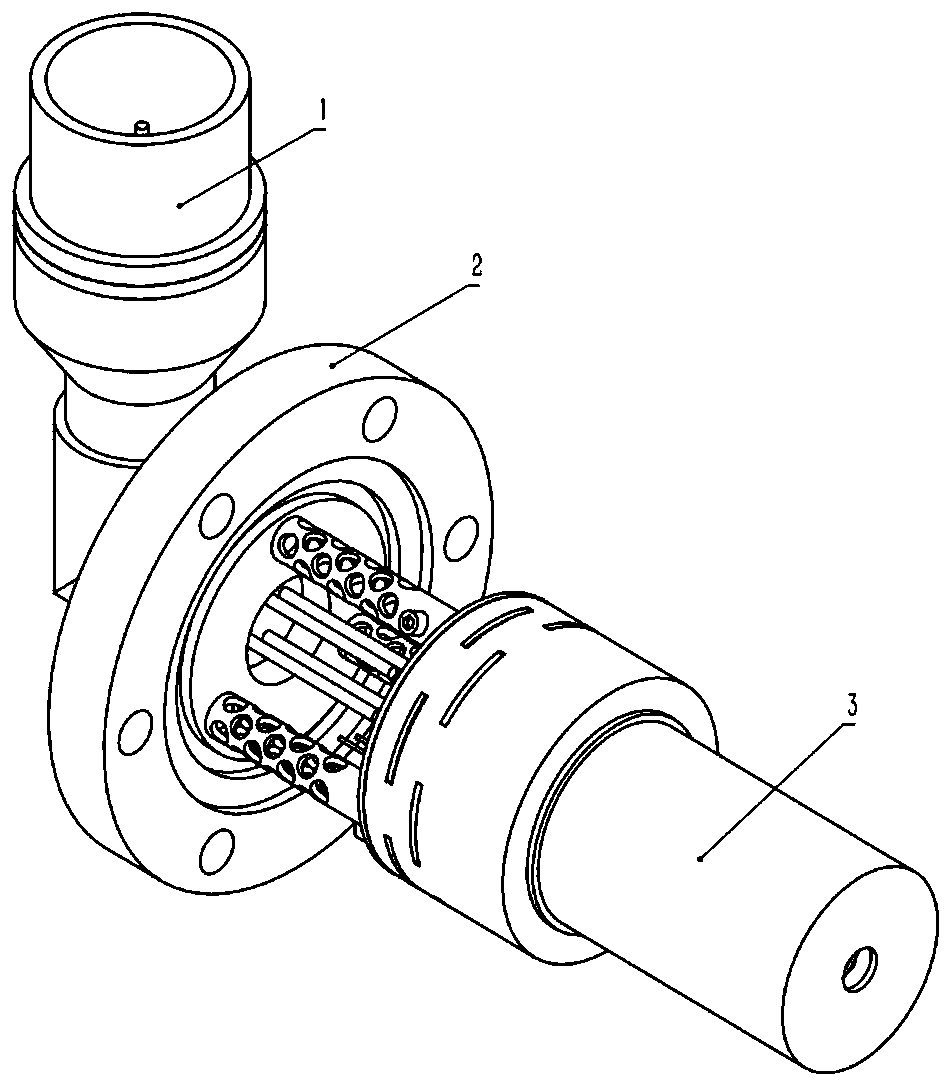

[0039] exist figure 1 , 2 , 3, and 5, the space strontium optical clock vacuum built-in high-temperature evaporation source device involved in the present invention, the vacuum electrode 1 is located at the right end of the flange 2 and connected with the heating device 3 through the flange 2, and the flange 2 is covered with the heating device 3 The external vacuum chamber 5 is connected, and the vacuum chamber 5 provides a vacuum environment for the device. The first outlet of the vacuum chamber 5 is connected with an ion pump 4 through a threaded fastening connector, and the ion pump 4 is used to maintain an ultra-high vacuum. The second outlet of the cavity 5 is connected with a collimating cavity 7 through a threaded fastener, and the orthogonal two-dimensional light beam injected from the outside can shape the atomic beam prepared by the heating unit 3 in the collimating cavity 7, The third outlet of the vacuum chamber 5 is fixedly connected with an angle valve 6 throug...

Embodiment 2

[0046] In this embodiment, four stud holes h are evenly distributed on the end surface of the heat insulation groove j of the middle plate in the above embodiment 1, and four common middle plate holes are processed on the end surface of the heat insulation middle plate body 3-9-1. Bolt hole i, 4 base universal bolt holes are evenly distributed on the outer end surface of the heat insulating base body 3-11-1, and four studs 3-5 are evenly distributed on the left end surface of the clamp pot body 3-5-1 -2. The other components and the connection relationship of the components are exactly the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com