Device and method for rapidly measuring surface electric field noise of metal

A technology of metal surface and electric field, applied in the direction of measuring device, measuring device casing, measuring electricity, etc., can solve the problems of high requirements, inability to quickly replace the metal sample to be measured, and long detection period of the electric field noise on the surface of the sample to be measured, etc. Measuring the effect of maneuvering difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

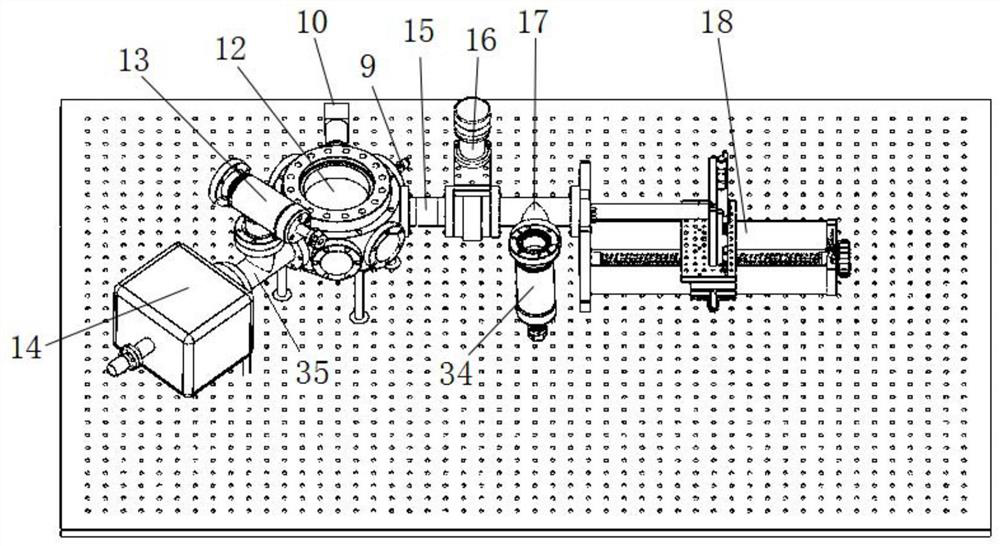

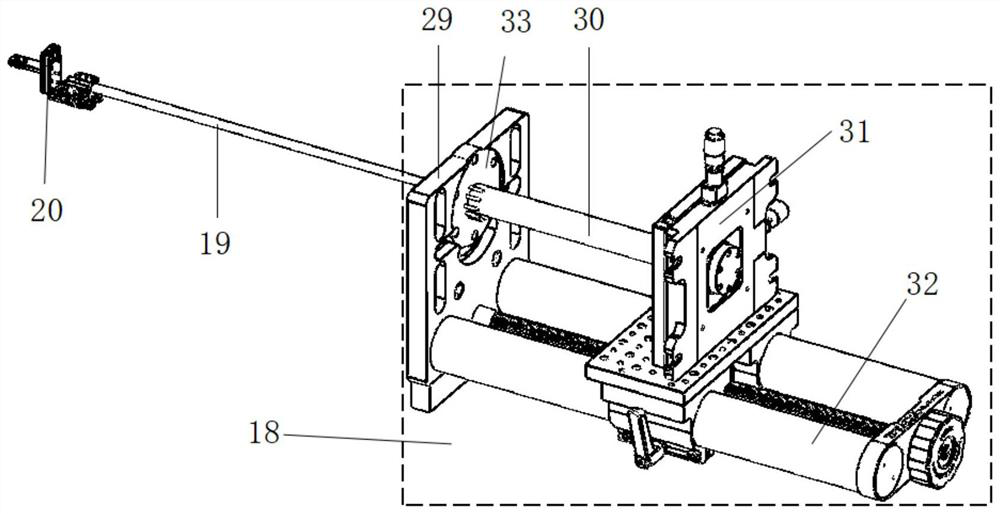

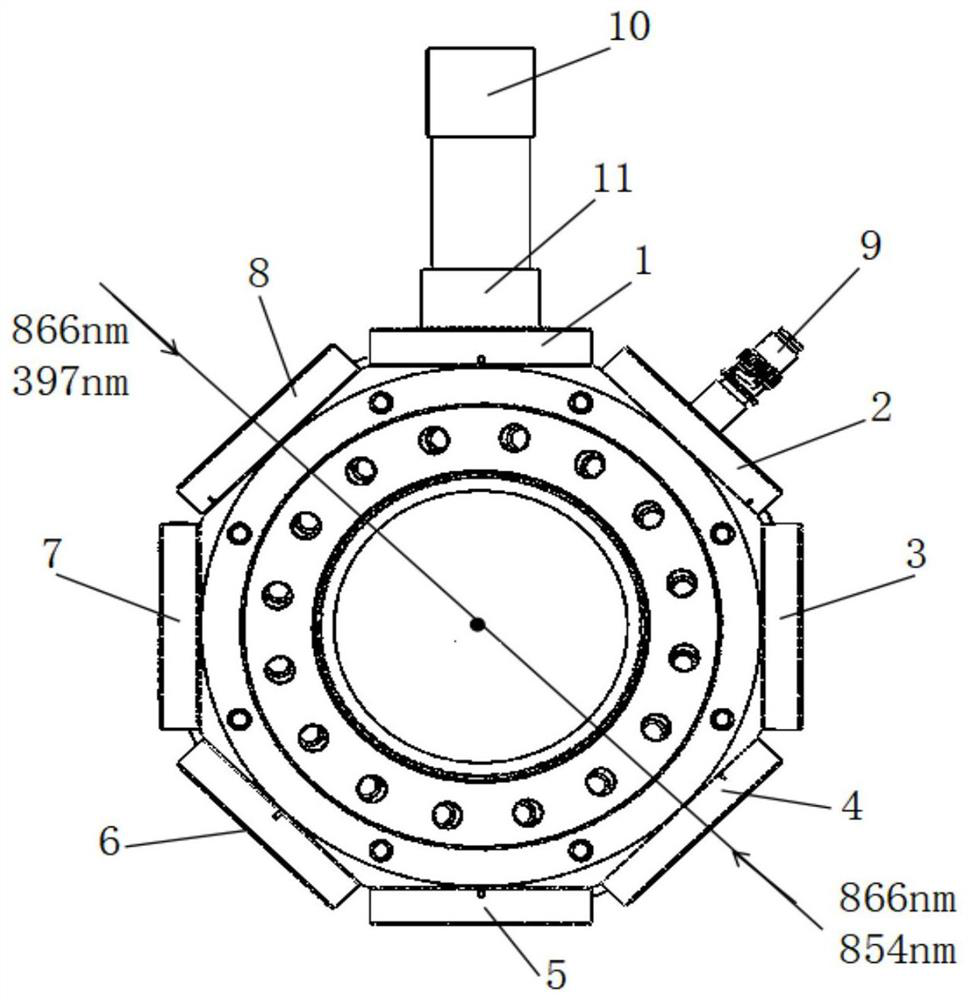

[0046] A device for quickly measuring the electric field noise on the metal surface, including a vacuum chamber 12, a CCD camera 10, a first vacuum angle valve 13, an ion pump 14, a vacuum baffle valve 16, a first three-way vacuum connector 17, and a second vacuum angle valve 34 , three-dimensional driver 18, three-dimensional nano mobile platform 20 and sample holder 24 to be tested, also comprise the chip support frame 21 that is arranged in the vacuum chamber, the chip support frame 21 is provided with calcium atomic furnace 22 and filter circuit board 26, filter circuit board An ion trap chip 25 is arranged in the chip placement hole of 26, and a light-through window is arranged on the vacuum chamber.

[0047] The above-mentioned ion trap chip 25 includes 15 DC electrodes and 2 RF electrodes, and the ion trap chip 25 can adopt the existing ion trap chip 25 . The filter circuit board 26 is provided with a filter circuit and a radio frequency wire, and the DC electrode is co...

Embodiment 2

[0070] At this time, the metal sample 27 to be tested has been driven by the one-dimensional driver 32 to be trapped in the trapped trapped ions ( 40 Ca + ion) above 28 Figure 4b location shown.

[0071] Such as Figure 6a shown. After the ions are cooled to the Doppler limit, turn off the cooling laser to let the ions heat up for a certain period of time, then turn on the cooling laser and quickly use the CCD camera to capture the image of the ions.

[0072] Such as Figure 6b shown. The image after Gaussian function fitting represents the probability distribution of ions at different positions on the two-dimensional plane, and the temperature of the ions can be known.

[0073] Such as Figure 7 shown.

[0074] A method for quickly measuring electric field noise on a metal surface, comprising the following steps:

[0075] Step 1: Apply electricity to the calcium atom furnace 22 to make the calcium atoms diffuse to the surface of the ion trap chip 25 .

[0076] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com